Truck loading device for logistics transportation

A logistics and storage board technology, applied in the directions of transportation and packaging, trolleys, motor vehicles, etc., can solve the problems of reducing the efficiency of loading vehicles and increasing the labor level, and achieve the effect of convenient unloading and unloading.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

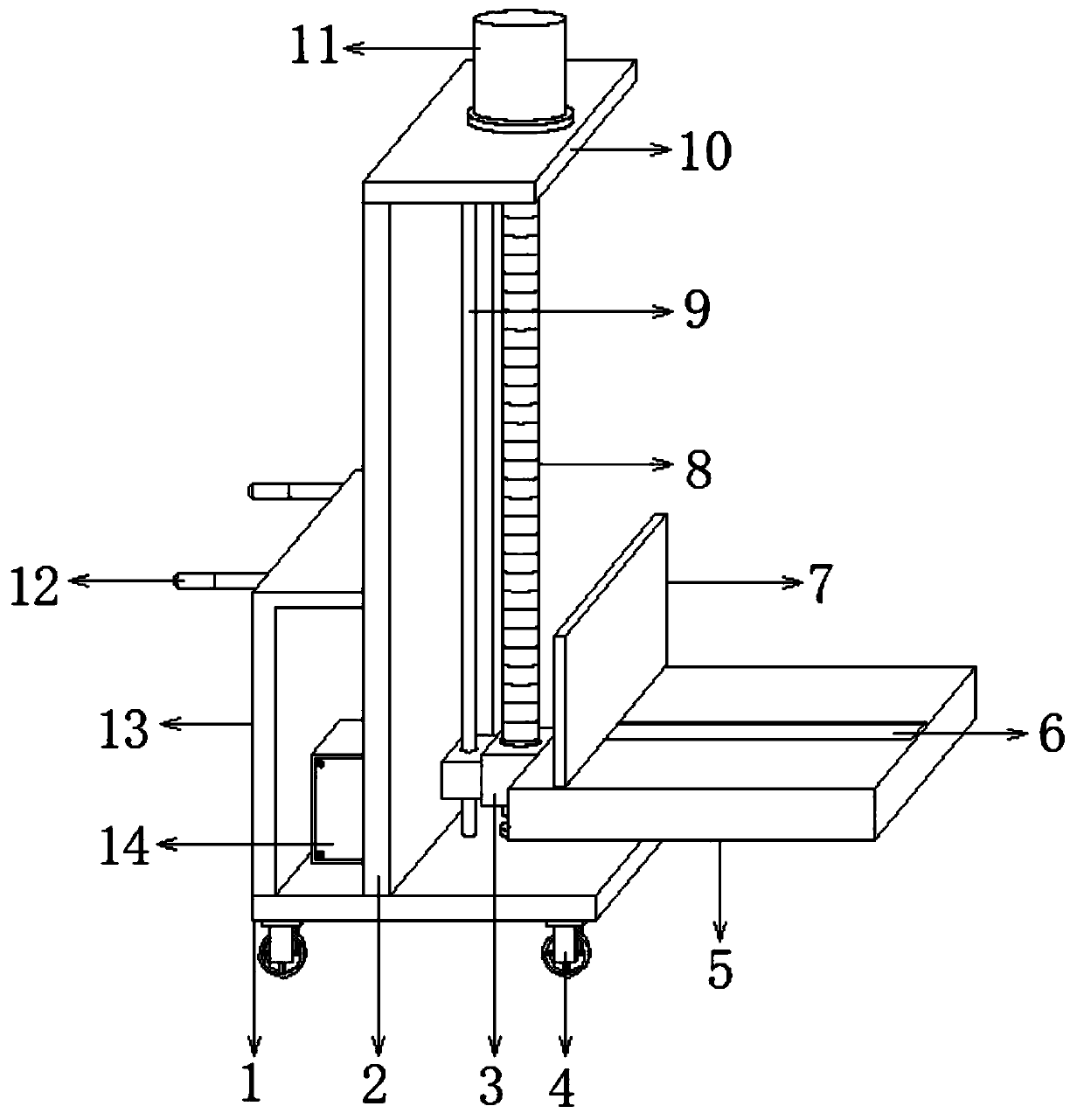

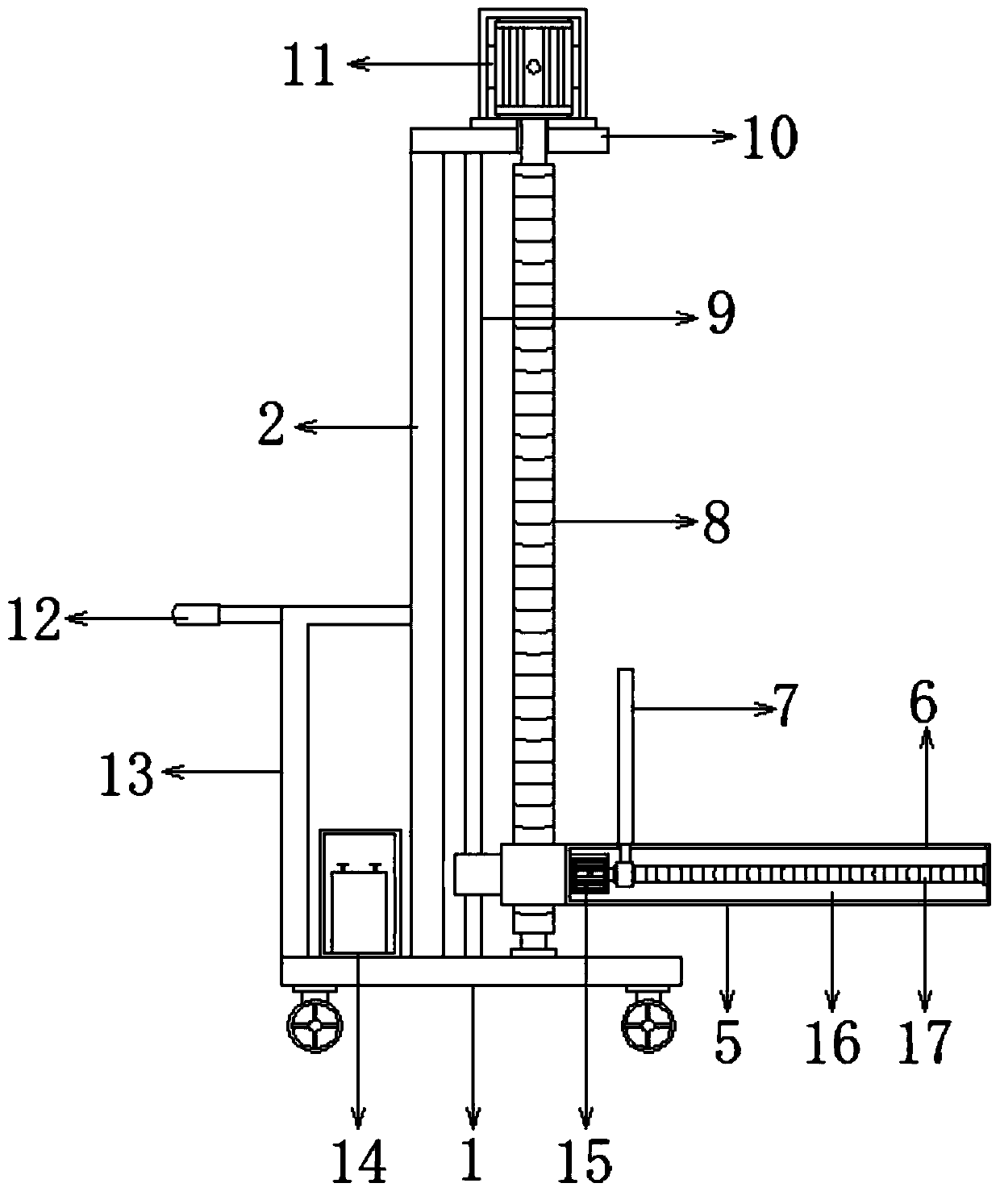

[0025] Reference Figure 1-2 , A loading device for logistics transportation, comprising a support table 1, a side plate 2 is welded on the top side of the support table 1 near the middle position, and the top of the side plate 2 is welded with a top plate 10, and the top of the top plate 10 is connected by bolts. The first forward and reverse motor 11, and the output shaft of the first forward and reverse motor 11 is welded with a first threaded screw 8 rotatably connected to the outer wall of the top of the support table 1, and the outer wall of the first threaded screw 8 is threadedly connected with a first The movable sleeve 3, and one side of the first movable sleeve 3 is connected with a holding plate 5 through bolts, a cavity 16 is opened in the middle of the inside of the holding plate 5, and one side of the inner wall of the cavity 16 is connected with a second front and back through bolts The output shaft of the second forward and reverse motor 15 is welded with a sec...

Embodiment 2

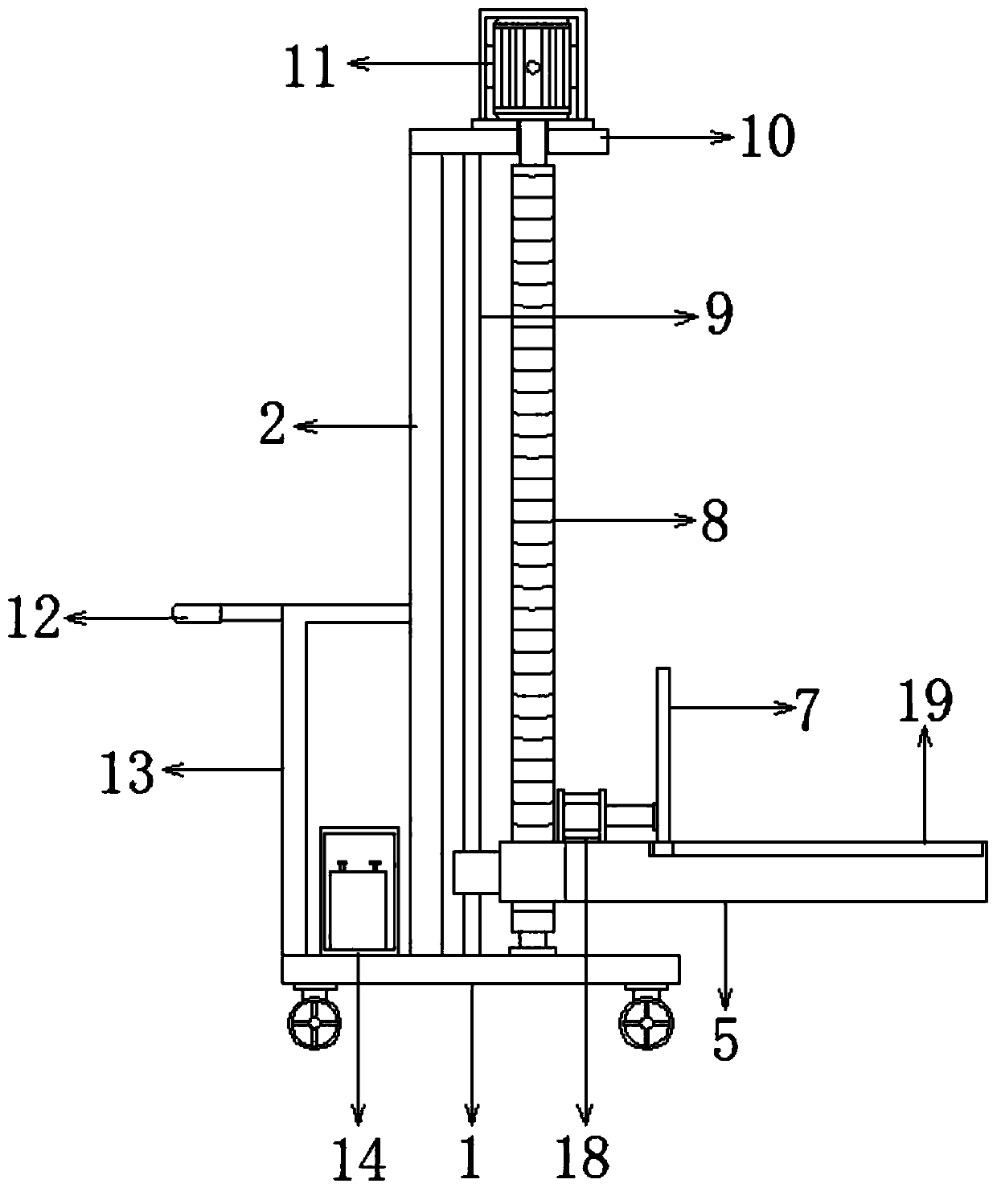

[0032] Reference image 3 , A loading device for logistics transportation. Compared with the first embodiment, the top side of the storage plate 5 is connected to the hydraulic cylinder 18 by bolts, and the piston end of the hydraulic cylinder 18 is connected to the outer wall of the push plate 7 Through bolt connection, a sliding groove 19 is opened on the top side of the storage plate 5, and a sliding seat that is slidably connected with the inner wall of the sliding groove 19 is welded on the bottom of the push plate 7.

[0033] Working principle: The user connects the hydraulic cylinder 18 to the hydraulic system, and directly adjusts the position of the push plate 7 on the shelf 5 through the hydraulic cylinder 18, so that the sliding seat slides in the chute 19 and pushes the goods away from the shelf 5 .

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap