Mopping robot and mopping method

A mopping robot and activity floor technology, applied in the field of robotics, can solve the problems of reducing user experience, unable to realize fully automatic mopping, etc., to achieve the effect of improving user experience

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

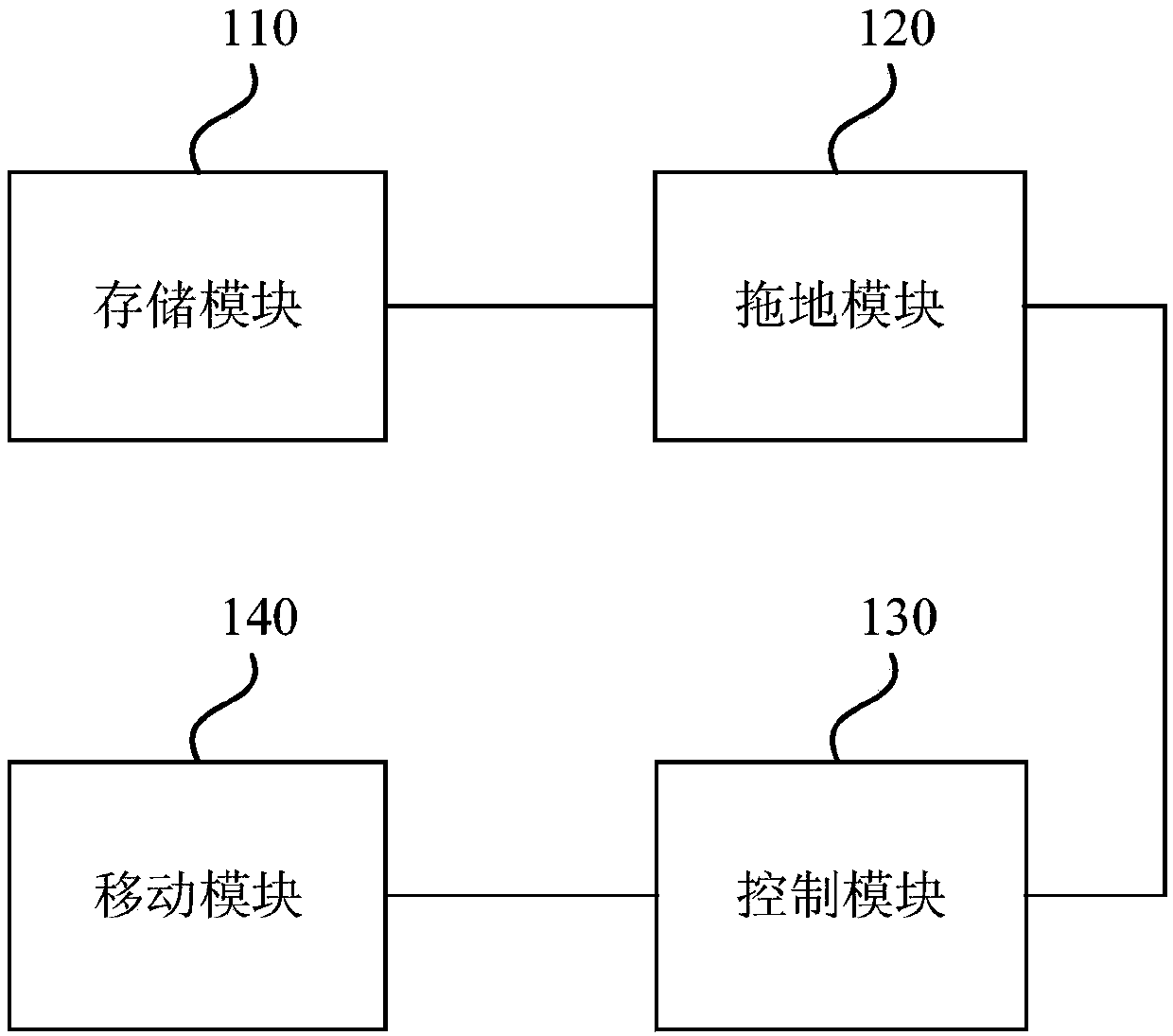

[0040] figure 1 It is a schematic structural diagram of a floor mopping robot provided in Embodiment 1 of the present invention. The floor mopping robot of this embodiment is applicable to the field of robot technology, and the floor mopping robot includes:

[0041] Storage module 110, mopping module 120, control module 130 and mobile module 140;

[0042] Wherein, the storage module 110 is used to store and output the cleaning medium;

[0043] The mopping module 120 is connected to the storage module 130, and can be movably arranged on the bottom of the mopping robot. position such that the sweeping medium contacts the ground;

[0044] The control module 130 is configured to receive an externally input operation command, and form a control instruction according to the operation command;

[0045] The moving module 140 is configured to receive the control instruction, and drive the mopping robot to change its displacement under the action of the control instruction.

[0046]...

Embodiment 2

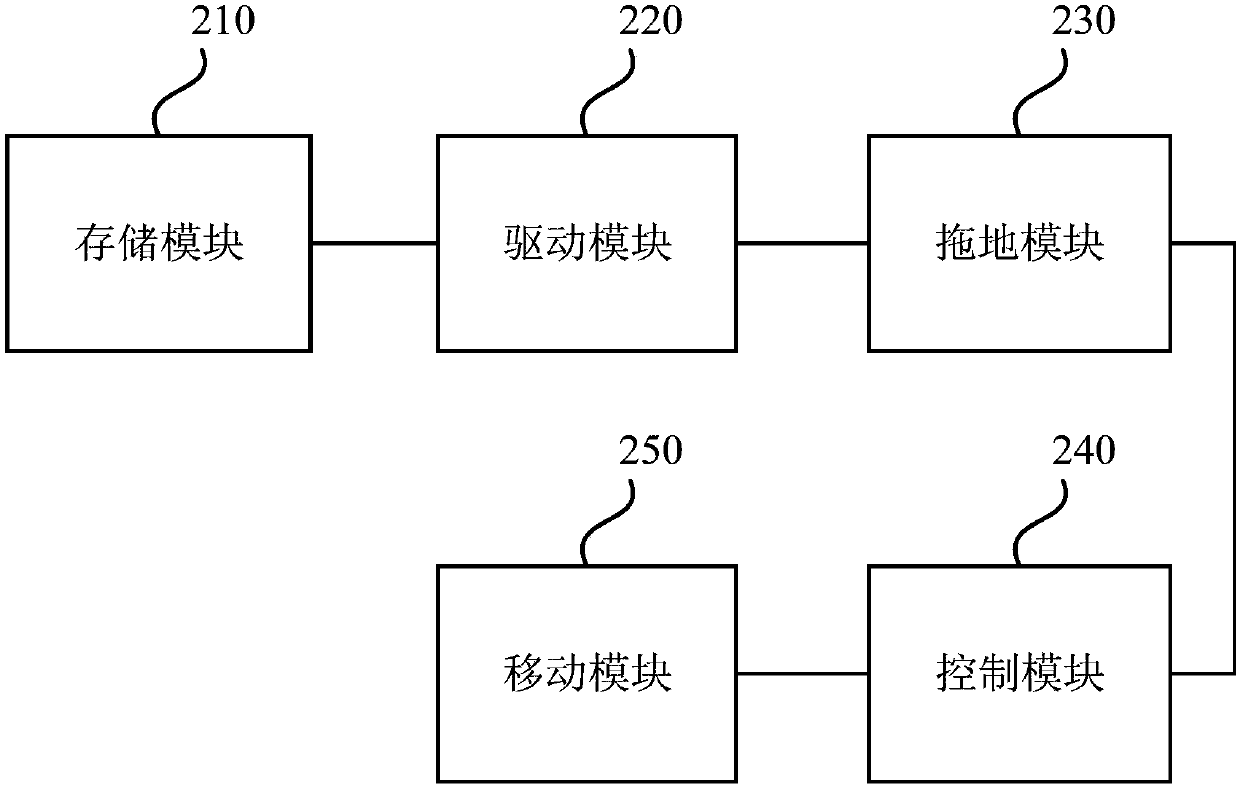

[0051] figure 2 It is a schematic structural diagram of a mopping robot provided in Embodiment 2 of the present invention. On the basis of the above-mentioned embodiments, this embodiment preferably further includes:

[0052] The driving module is respectively connected to the storage module and the mopping module, and is used to drive the storage module to output the cleaning medium and install the cleaning medium at a predetermined position of the mopping module.

[0053] The mopping robot includes:

[0054] Storage module 210, driving module 220, mopping module 230, control module 240 and mobile module 250;

[0055] Wherein, the storage module 210 is used to store and output the cleaning medium;

[0056]The driving module 220 is connected to the storage module 210 and the mopping module 230 respectively, and is used to drive the storage module 210 to output the cleaning medium and install the cleaning medium at a predetermined position of the mopping module 230;

[0057...

Embodiment 3

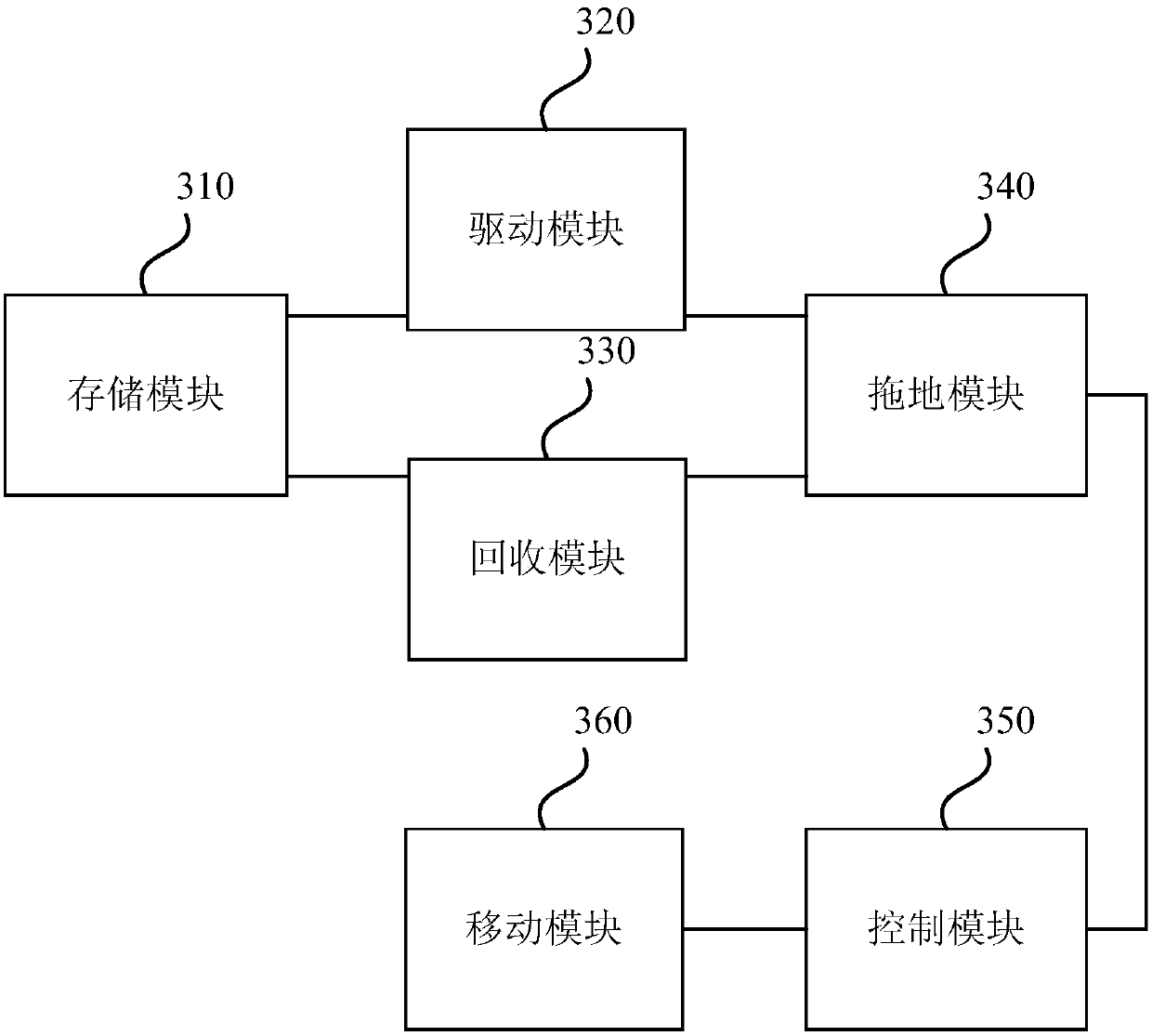

[0069] image 3 A schematic structural diagram of a mopping robot provided by Embodiment 3 of the present invention. On the basis of the above-mentioned embodiments, this embodiment preferably further includes:

[0070] The recovery module is respectively connected to the storage module and the mopping module, and is used for recovering the cleaning medium released by the mopping module and storing the cleaning medium in a predetermined position of the storage module.

[0071] The mopping robot includes:

[0072] Storage module 310, driving module 320, recycling module 330, mopping module 340, control module 350 and moving module 360;

[0073] Wherein, the storage module 310 is used to store and output the cleaning medium;

[0074] The driving module 320 is connected to the storage module and the mopping module respectively, and is used to drive the storage module to output the cleaning medium and install the cleaning medium at a predetermined position of the mopping module;...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com