Manual operation mechanism of cassette recorder with automatic conversion

An automatic reverse and manual operation technology, applied in manual/electromagnetic control, filamentary/mesh carrier operation control, data recording, etc., can solve problems such as complex structure, and achieve the effect of improving the cab environment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0052] Embodiments of the present invention will be described below.

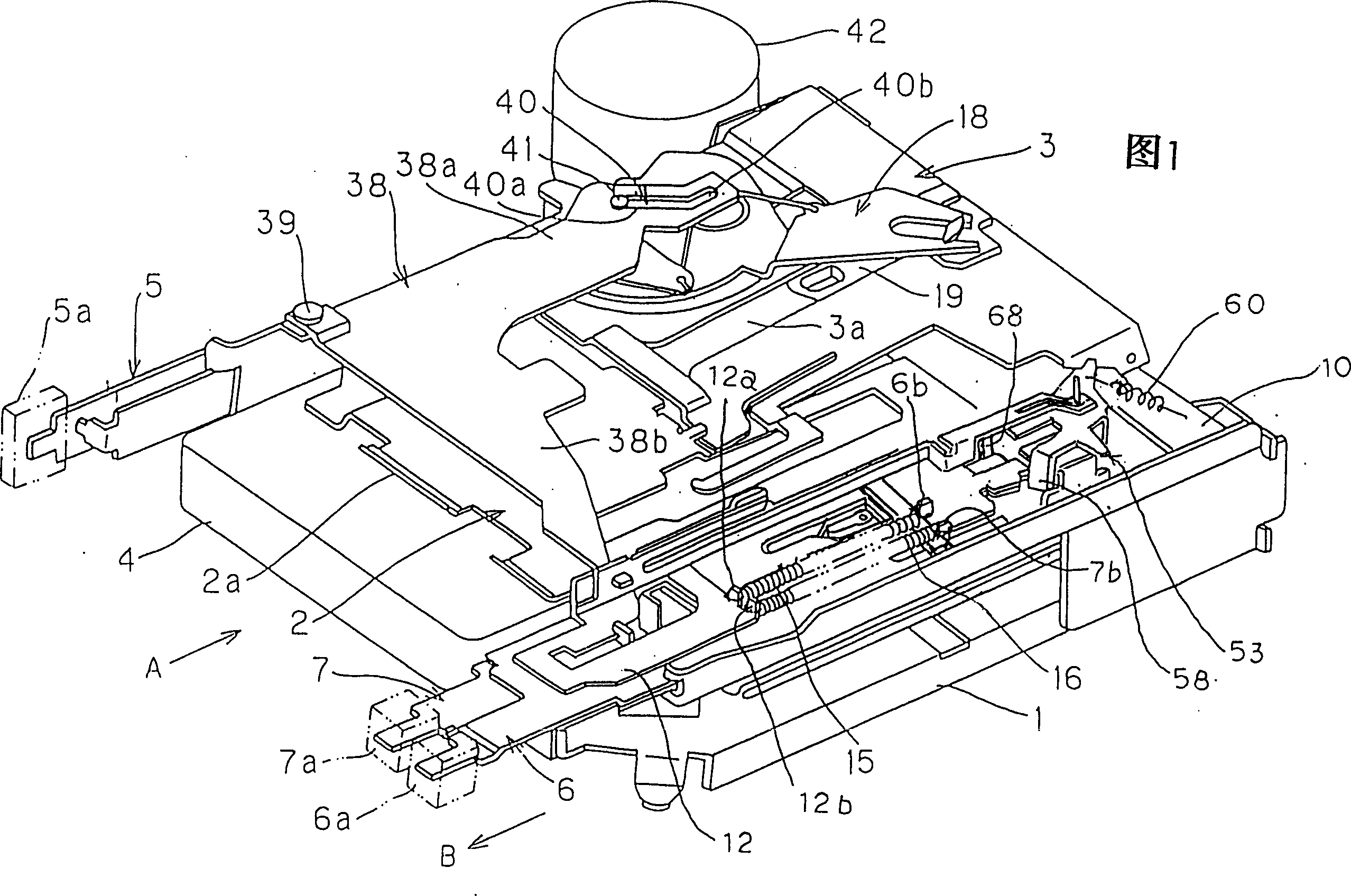

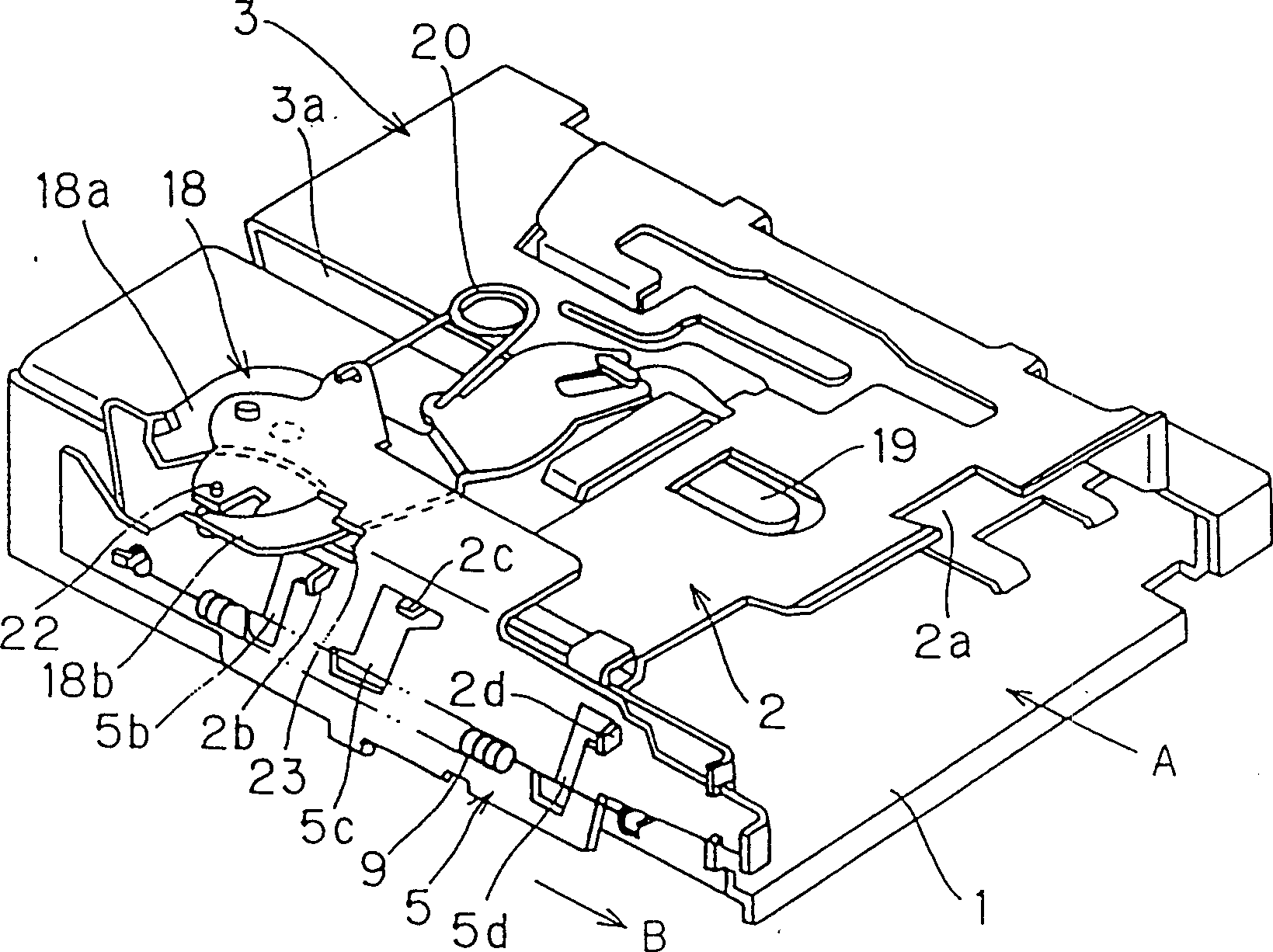

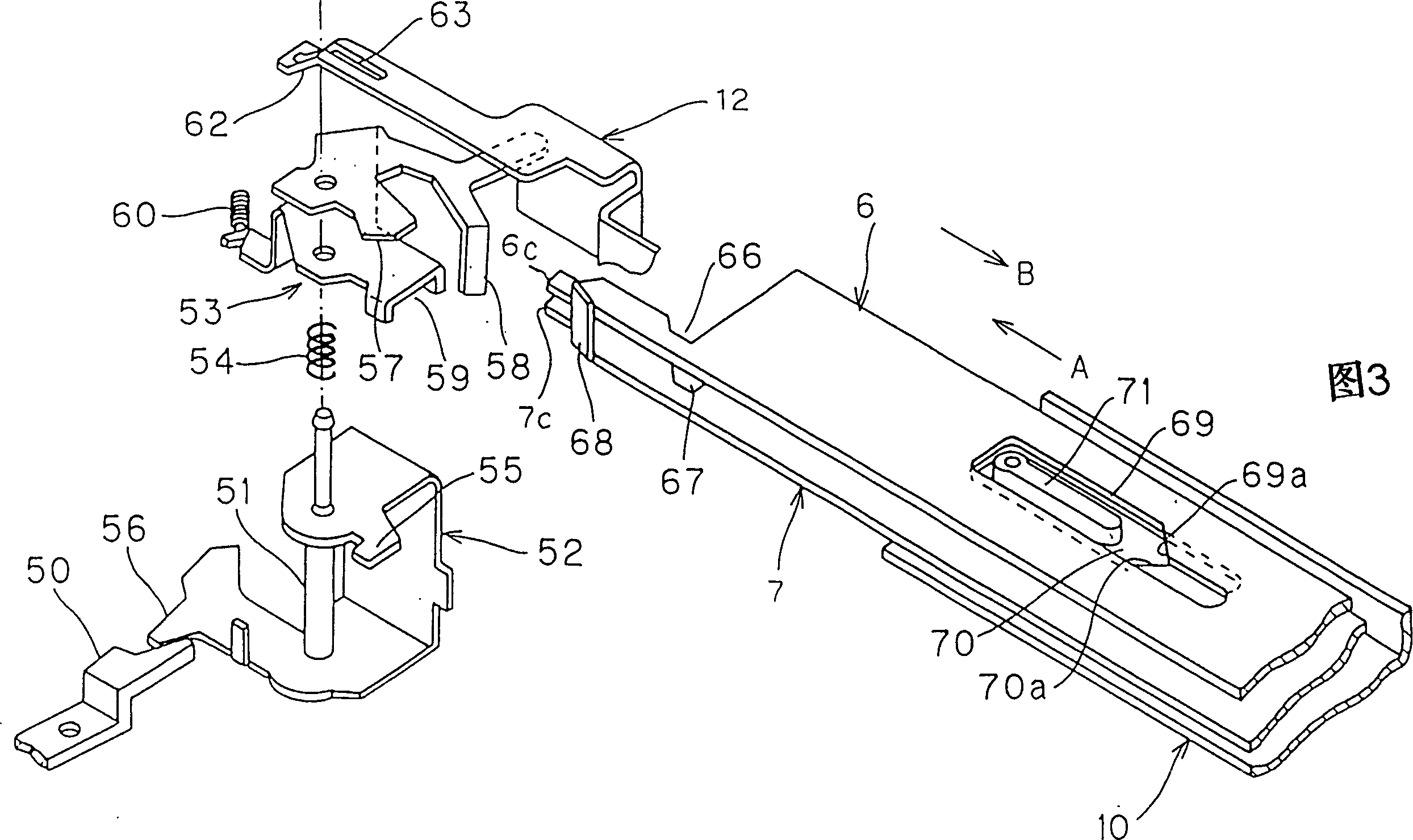

[0053] Fig. 1 is a three-dimensional schematic diagram of the mechanism part of the vehicle-mounted automatic reversing cassette recorder loaded with the manual operation mechanism of the present invention. The cassette holder 2 is mounted on the base plate 1 by a swing plate 3 . Specifically, the pendulum plate is installed on the upper part of the rear side of the base plate 1 (the right end in the figure), and can swing freely, and the tape cassette holder 2 is pivotally supported at its swing end. The tape cassette 4 is inserted in the direction indicated by the arrow A through the cassette insertion port 2a provided at the front end of the cassette holder 2 (the left end in the drawing). What Fig. 1 showed is the state that tape cassette 4 is loaded into and playing sound in the tape recorder.

[0054] The above-mentioned tape recorder is installed in the dashboard of the car with its cassette insert...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com