Dual-channel electric supercharger

An electric supercharger, dual-channel technology, applied in the direction of engine components, machines/engines, mechanical equipment, etc., can solve problems such as small pressure ratio and air mass flow rate, increase the manufacturing cost of the supercharging system, and low compression efficiency of the compressor , to achieve the effect of high compression efficiency, easy automatic coupling and low manufacturing cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

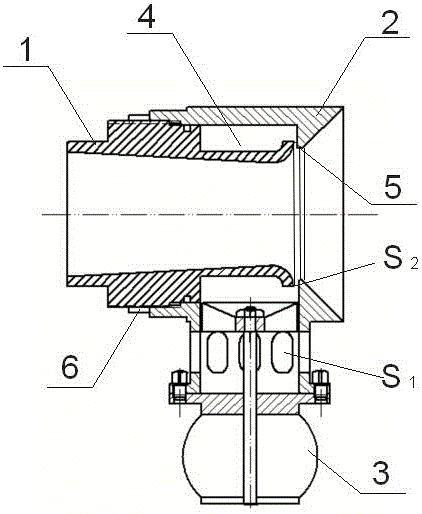

[0025] Example: see figure 1 , a dual-channel electric supercharger, comprising a main intake pipe 1 , an adjustable intake pipe 2 and an electric compressor 3 . An annular groove 4 is formed on the outside of the rear part of the main air intake pipe 1 , and the annular groove 4 runs through the rear end of the main air intake pipe 1 . The rear end of the main air intake pipe 1 expands and bends outwards, so that the section of the main air intake pipe 1 rear end is an arc section, and the inner diameter of the main air intake pipe 1 gradually increases from the rear end to the front end, so that the main air intake pipe 1 The inner hole of 1 is in the shape of a (hyperboloid) cone as a whole.

[0026] The inner hole of the adjustable intake pipe 2 is stepped, and the inner diameter of the front part is greater than the inner diameter of the rear part. The front end of the adjustable intake pipe 2 is inserted into the main intake pipe 1 from the rear end of the main intake p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com