Material jacking device for stainless steel pipe shrinkage machine

The technology of a jacking device and a stainless steel pipe is applied in the field of jacking of a tube shrinking machine, which can solve the problem of fixing the installation position of the jacking device, and achieve the effects of convenient height adjustment, in place protective measures, and improved safety.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

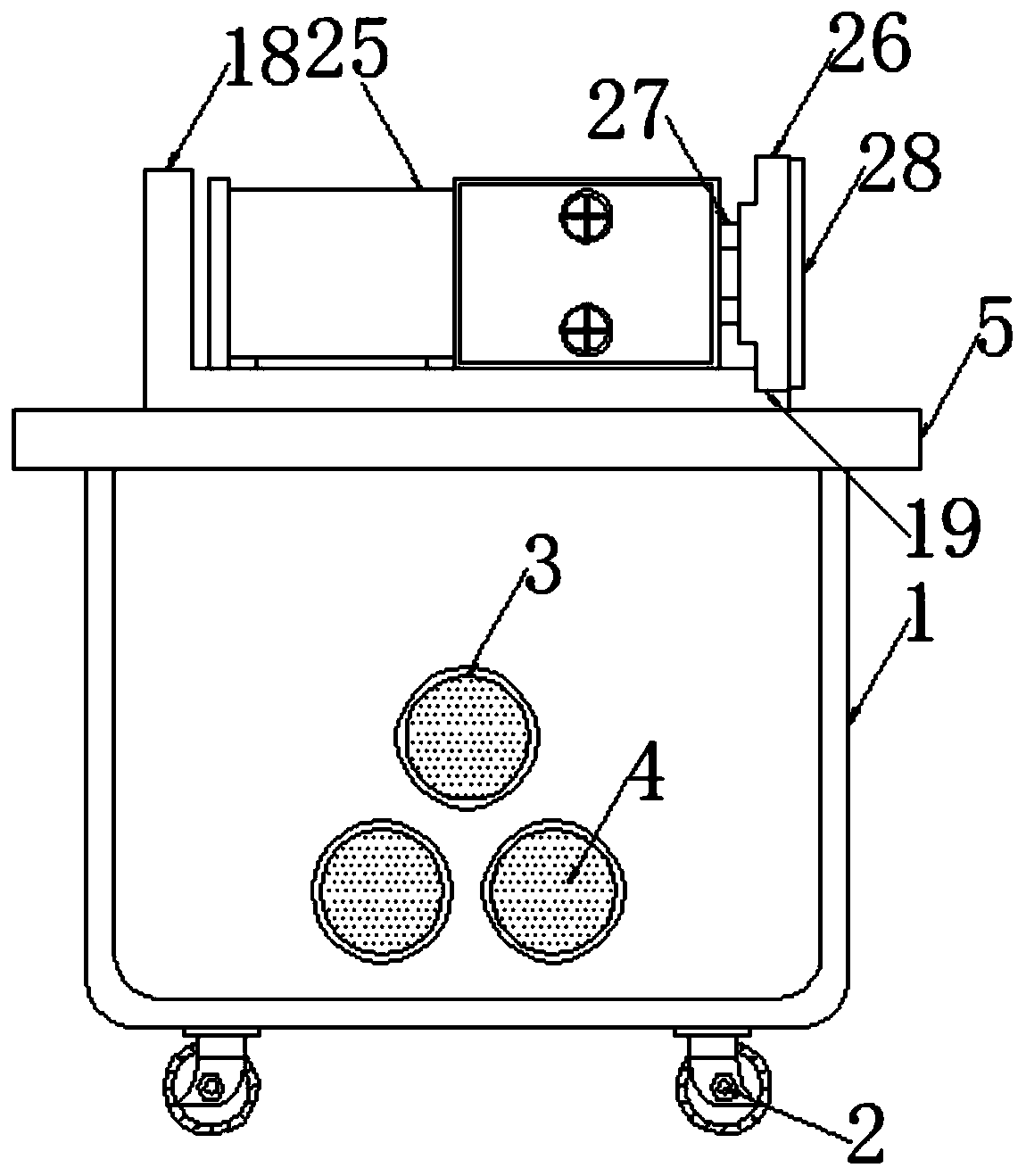

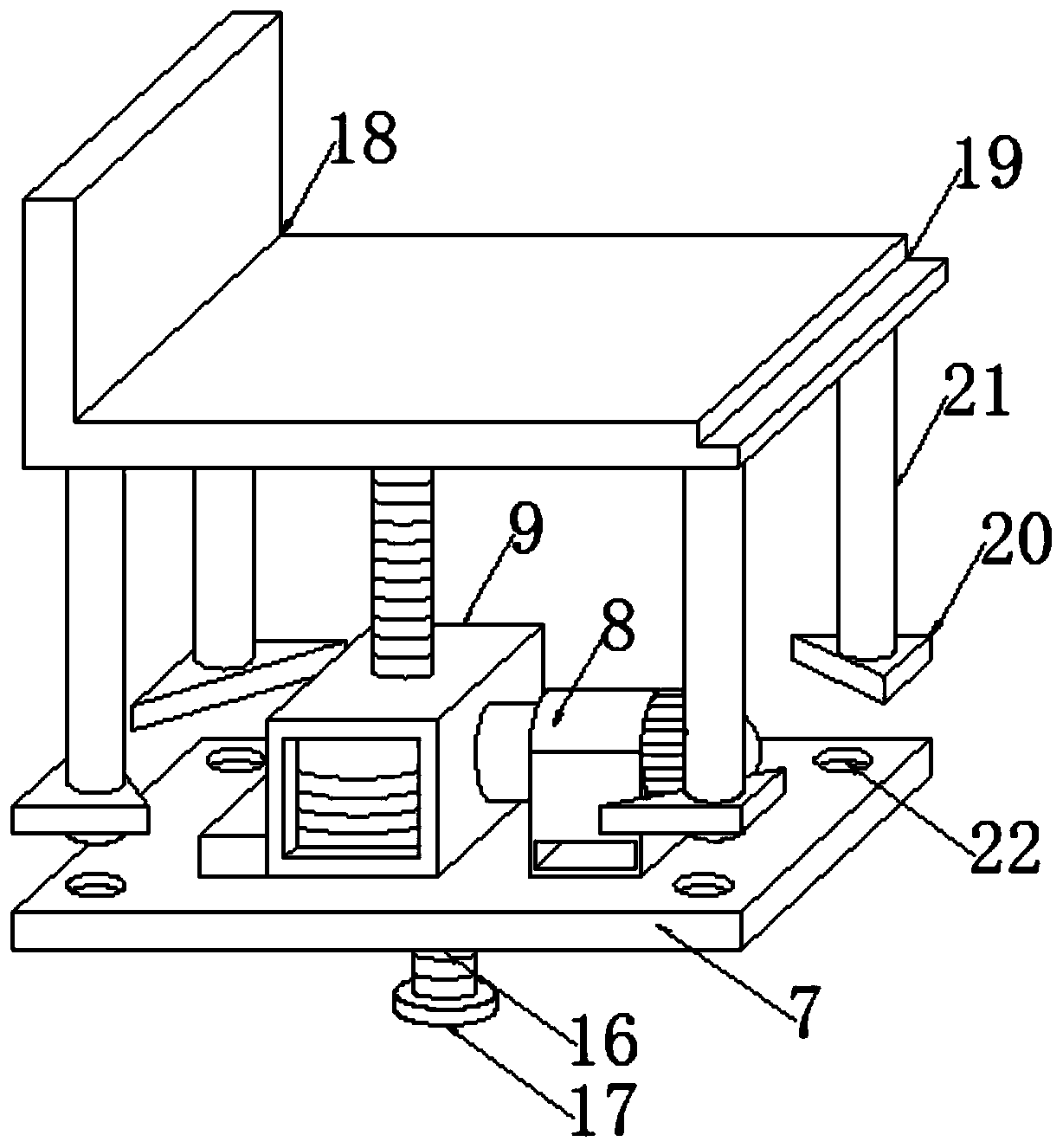

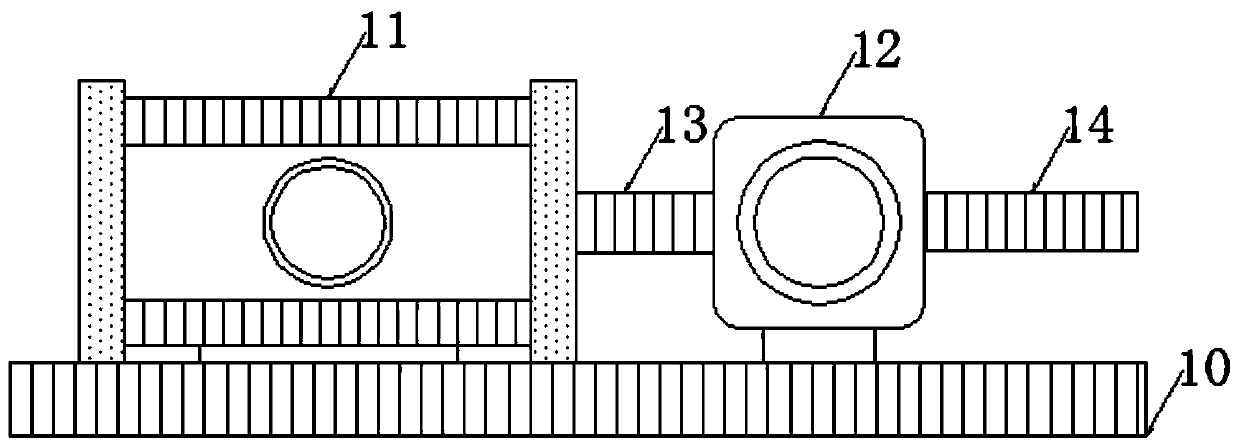

[0022] Such as Figure 1-7 As shown, this embodiment adopts the following technical solutions:

[0023] A jacking device for a stainless steel tube shrinking machine, comprising a storage box 1, the storage box 1 is designed in a square shape, and the four corners of the lower end surface of the storage box 1 are all treated with chamfered corners, and the storage box 1 Rollers 2 are fixedly installed at the four corners of the lower end surface of 1. The four rollers 2 have the same specifications and are distributed in a rectangular array. The upper end surface of the storage box 1 is provided with a square cavity 6. The storage box 1 The two opposite sides of the box 1 are connected to the square cavity 6 and are provided with three round holes 3. The three round holes 3 on the same side of the storage box 1 have the same specifications and are distributed in a triangular array. An air intake cover 4 is installed, and the upper end of the storage box 1 is fixedly equipped ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com