A method and device for troubleshooting a motor temperature sensor

A sensor failure, temperature sensor technology, applied in electromechanical devices, motor control, cooling/ventilation devices, etc., can solve problems such as motor shutdown and vehicle safety hazards

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The purpose of the present invention is to provide a motor temperature sensor failure processing method and device, which are used to solve the problem in the prior art that the motor is shut down due to the failure of the motor temperature sensor, thereby causing a relatively large safety hazard to the vehicle.

[0033] To achieve the above object, the technical solution provided by the invention is:

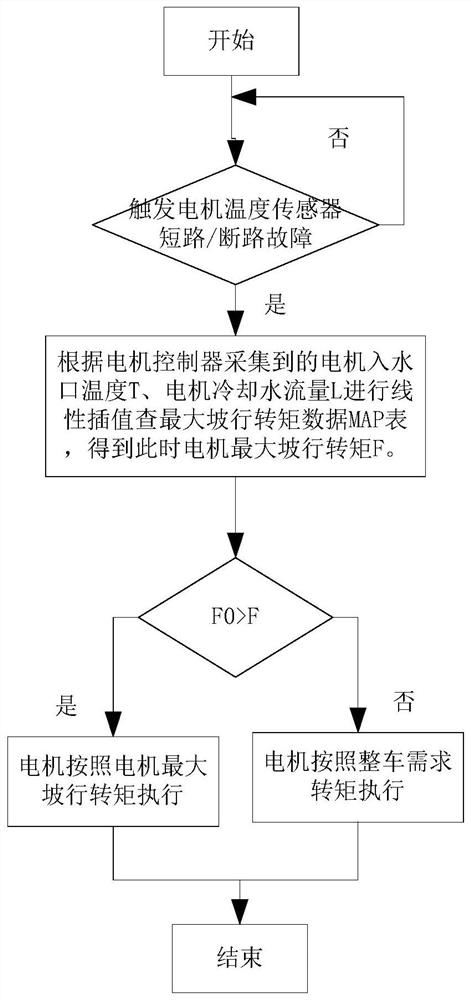

[0034] A method for troubleshooting a motor temperature sensor, comprising the steps of:

[0035] During the operation of the motor, detect the flow rate of the coolant in the motor cooling pipe and the temperature of the water inlet of the motor cooling pipe;

[0036] If the temperature sensor breaks down, then according to the flow rate of the coolant in the motor cooling pipe and the temperature of the water inlet of the motor cooling pipe when the temperature sensor breaks down, the maximum ramping torque of the motor when the temperature sensor breaks down is obtain...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com