Drive module and linear transport system

A transmission system and drive module technology, applied in the direction of propulsion systems, conveyors, electric components, etc., can solve problems such as difficult cleaning, and achieve the effect of extending the cleaning interval

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

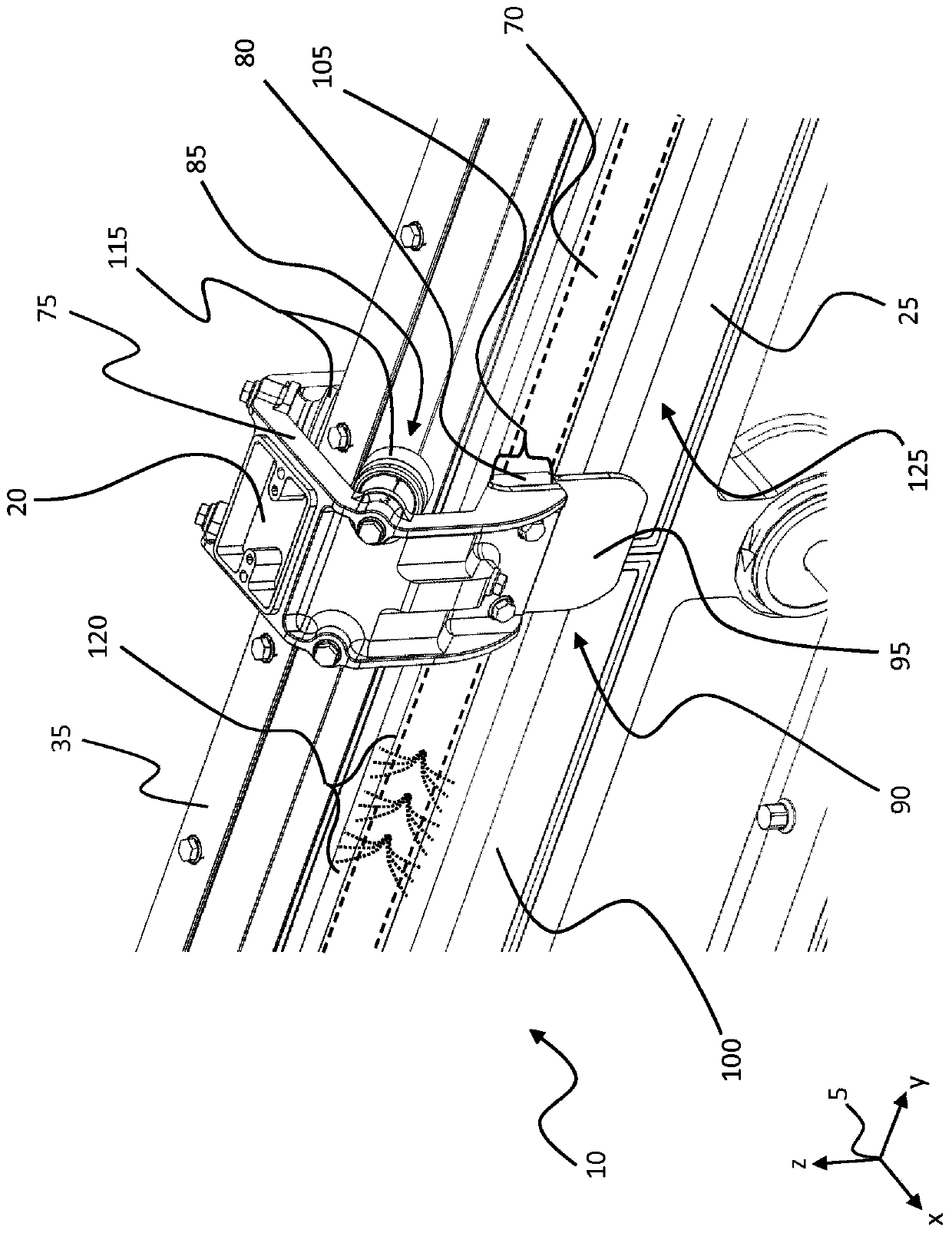

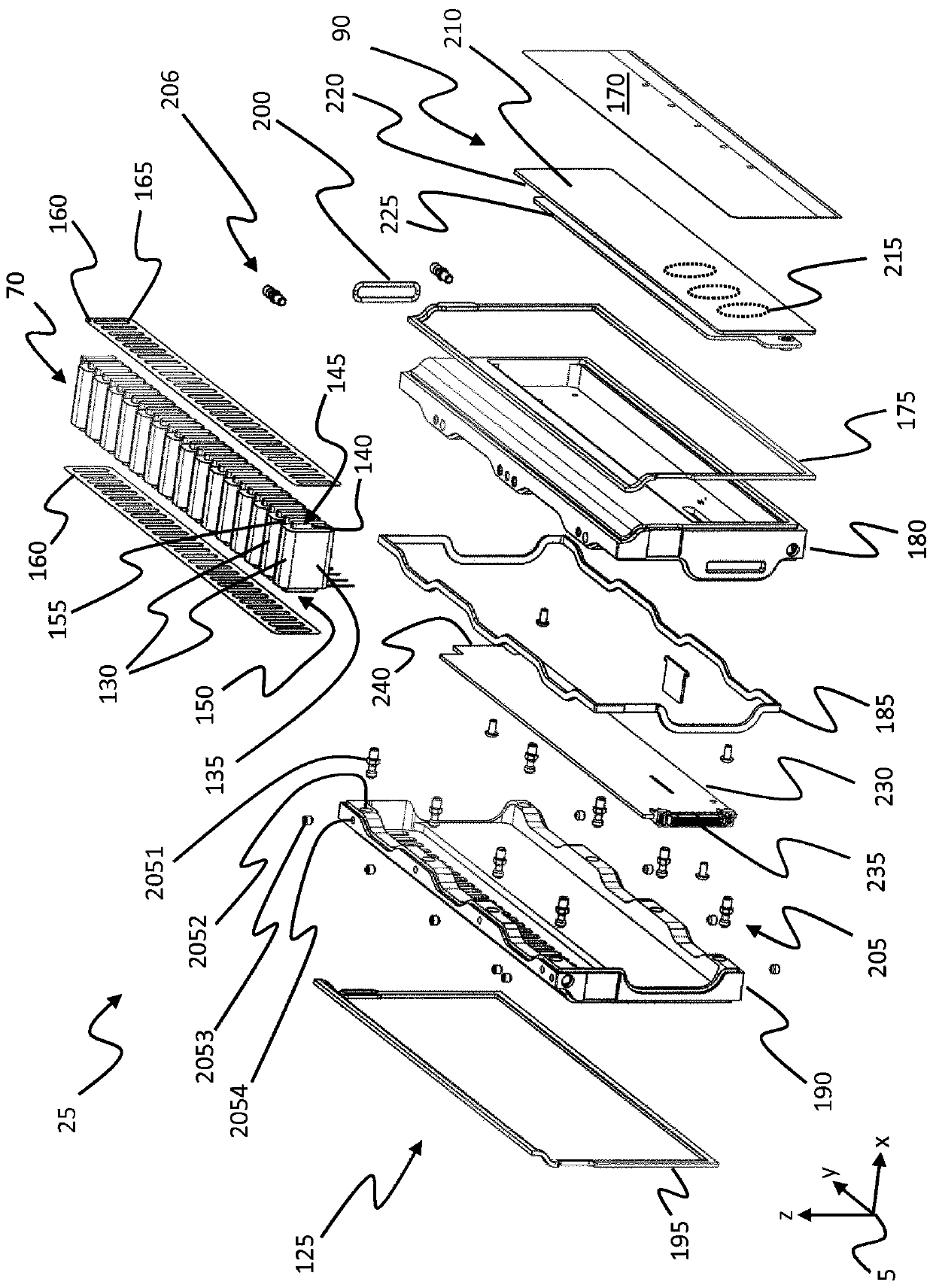

[0038] Here and hereinafter reference is made to the coordinate system 5 in the drawings. The coordinate system 5 is configured as a right-handed system, and has an x-axis (vertical direction), a y-axis (longitudinal direction), and a z-axis (lateral direction). It goes without saying that the coordinate system 5 can also be configured in different ways.

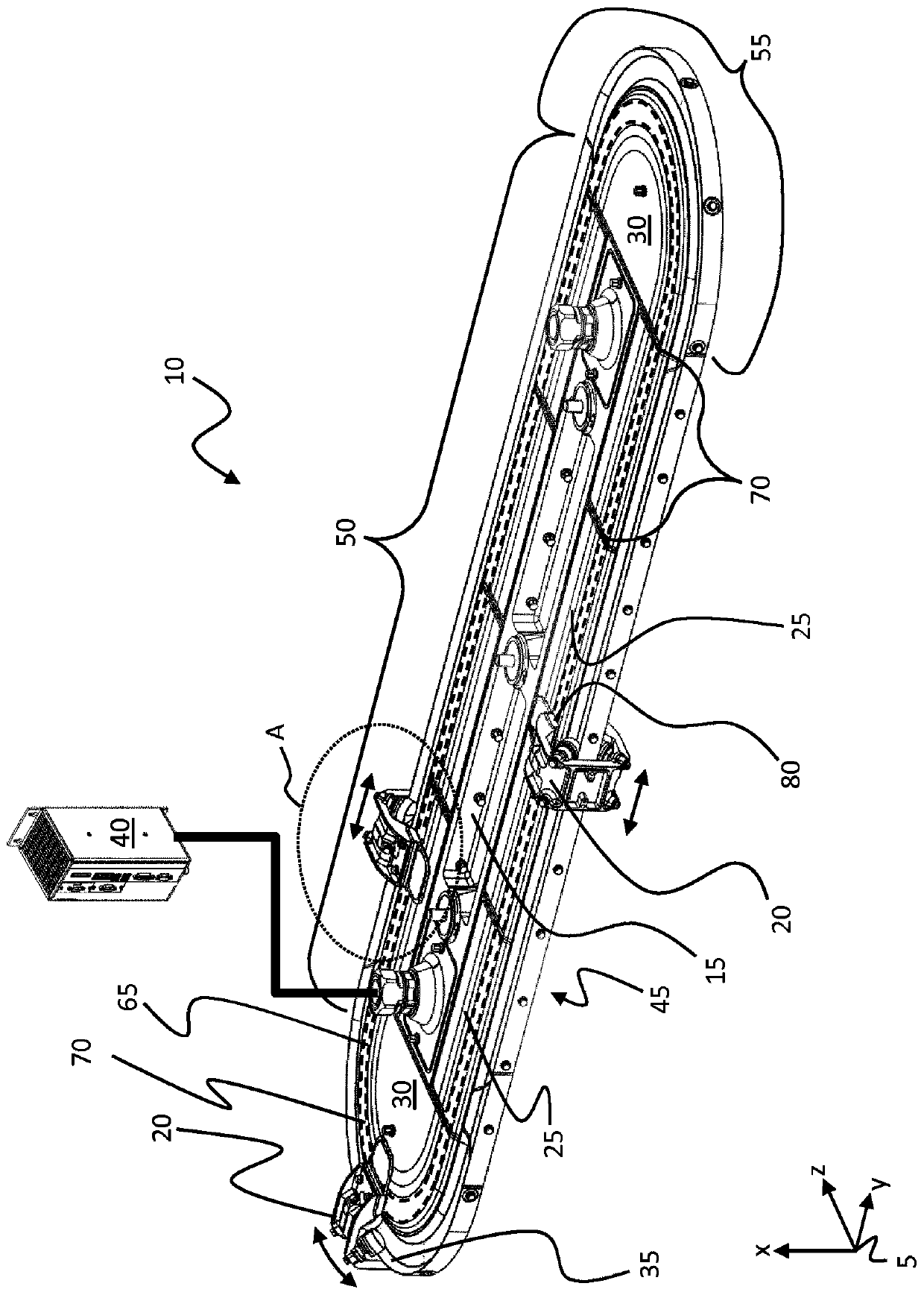

[0039] figure 1 A perspective illustration of the linear transport system 10 is shown.

[0040] The linear transport system 10 has a plurality of conveying devices 20 of identical design, a first drive module 25 , optionally at least one second drive module 30 and a slide rail 35 . On the inner side, the drive modules 25 , 30 are fastened on the machine tool 15 . On the outside, slide rails 35 are arranged in the form of rings on the drive modules 25 , 30 . The transport device 20 is fastened on the slide rail 35 and engages at least partially around the drive modules 25 , 30 .

[0041] In the embodiment illustrated her...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com