Fixed installation structure of drainage pipeline

A technology for installing structures and drainage pipes, which is applied in the direction of pipe brackets, pipe components, pipes/pipe joints/pipe fittings, etc., and can solve the problems of uncoordinated expansion and contraction of drain pipes, low installation efficiency, and extrusion damage of drain pipes, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

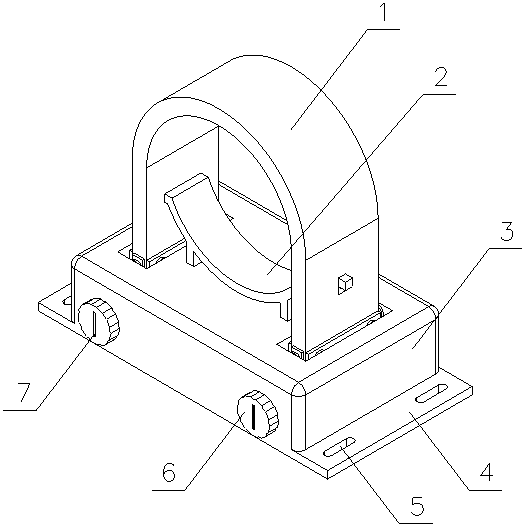

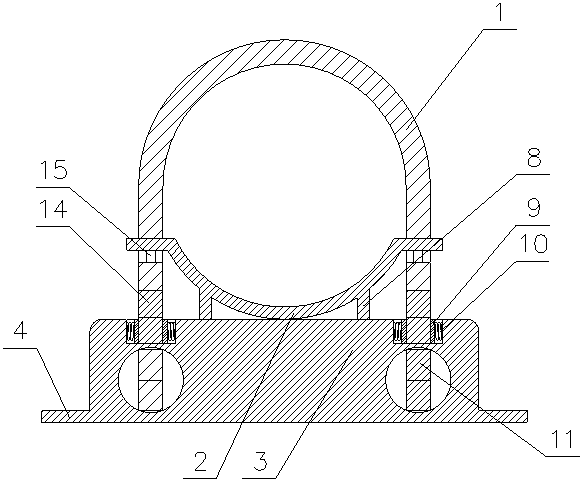

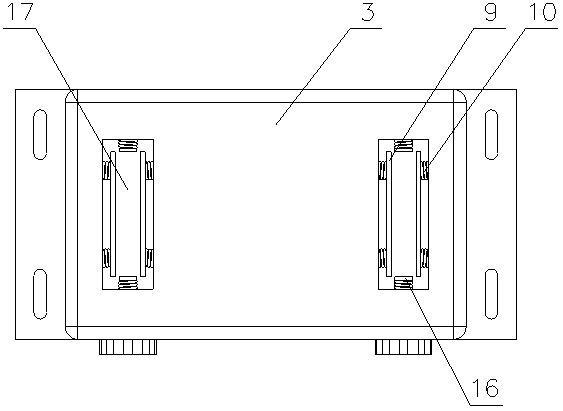

[0019] A fixed installation structure of a drainage pipe in the present invention is realized in this way. It is composed of a main device and a fixing device. The main device is composed of a fixing seat (3), a connecting plate (4), a connecting groove (5) and a fixing groove (17). The connecting plate (4) is fixedly placed at the bottom of the fixing seat (3), the length of the connecting plate (4) is longer than that of the fixing seat (3), and the connecting plate (4) has a plurality of connecting grooves near one end ( 5), the connecting plate (4) has a plurality of connecting grooves (5) near the other end, and two fixing grooves (17) are symmetrically opened on the top of the fixing base (3), and the fixing grooves (17) It is a rectangular slot, and the fixing device consists of a main fixing plate (1), an auxiliary fixing plate (2), a knob (6), an indicator groove (7), a limit block (8), a long splint (9), a spring (10), The rotating magnet (11), the fixed magnet (14),...

Embodiment 2

[0024] The difference between this embodiment and Embodiment 1 is: the rotating shaft is provided with a plurality of sockets (13) at equal angles, and a limit screw (19) is additionally provided on the fixing base (3), and the limit screw One end of (19) passes through the fixing seat (3) and is placed in the socket (13); when in use, it can prevent the main fixing plate (1) from falling off due to the automatic reset of the knob (6).

[0025] The chute (15) is a cross-shaped groove, and the insert block is a cross-shaped structure, which can make the movement of the insert block in the chute (15) more stable.

[0026] The main fixed plate (1) is adsorbed and fixed through the cooperation of the rotating magnet (11) and the fixed magnet (14), and the purpose of corresponding expansion and contraction is achieved when the drain pipe expands with heat and contracts with cold through the cooperation of the slider and the chute (15). .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com