Spring pin dismounting device

A dismantling device and spring pin technology, which is applied in the direction of hand-held tools and manufacturing tools, can solve the problems of difficult operation, high operator experience and technical requirements, and long time consumption, so as to achieve simple and convenient operation, avoid adverse effects, and rely on technology Sexually low effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

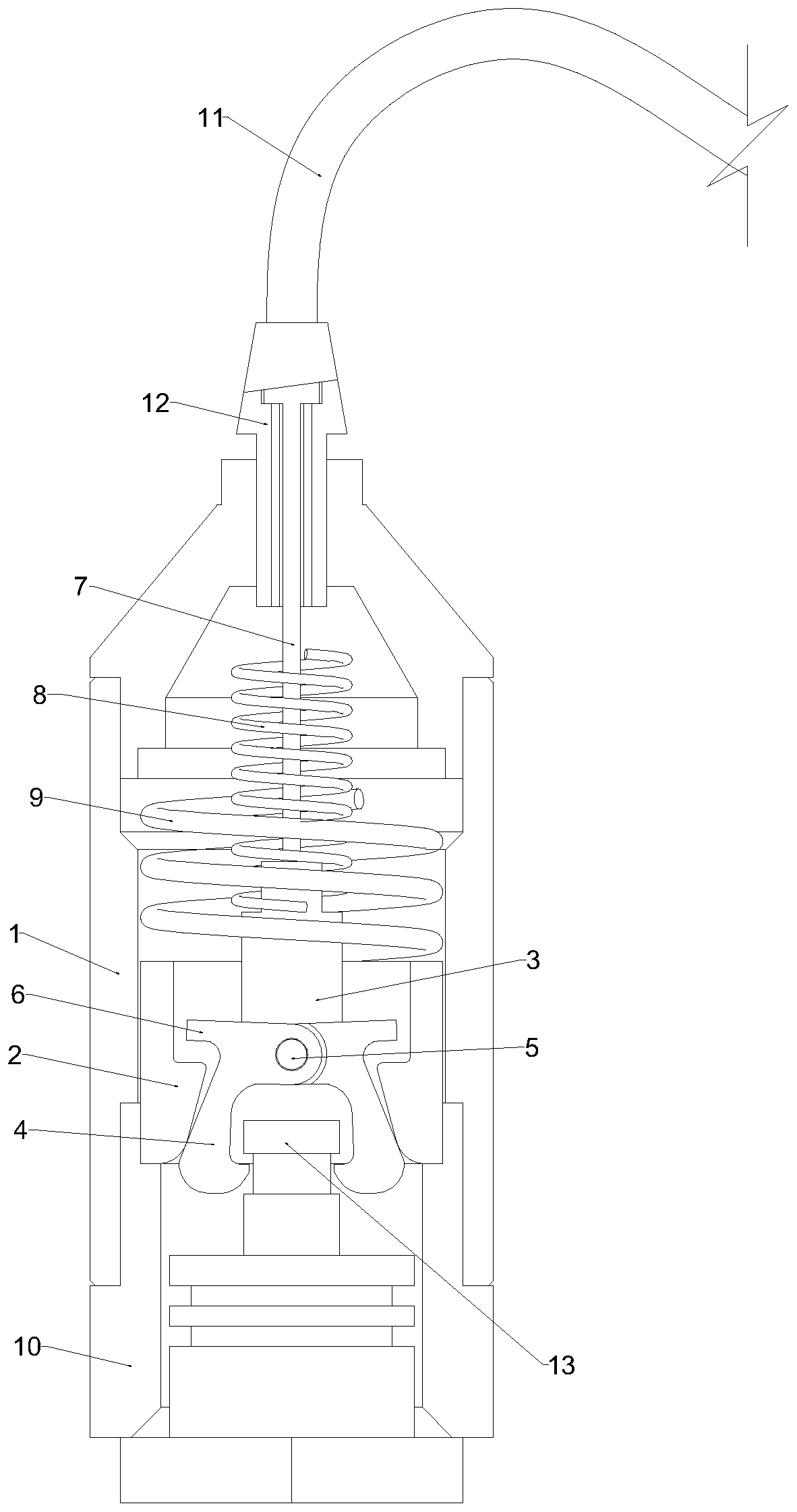

[0017] A spring pin removal device such as figure 1 As shown, it includes a shell 1 with an open lower end, and the shell 1 is provided with a clamping sleeve 2, a grasping structure and a connecting frame 3;

[0018] The clamping sleeve 2 is provided with a through hole through the top and bottom. The through hole can be divided into two sections, the upper section hole and the lower section hole. The diameter of the lower section hole gradually decreases from bottom to top, and it is in the shape of a trumpet with an opening punched down. The upper section hole is cylindrical. Hole, the diameter of which is greater than the diameter of the hole at the top of the lower hole, and the connection between the upper hole and the lower hole forms an annular circular platform;

[0019] The grasping structure includes two claws 4 that are set up oppositely, and the upper ends of the opposite sides of the two claws 4 are provided with openings, and the connecting rod 5 passes through ...

Embodiment 2

[0028] A kind of spring pin removal device, different from embodiment 1 is:

[0029] The bottom of the shell 1 is provided with an adjustable bottom support 10, which is a hollow structure with upper and lower ends open, and the inner wall of the shell 1 is threadedly connected with the outer wall of the adjustable bottom support 10; height of the spring pin;

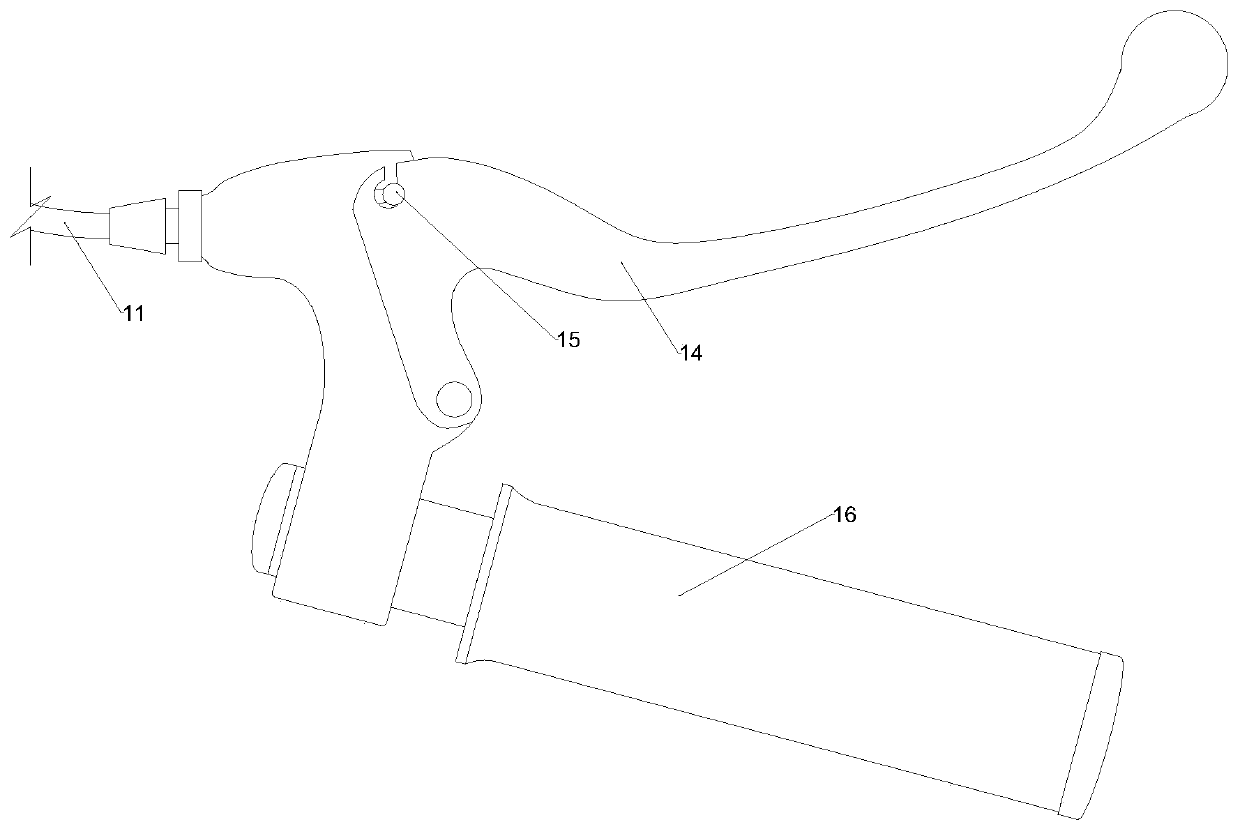

[0030] The brake line 7 is provided with a brake line cover 11, one end of the brake line cover 11 is connected to the brake handle, the other end of the brake line cover 11 is provided with a brake handle fine-tuning structure 12, and the brake handle fine-adjustment structure 12 is provided with a brake line 7 The line hole, the outer wall of the brake handle fine-tuning structure 12 is threadedly connected with the inner wall of the top opening of the shell 1; the brake handle fine-adjustment structure 12 is used to adjust the length of the pin pulling action.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com