Pre-cleaning device for net-in sampled and checked hardware fittings in power industry

A pre-cleaning technology in the power industry, applied in the field of pre-cleaning of power fittings, can solve problems such as difficulty, volume difficulty, and many different structures of power fittings, and achieve the effect of reducing the number of inspectors, shortening the pre-cleaning time, and achieving ideal cleaning effects.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention is further described in detail through the following examples, but the technical content described in this example is illustrative rather than limiting, and should not limit the protection scope of the present invention accordingly.

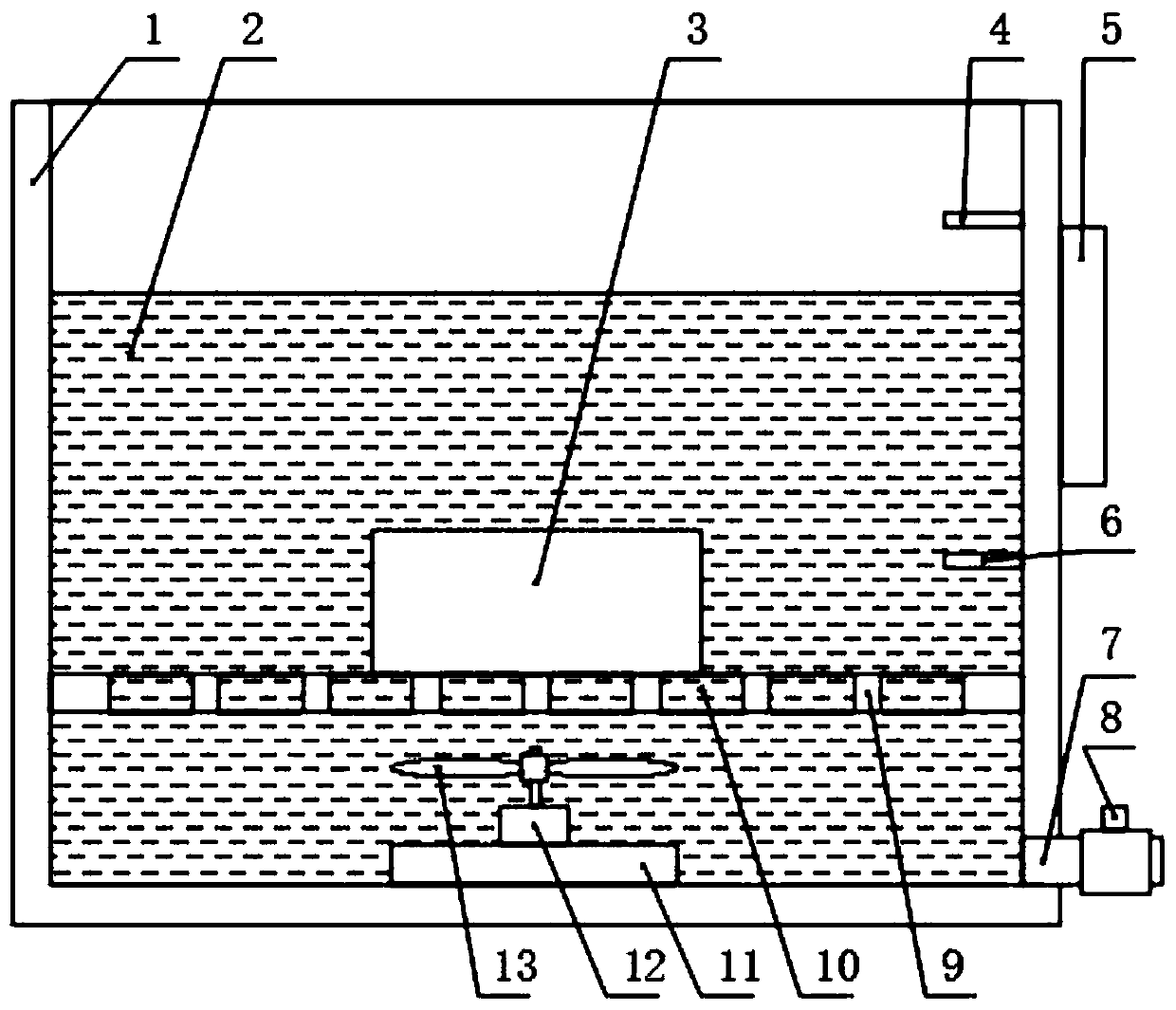

[0017] A kind of pre-cleaning equipment suitable for sampling inspection of fittings in the power industry, such as figure 1 As shown, the innovation of the present invention is: comprising box body 1, control module 5 and stirring module, puts cleaning solution 2 in the box body, soaks the metalware 3 to be cleaned in cleaning solution, arranges stirring module at the bottom of box body, in box body A control module is arranged on the outer wall of the body, and the control module is connected to the stirring module.

[0018] In this embodiment, a liquid level detection module is provided on the inner wall of the tank, and the liquid level detection module is connected to the control module. The liquid level detecti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com