A method for improving the magnetic anisotropy of high-grade non-oriented silicon steel

A technology of magnetic anisotropy and oriented silicon steel, which is applied in the field of iron and steel metallurgy, can solve the problems of insignificant effect and unsuitable large-scale production process of conventional equipment, etc., to increase the growth time, improve magnetic anisotropy, and homogenize grains Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] A method for improving the magnetic anisotropy of high-grade non-oriented silicon steel. The process includes: smelting, hot rolling, normalization, cold rolling, and annealing; wherein:

[0030] Chemical composition: C: 0.0022%, Si: 3.01%, Mn: 0.45%, P: 0.009%, S: 0.0011%, Als: 0.68%, N: 0.0021%; the rest is iron and unavoidable impurity elements.

[0031] Main control process:

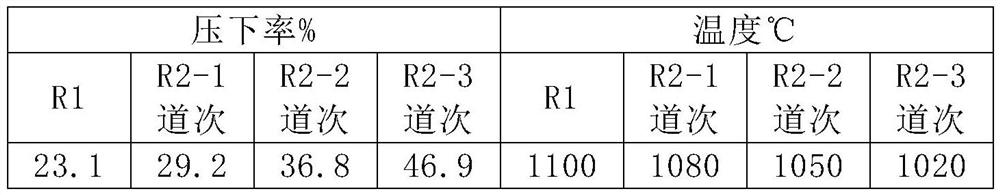

[0032] 1. See Table 1 for the hot rolling process;

[0033] Table 1:

[0034]

[0035] 2. Annealing process

[0036] The strip tension in the annealing furnace is 2.5KN, the strip speed is 70m / min, and the annealing temperature is 930°C.

Embodiment 2

[0038] A method for improving the magnetic anisotropy of high-grade non-oriented silicon steel. The process includes: smelting, hot rolling, normalization, cold rolling, and annealing; wherein:

[0039] Chemical composition: C: 0.0025%, Si: 2.95%, Mn: 0.48%, P: 0.009%, S: 0.0017%, Als: 0.72%, N: 0.0023%; the rest is iron and unavoidable impurity elements.

[0040] Main control process:

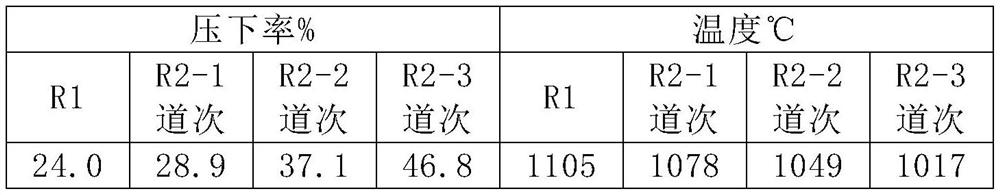

[0041] 1. See Table 2 for the hot rolling process;

[0042] Table 2:

[0043]

[0044] 2. Annealing process

[0045] The strip tension in the annealing furnace is 2.9KN, the strip speed is 75m / min, and the annealing temperature is 920°C.

Embodiment 3

[0047] A method for improving the magnetic anisotropy of high-grade non-oriented silicon steel, comprising:

[0048] Chemical composition: C: 0.0024%, Si: 3.10%, Mn: 0.54%, P: 0.010%, S: 0.0015%, Als: 0.70%, N: 0.0020%; the rest is iron and unavoidable impurity elements.

[0049] Main control process:

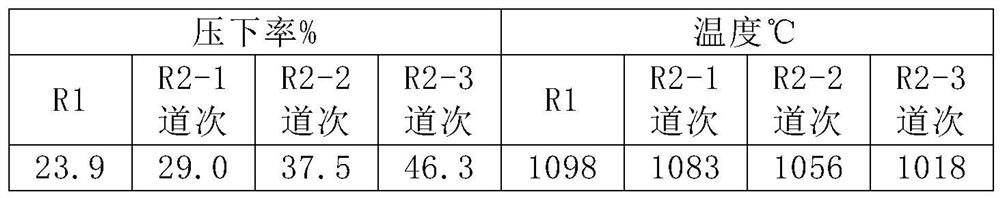

[0050] 1. See Table 3 for the hot rolling process;

[0051] table 3:

[0052]

[0053] 2. Annealing process

[0054] The strip tension in the annealing furnace is 3.2KN, the strip speed is 68m / min, and the annealing temperature is 935°C.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com