Three-way air pressure adjusting valve

An air pressure regulating valve and three-way technology, which is applied in the direction of multi-way valves, safety valves, balance valves, etc., can solve the problems of ensuring the impact force of liquid output, changing, and unable to maintain a stable strong pressure source all the time, so as to ensure that the impact force does not change effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

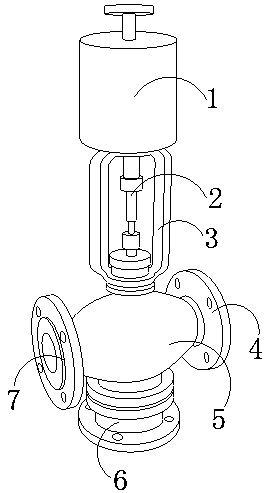

[0024] see Figure 1-Figure 6 , the present invention provides a three-way air pressure regulating valve, the structure of which includes a pneumatic bottle 1, a pressure delivery pipeline 2, a protective cover 3, a No. 1 nozzle 4, a pressure control device 5, a fixing seat 6, and a No. 2 nozzle 7. The air pressure bottle 1 communicates with the pressure delivery pipeline 2, and the end of the pressure delivery pipeline 2 far away from the air pressure bottle 1 is connected with the pressure control device 5, and the two ends of the pressure control device 5 are connected with the No. 1 nozzle 4 and the second nozzle respectively. The No. 1 nozzle 7 is connected, the No. 1 nozzle 4 and the No. 2 nozzle 7 are set up in a symmetrical structure, the pressure transmission pipeline 2 is installed in the protective cover 3, and the protective cover 3 is set up in an O shape. The protective cover 3 fixedly connects the air pressure bottle 1 with the outer wall of the pressure control...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com