Middle row seat mounting cross beam

A seat and crossbeam technology, which is applied in the field of middle row seat installation crossbeams, can solve the problems of poor torsional rigidity and side impact resistance, poor seat installation point stiffness, and long side impact force transmission path, etc., to improve the overall strength , Convenient installation and positioning, and the effect of reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be described in further detail below in conjunction with accompanying drawing embodiment:

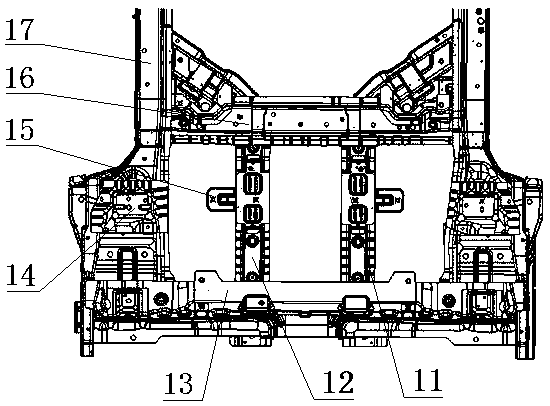

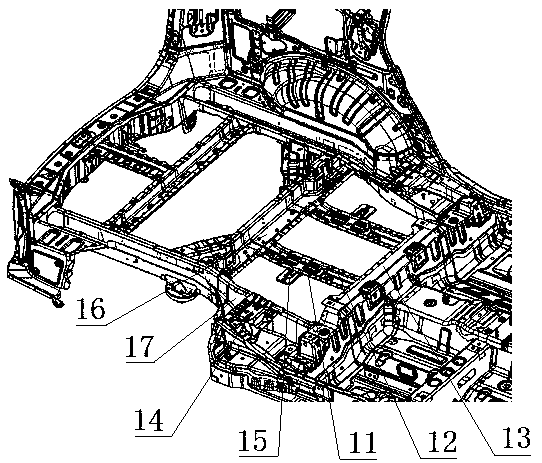

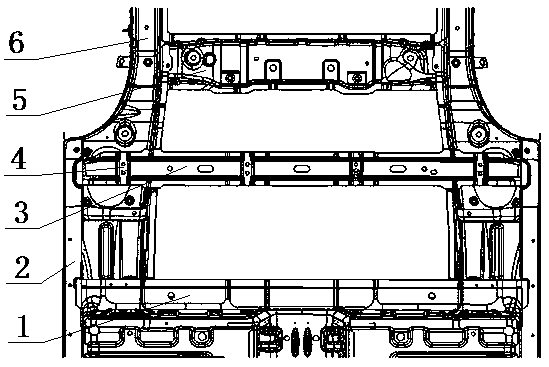

[0021] Such as image 3 The shown middle row seat installation beam includes a seat beam 3 located between the rear floor front beam 1 and the rear floor lower beam 5, and the two ends of the seat beam 3 respectively pass through the rear longitudinal beam 6 and the door sill beam 2 welding, four seat mounting brackets 4 are arranged at intervals on the seat beam 3 . The seat beam 3 has two side support plates 3-1 protruding upwards, and the two side support plates 3-1 are arranged oppositely along the length direction of the seat beam 3, and the side support plates 3-1 are provided at intervals for restricting the seat. The four positioning slots at the 4 positions of the chair mounting bracket, such as Figure 5 shown. The seat mounting bracket 4 has a mounting plate 4-1, and the mounting plate 4-1 is provided with two seat mounting holes, and the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com