Patents

Literature

124results about "Carrier container guidance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

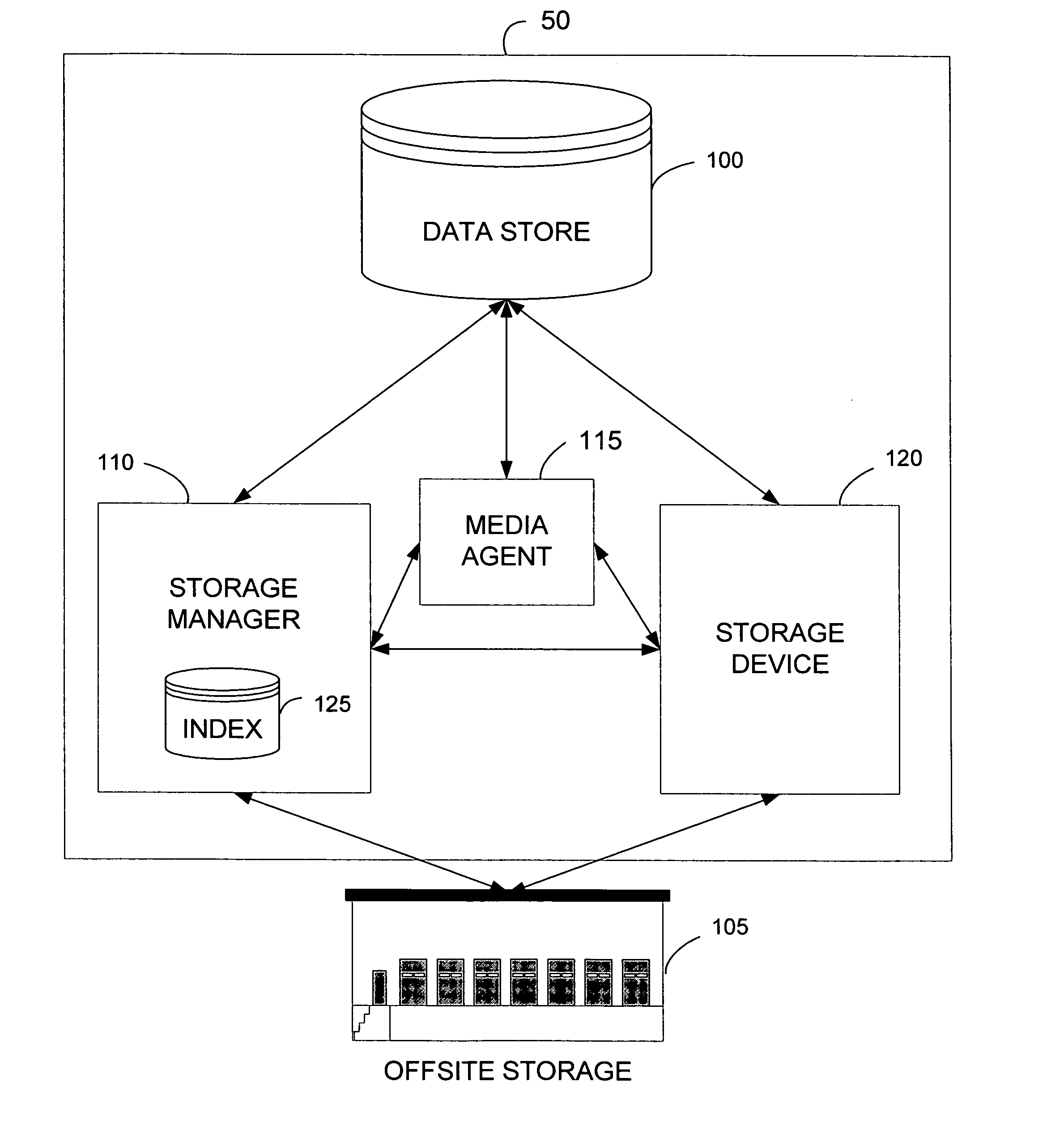

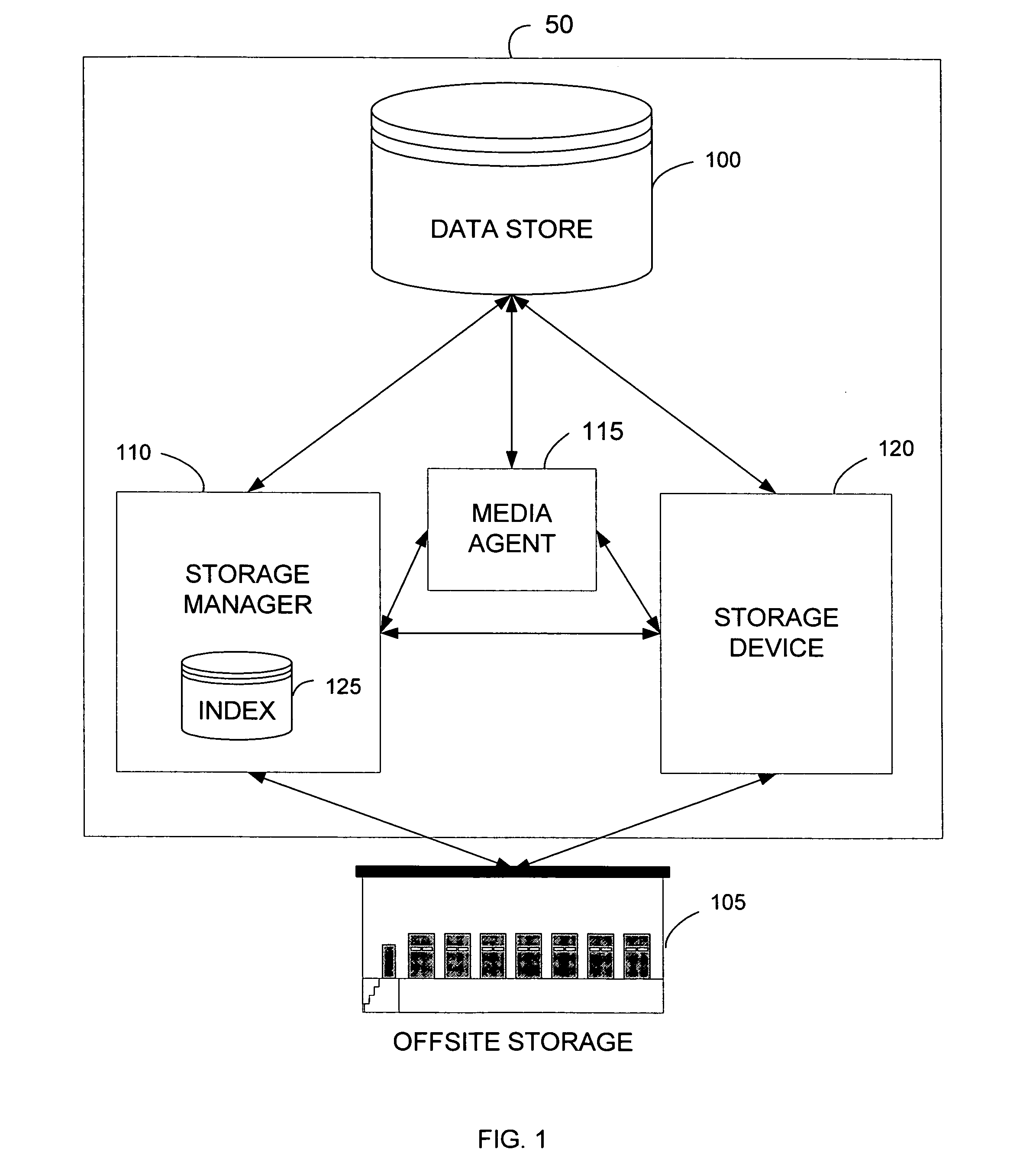

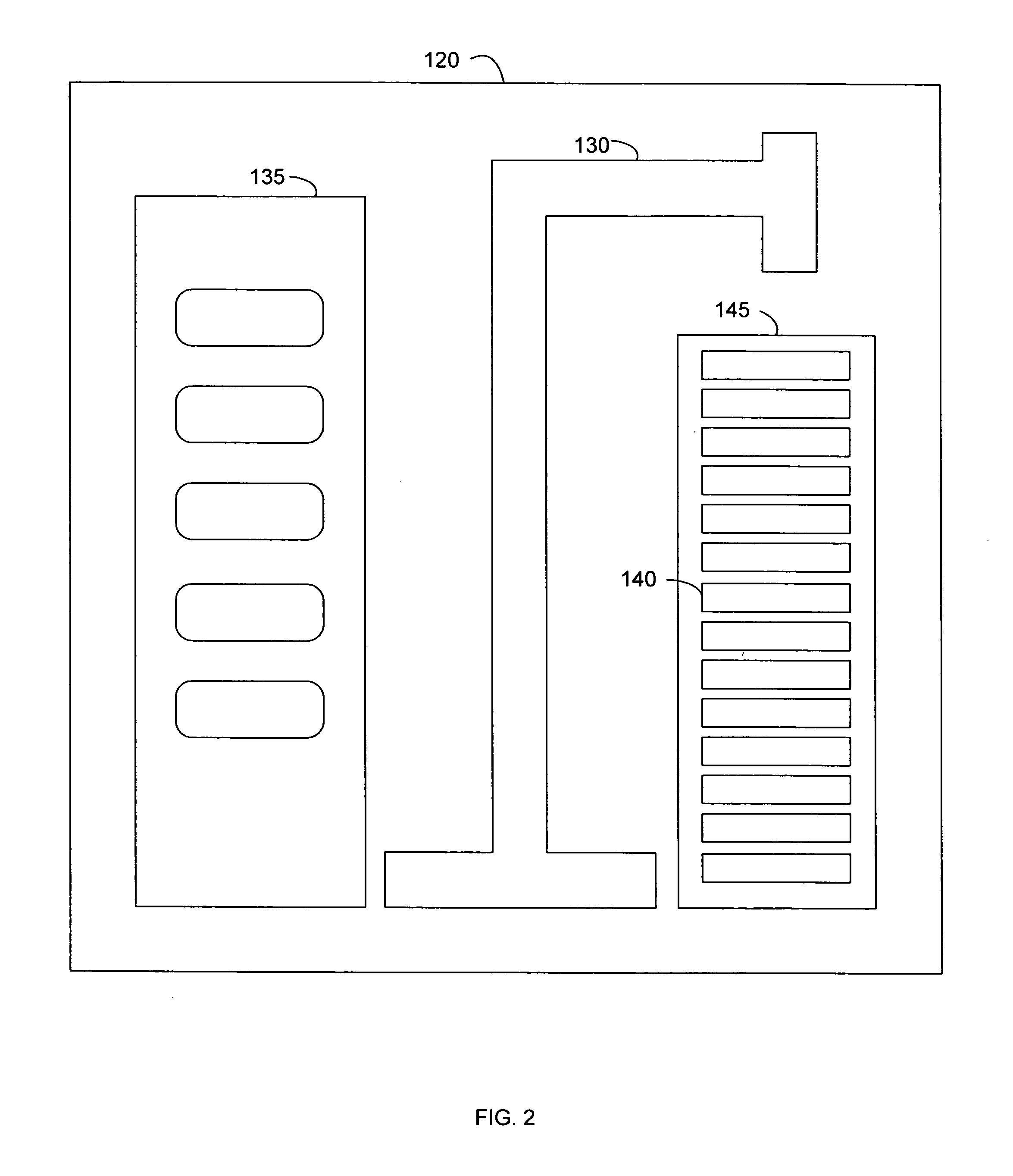

System and method for data storage and tracking

The invention provides a method and system for transferring storage media scheduled for export from a storage device. The storage media is identified according to retention characteristics for export, and placed in a location near to the storage device exit point prior to it scheduled export out of the storage device to offsite storage. The storage device interfaces with the storage management system used at the offsite storage to provide tracking of the storage media at the offsite location. The location of the media is tracked within the storage system and at the offsite storage, for administrative, reporting or other uses.

Owner:COMMVAULT SYST INC

Magnetic tape device and magnetic reproducing method

ActiveUS20180182430A1Avoid it happening againReduce resistanceRecord information storageTape carriersMagnetic tapeFull width at half maximum

The magnetic tape device includes: a magnetic tape; and a reproducing head, in which the reproducing head is a TMR head, the magnetic tape includes a non-magnetic support, and a magnetic layer including ferromagnetic powder, a binding agent, and fatty acid ester on the non-magnetic support, a full width at half maximum of spacing distribution measured by optical interferometry regarding a surface of the magnetic layer before performing a vacuum heating with respect to the magnetic tape is greater than 0 nm and equal to or smaller than 7.0 nm, a full width at half maximum of spacing distribution measured after performing the vacuum heating is greater than 0 nm and equal to or smaller than 7.0 nm, and a difference between a spacing measured by optical interferometry regarding the surface of the magnetic layer after performing the vacuum heating with respect to the magnetic tape and a spacing measured before performing the vacuum heating is greater than 0 nm and equal to or smaller than 9.0 nm.

Owner:FUJIFILM CORP

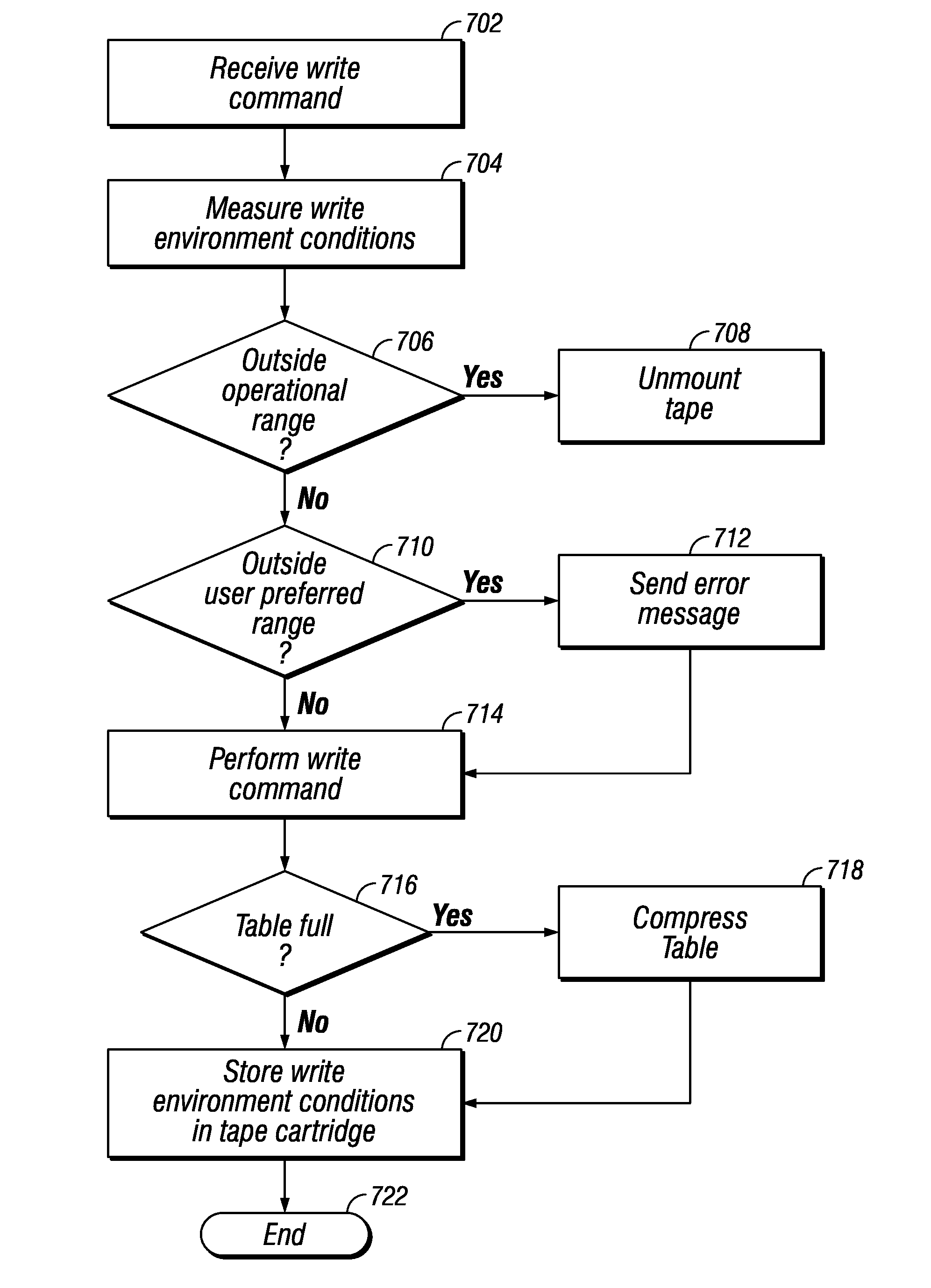

Storing write environment conditions

ActiveUS9190112B1Filamentary/web carriers operation controlCarrier drive disengaging meansMagnetic tapeFailure analysis

Described are embodiments of an invention for storing write environment conditions of a tape cartridge. A tape drive measures and stores the write environment conditions for a portion of tape as a result of receiving a write command to write data to the same portion of tape. In one embodiment, the write environment conditions are measured and stored to the tape cartridge each time a write command is received such that each portion of tape written has corresponding stored write environment conditions. The write environment conditions include temperature and relative humidity in one embodiment. The stored write environment conditions for each portion of tape written creates a historical log of the environment conditions that the tape was written within. The historical log can provide information to a manufacturer or user regarding the environmental conditions the user operates their tape drive within and provides information to assist with failure analysis.

Owner:IBM CORP

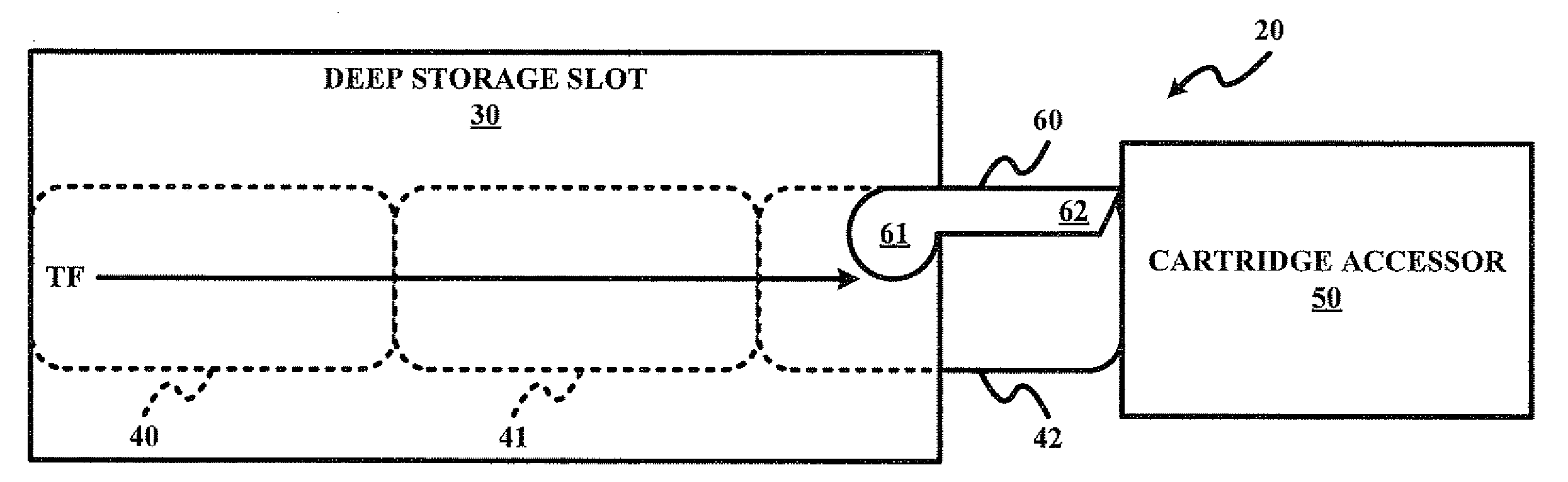

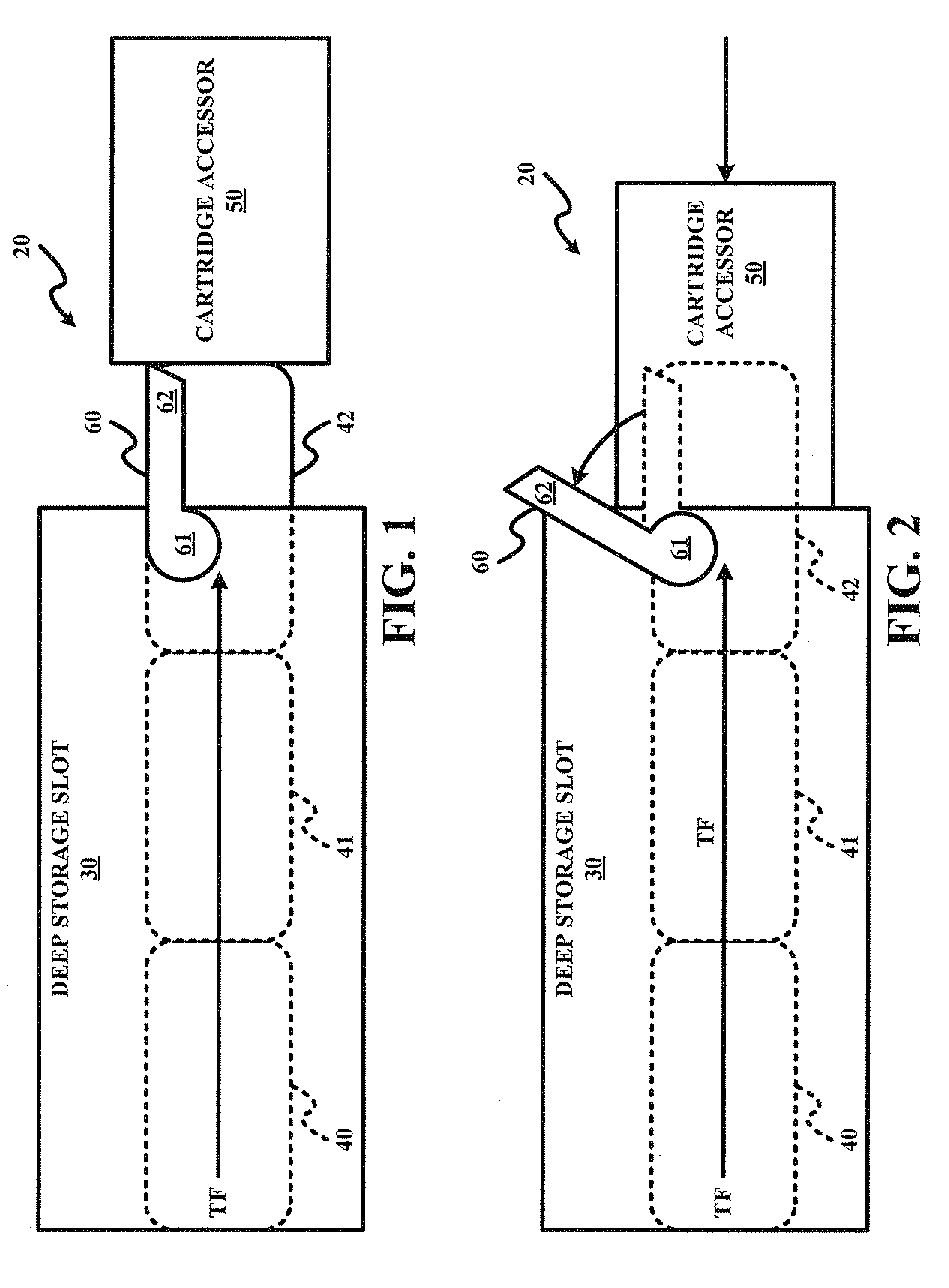

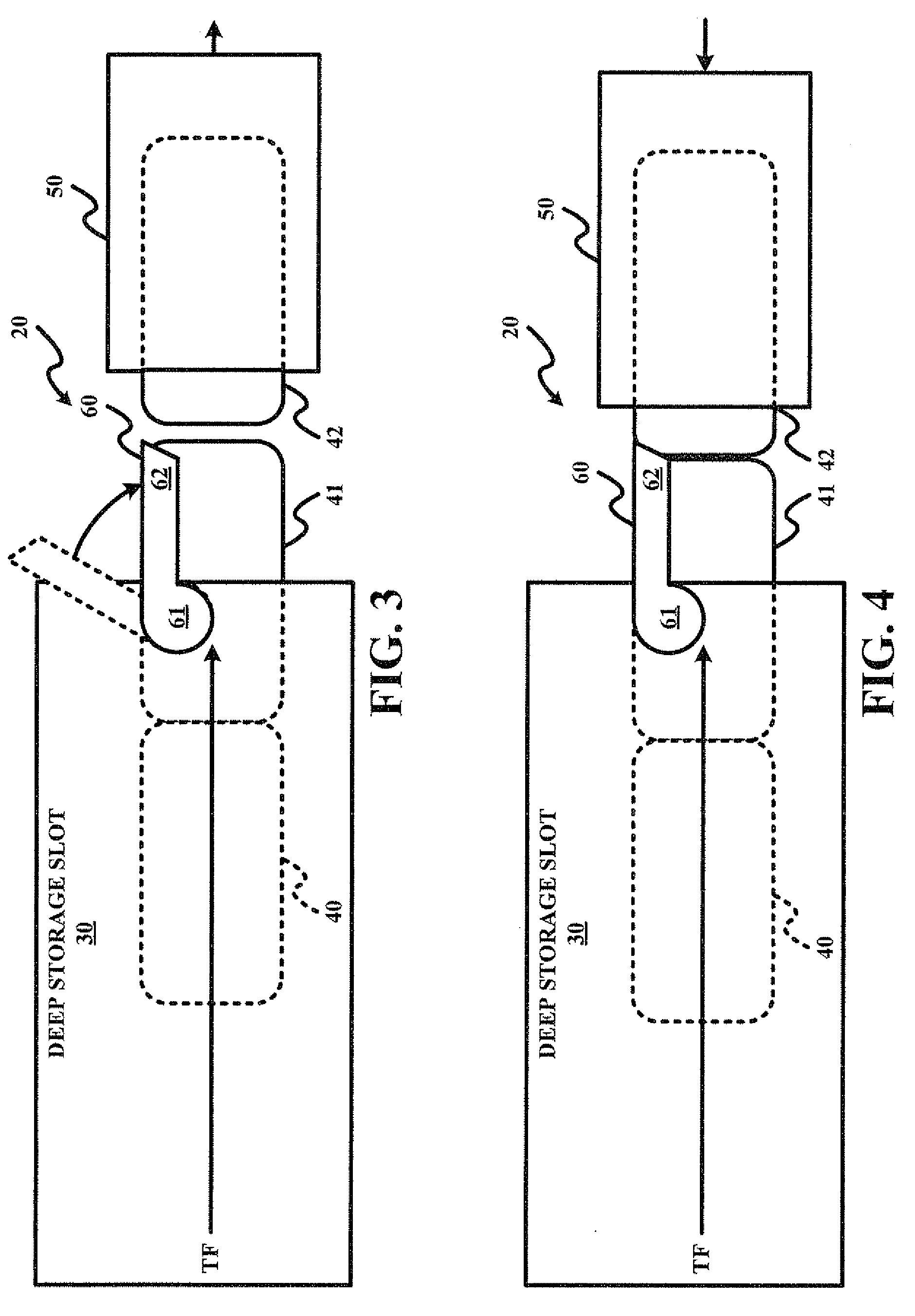

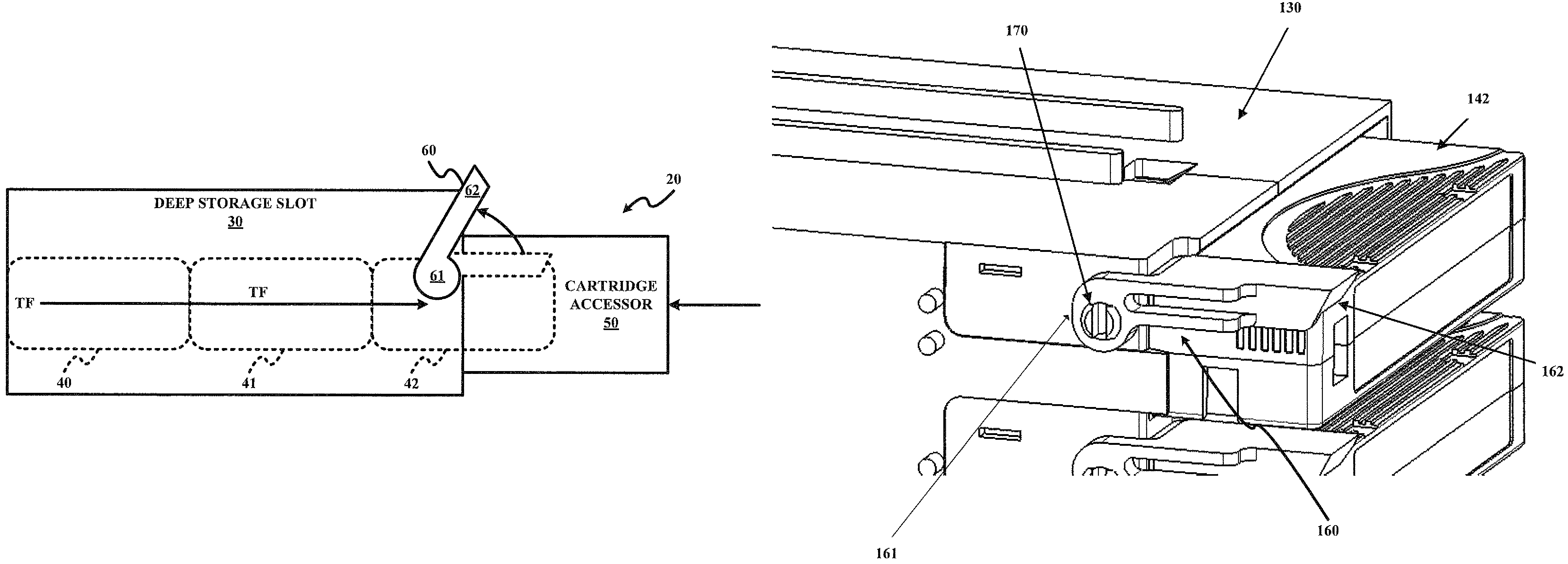

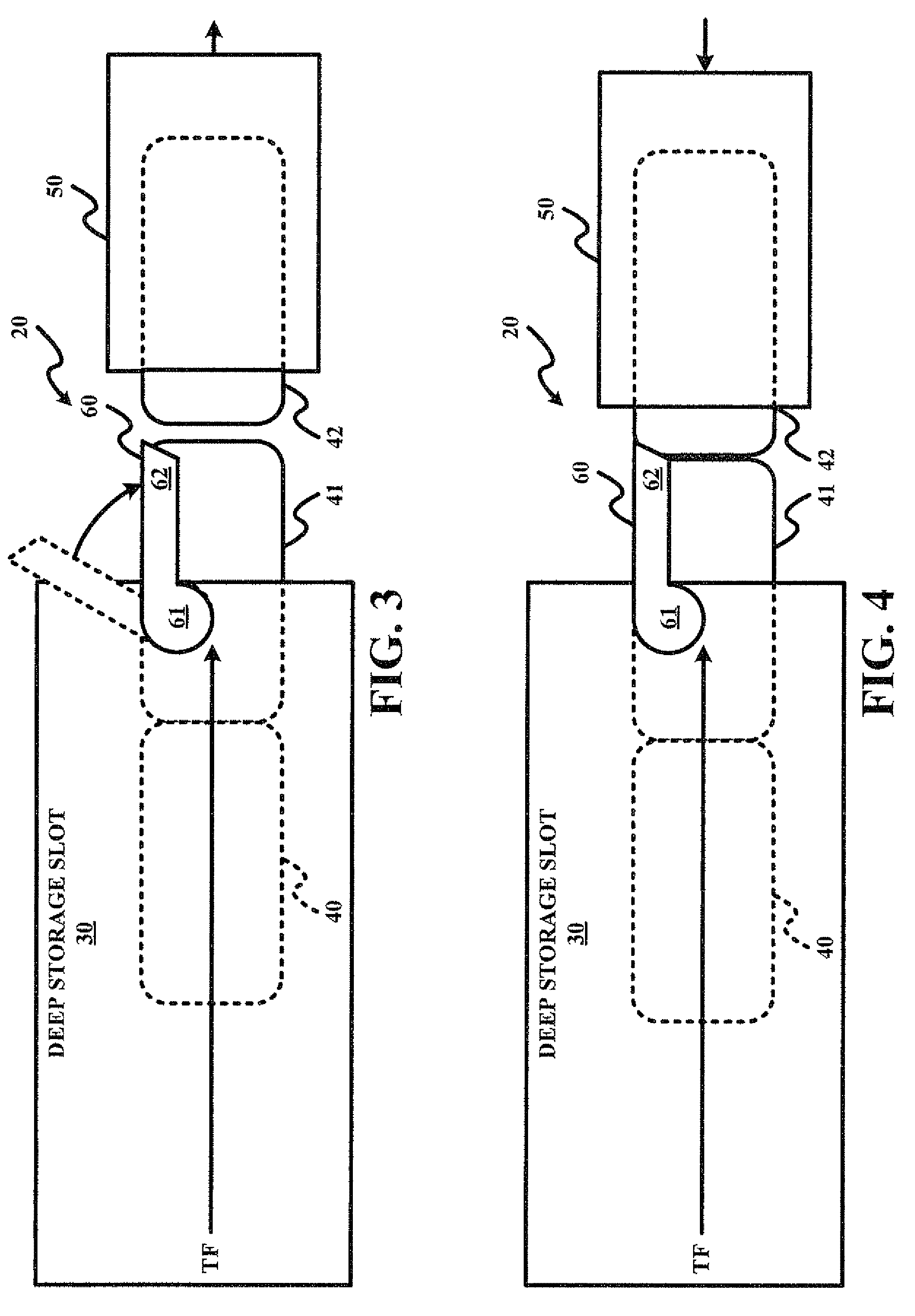

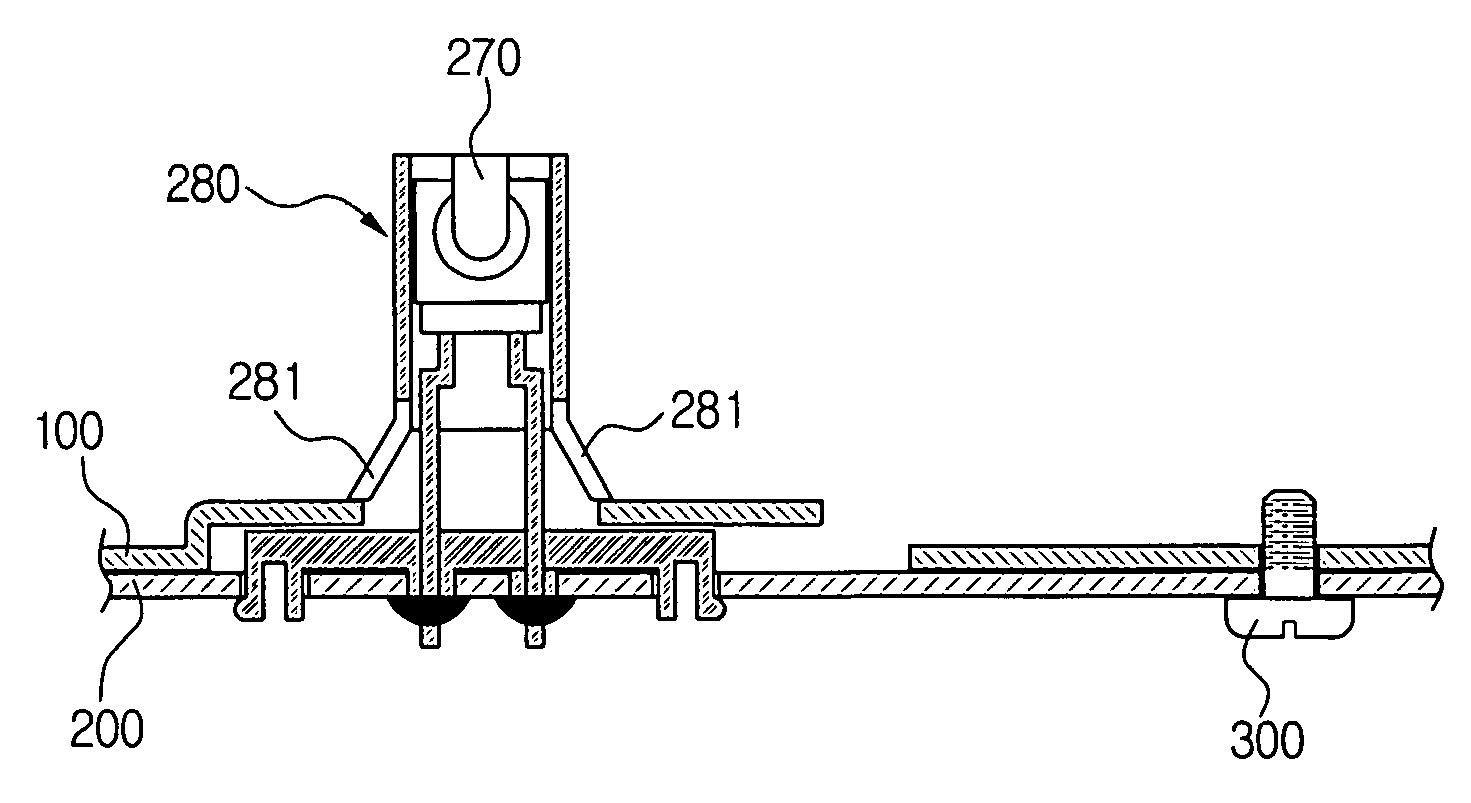

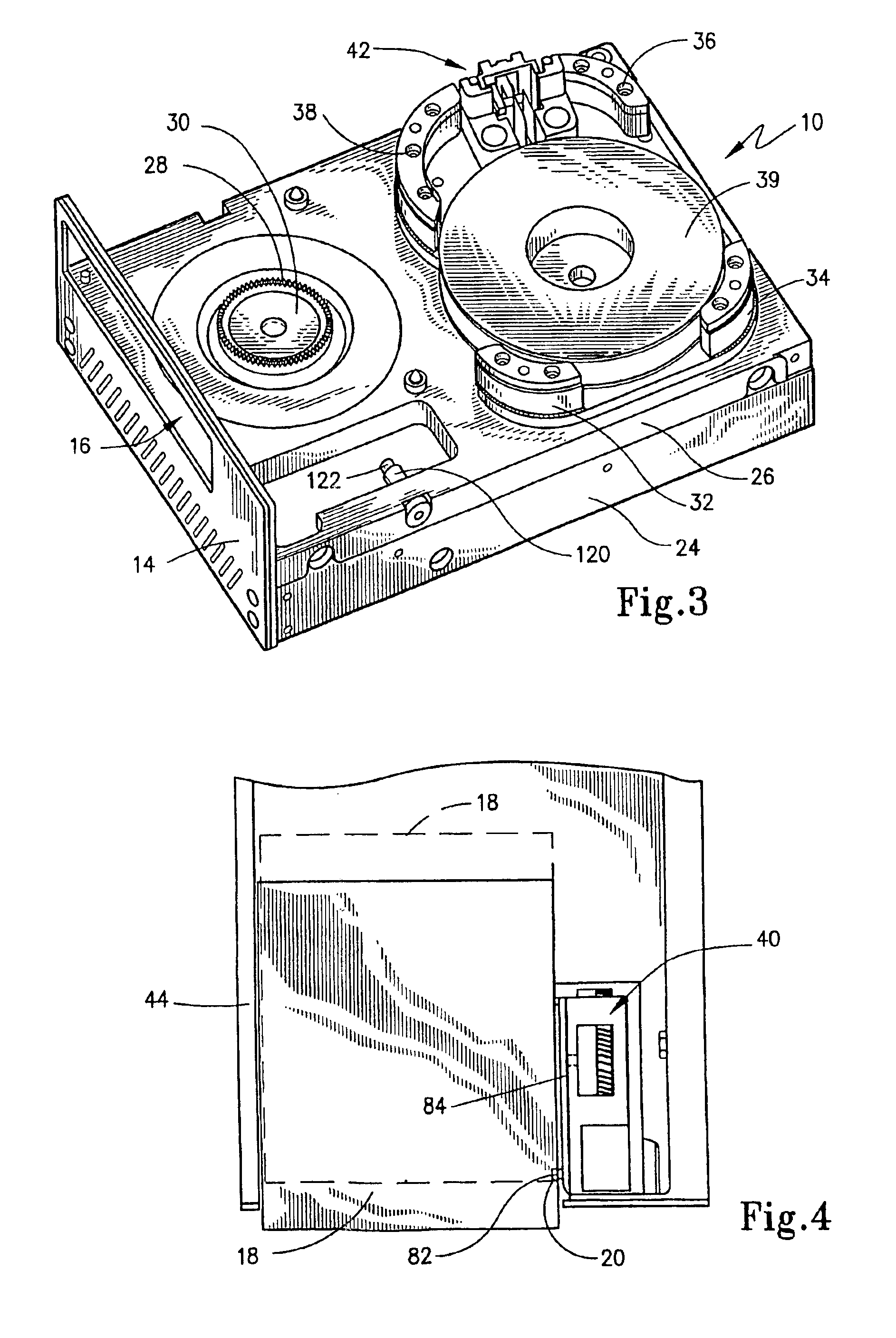

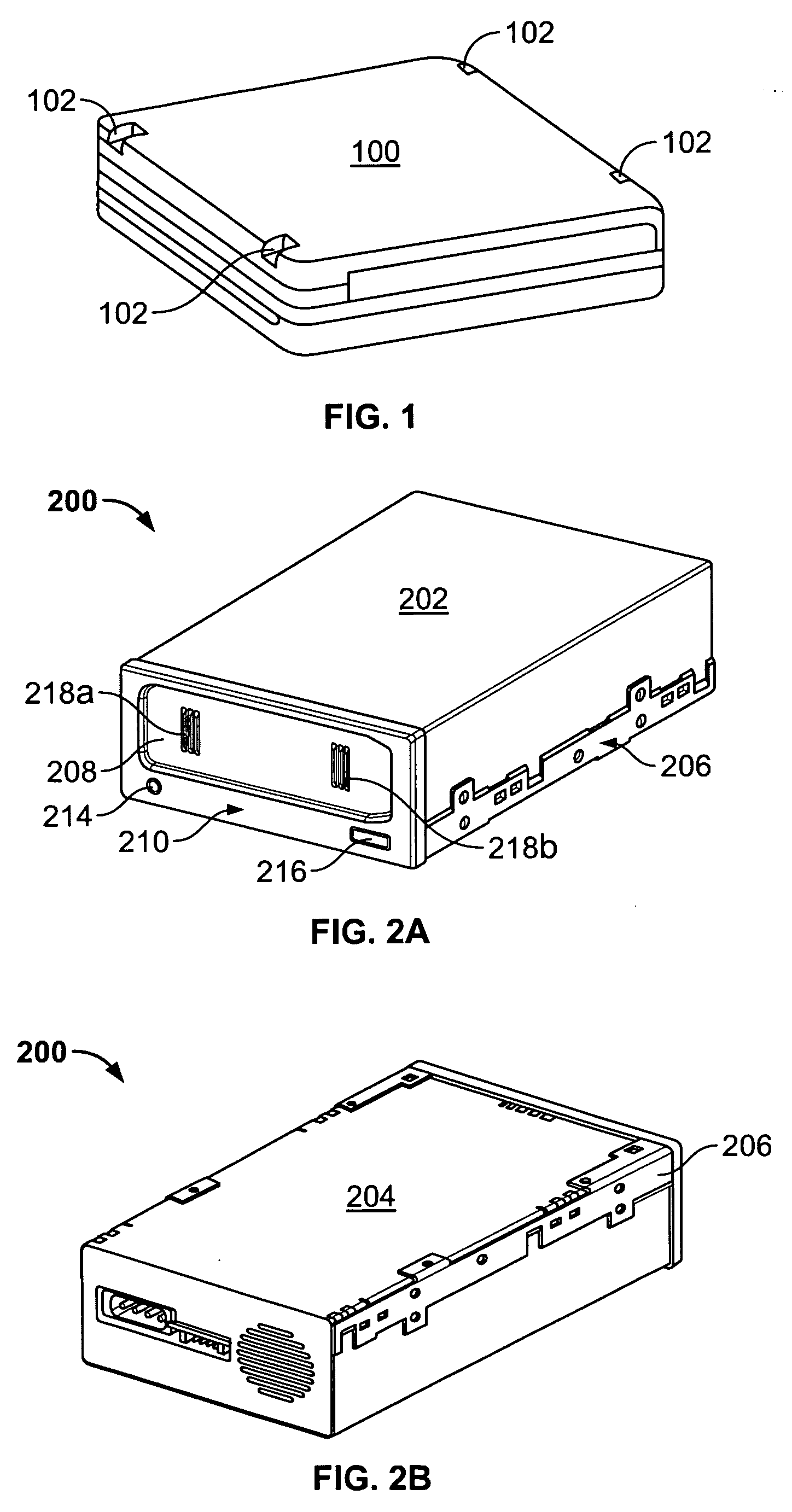

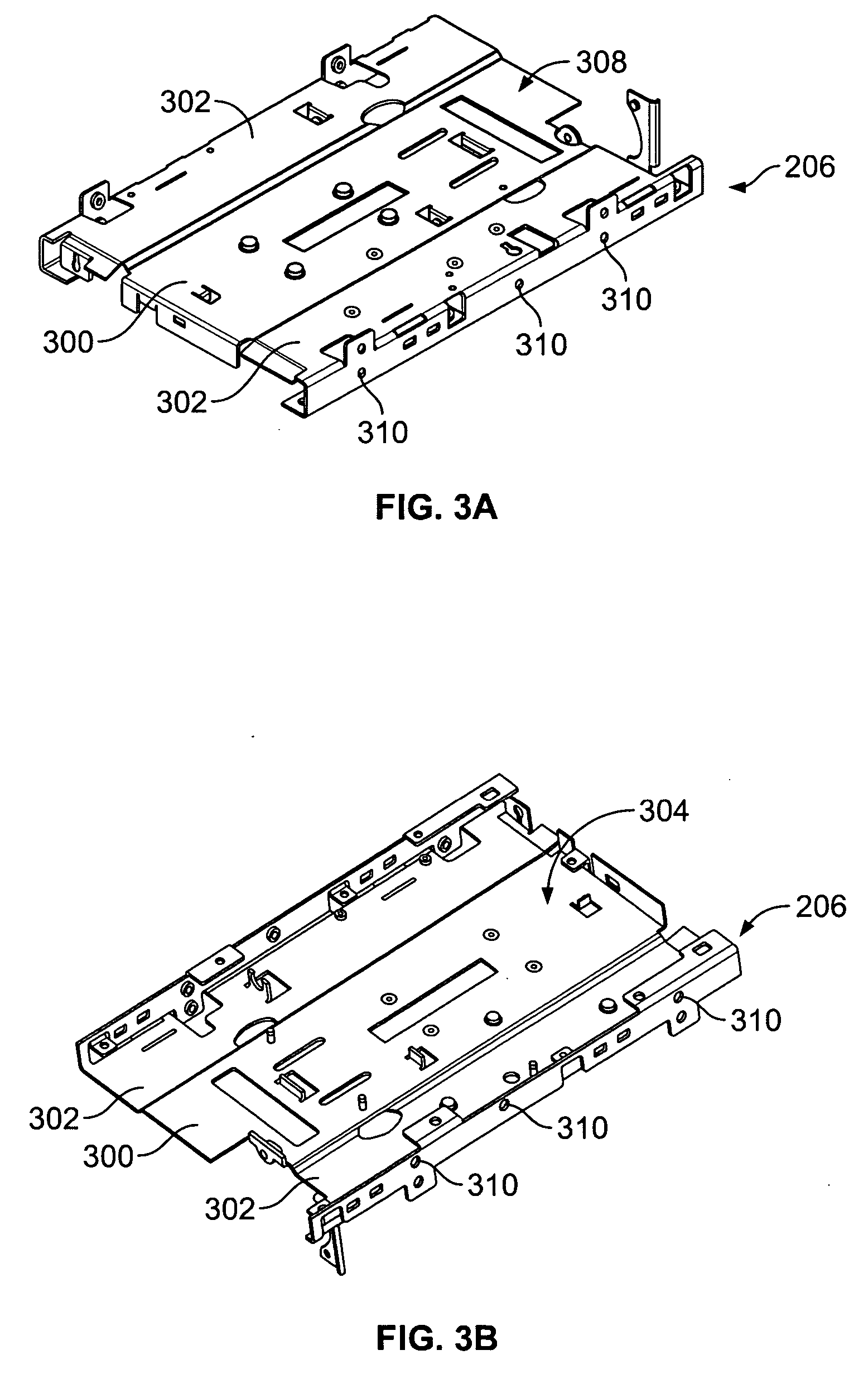

Retaining Gate for Deep Storage Slot Retention of Storage Cartridges

InactiveUS20080231988A1Promote sportsRecord information storageAutomatic cassette changing arrangementsEmbedded system

A storage cartridge retention device employs a deep storage slot for storing one or more storage cartridge(s) through its front opening and biases the stored storage cartridge(s) in a direction of its front opening. The storage cartridge retention device further employs a retaining gate external to the deep storage slot and movable relative to the front opening of the deep storage slot between a retaining position and a releasing position. The retaining position engages a front storage cartridge to retain the storage cartridge(s) within the deep storage slot based on the bias of the storage cartridge(s) in the direction of the front opening of the deep storage slot, and the releasing position disengages the front storage cartridge to facilitate movement of the one storage cartridge(s) within the deep storage slot based on the bias of the storage cartridge(s) in the direction of the front opening of the deep storage slot.

Owner:IBM CORP

Retaining gate for deep storage slot retention of storage cartridges

InactiveUS7843663B2Promote sportsRecord information storageAutomatic cassette changing arrangementsEmbedded system

A storage cartridge retention device employs a deep storage slot for storing one or more storage cartridge(s) through its front opening and biases the stored storage cartridge(s) in a direction of its front opening. The storage cartridge retention device further employs a retaining gate external to the deep storage slot and movable relative to the front opening of the deep storage slot between a retaining position and a releasing position. The retaining position engages a front storage cartridge to retain the storage cartridge(s) within the deep storage slot based on the bias of the storage cartridge(s) in the direction of the front opening of the deep storage slot, and the releasing position disengages the front storage cartridge to facilitate movement of the one storage cartridge(s) within the deep storage slot based on the bias of the storage cartridge(s) in the direction of the front opening of the deep storage slot.

Owner:IBM CORP

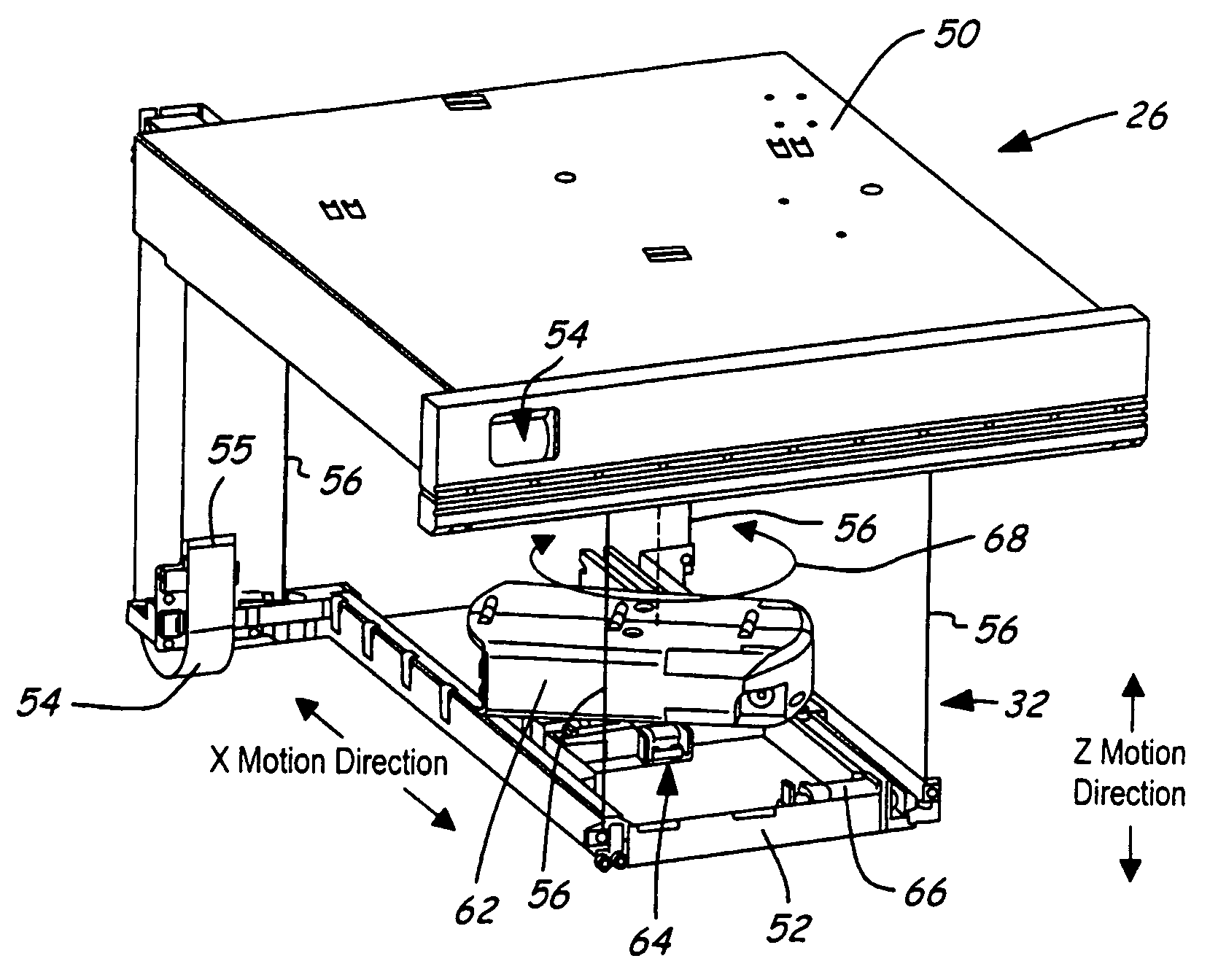

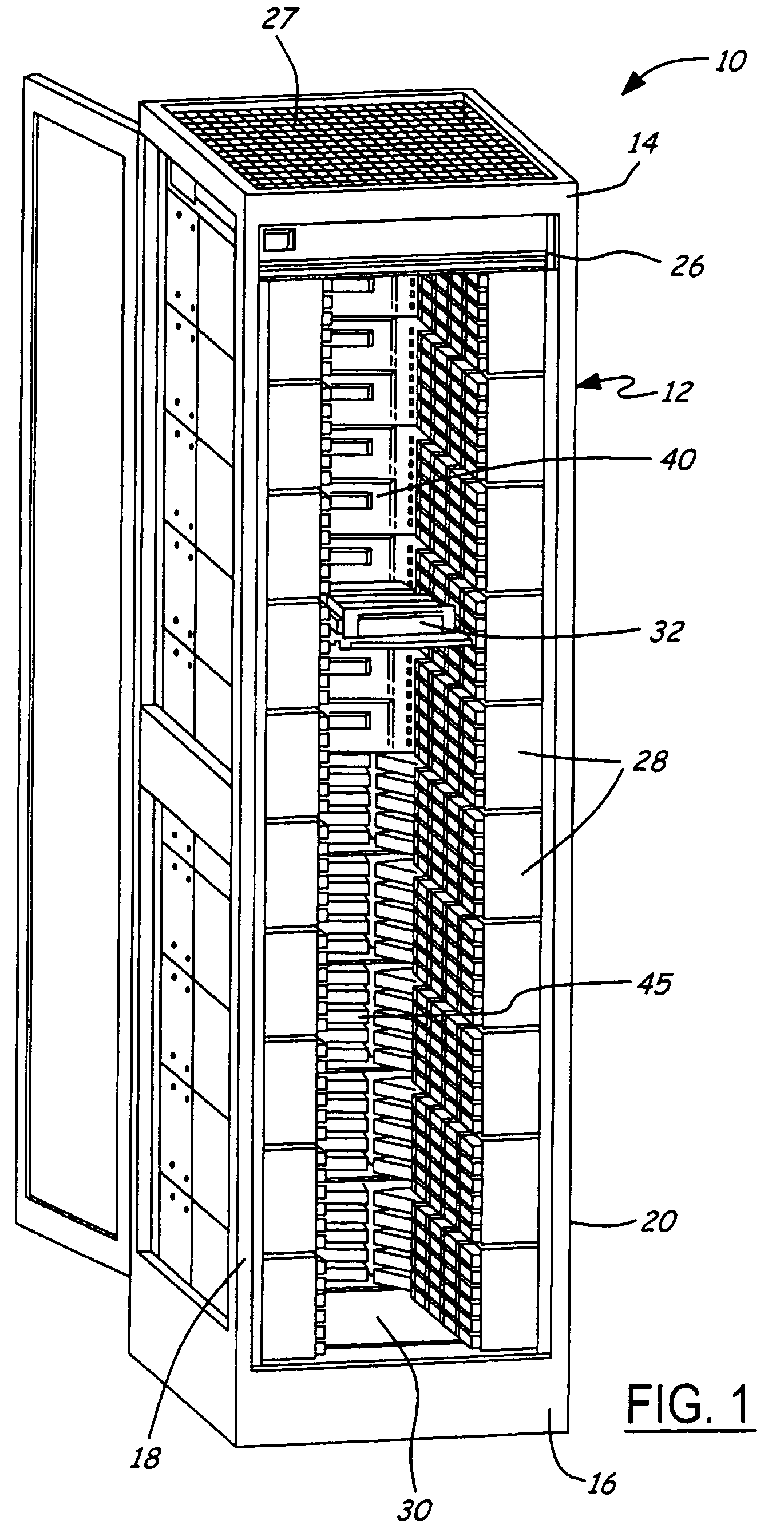

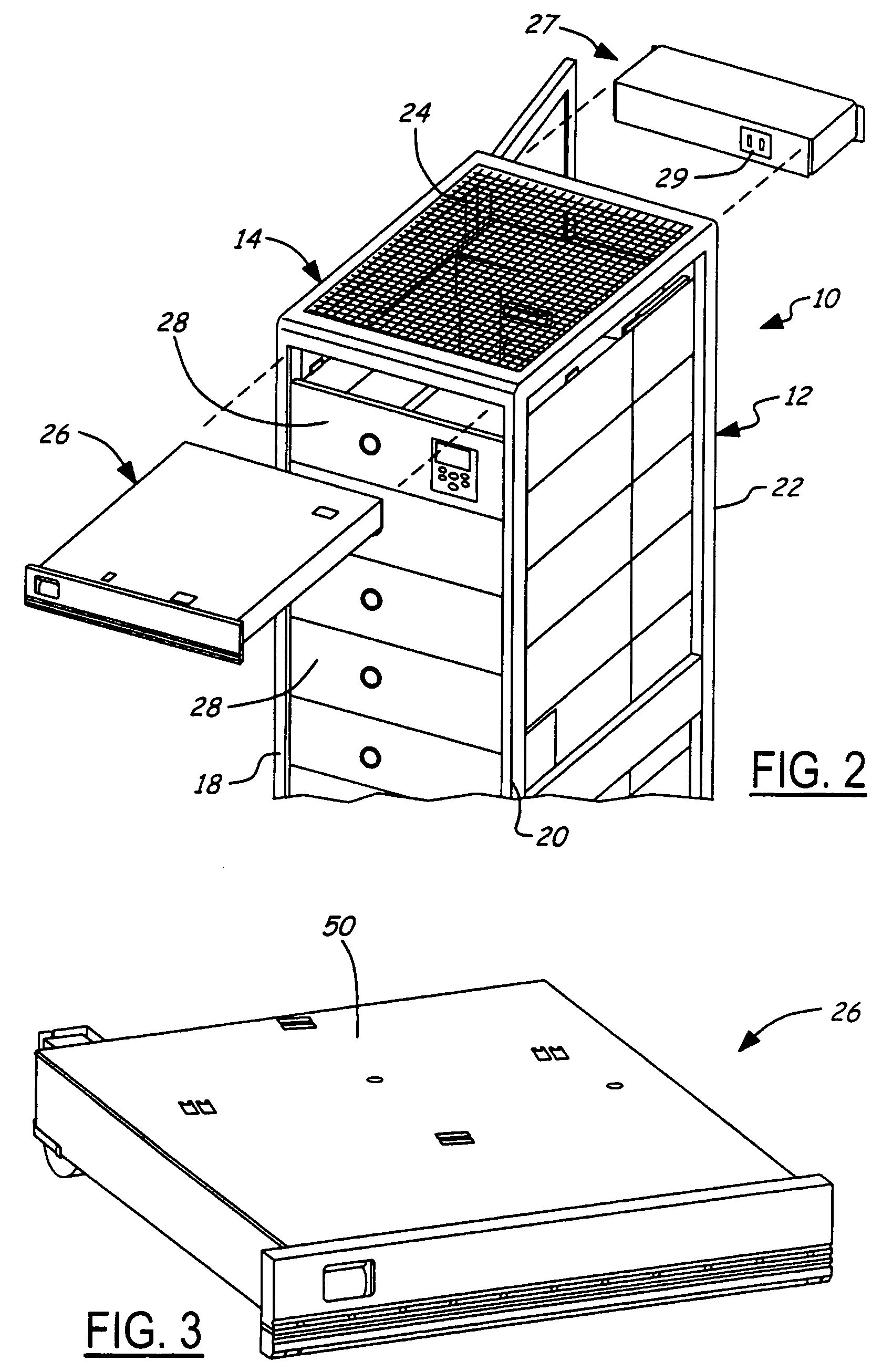

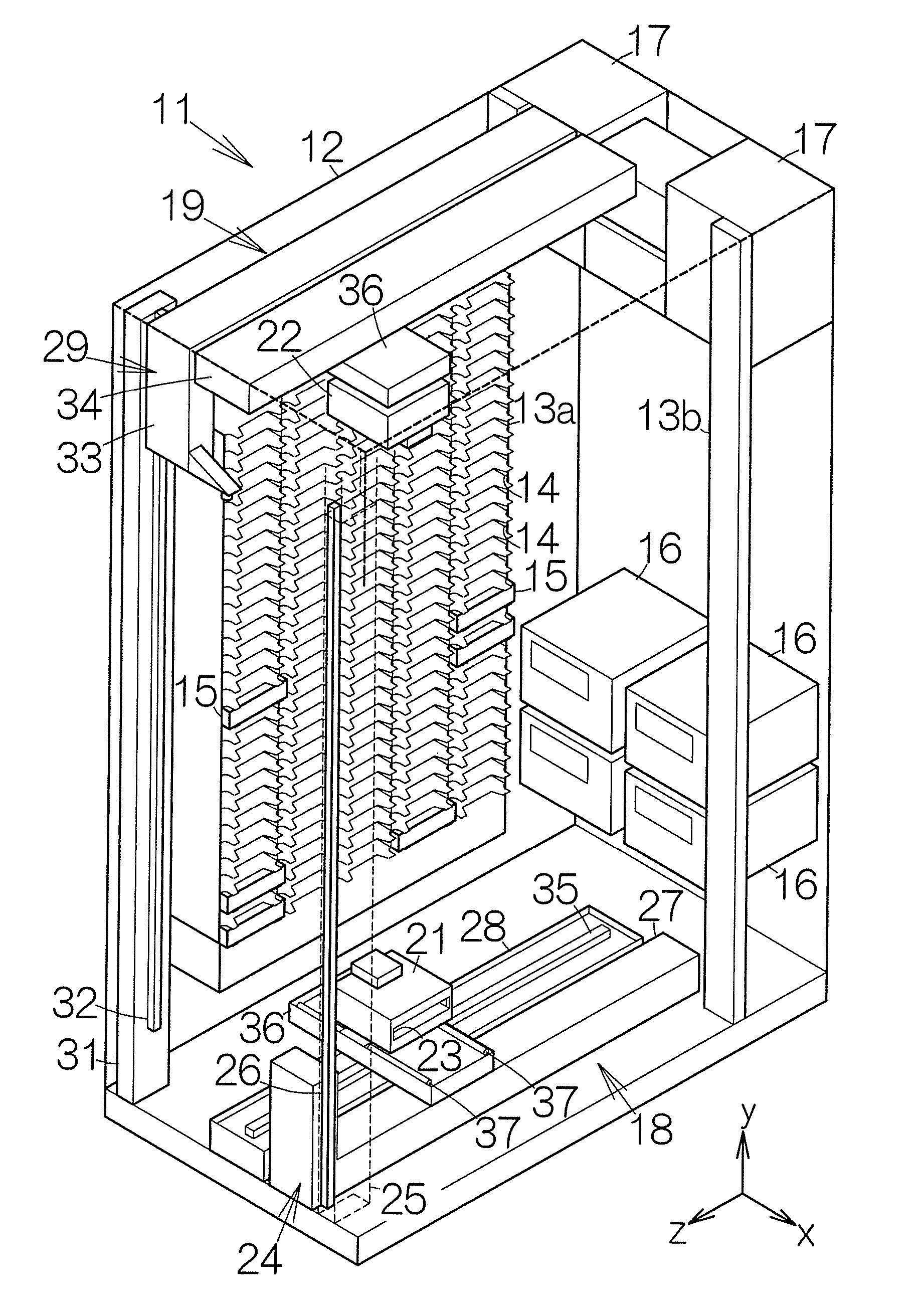

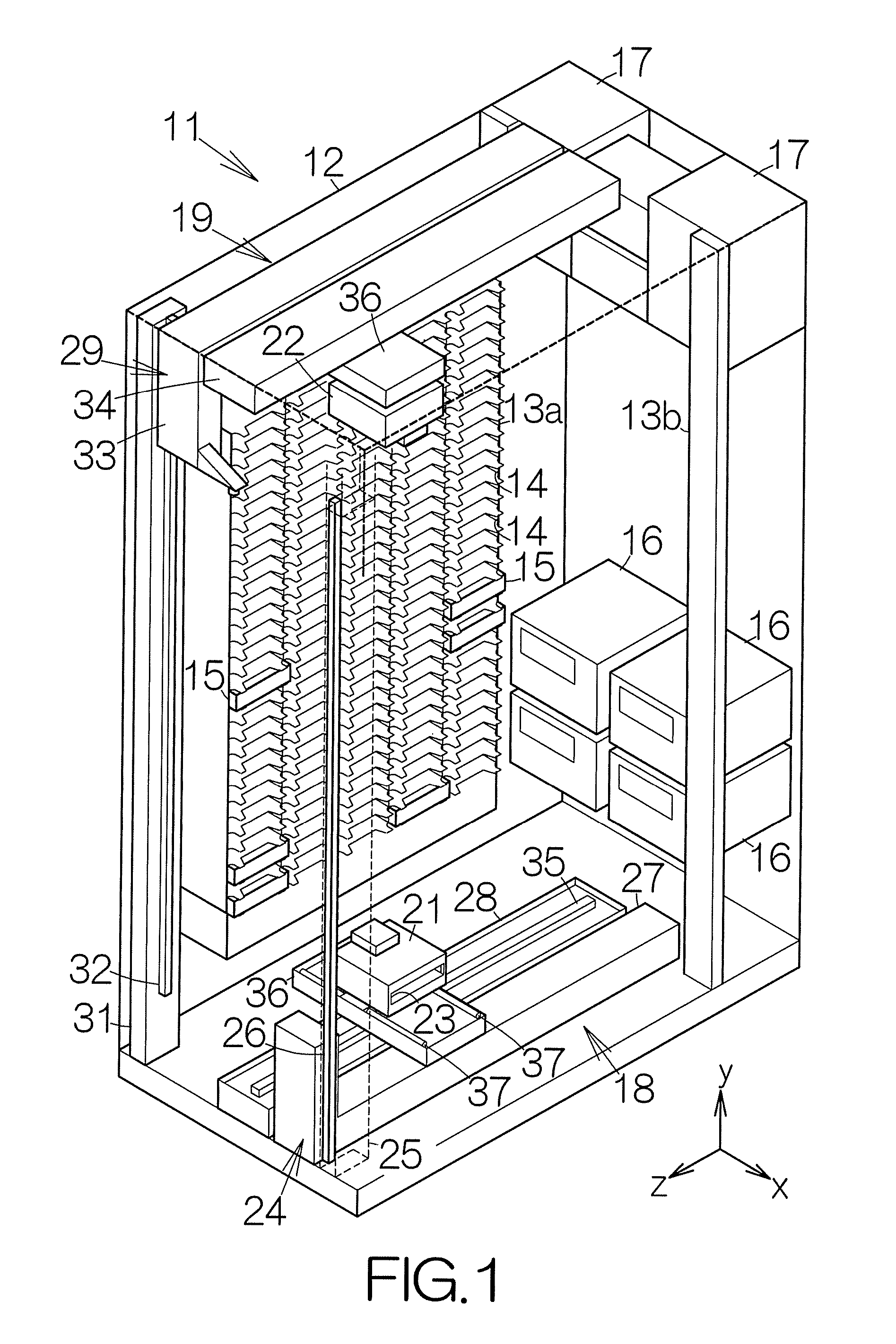

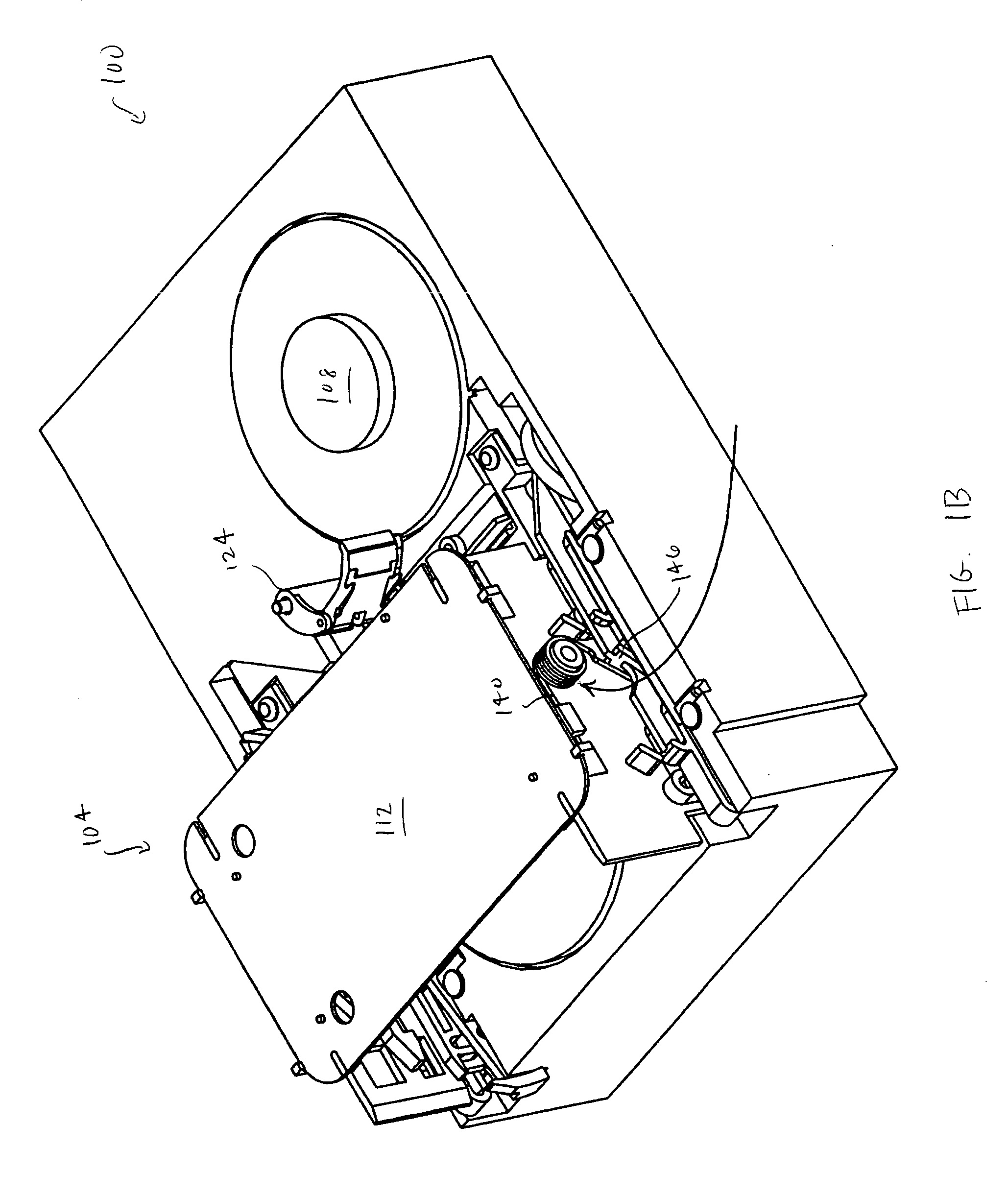

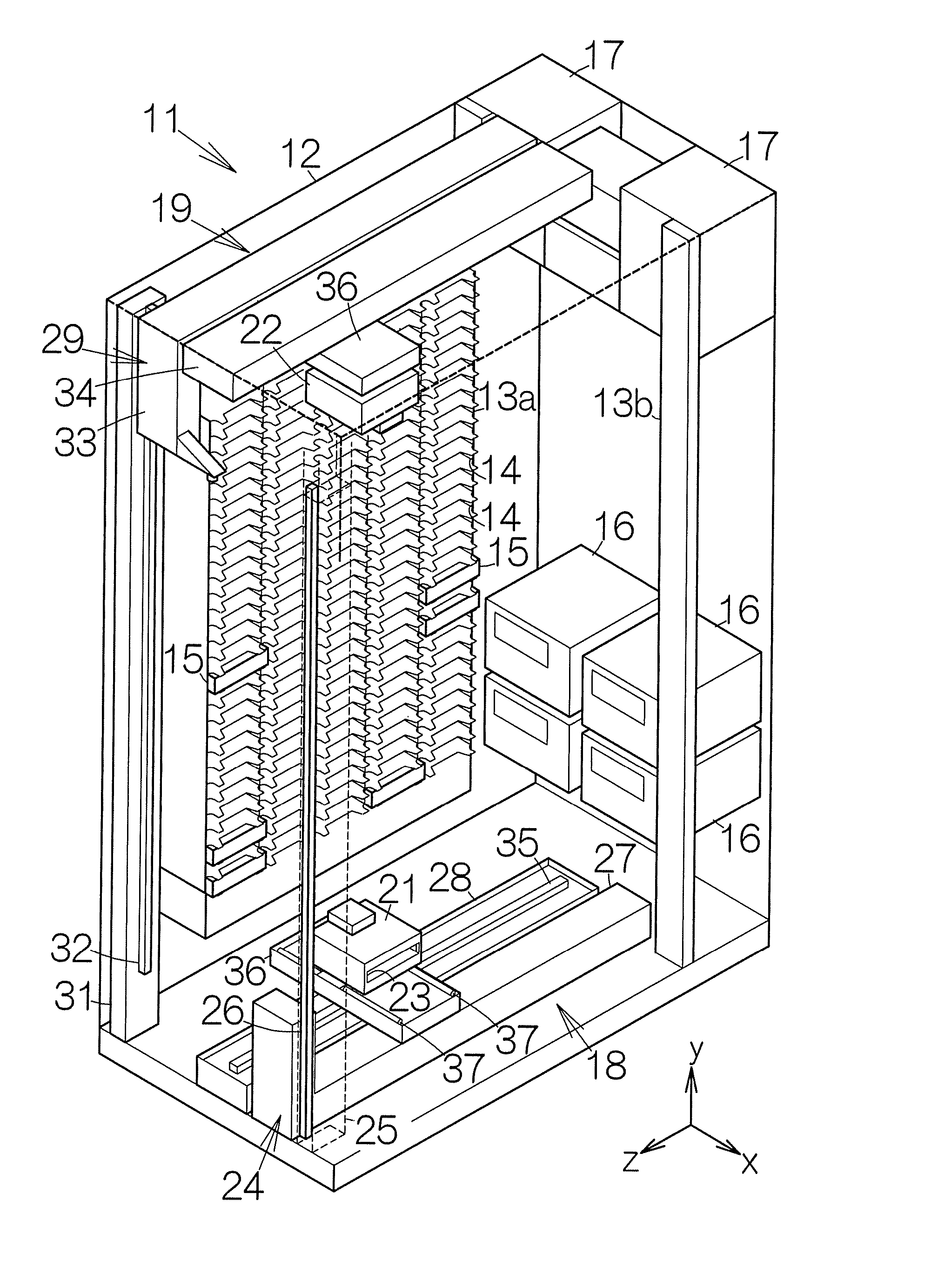

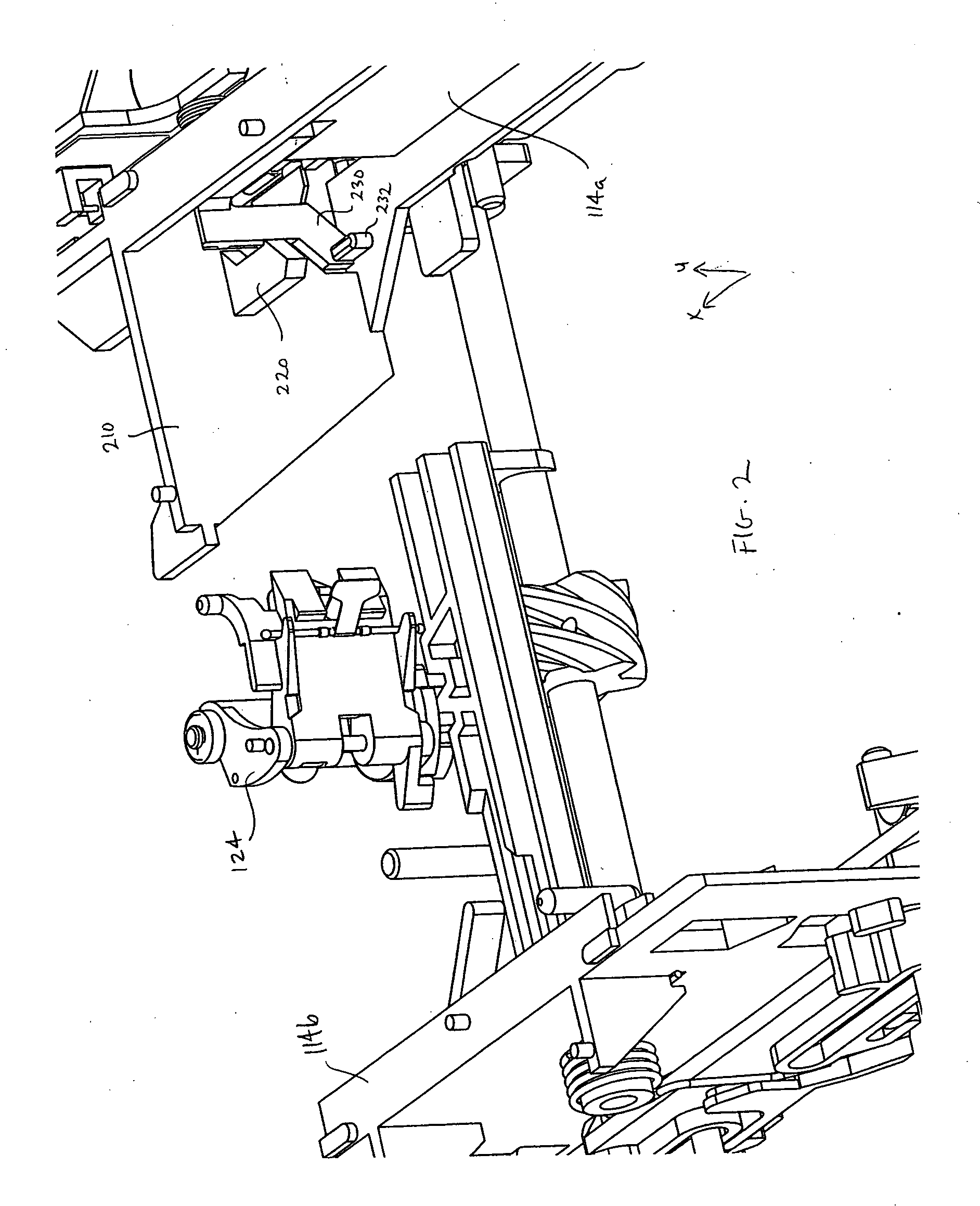

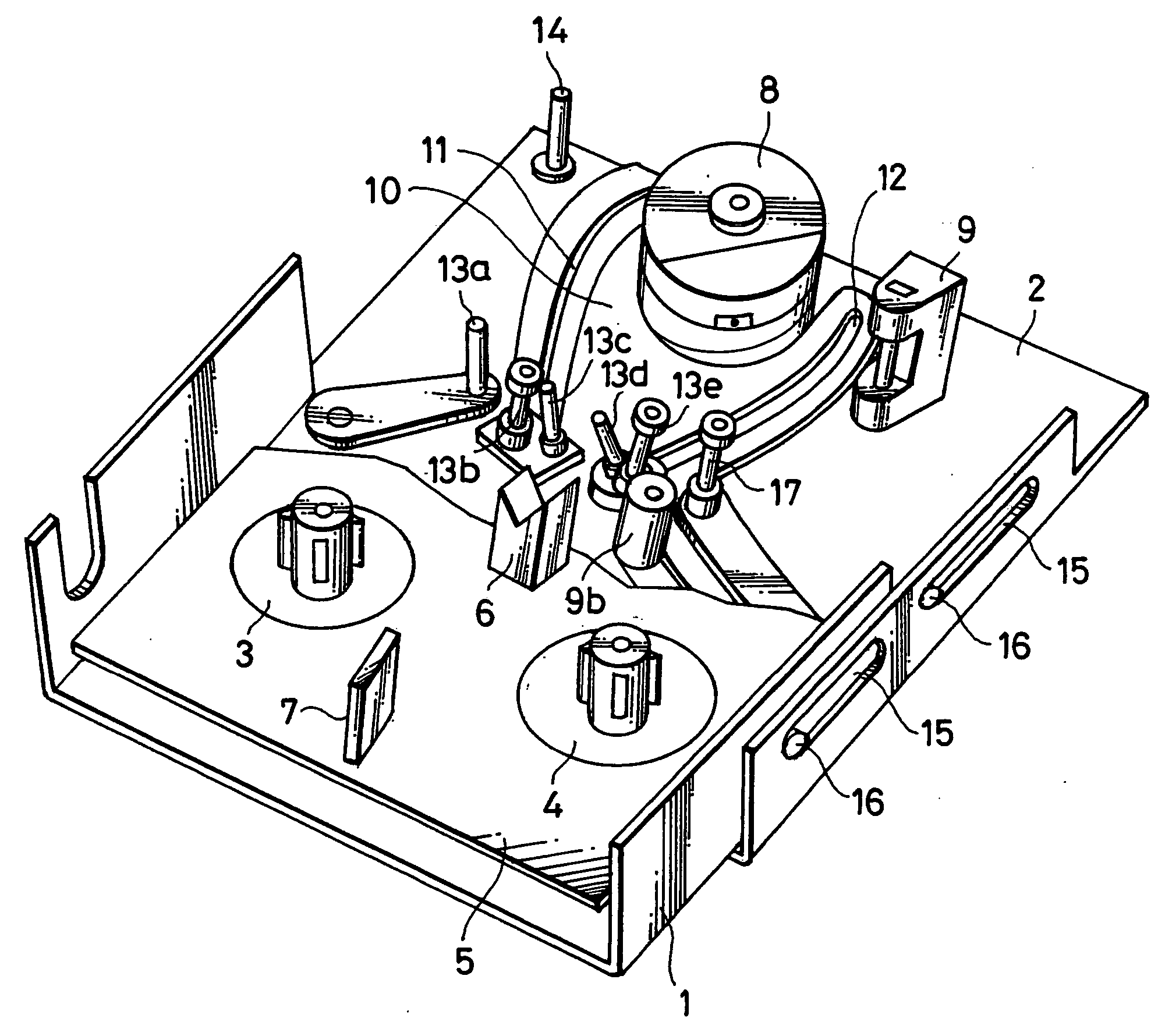

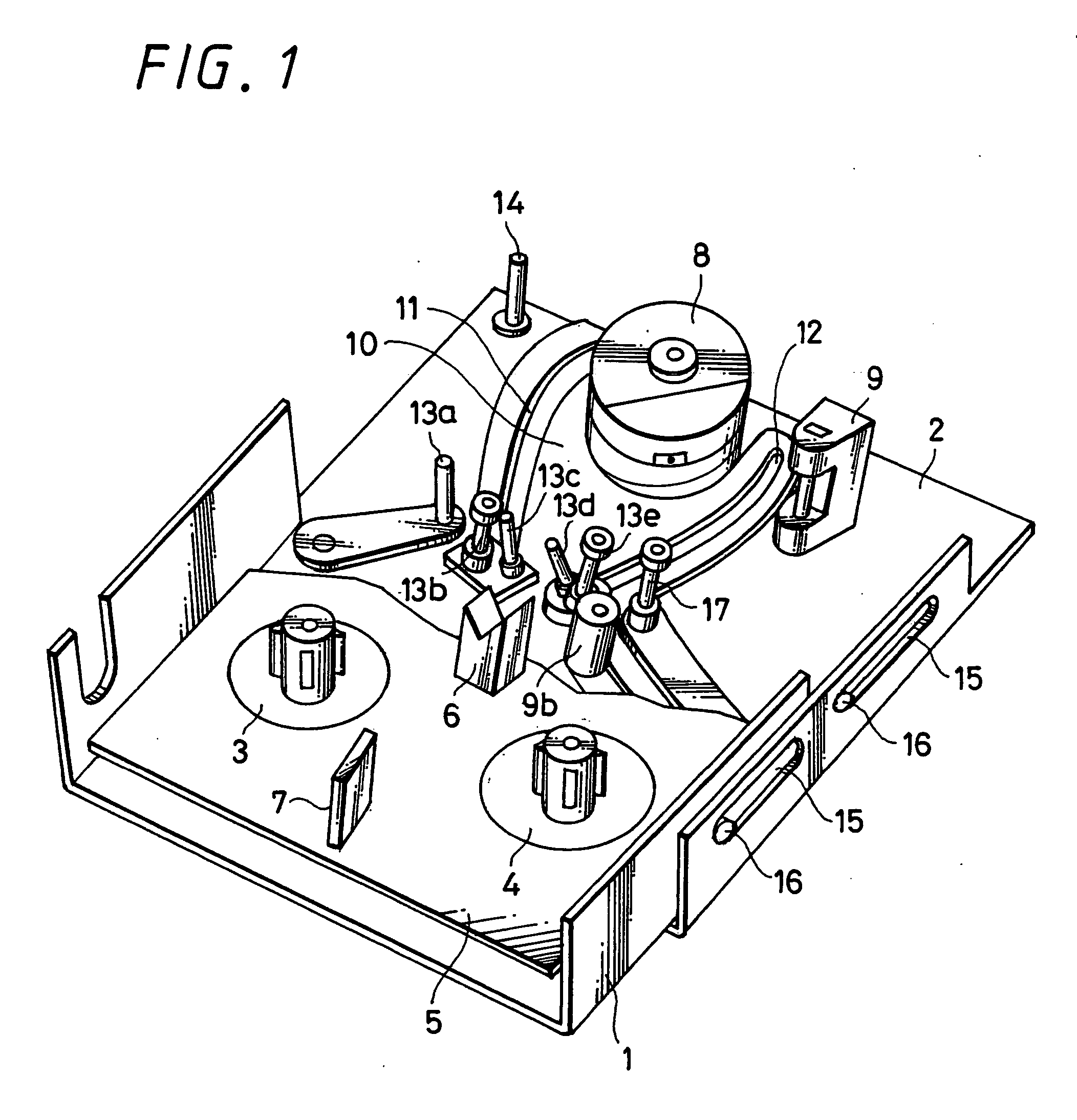

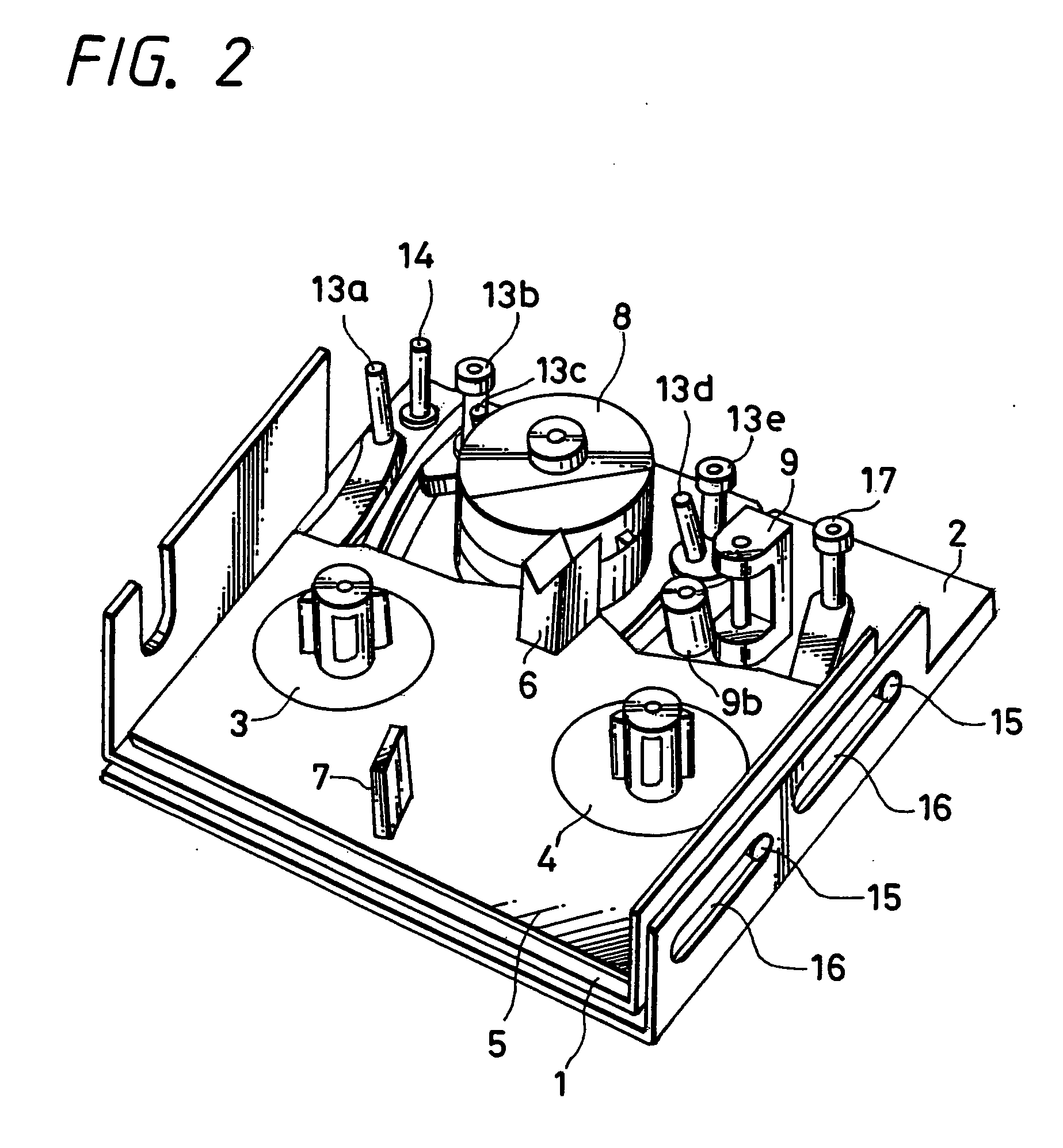

Self-contained robotics module for storage library

ActiveUS7184242B1Easy modular replacementEasy to disassembleRecord information storageAutomatic cassette changing arrangementsRoboticsModularity

A storage library includes cells supported within a frame for holding media elements. A robot assembly is operable for moving toward the cells and manipulating media elements held by the cells. The robot is containable within a module which is removably mountable to the frame to provide modular replacement and removal of the robot from the frame. The robot is contained within the module as the module is mounted to the frame and moves out from the module to move toward the cells and manipulate media elements held by the cells while the module is mounted to the frame. The module is removably dismounted out of the frame while the robot is contained within the module to provide the modular removal of the robot. The module is removably mounted into the frame while a new robot is contained within the module to provide the modular replacement of the robot.

Owner:ORACLE INT CORP

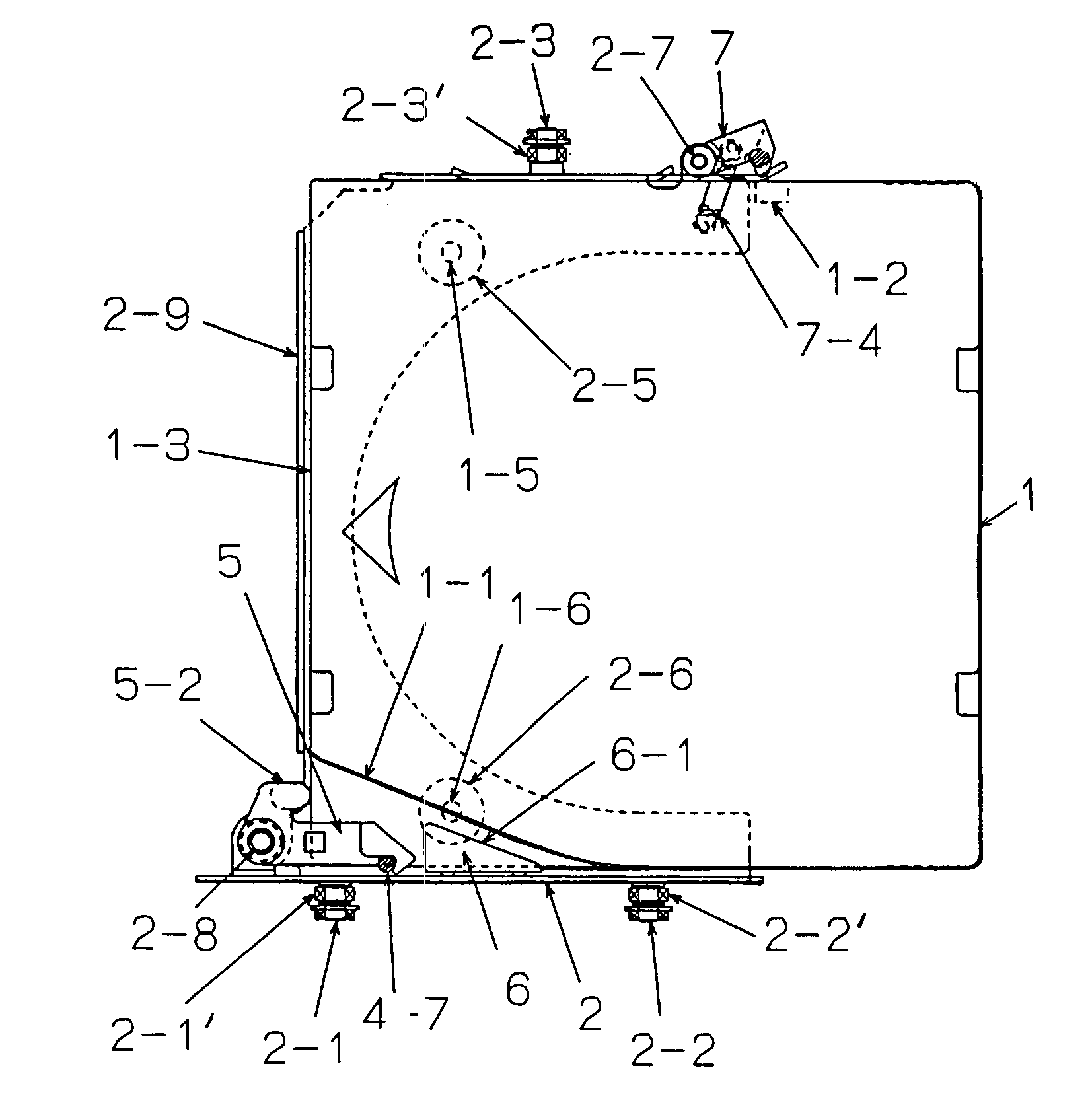

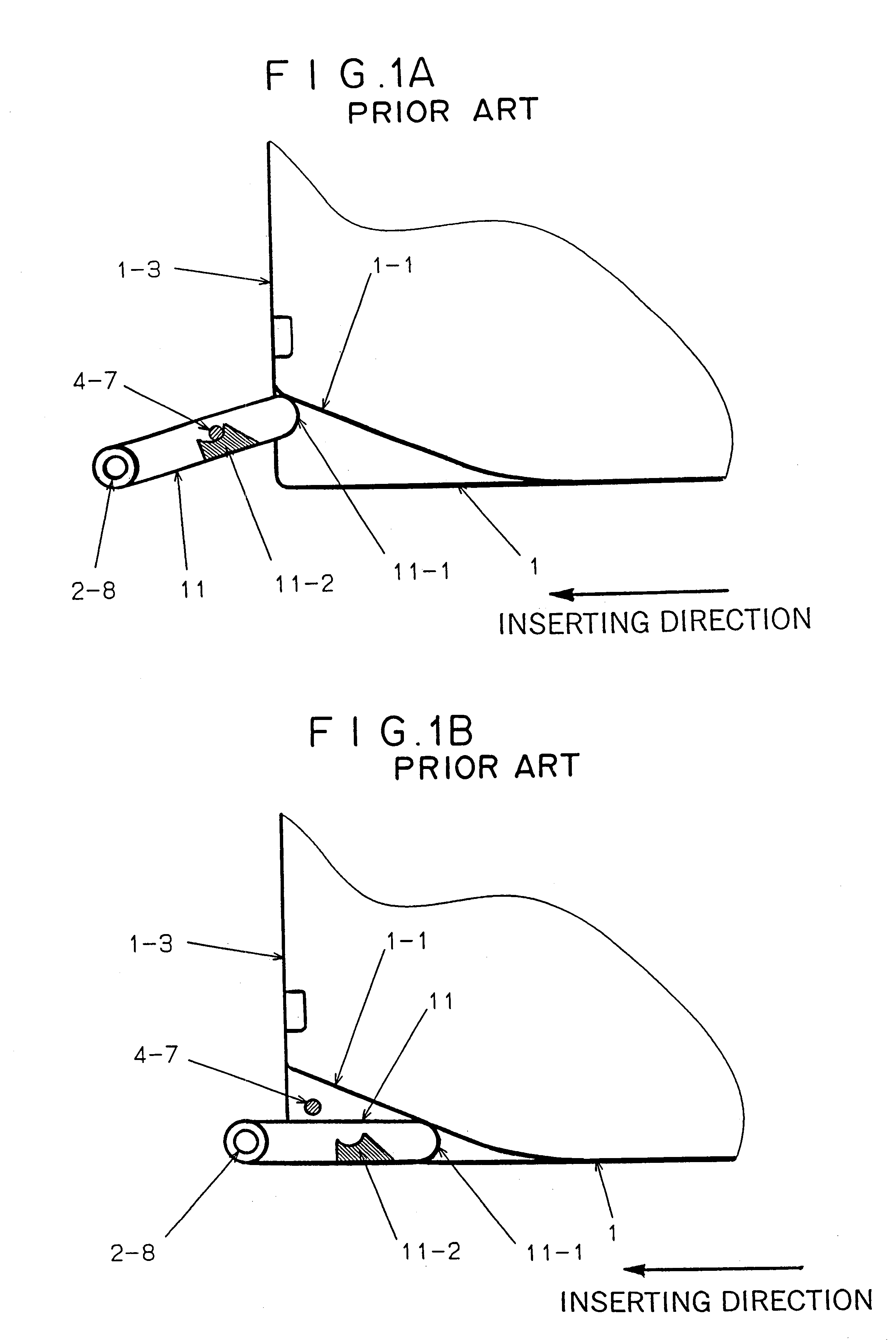

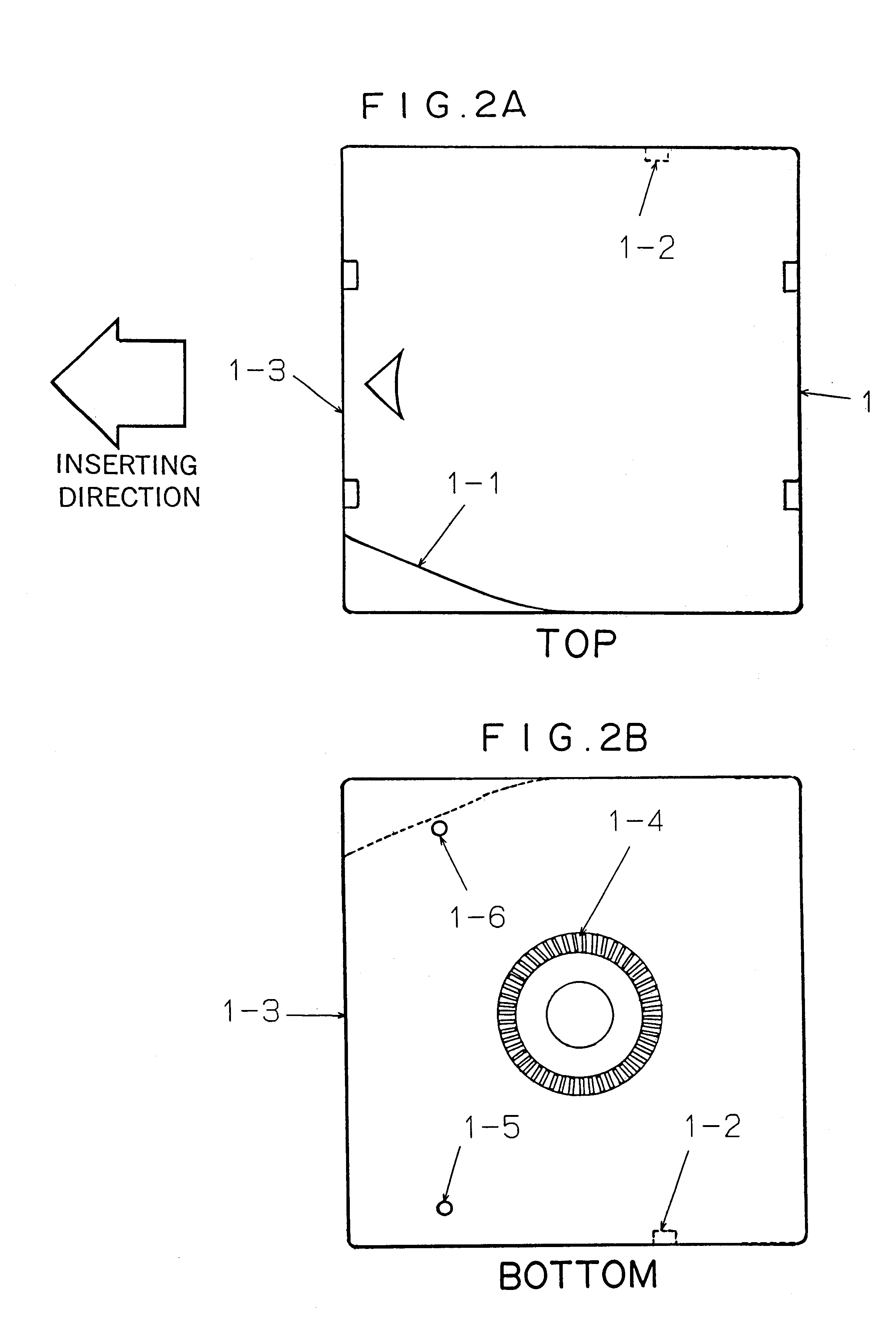

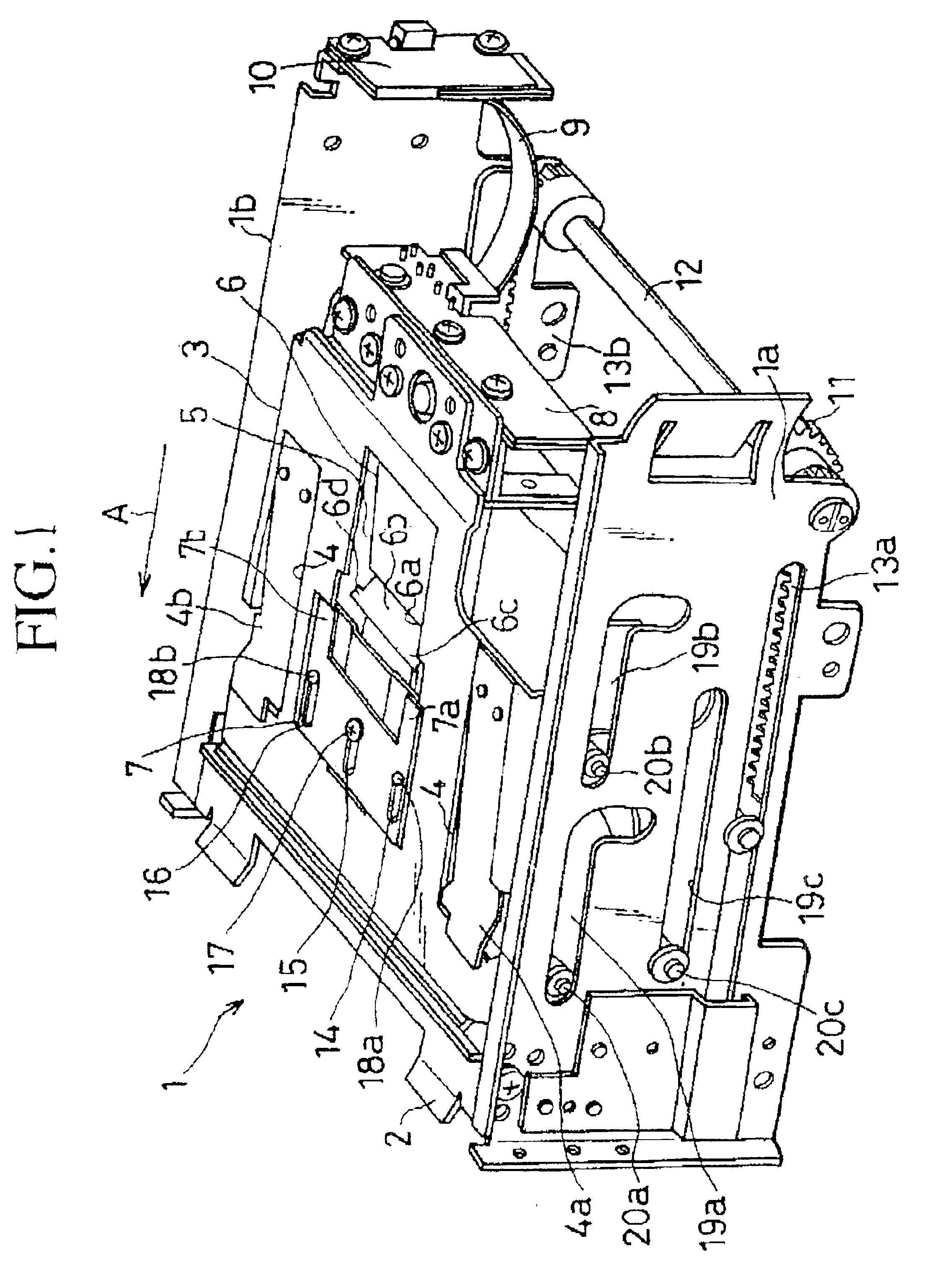

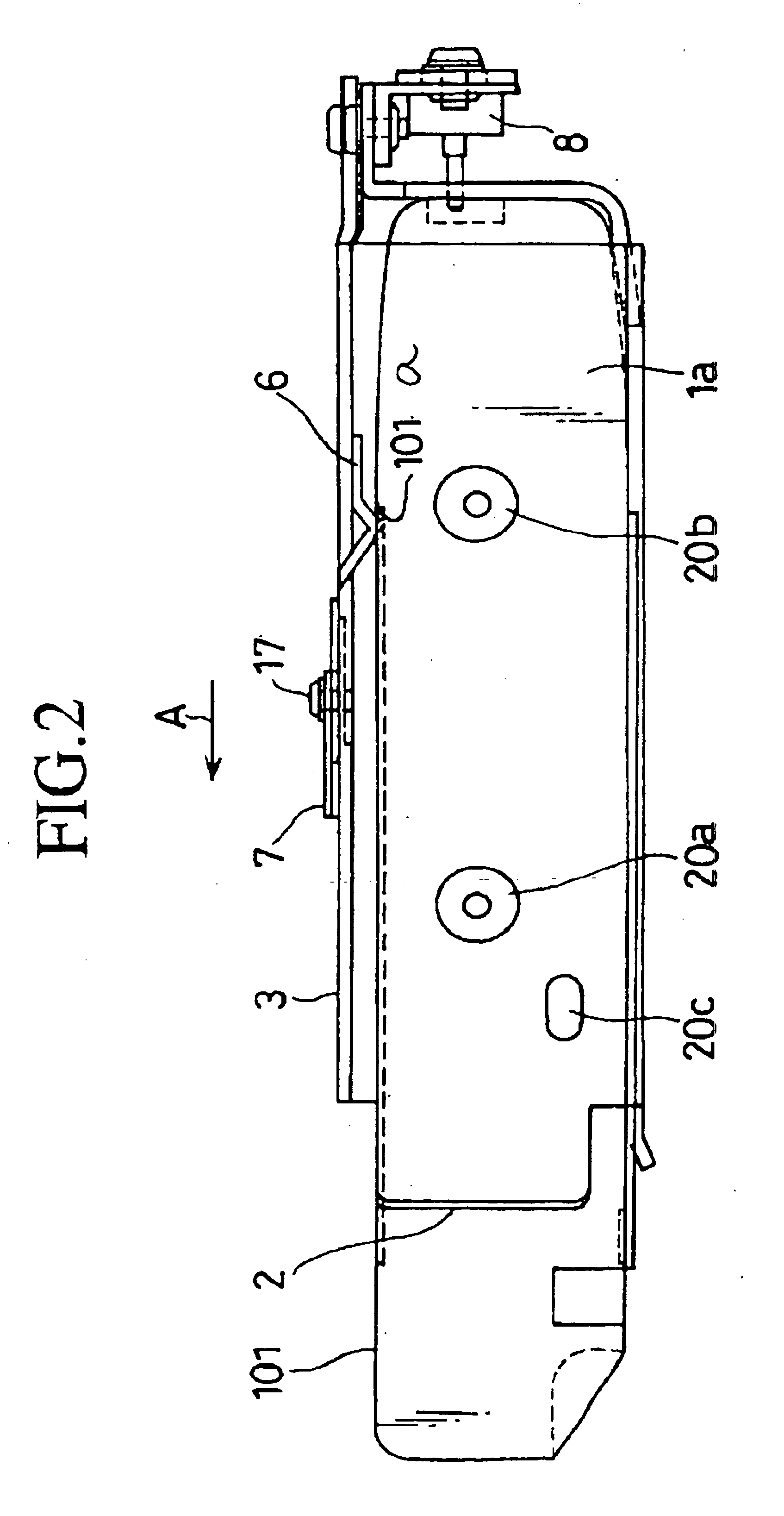

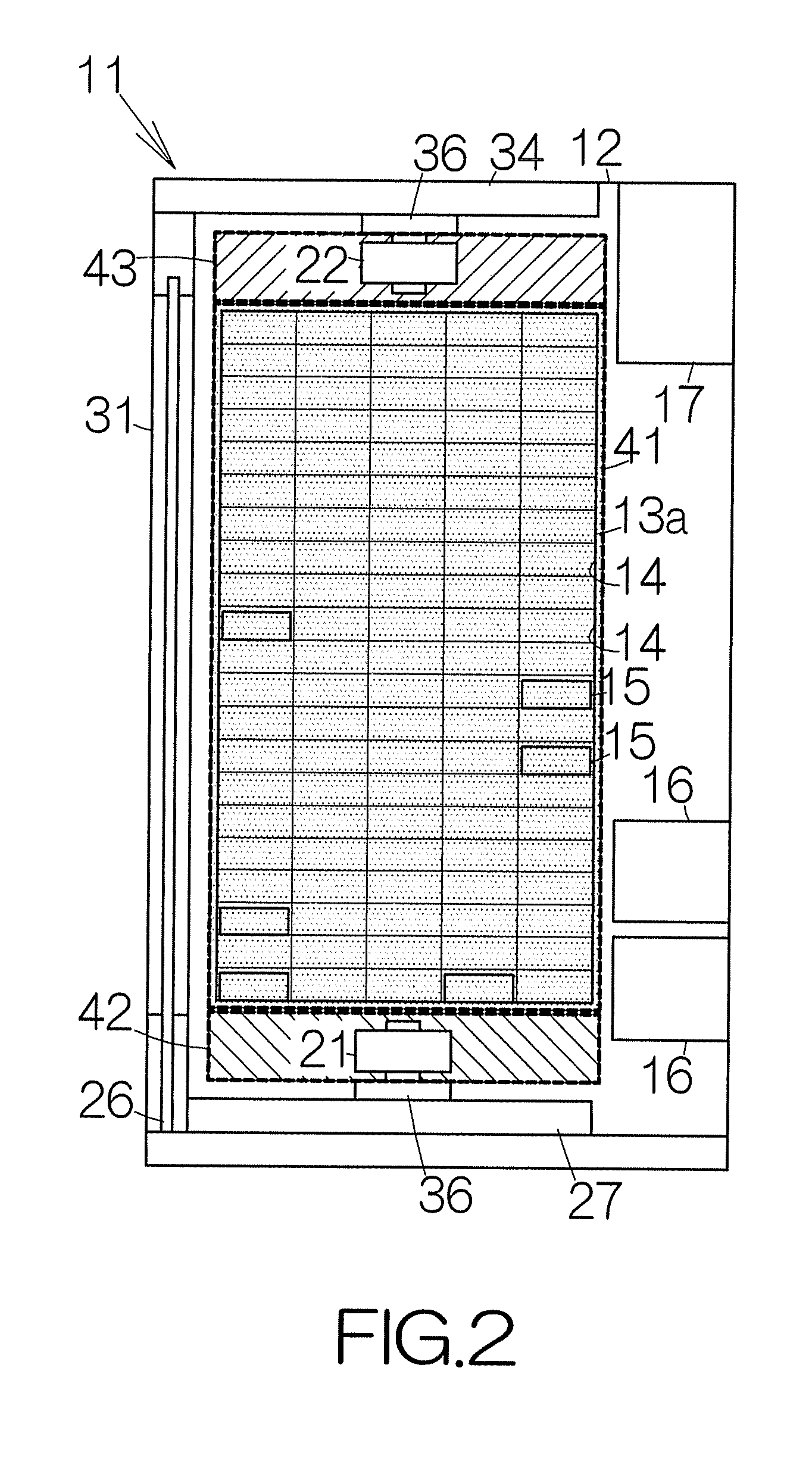

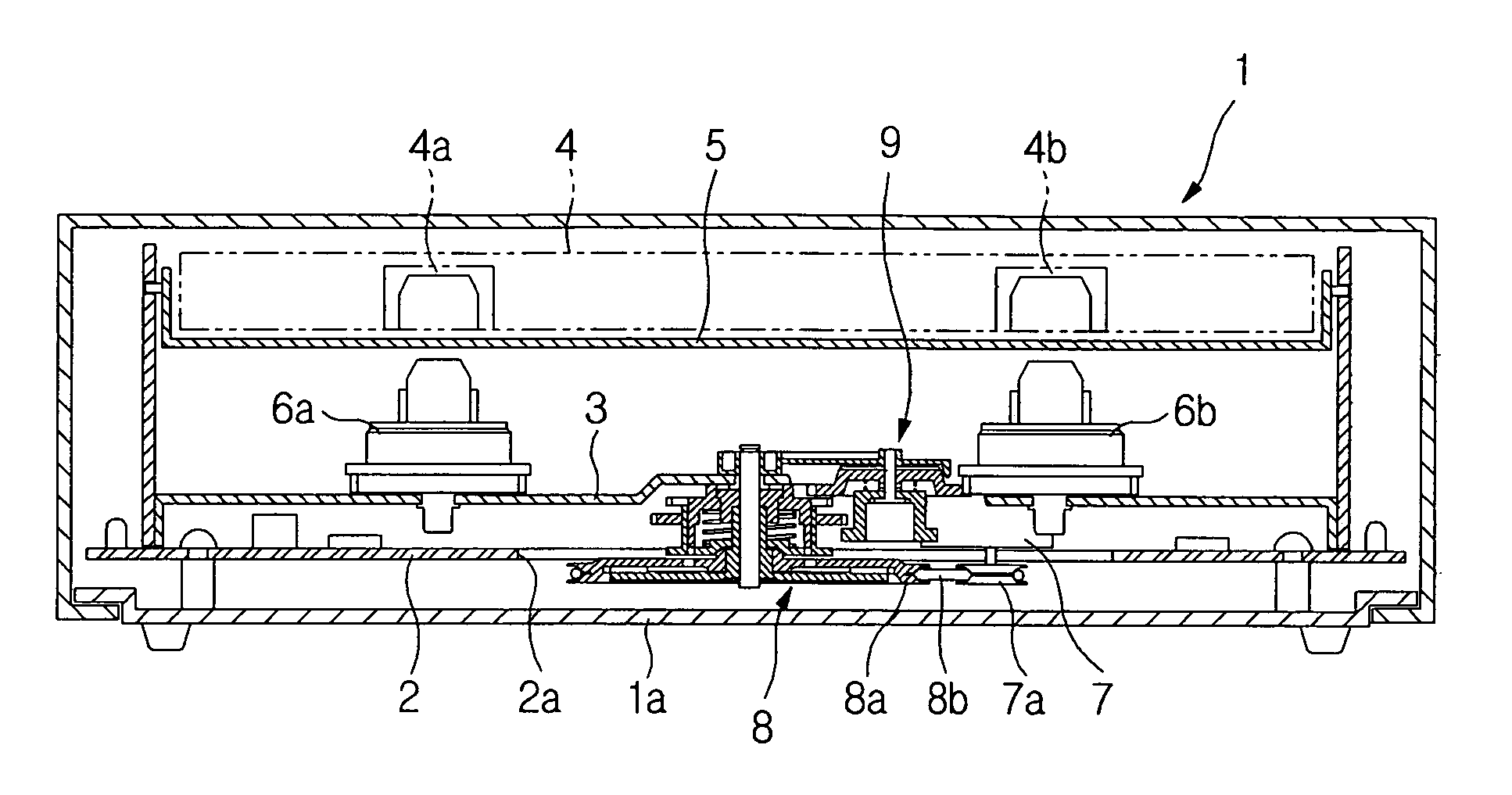

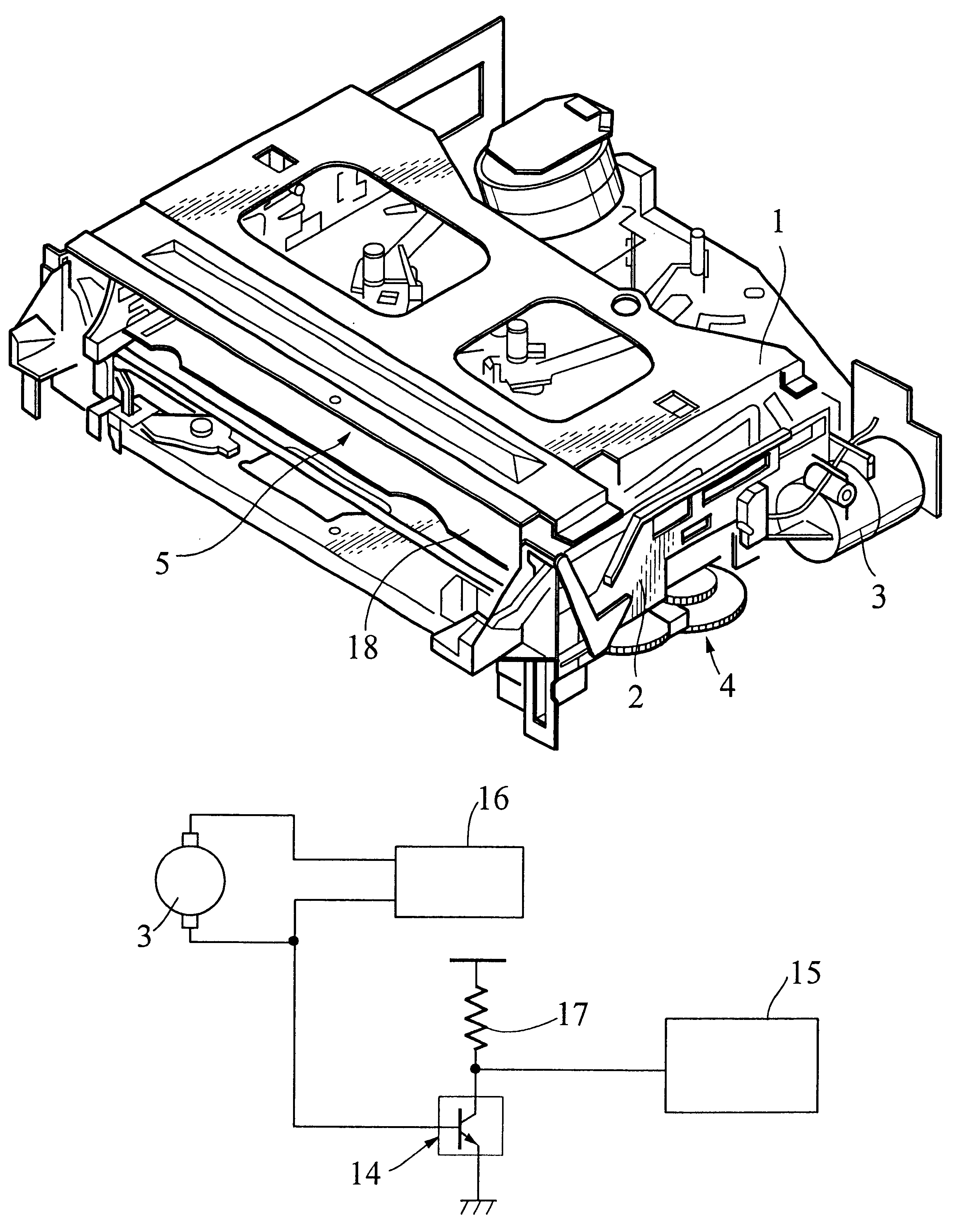

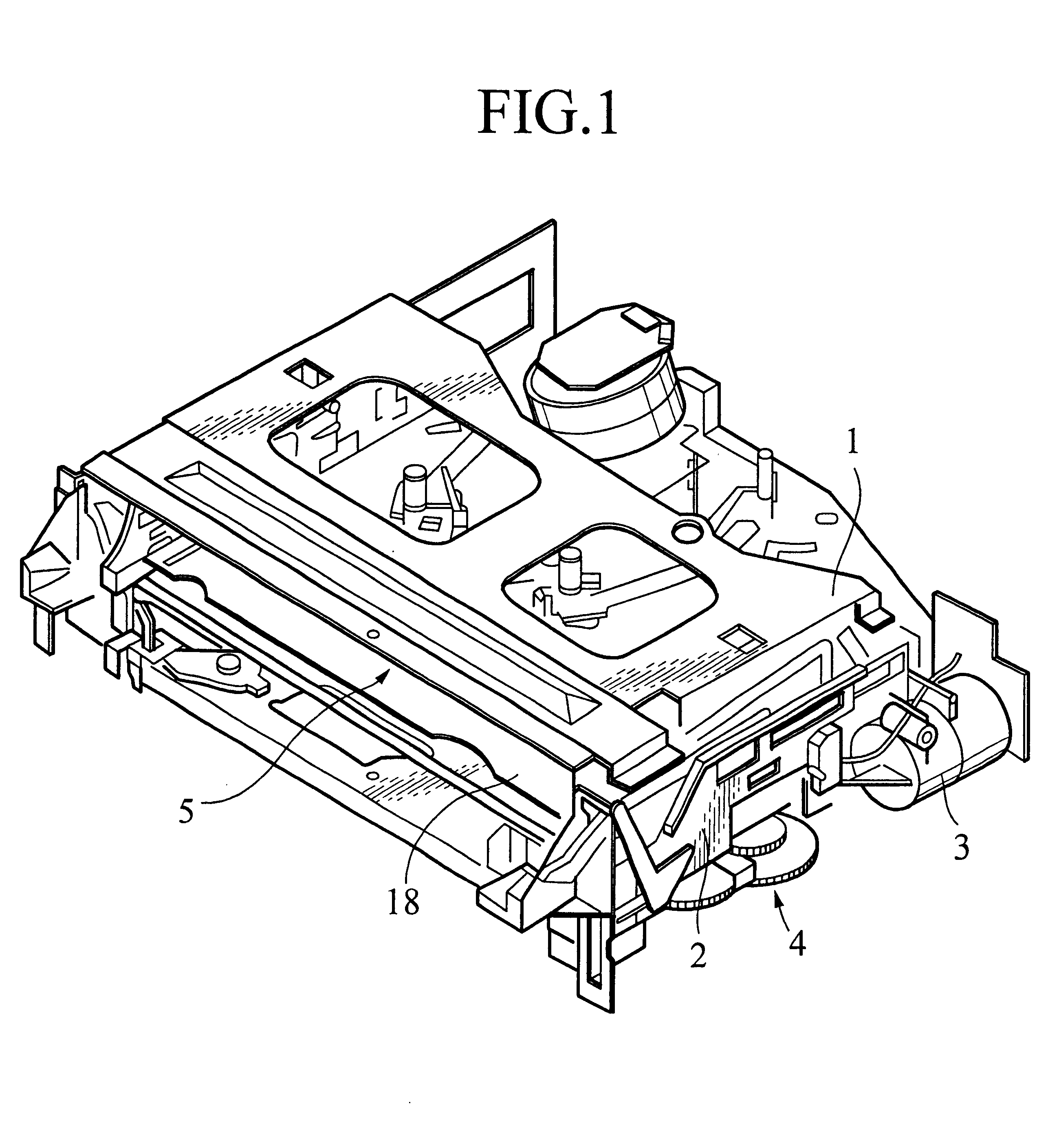

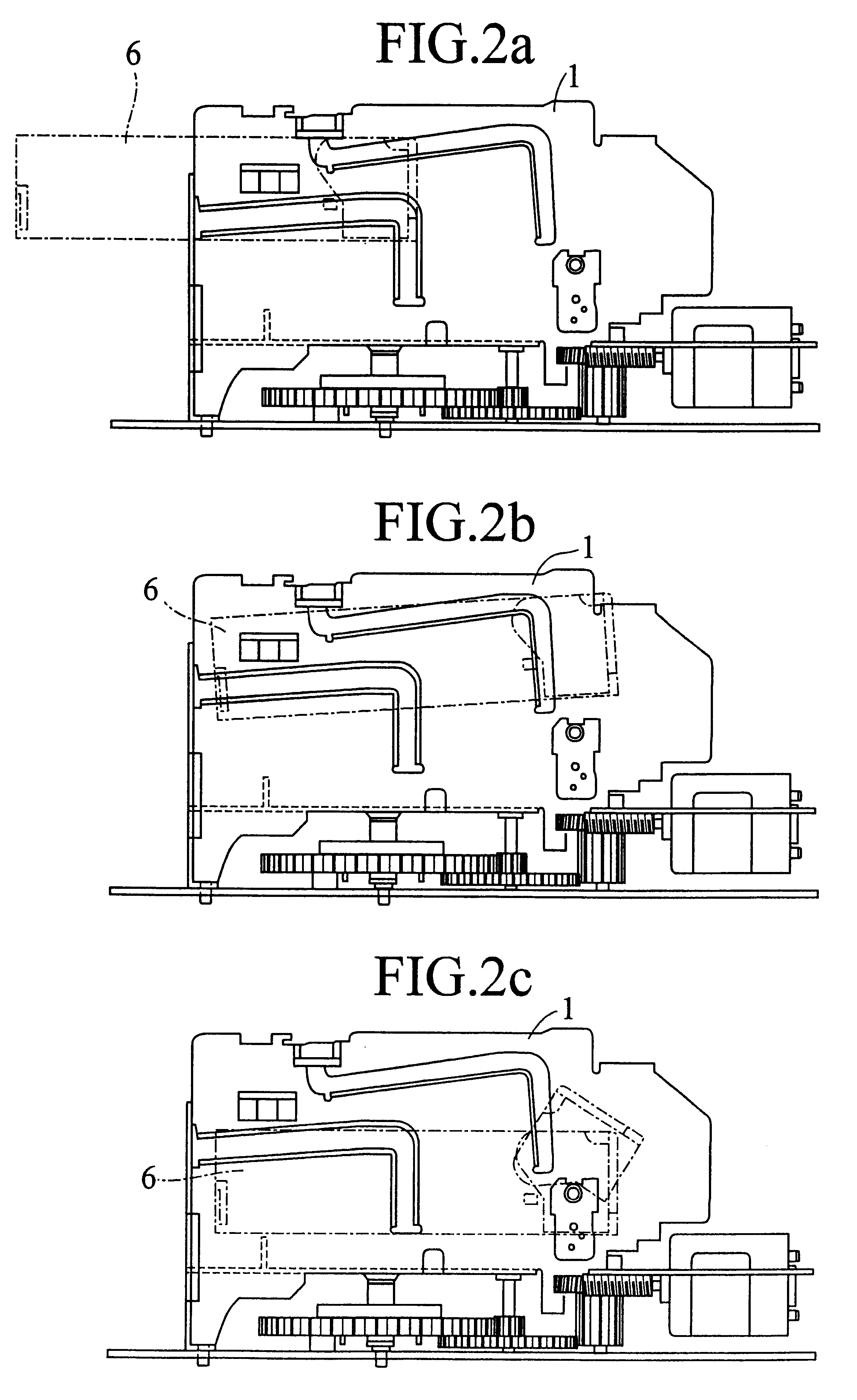

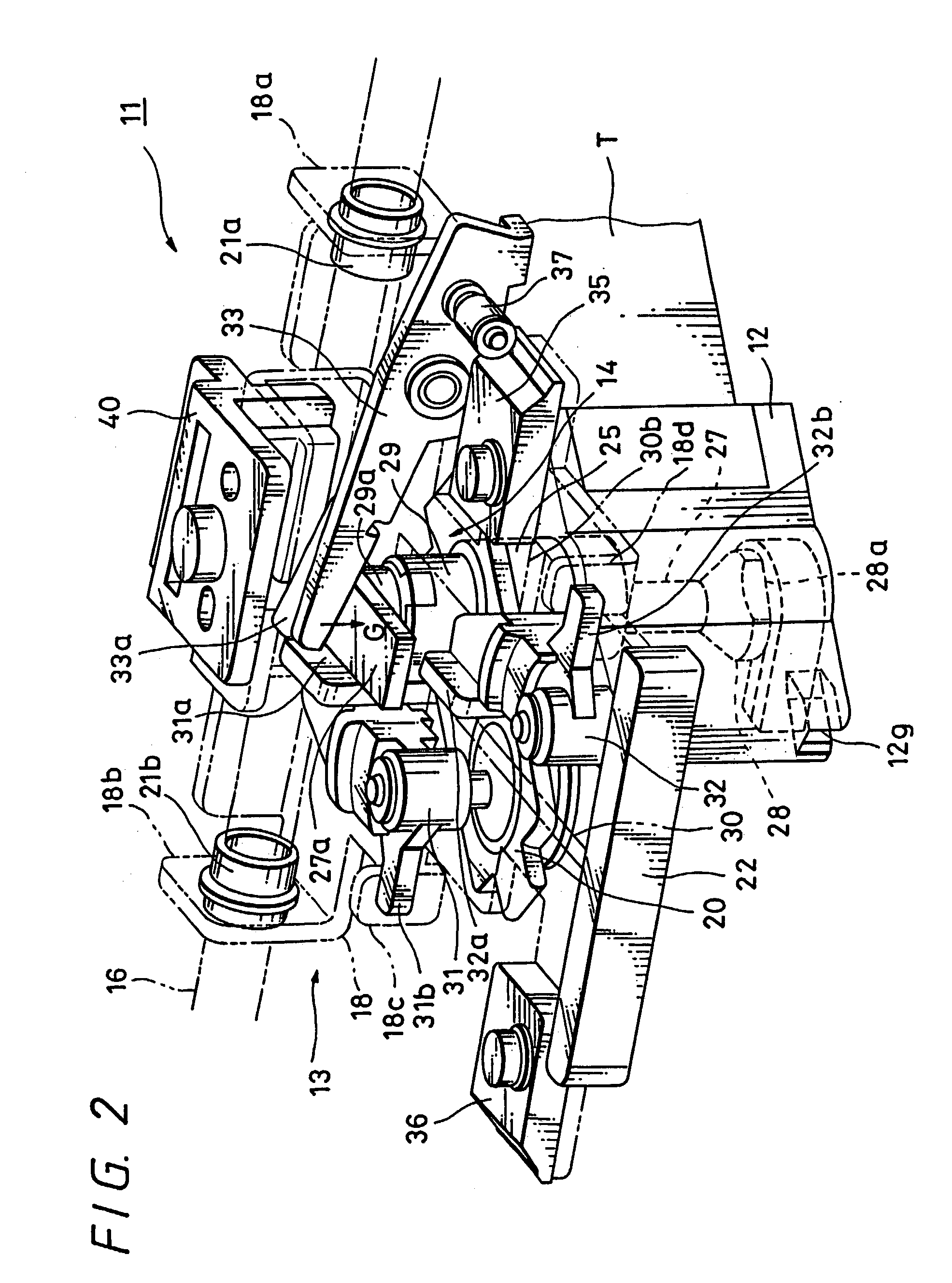

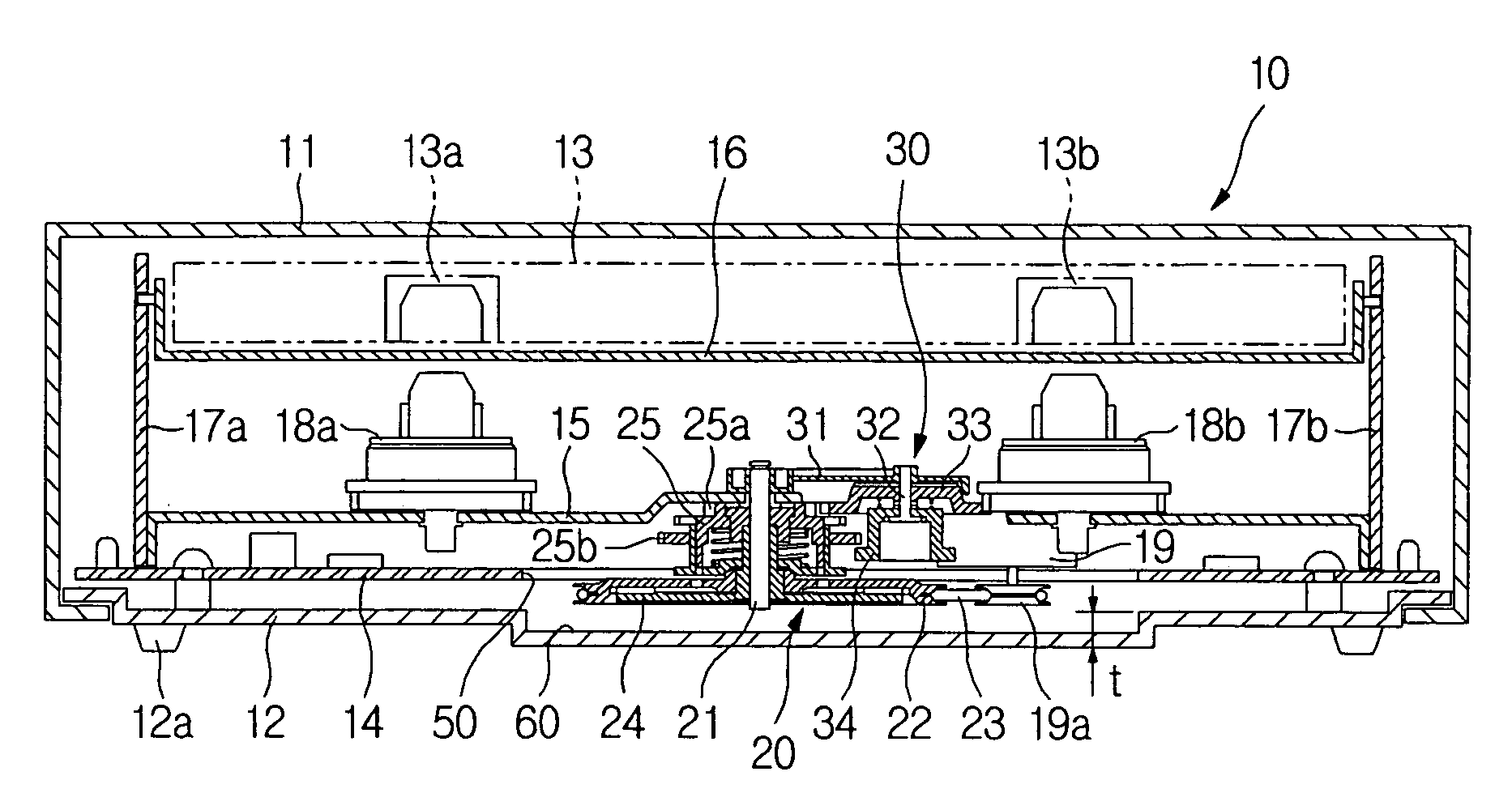

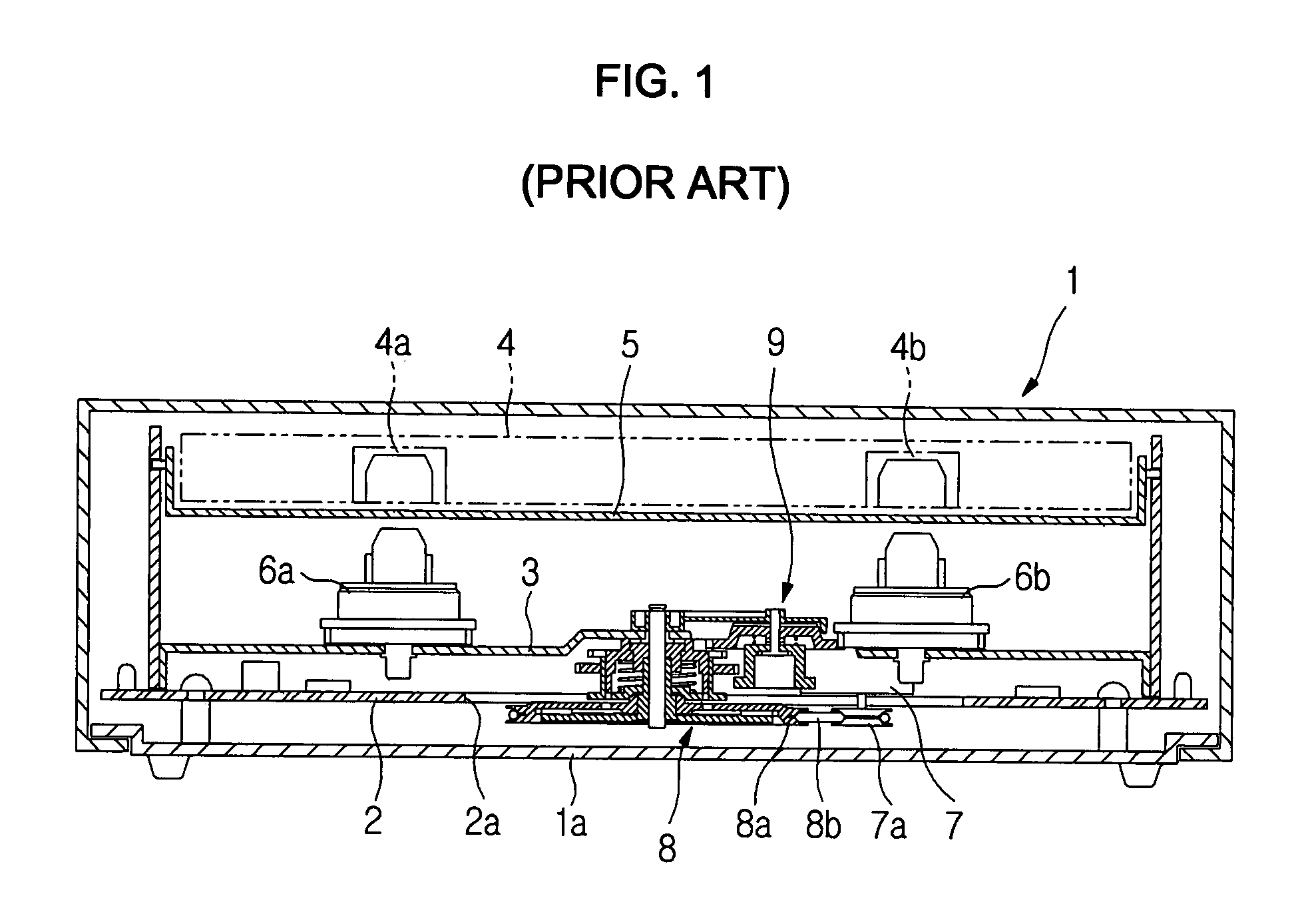

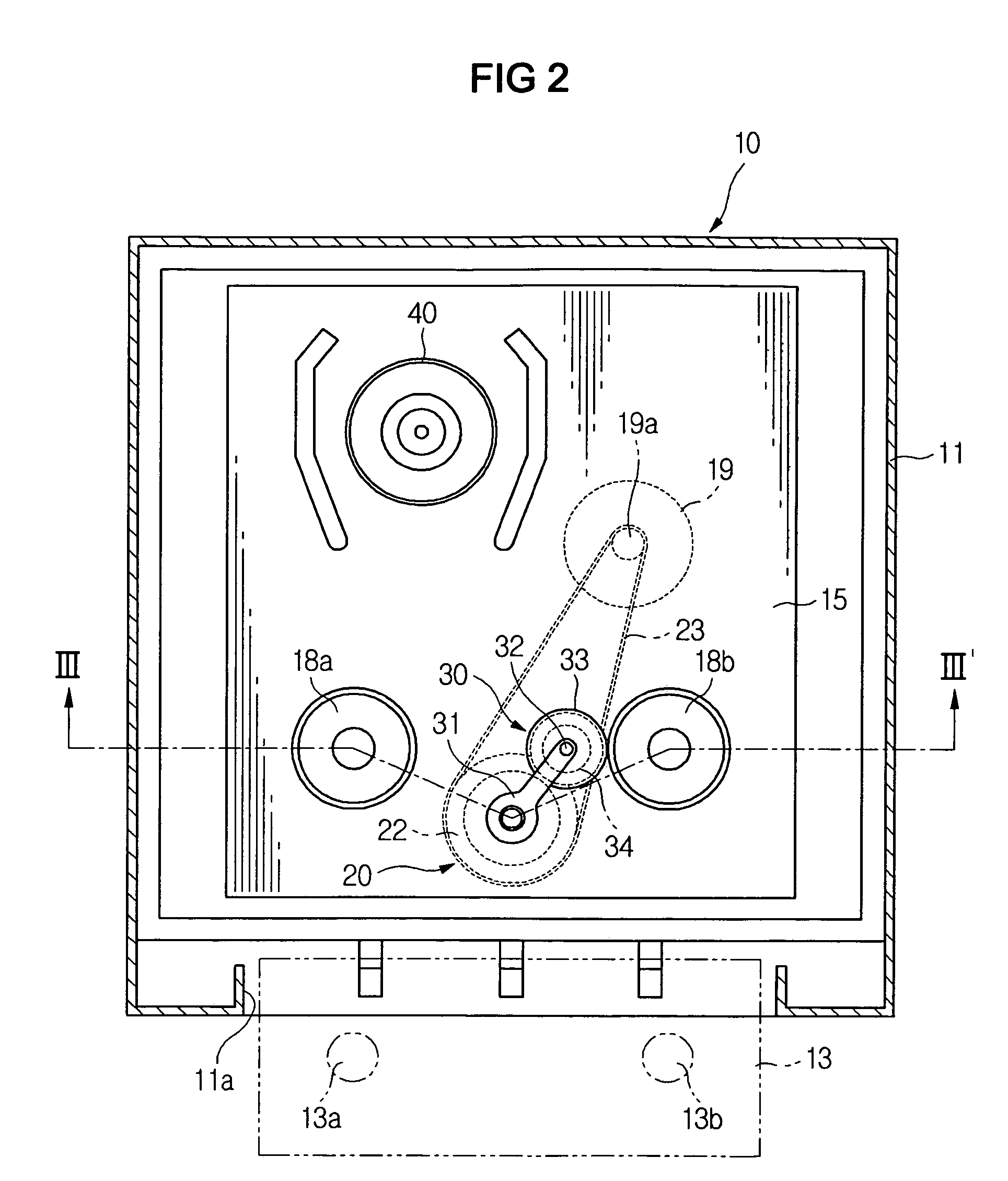

Cartridge mis-insertion preventing mechanism

InactiveUS6320722B1Record information storageCarrier container guidanceMagnetic tapeLocking mechanism

A cartridge mis-insertion preventing mechanism, comprising: a cartridge tray into which a cartridge is insertable; a loader plate into which the cartridge tray is insertable; a cartridge locking mechanism for locking the cartridge to the cartridge tray; a loading locking mechanism for preventing the cartridge tray and the loader plate from being inserted into a loader guide plate; and a restricting mechanism for changing the loading locking mechanism from a lock state to an unlock state only when the cartridge has been inserted into the cartridge tray in a correct direction; wherein the cartridge tray and the loader plate are inserted into the loader guide plate along with the cartridge when the cartridge is further inserted after the loading locking mechanism has been changed from the lock state to the unlock state; wherein before the cartridge is inserted into the cartridge tray, the cartridge locking mechanism is in an unlock state; wherein when the cartridge tray and the loader plate along with the cartridge have been inserted into the loader guide plate, the cartridge locking mechanism is changed from the unlock state to a lock state; and wherein before the cartridge is inserted into the cartridge tray, the loading locking mechanism is in the lock state.

Owner:NEC PLATFORMS LTD

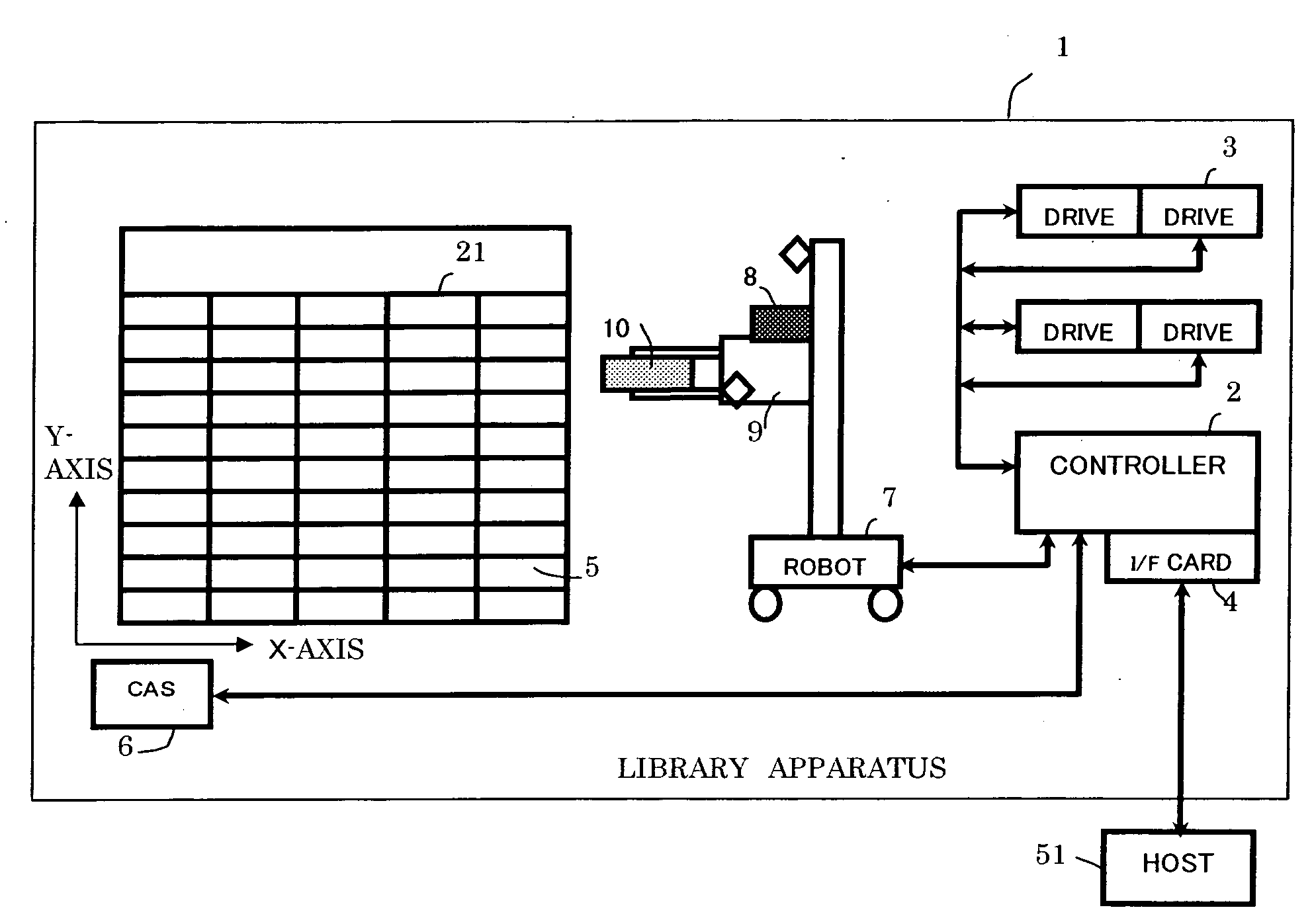

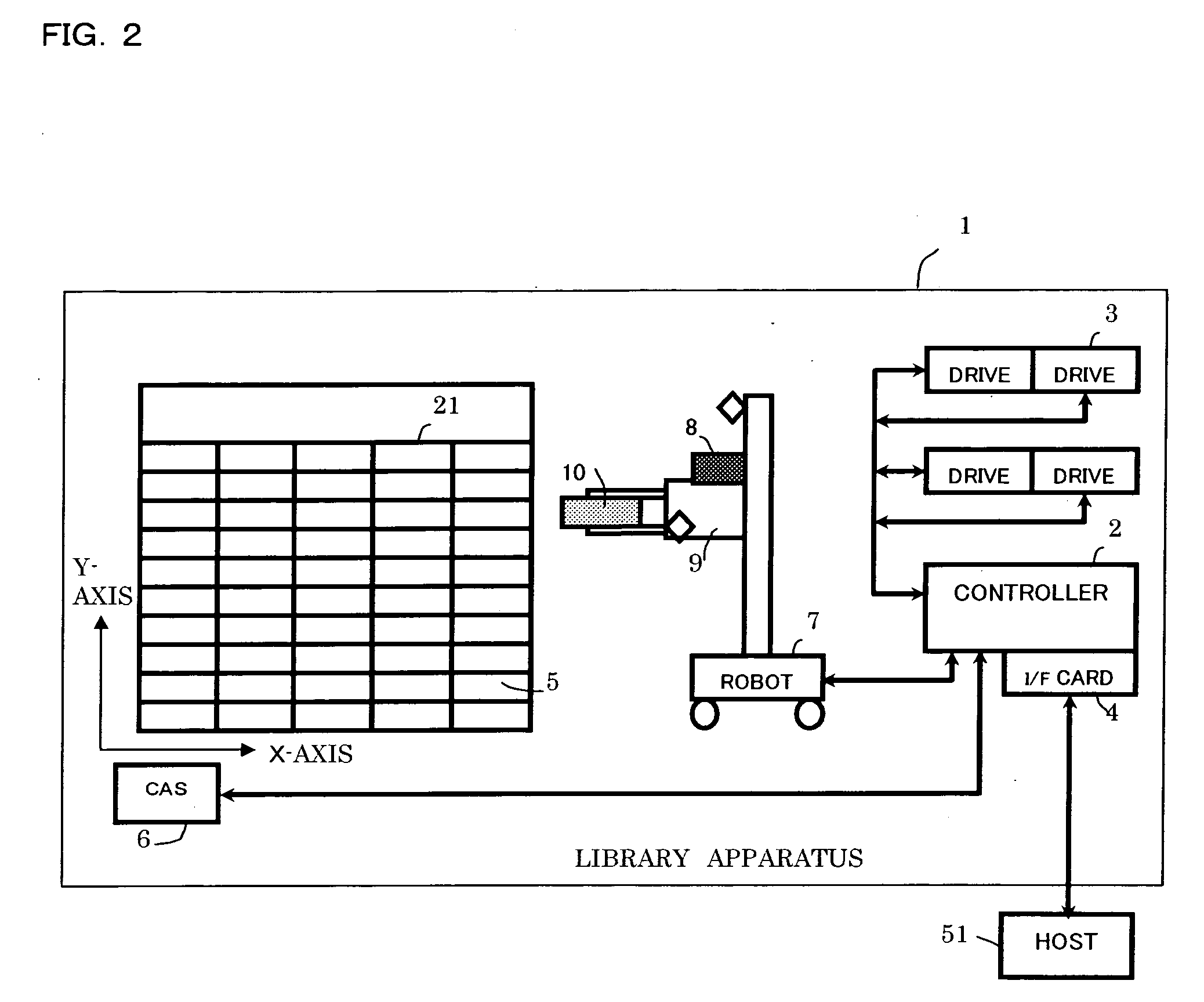

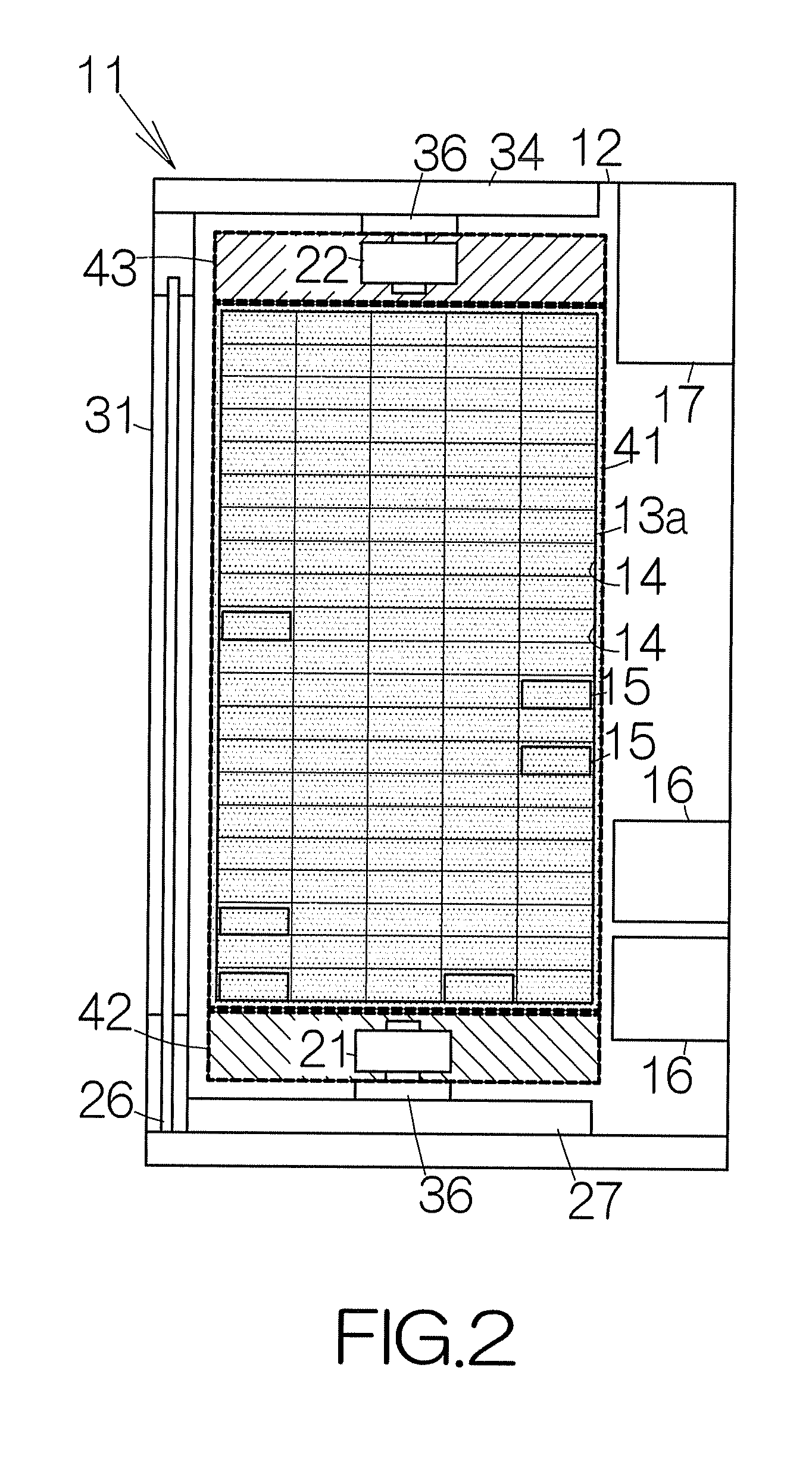

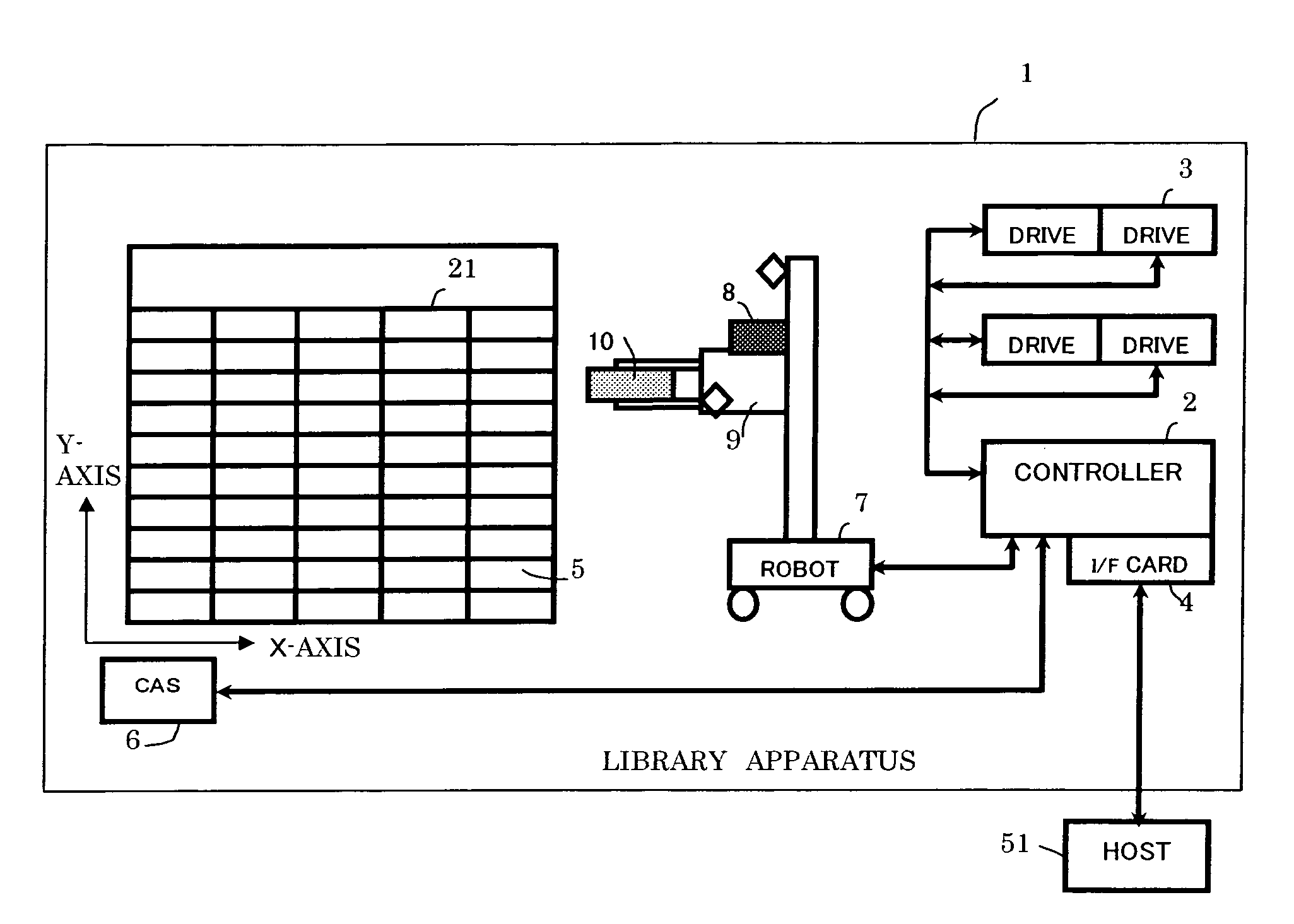

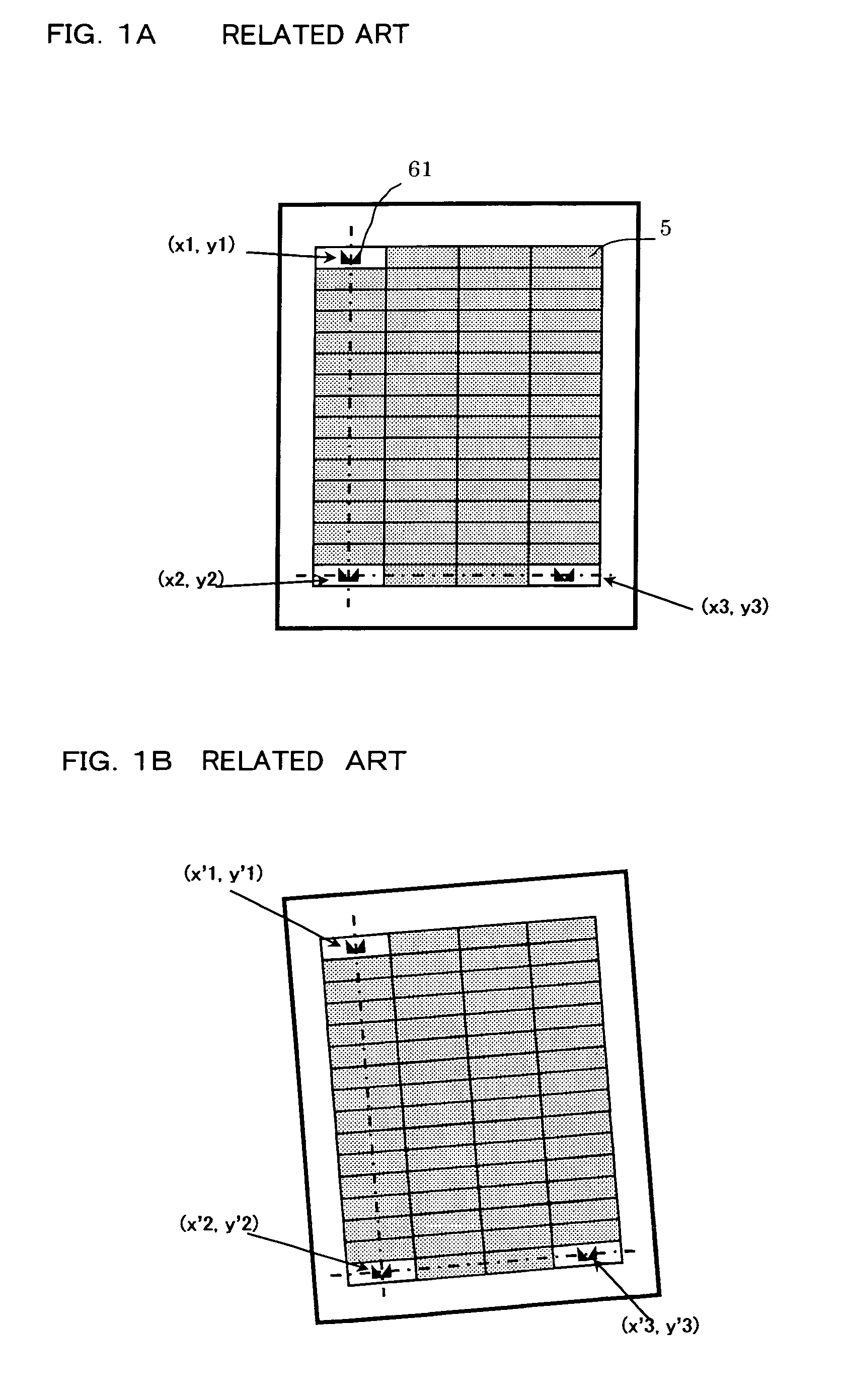

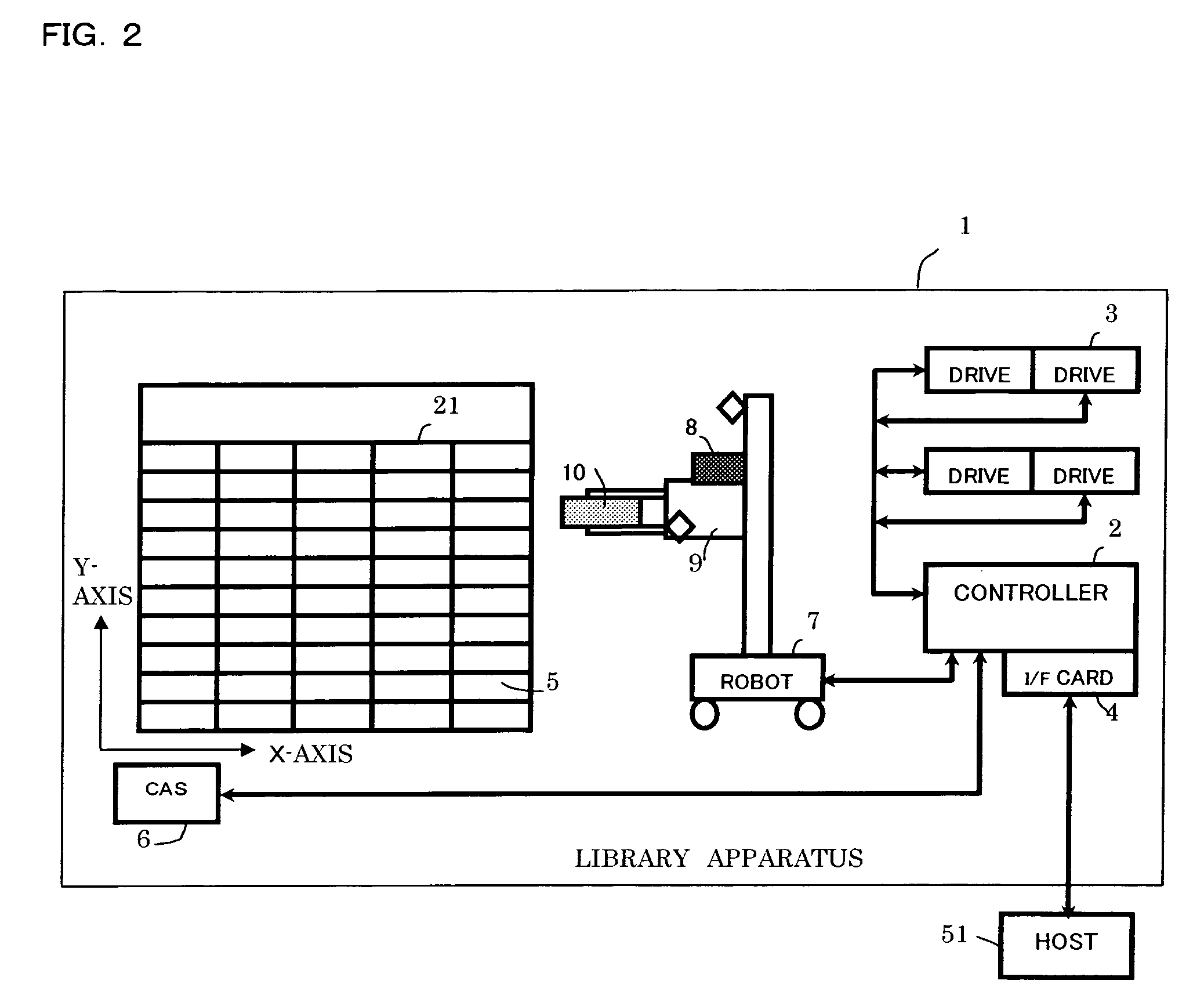

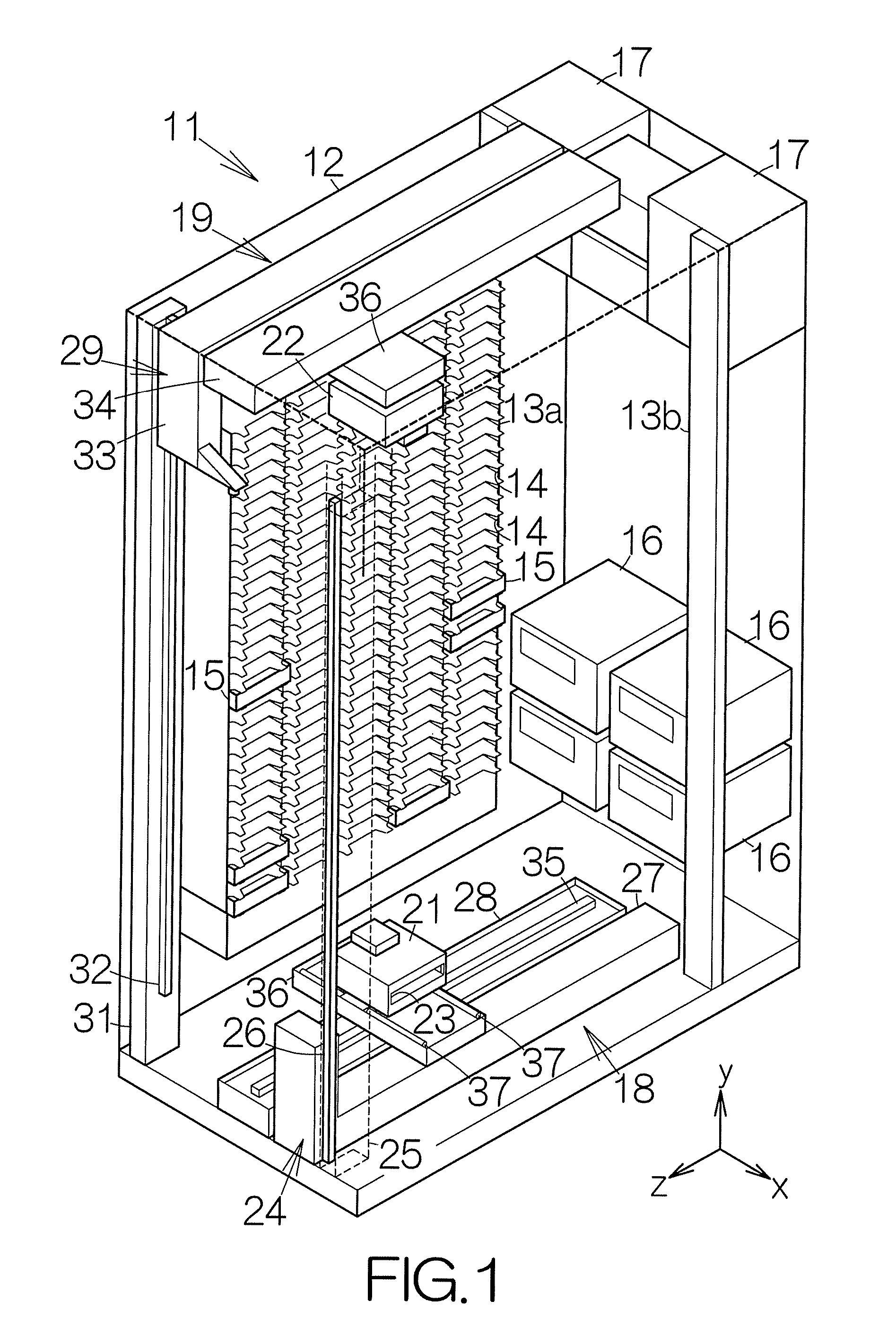

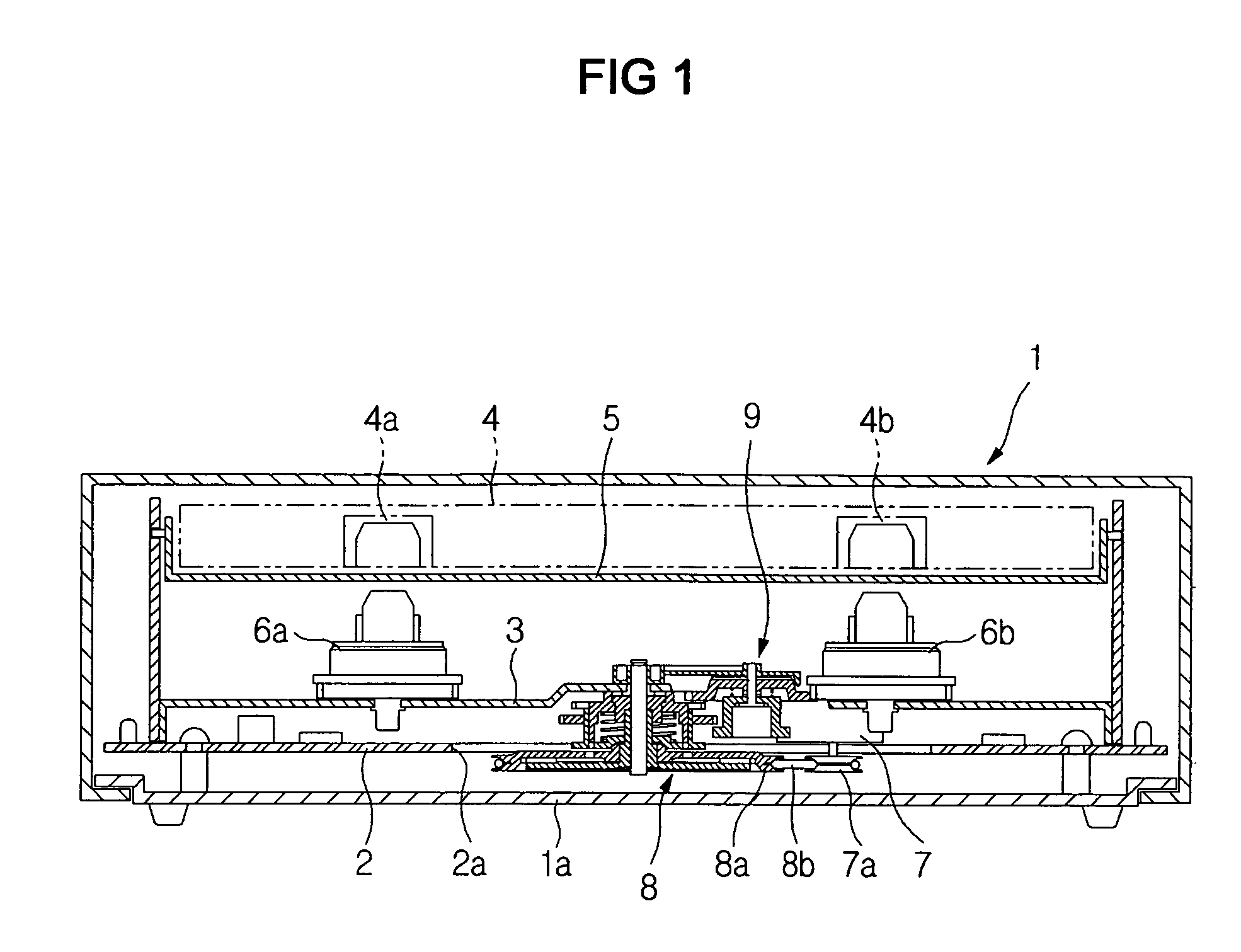

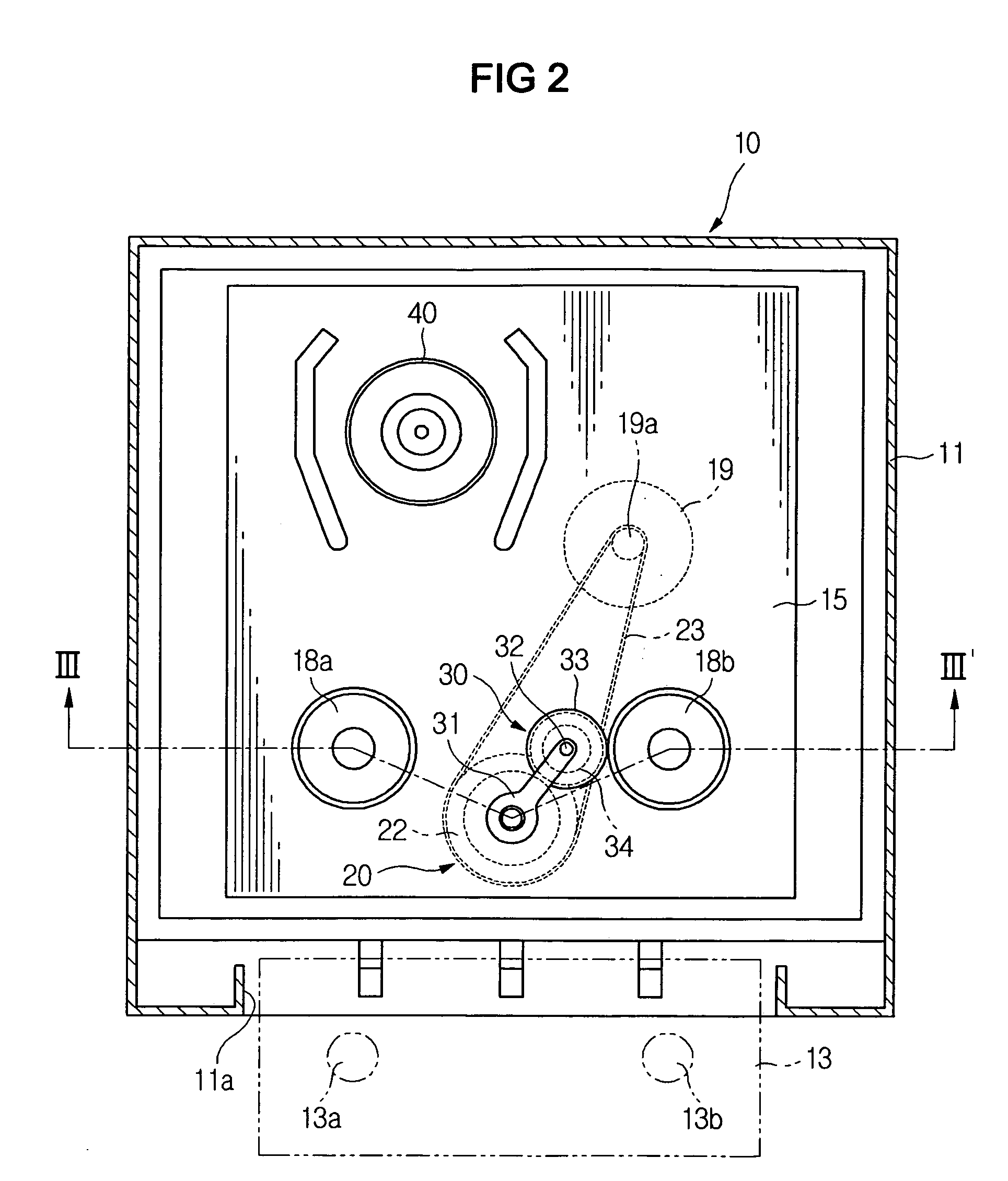

Library apparatus and position controlling method

InactiveUS20080201012A1Simple configurationFilamentary/web carriers operation controlDigital data processing detailsEngineeringElectrical and Electronics engineering

A library apparatus includes a cell unit having a plurality of cells arrayed in a matrix, a holder to insert the storage medium to one of the cells or extract the storage medium from the cell, and a position controller to move the holder over the cell unit in X-axis and Y-axis directions to position the holder at a desired position. The holder has a reading unit configured to acquire data of the edges on both sides of each cell. The position controller determines each position of the cells on the basis of the data of the edges acquired at a plurality of positions while moving the holder in a predetermined direction from a predetermined position of the cell unit.

Owner:FUJITSU LTD

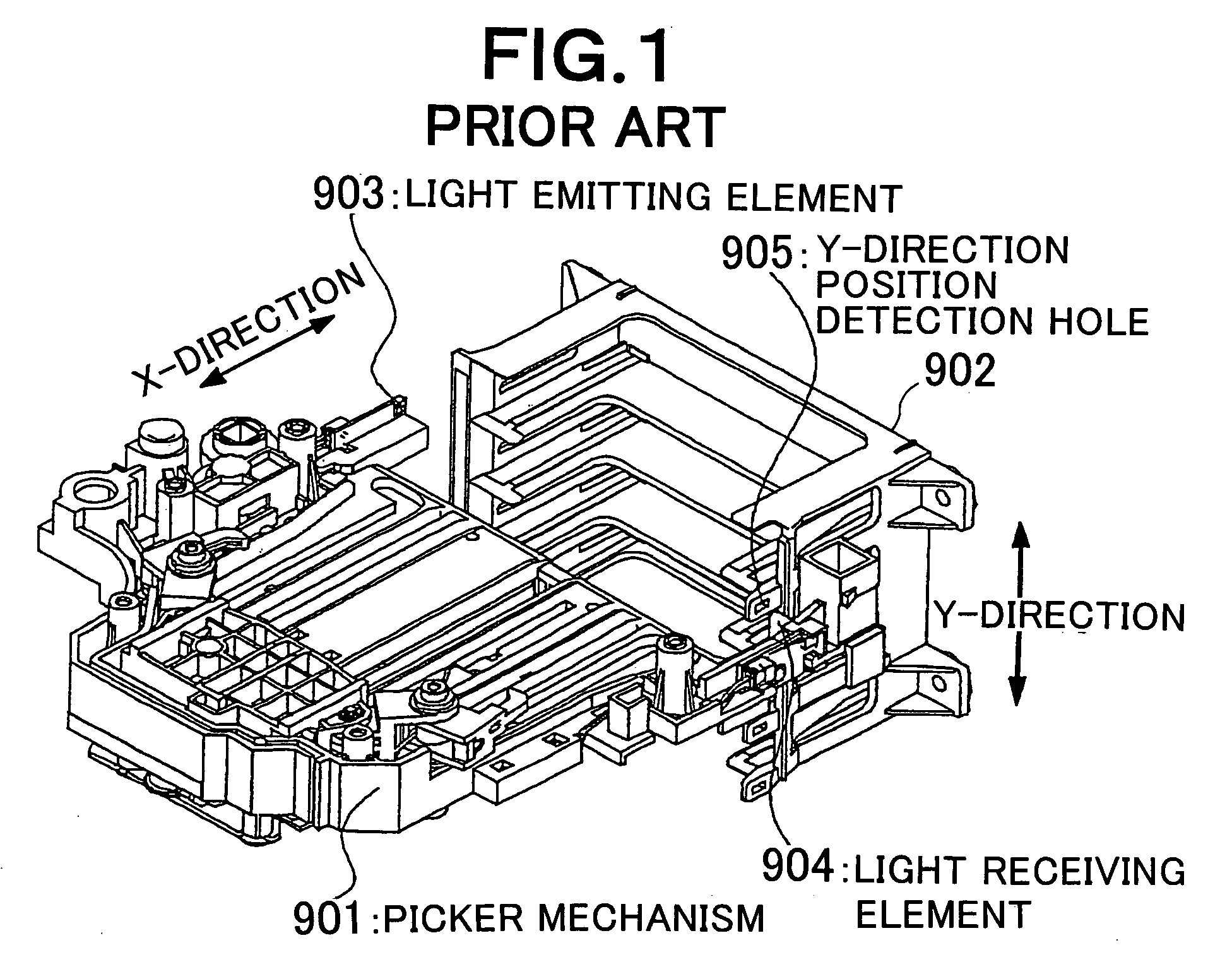

Robot hand having swaying mechanism in library apparatus

InactiveUS7753638B2Reliably allowing a robot hand to reach a standby regionRecord information storageAutomatic cassette changing arrangementsRobot handMechanical engineering

Owner:FUJITSU LTD

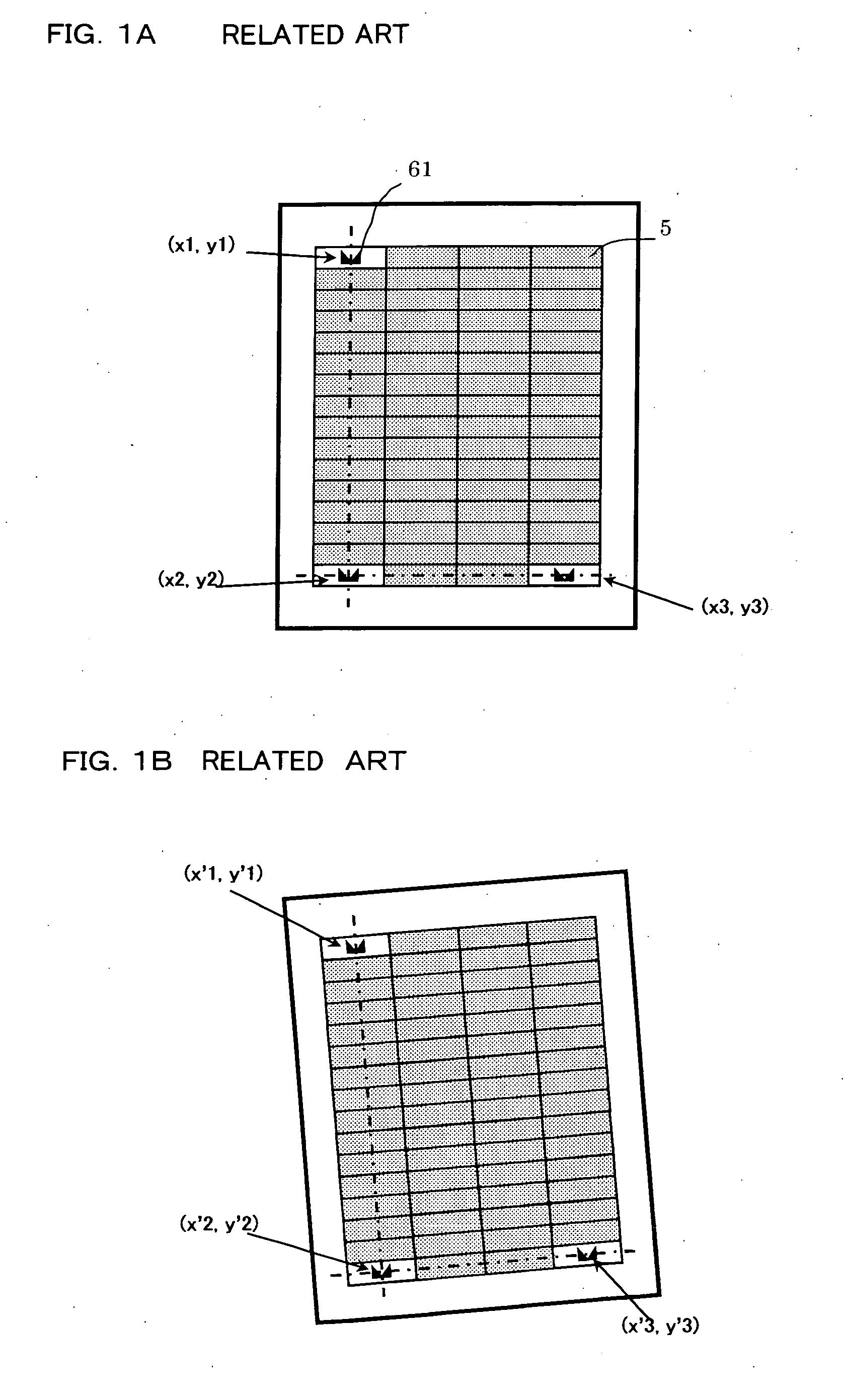

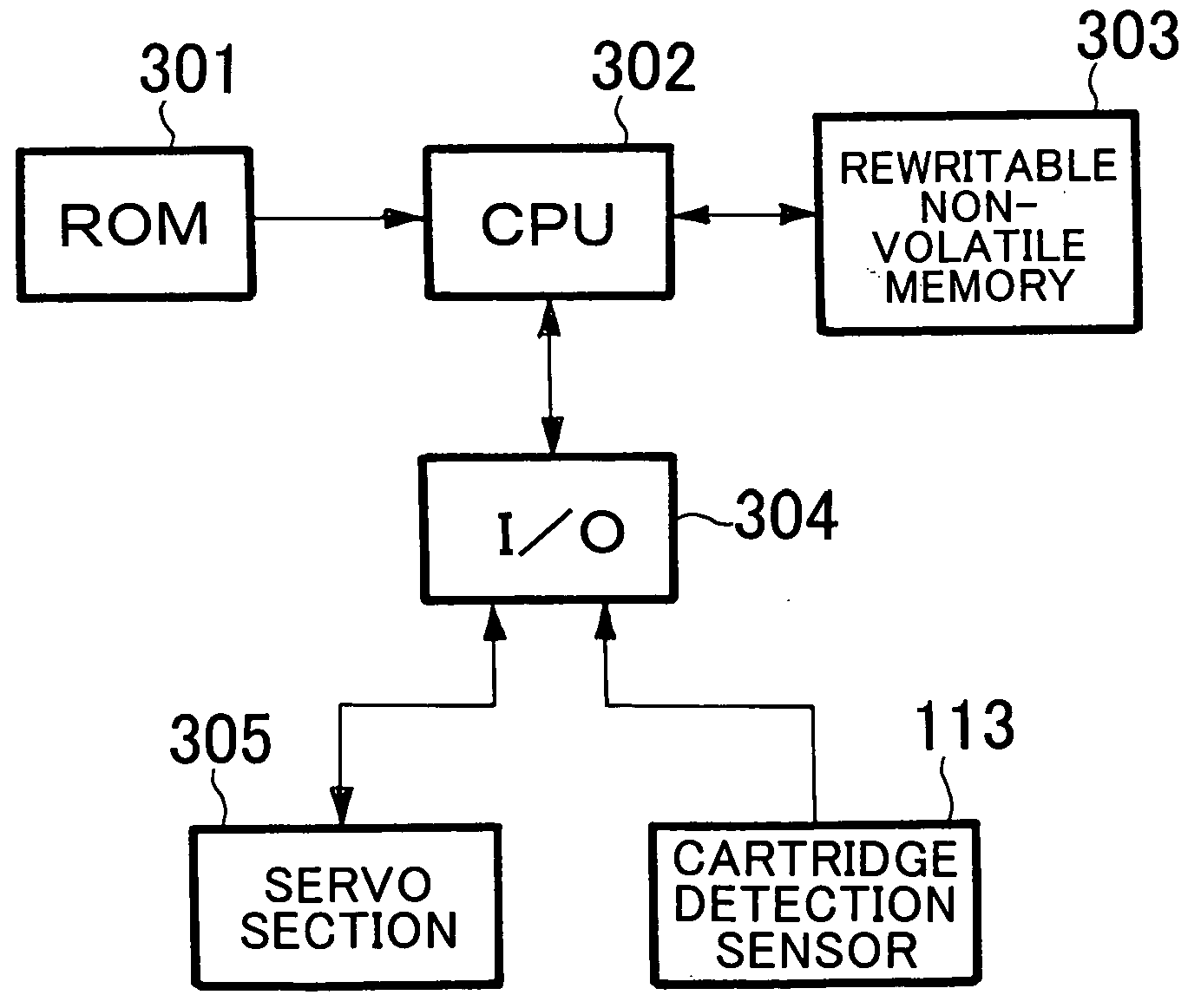

Coordinate offset adjustment system and coordinate offset adjustment method

InactiveUS20050163022A1Eliminate needComputer controlSimulator controlMechanical engineeringEngineering

According to an embodiment, a cartridge sensor shaft is allowed to butt against the vicinity of a positioning hole and is shifted toward the positioning hole. A coordinate offset error is then calculated based on a difference between the moving distance from the portion against which the cartridge sensor shaft butts to the portion at which the cartridge sensor shaft enters the positioning hole and the expected moving distance. The coordinate offset is adjusted by the calculated error. Further, in order to reduce measurement error, the cartridge sensor shaft is allowed to butt from both side of the positioning hole and shifted to detect the edges of the positioning hole, thereby calculating the coordinate offset error based on the two moving distances and two expected moving distances.

Owner:NEC CORP

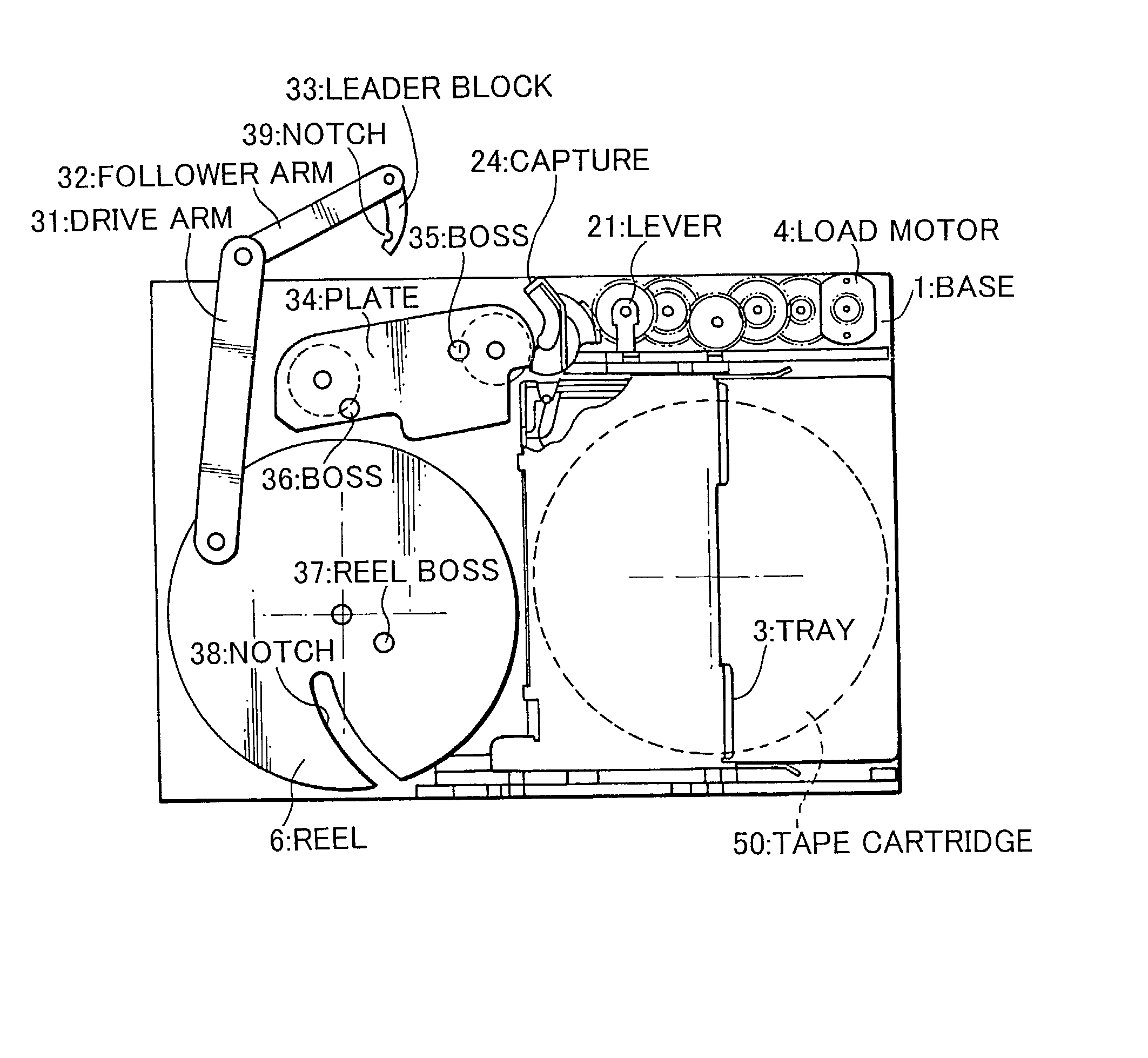

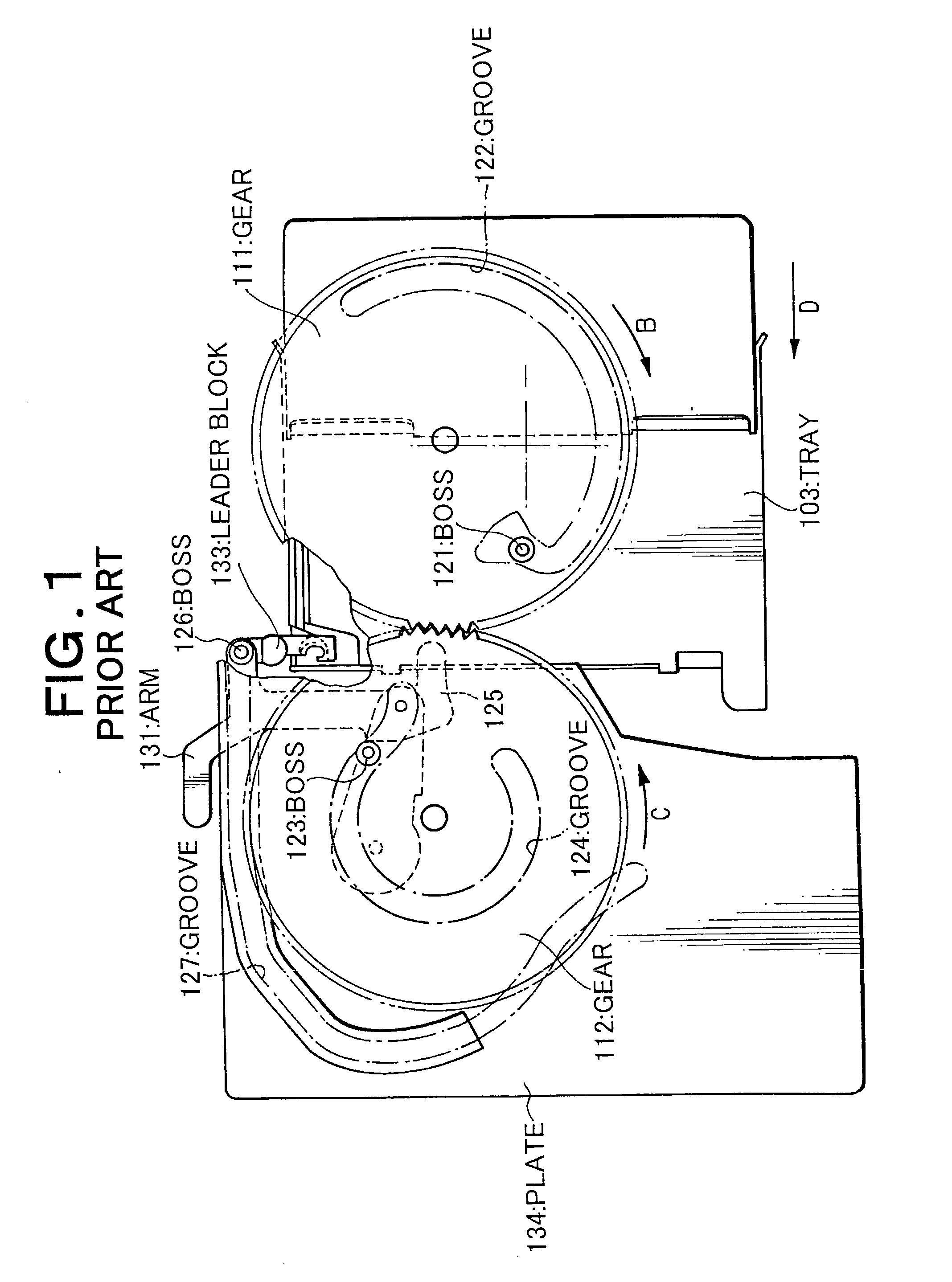

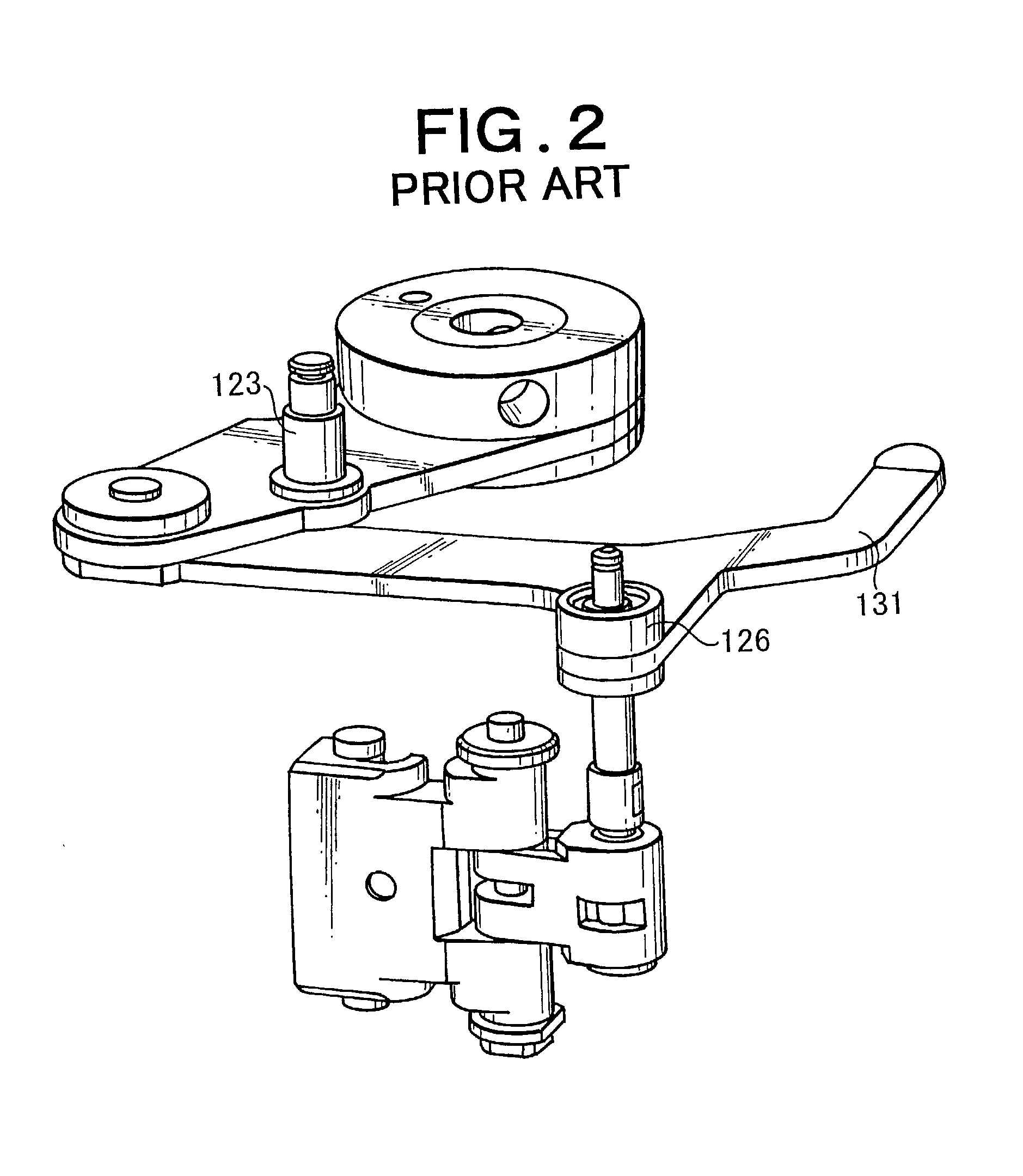

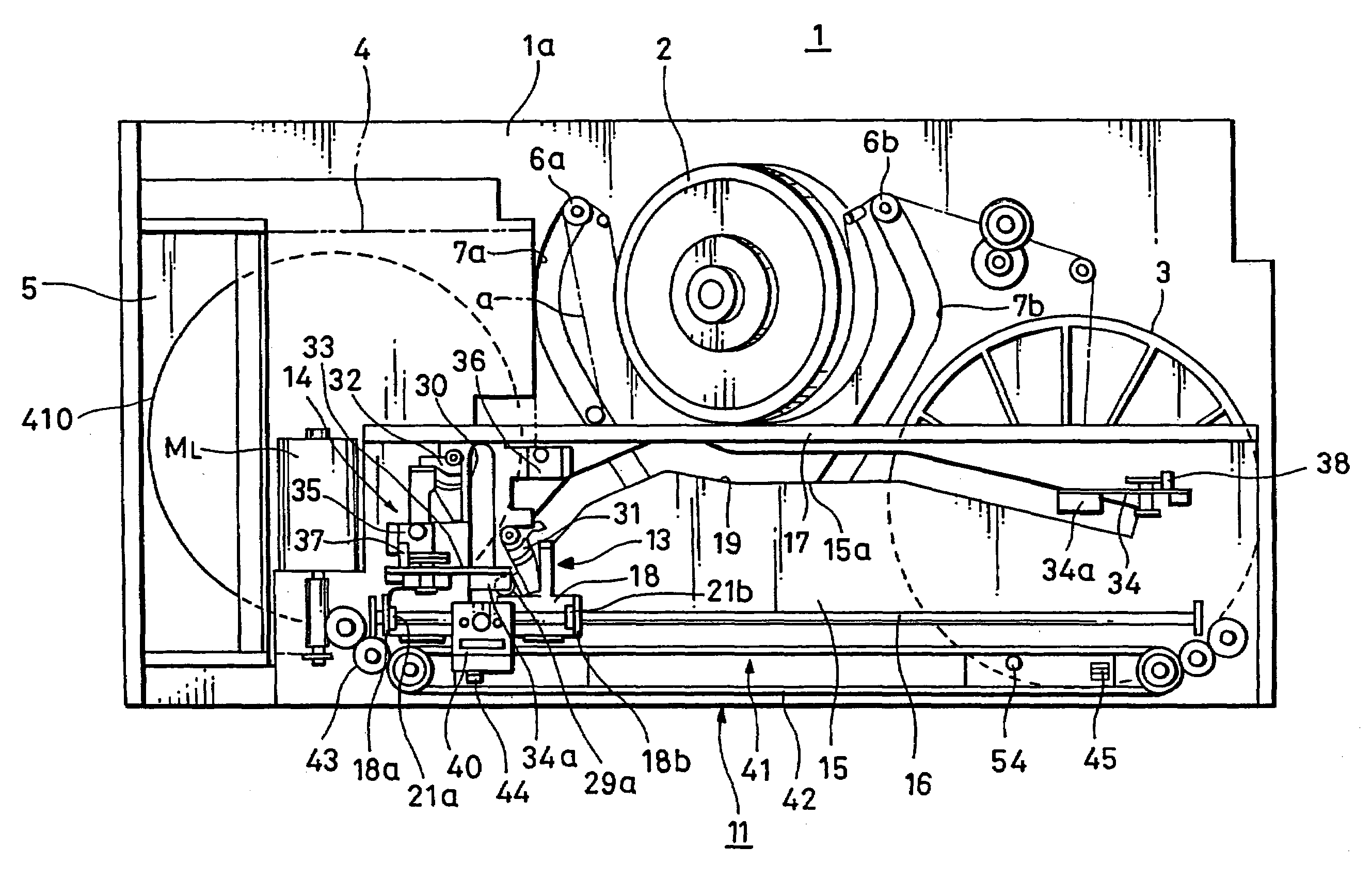

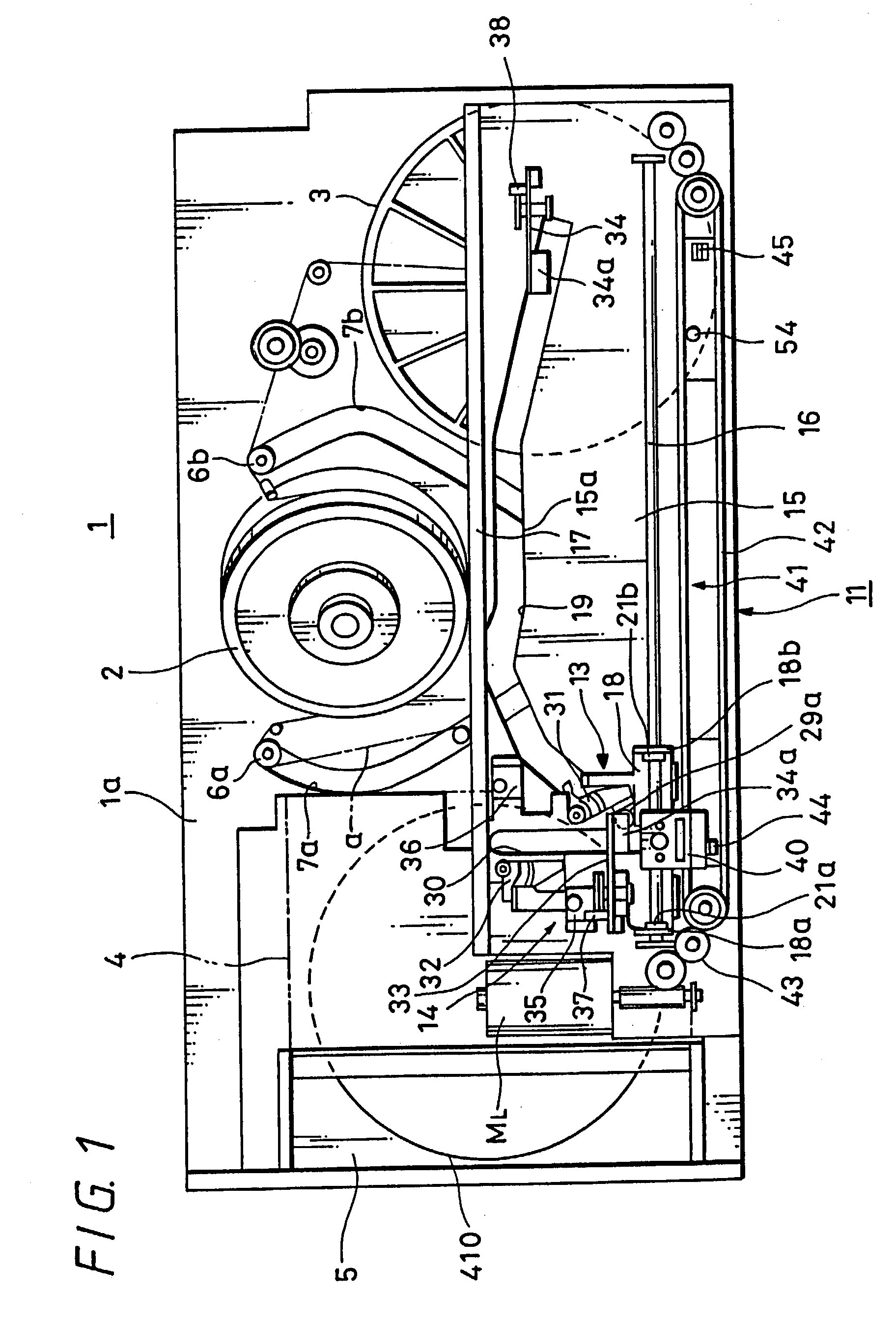

Magnetic tape apparatus

InactiveUS20030019968A1Projector film strip handlingCamera film strip handlingMagnetic tapeElectric machine

A magnetic tape apparatus according to the present invention has a reel and a motor. A tape is wound on the reel. The motor rotates the reel. A drive arm is disposed on the reel. A follower arm is disposed on the drive arm. The follower arm has a rotatable leader block. The leader block also has a notch for hooking a pin of the tape. As a load motor is rotated, a loader is moved. The loader places a tape cartridge that is inserted from the outside at a predetermined position of a base. At that point, a motive power of the load motor is transferred to a capture gear. A capture that rotates the leader block is connected to the capture gear.

Owner:NEC CORP

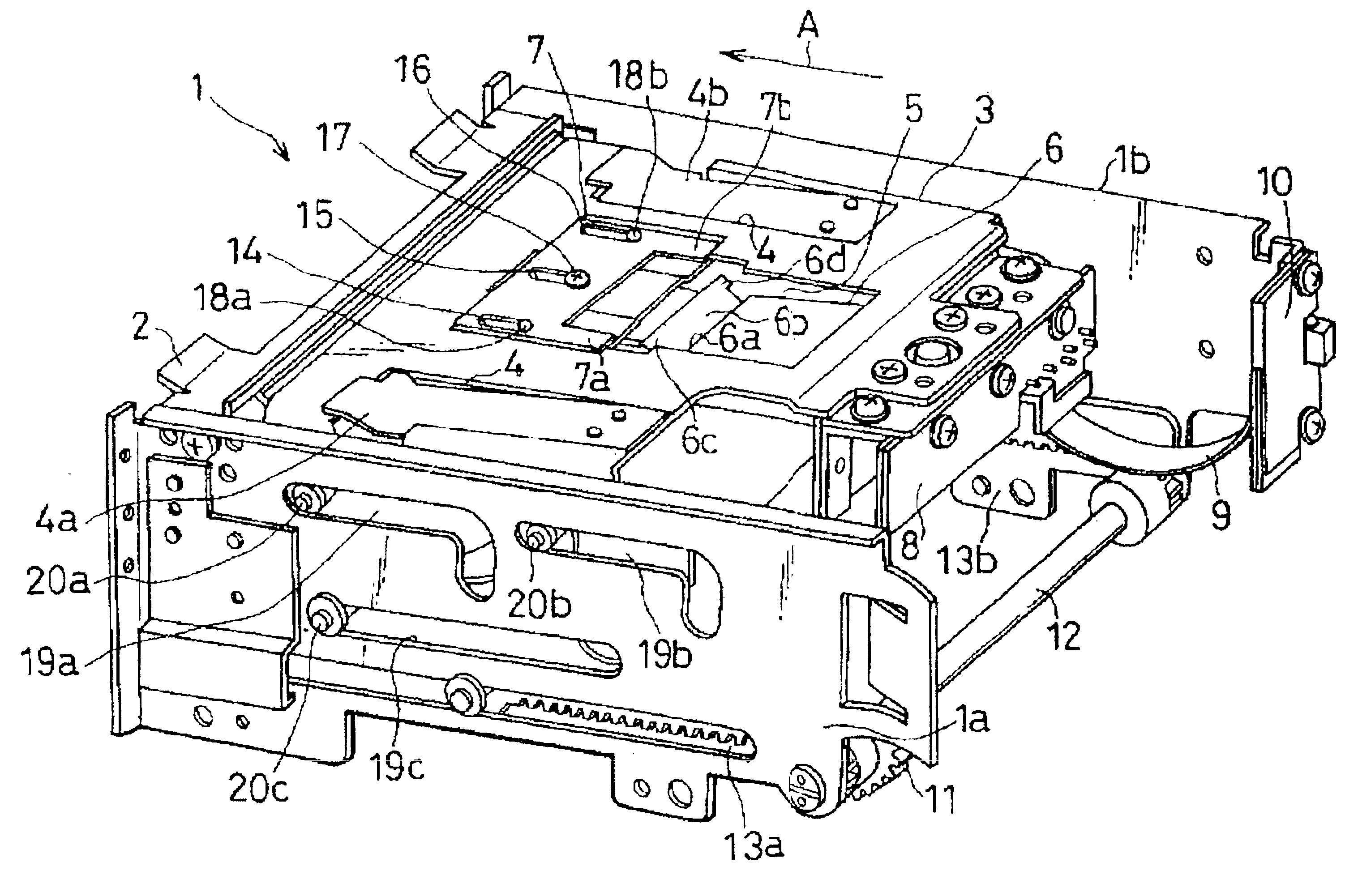

Loading mechanism of storage device

InactiveUS6857574B2Easy to manageSimple designConveying record carriersRecord information storageEngineeringMechanical engineering

A loading mechanism of a storage device includes a loader tray into which cartridge is loaded. A stopper spring is arranged on an opening of the loader tray. One side of the stopper spring is attached onto the loader tray, and the stopper spring is bent so as to include an engagement portion in a “V-like” shape. A pair of extending portions, extending toward the stopper spring, are formed on a side of a release plate. If the release plate is moved toward the stopper spring, the pair of extending portions move underneath an inclined portion of the stopper spring, so as to push up the engagement portion.

Owner:NEC CORP

Tape cartridge soft load system

InactiveUS20050051653A1Picture changing apparatusProjector film strip handlingMagnetic tapeEngineering

A tape drive system and method of operating a tape drive system are provided. The tape drive system may include: a stationary base; at least one guide projection mounted to the stationary base; and a receiver for receiving a tape cartridge and transporting the tape cartridge from an ejected position to a loaded position, the receiver including at least one guide slot mating with one of the guide projections, each guide slot being shaped to allow the receiver to move a first distance in a horizontal direction and a second distance in a vertical direction. The method of loading a tape cartridge into a tape drive system having a stationary base and at least one guide projection mounted to the stationary base may include: receiving a tape cartridge in a receiver having at least one guide slot having a first portion and a second portion; and moving the receiver from an ejected position to a loaded position. This moving of the receiver may be performed by passing the guide projection through the first portion of the guide slot to move the receiver a first distance in a horizontal direction; and passing the guide projection through the second portion of the guide slot to move the receiver a second distance in a vertical direction.

Owner:QUANTUM CORP

Library apparatus and position controlling method

InactiveUS8065033B2Simple configurationFilamentary/web carriers operation controlDigital data processing detailsEngineeringElectrical and Electronics engineering

A library apparatus includes a cell unit having a plurality of cells arrayed in a matrix, a holder to insert the storage medium to one of the cells or extract the storage medium from the cell, and a position controller to move the holder over the cell unit in X-axis and Y-axis directions to position the holder at a desired position. The holder has a reading unit configured to acquire data of the edges on both sides of each cell. The position controller determines each position of the cells on the basis of the data of the edges acquired at a plurality of positions while moving the holder in a predetermined direction from a predetermined position of the cell unit.

Owner:FUJITSU LTD

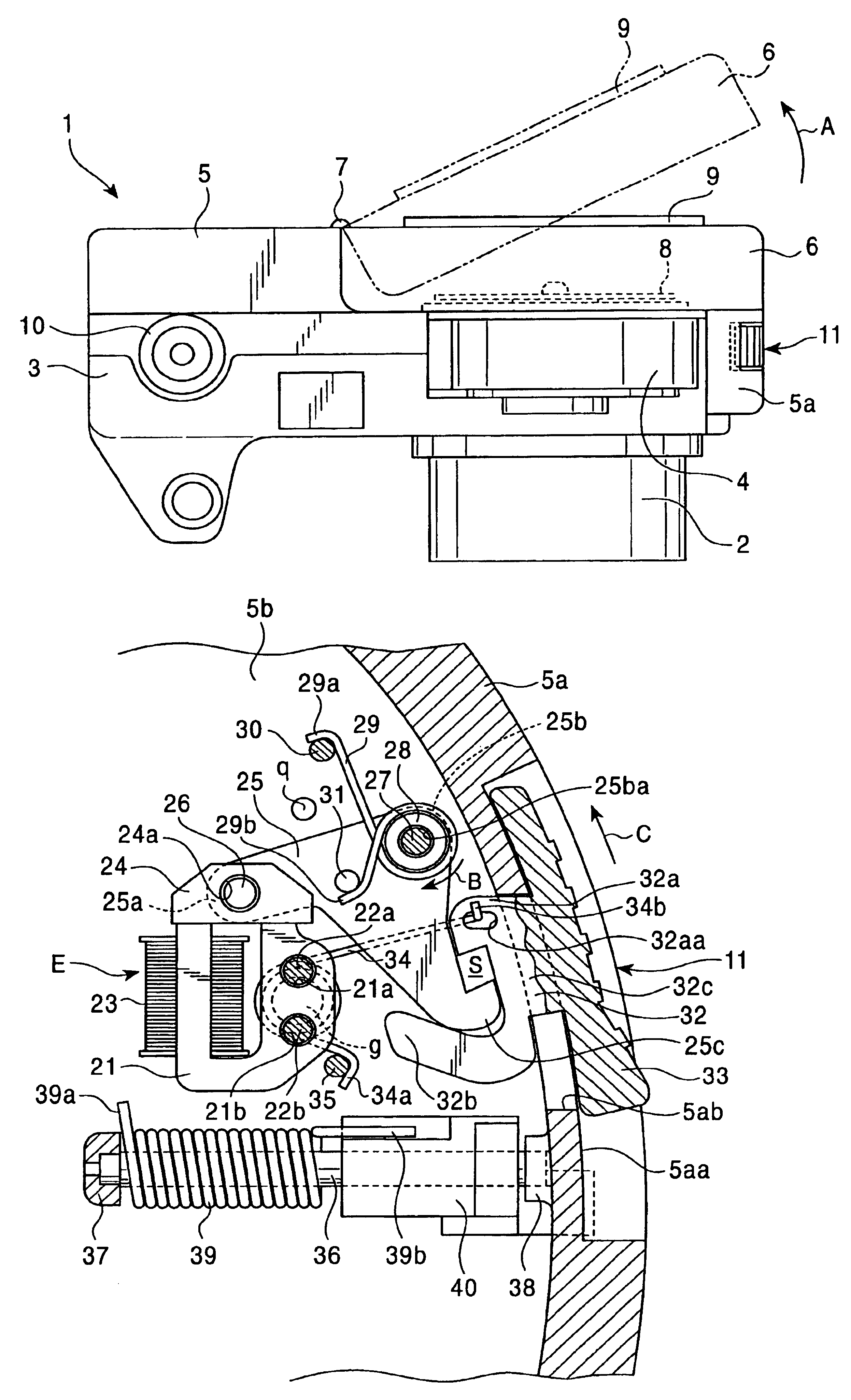

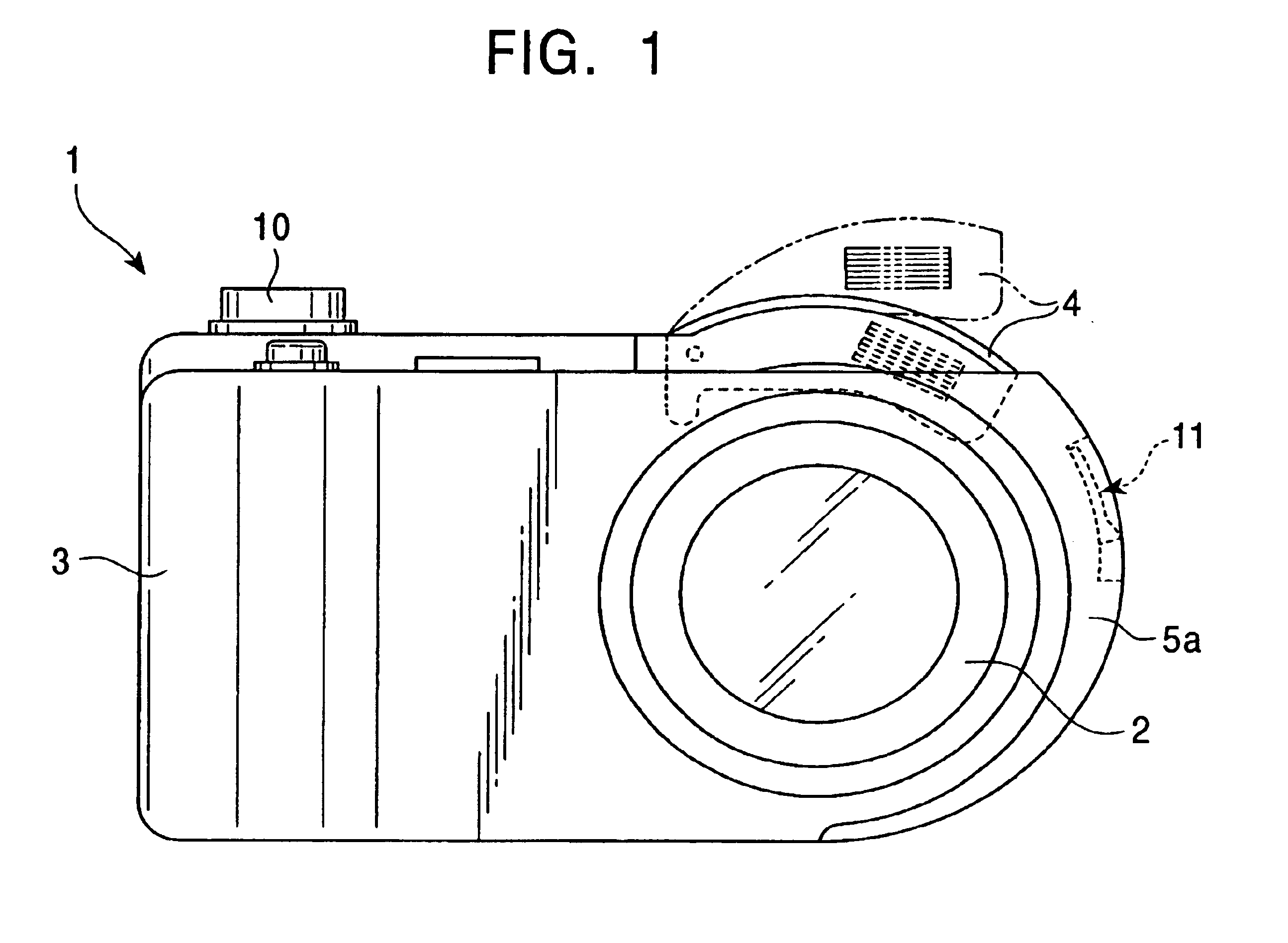

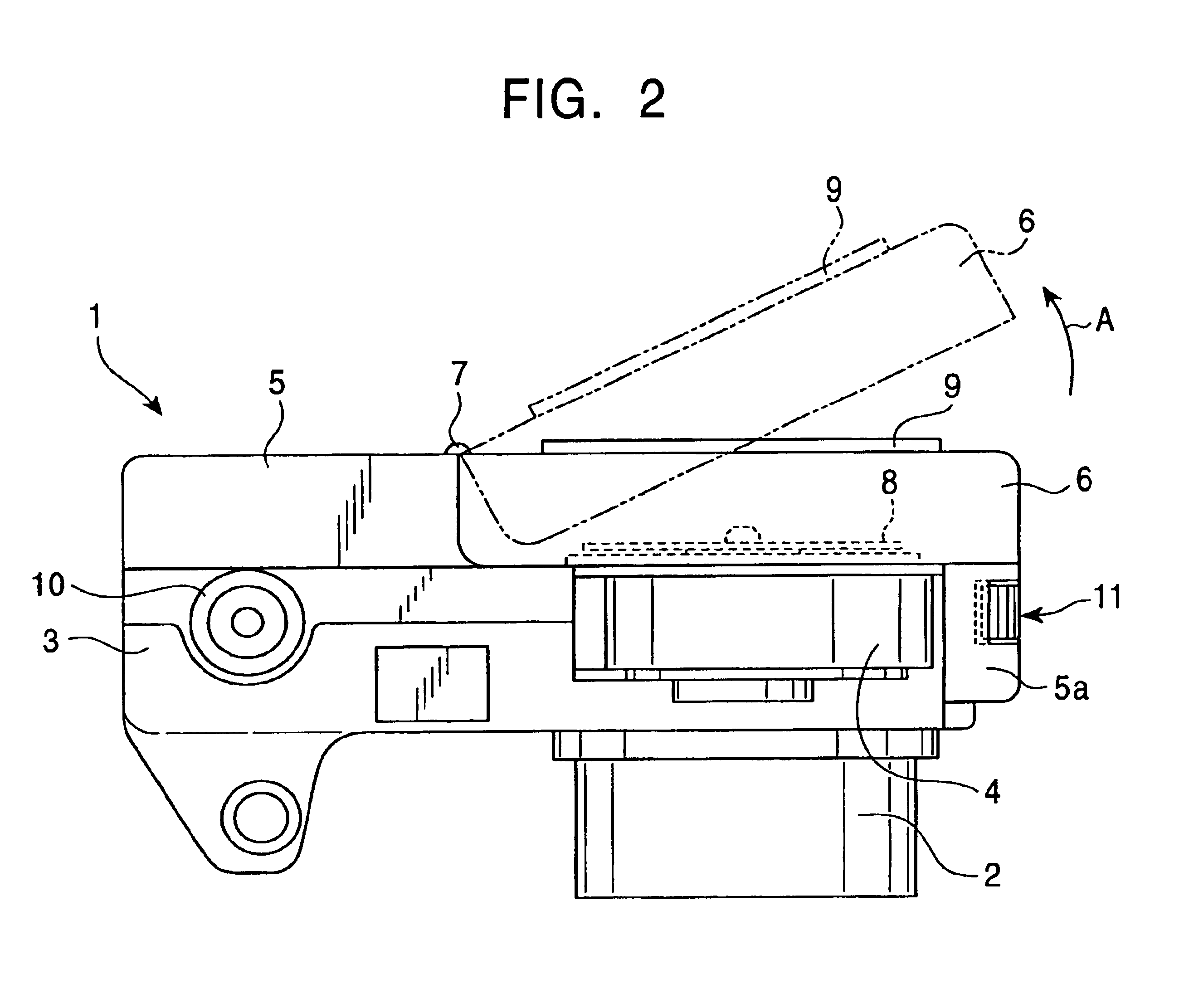

Protection-cover opening/closing mechanism for recording/playback apparatus

InactiveUS6930727B2Reliable preventionTelevision system detailsCarrier constructional parts dispositionRecordable CDReciprocating motion

A protection-cover opening / closing mechanism for a digital still camera includes an electromagnet having stator around which an electromagnetic coil is formed and a movable member, a first lever to which the movable member is pivotally attached at a first end portion and which receives a rotational force, a second lever which is able to reciprocate on a stationary member, which is engageable with a second end portion of the first lever, and which is pressed toward an initial position thereof. While a CD-R is being operated, current is applied to the electromagnetic coil to restrain the movable member on the stator and thereby prevent the first lever from rotating, and the movement of the second lever in the direction away from the initial position is limited due to the engagement between the first lever and the second lever, thereby locking a protection cover at a closed position.

Owner:SONY CORP

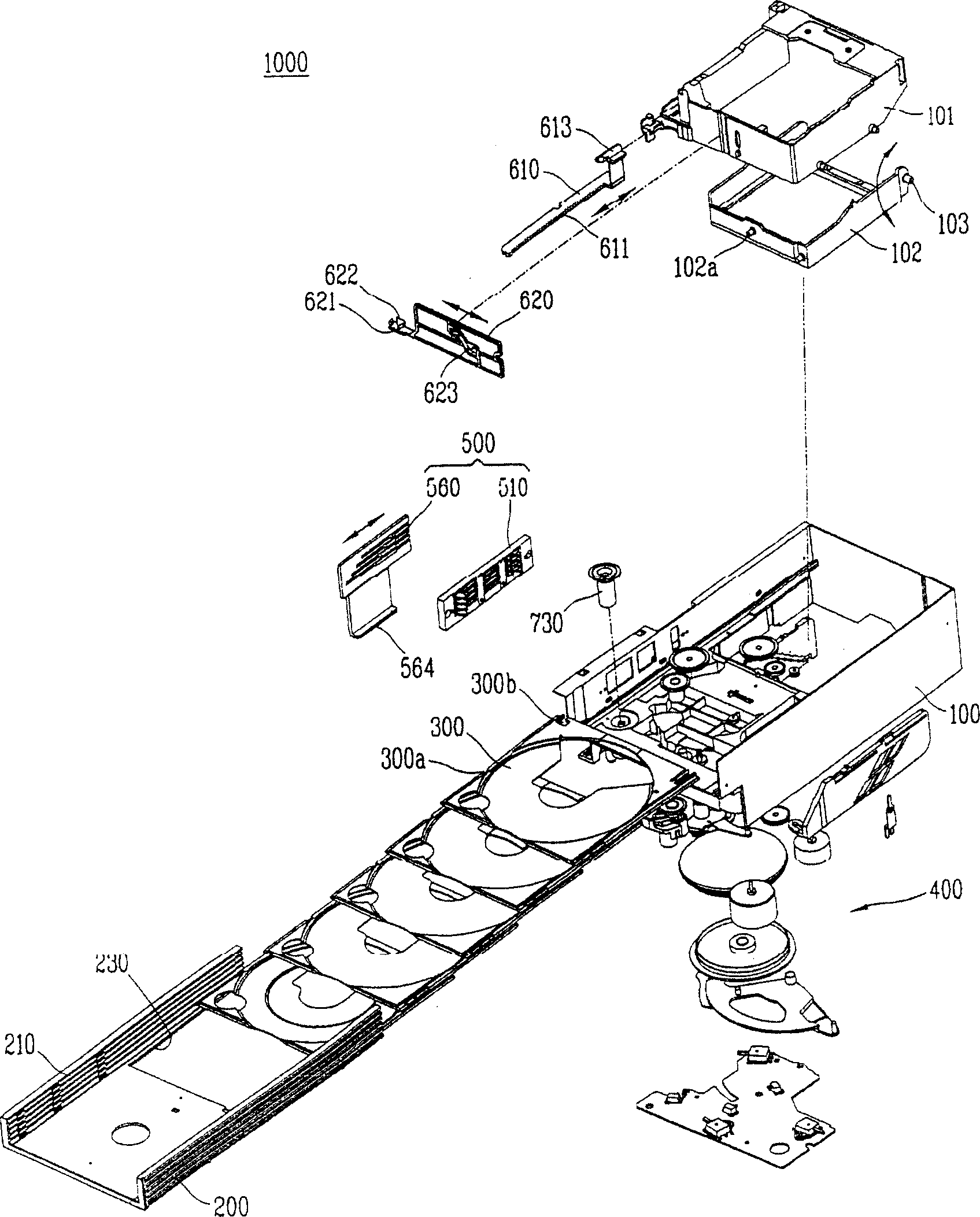

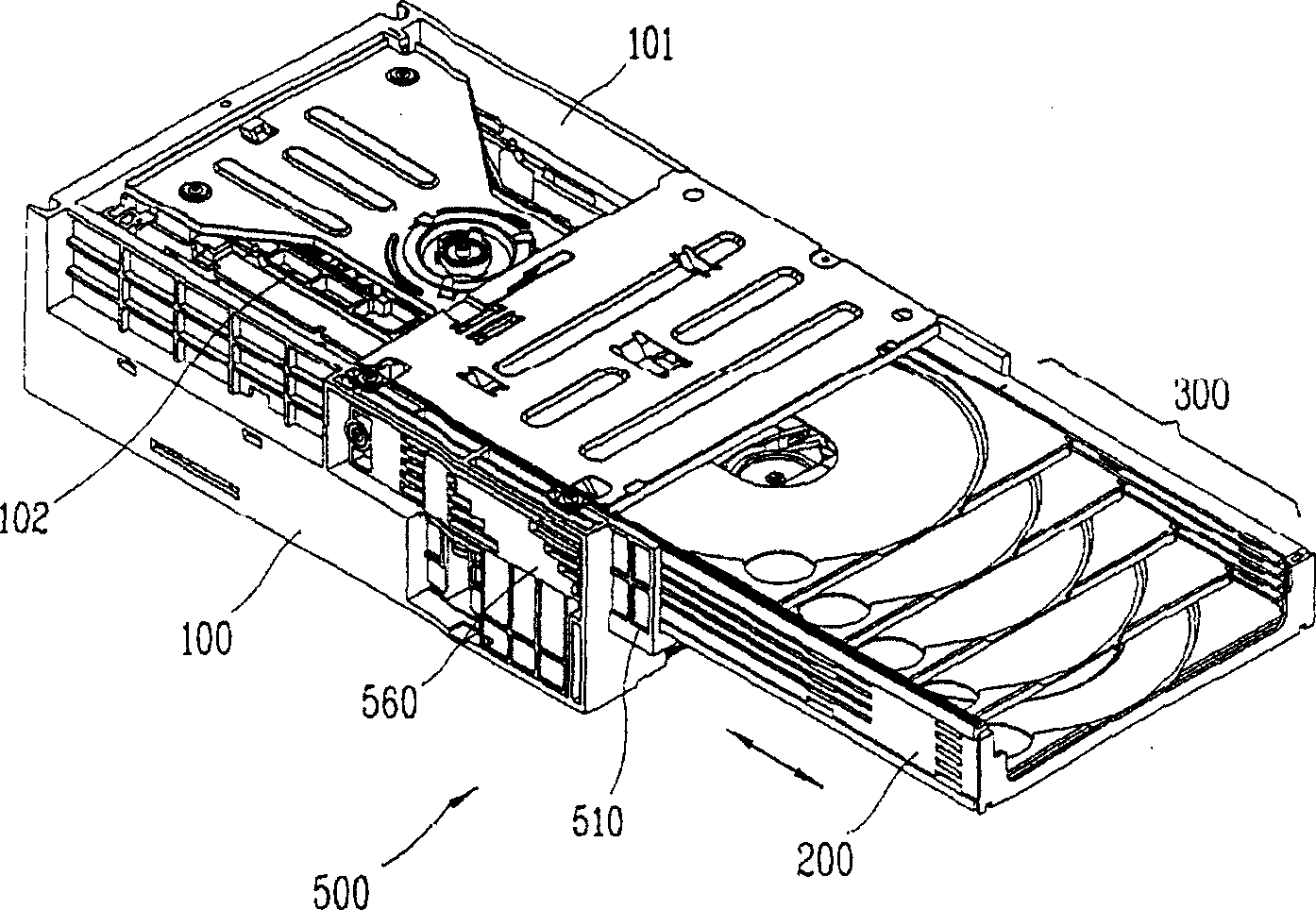

Disk drive

InactiveCN1551173ASmall sizeRecord information storageCarrier container guidanceEngineeringMechanical engineering

A disk drive includes a main frame; a cartridge slidably installed in the main frame; a plurality of trays stacked in the cartridge and slidably installed therein; an elevation unit for controlling a height of a turn table; a tray selecting unit for locking each tray to a state that each tray can be loaded or unlocking a specific tray among a plurality of locked trays to draw it out of the main frame; a loading unit for loading the specific tray, among the plurality of trays locked by the tray selecting unit to reproduce / record a disk by means of an optical pick-up unit, onto the turn table; and a driving unit for driving the cartridge, the elevation unit, the tray selecting unit and the loading unit.

Owner:LG ELECTRONICS INC

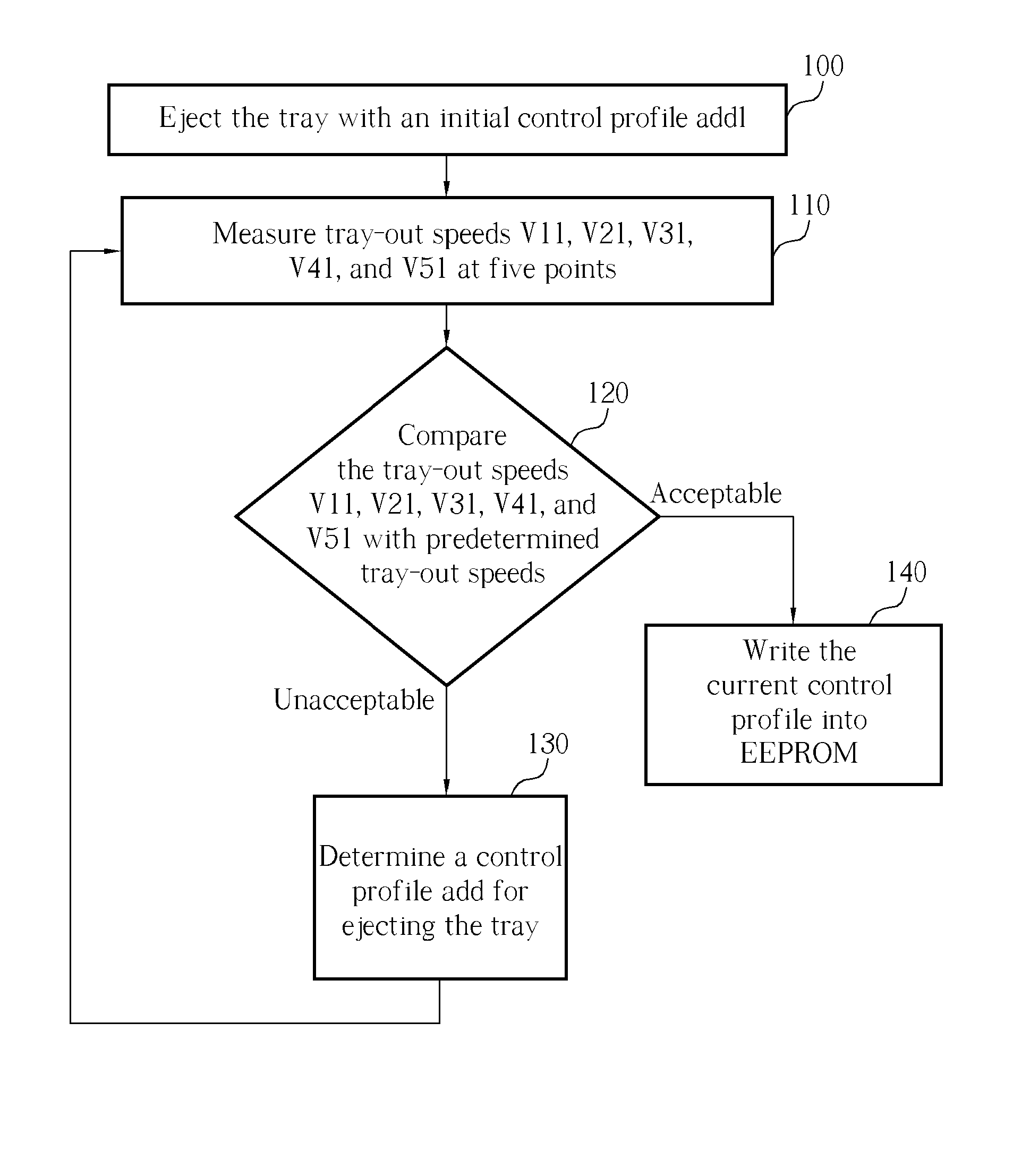

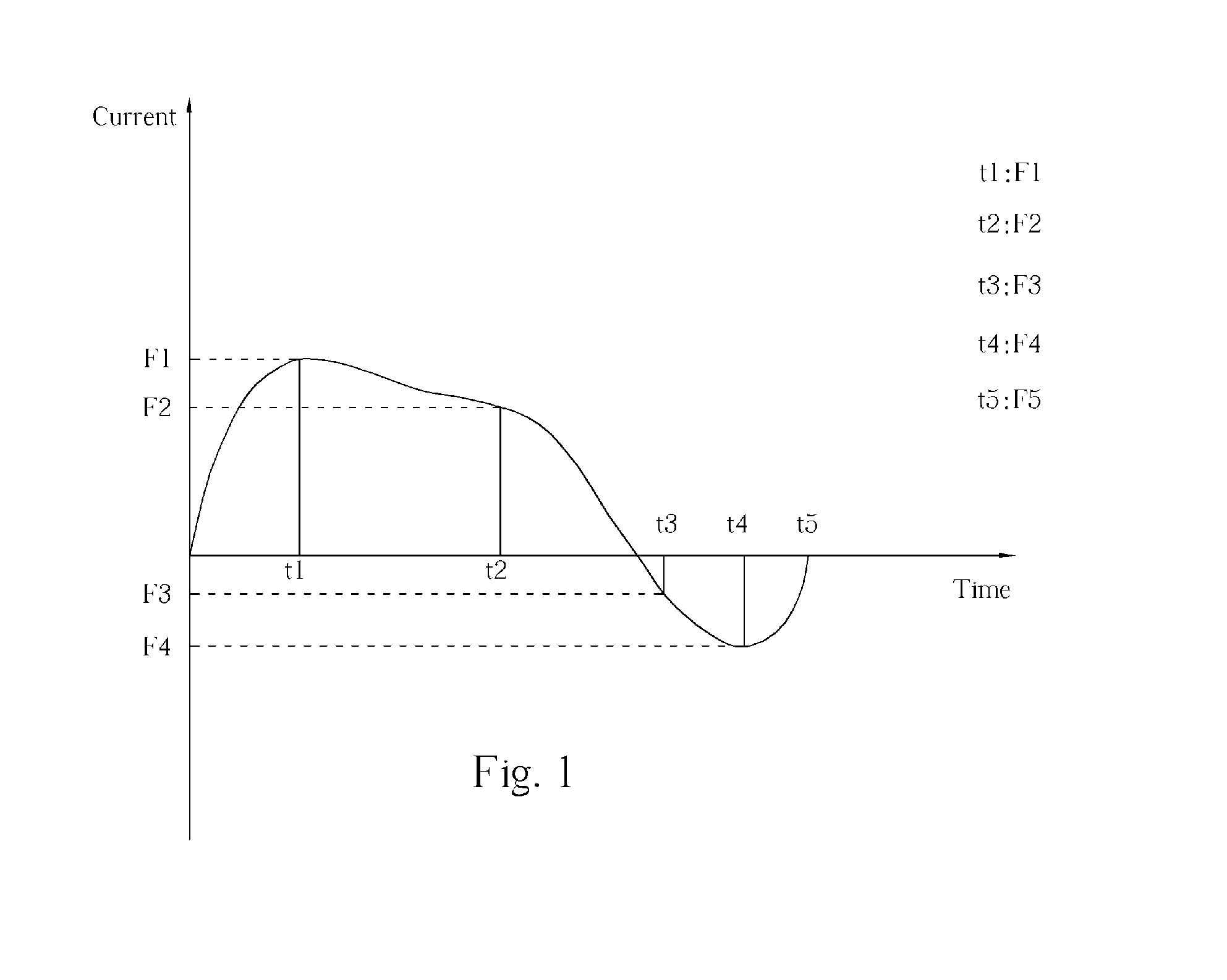

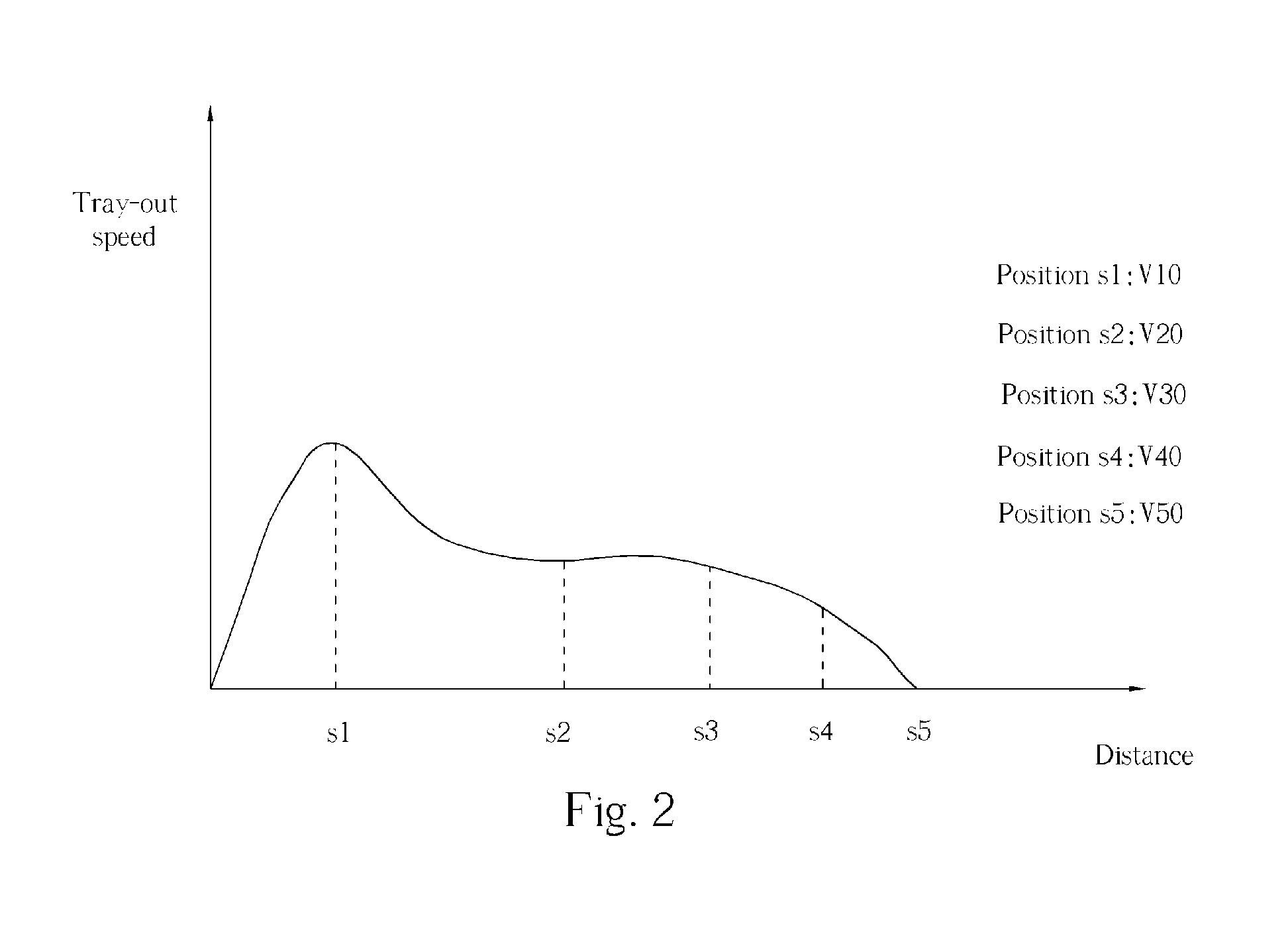

Method of determining an optimal control profile for adjusting tray-in/out speeds of an optical disk drive

InactiveUS20050052959A1Combination recordingDisposition/mounting of recording headsOptimal controlEngineering

The present invention discloses an adjusting method applicable to tray-in and tray-out speeds in optical disk drives. Firstly, a number of control profiles are set up, a tray-out operation of is executed by an initial control profile, and the tray speed measured by means of sensors. If the tray speed is not acceptable, then an optimal control profile is selected from the preset control profiles according to the unacceptable tray speed.

Owner:LITE ON IT

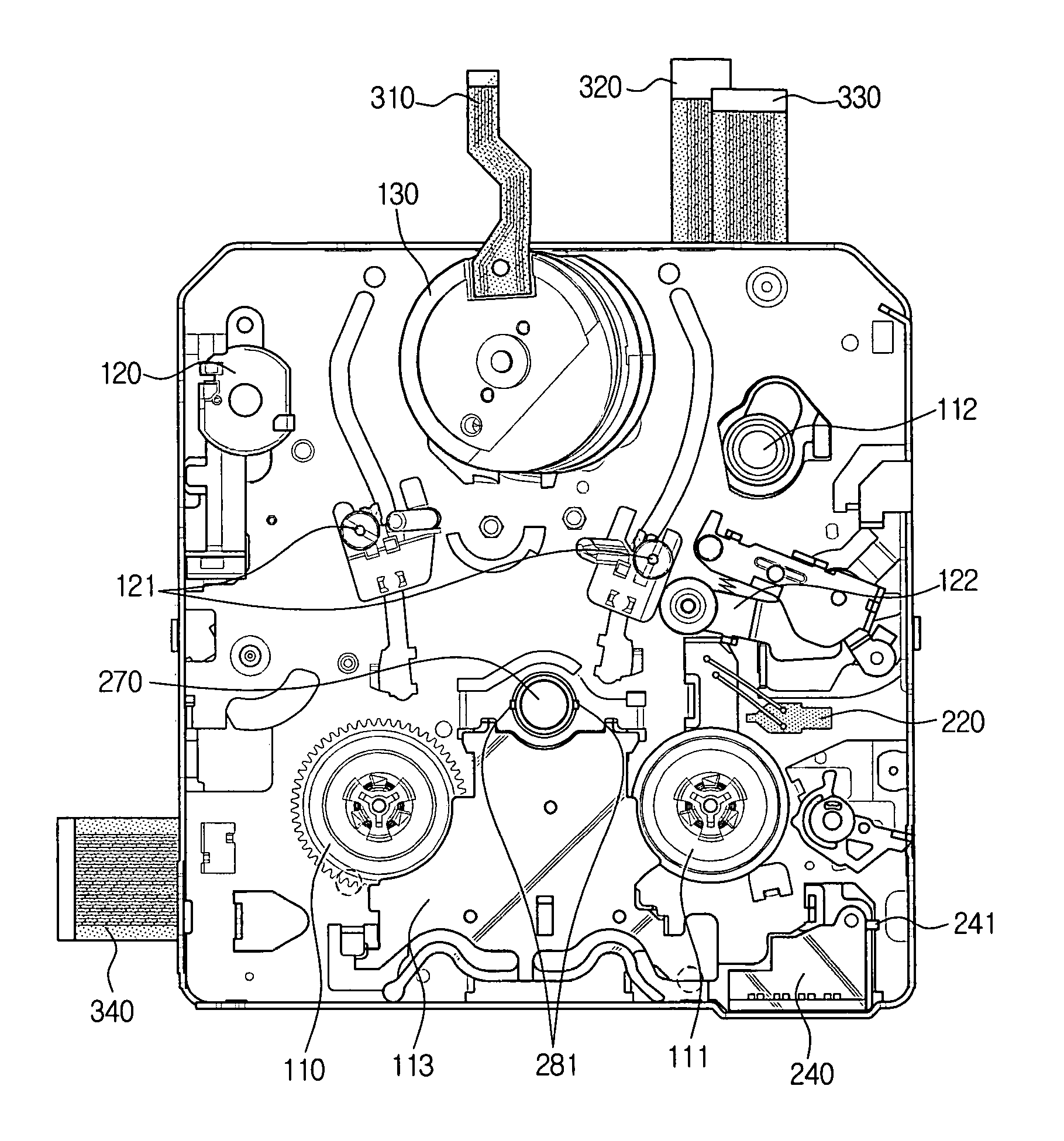

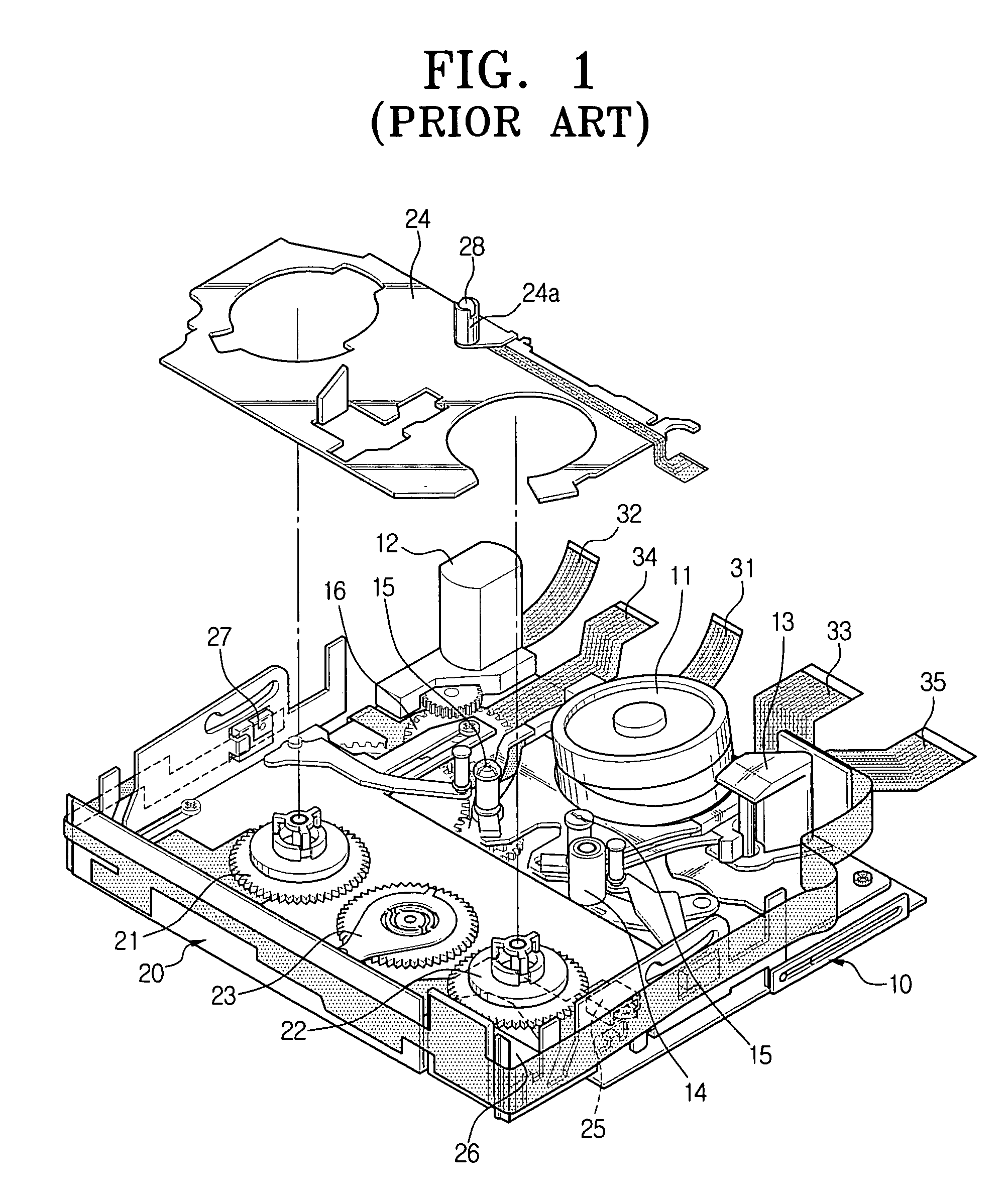

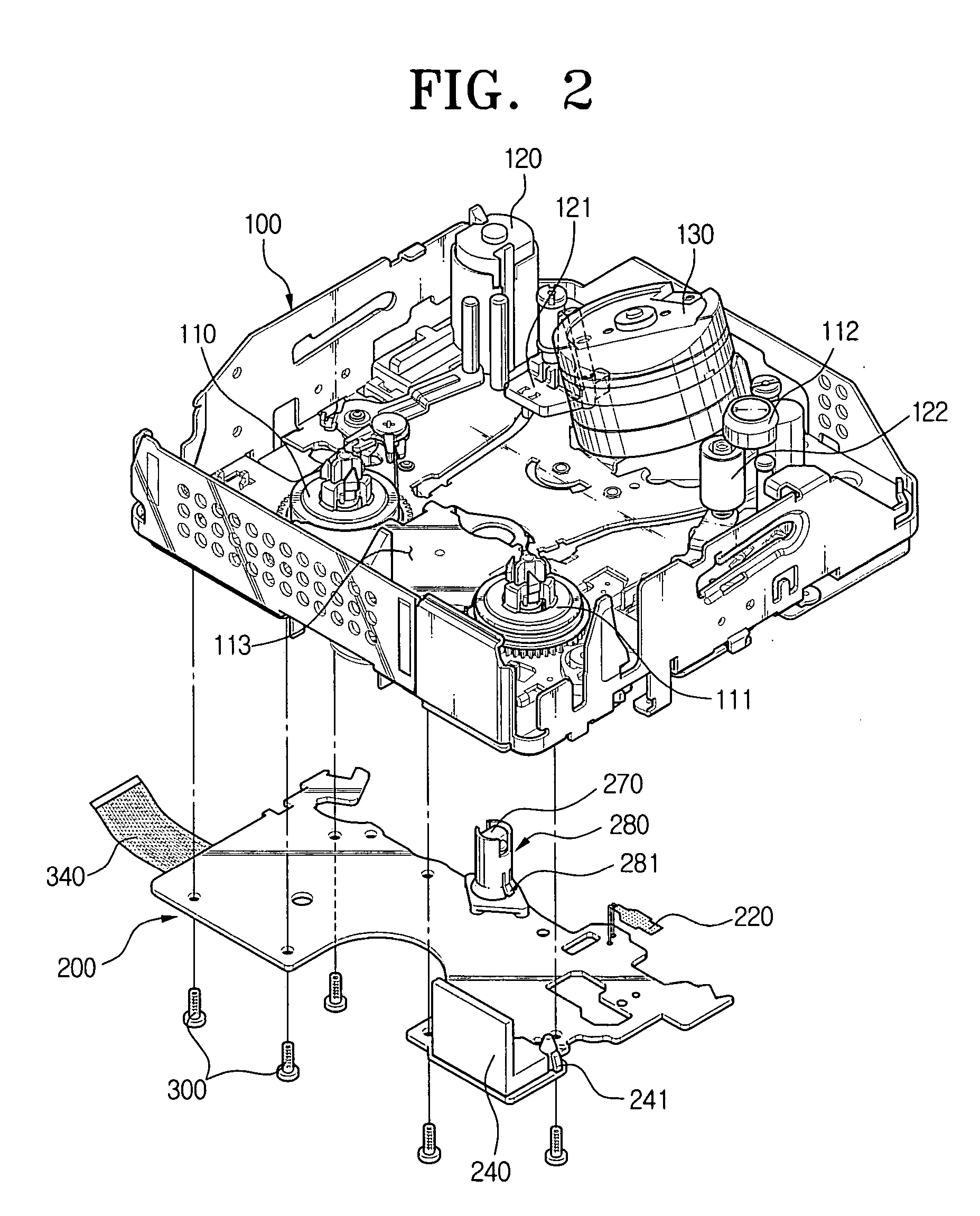

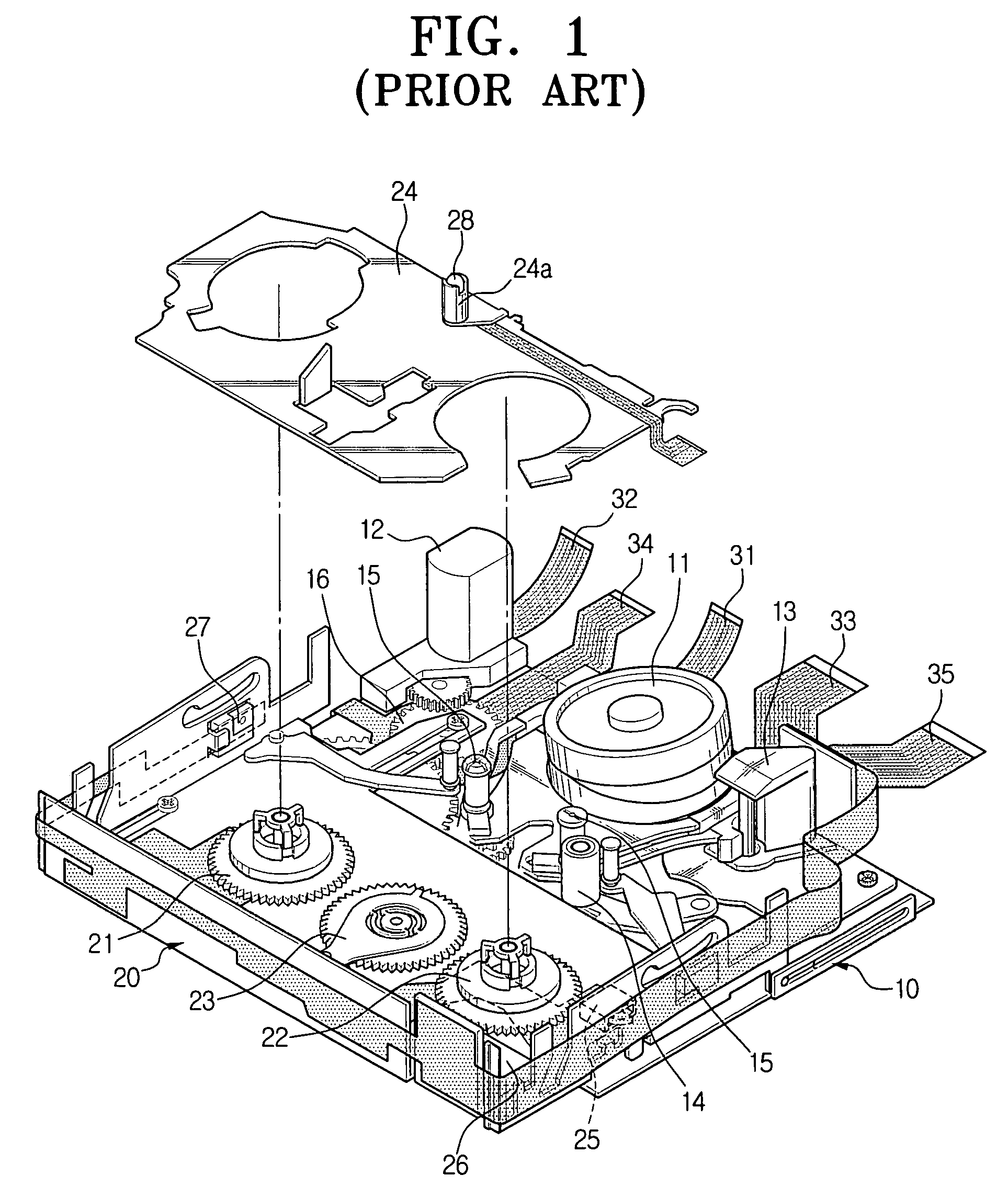

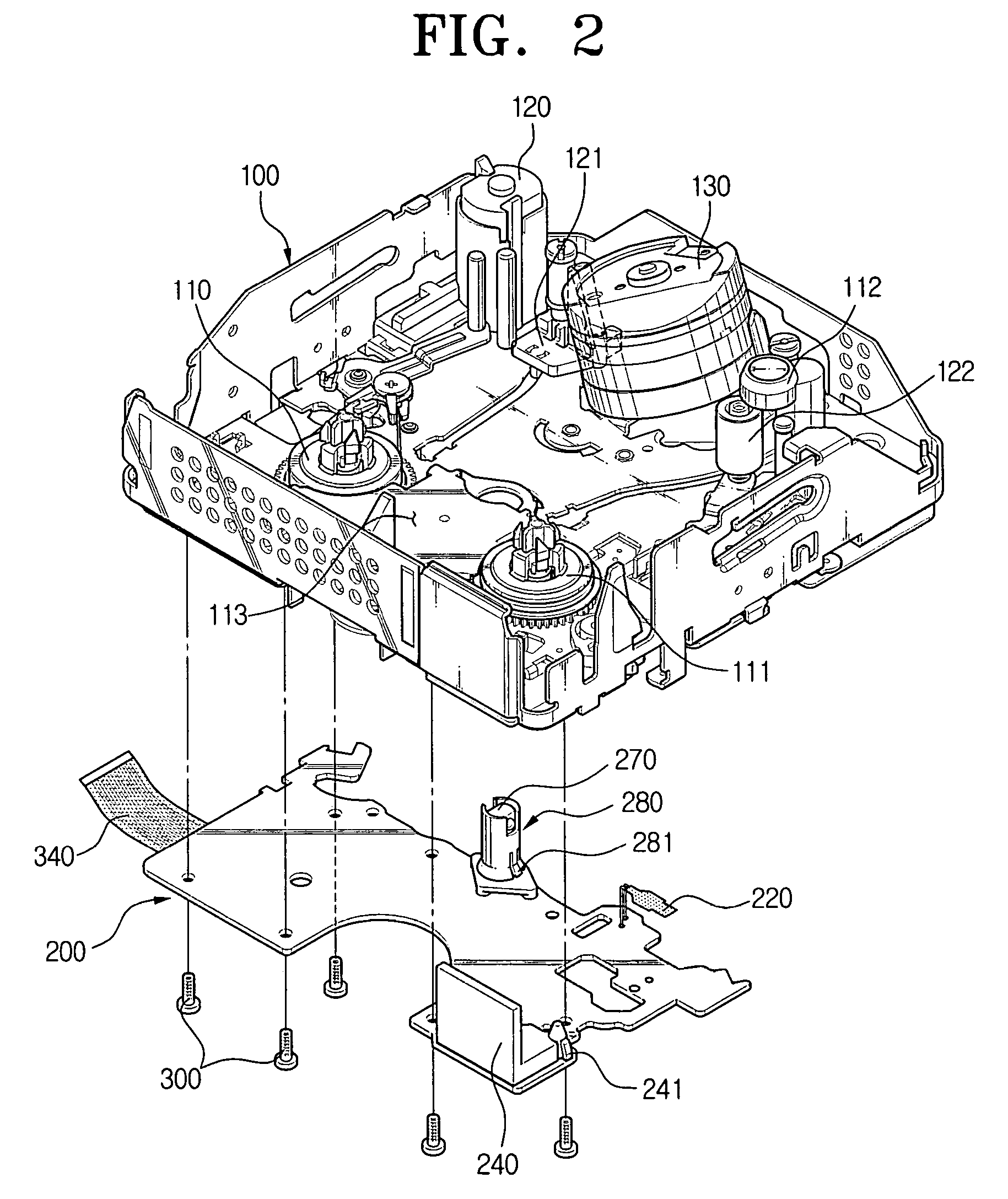

Deck for magnetic recording/reproducing apparatus

InactiveUS20050280926A1Minimized in sizeReduce connectionsCarrier constructional parts dispositionRecord information storageMagnetic tapeEngineering

Disclosed is a deck for a magnetic recording / reproducing apparatus. The deck has a chassis in which a plurality of structures constituting a mechanical mechanism for loading a tape and recording or reproducing information; and a switch / sensor circuit board in which a plurality of switches and sensors constituting an electronic mechanism for detecting an operation of the deck and a state of the structures. The switch / sensor circuit board is formed of a PCB and assembled to a lower surface of the chassis.

Owner:SAMSUNG ELECTRONICS CO LTD

Robot hand having swaying mechanism in library apparatus

InactiveUS20070196197A1Reliably allowing a robot hand to reach a standby regionRecord information storageAutomatic cassette changing arrangementsRobot handEngineering

A library apparatus includes cells. A positioning mechanism serves to position a carriage relative to the cells within an operating region adjacent to a standby region. A transporting mechanism drives the carriage toward the standby region. A swaying mechanism allows grasping fingers on the carriage to go around an object lying on the movement path of the grasping fingers when the transporting mechanism carries the carriage to the standby region. The grasping fingers acts to hold an object within the cell. If the positioning mechanism malfunctions, the transporting mechanism transfers the carriage to the standby region. Even if an object exits on the movement path of the grasping finger, the carriage is allowed to keep moving because the swaying mechanism allows the grasping finger or fingers to sway around the object on the movement path. The carriage thus reliably reaches the standby region.

Owner:FUJITSU LTD

Deck for magnetic recording/reproducing apparatus

InactiveUS7327529B2Minimized in sizeReduce connectionsCarrier constructional parts dispositionRecord information storageMagnetic tapeEngineering

Owner:SAMSUNG ELECTRONICS CO LTD

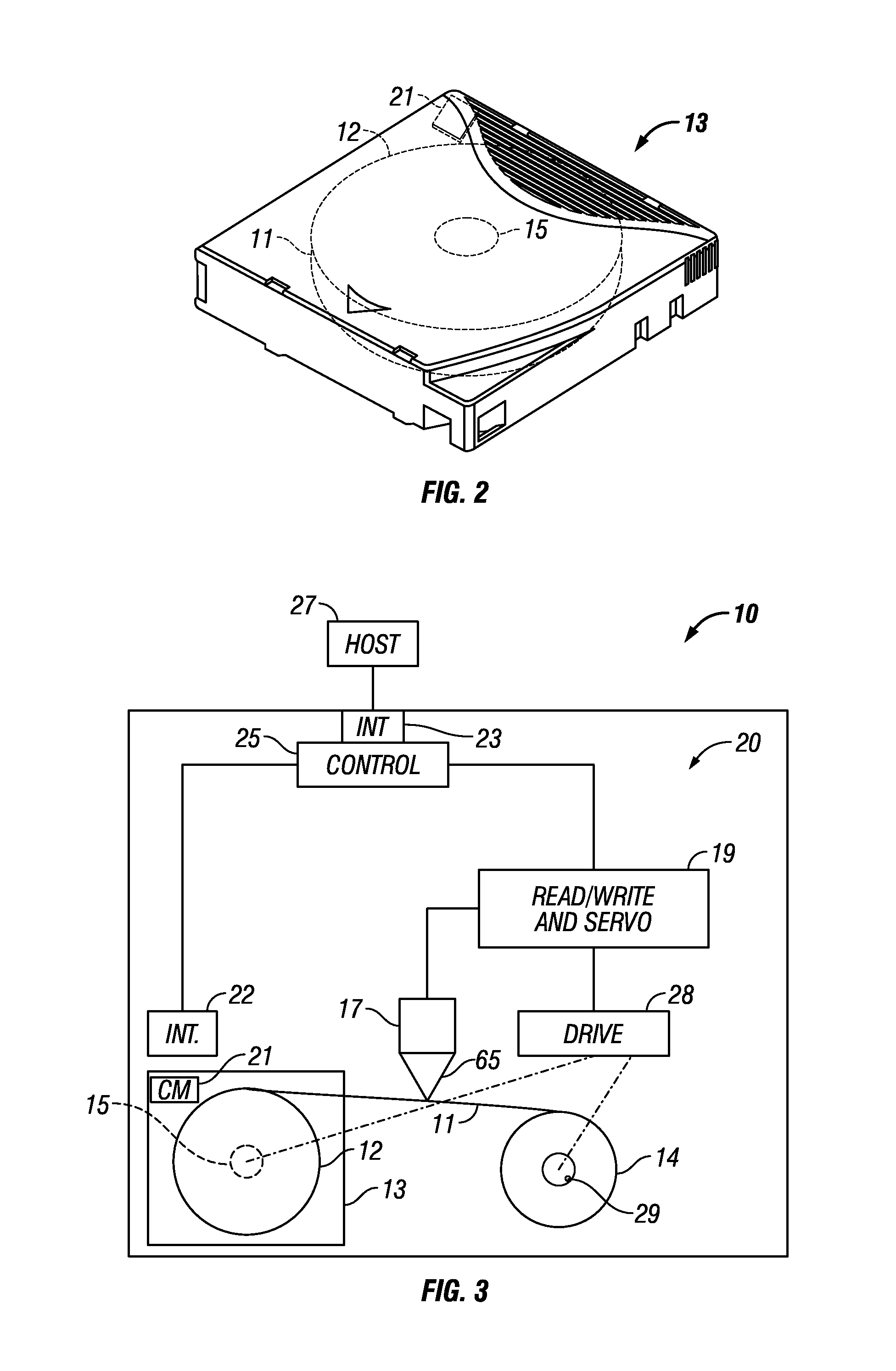

Tape drive sensor system

InactiveUS20050231847A1Record information storageMagazines/cassettes storageTape driveEmbedded system

Data drives and methods of operating a data drive are described. The drive includes: a drive base; a receiver for receiving a storage media device, the receiver being movably coupled to the drive base and translatable from an unloaded position to a loaded position; a media flag movably coupled to the receiver and translatable from a first position to a second position when the storage media device is inserted into the receiver; a media flag sensor fixedly coupled to the drive base for detecting movement of the receiver flag; a receiver flag fixedly coupled to the receiver; and a receiver flag sensor fixedly coupled to the drive base for detecting movement of the receiver flag. The method includes: receiving a storage media device into a receiver such that the storage media device contacts a media flag movably coupled to the receiver; detecting movement of the media flag using a media flag sensor; actuating movement of the receiver from an unloaded position to a loaded position; and detecting movement of a receiver flag fixedly coupled to the receiver using a receiver flag sensor.

Owner:QUANTUM CORP

Video cassette recorder

InactiveUS20060146438A1Minimized in sizeRecord information storageAnalogue recordingCassette recorderMechanical engineering

A video cassette recorder has a recorder body with an outer case, a bottom plate, and operating parts mounted in the recorder body. The recorder includes a depression partially formed on the bottom plate which corresponds to the operating parts to lower the positions of the operating parts for minimizing the size of the video cassette recorder.

Owner:SAMSUNG ELECTRONICS CO LTD

Tape or disc record player equipped with standby power-saving means

InactiveUS6590736B2Save electricityDriving/moving recording headsRecord information storageMagnetic tapeStandby power

Owner:ORION ELECTRIC CO LTD

Tape drive device, tape extraction device and tape cassette

InactiveUS6991193B2Reliably on the takeup reelProjector film strip handlingCamera film strip handlingMagnetic tapeEngineering

Owner:SONY CORP

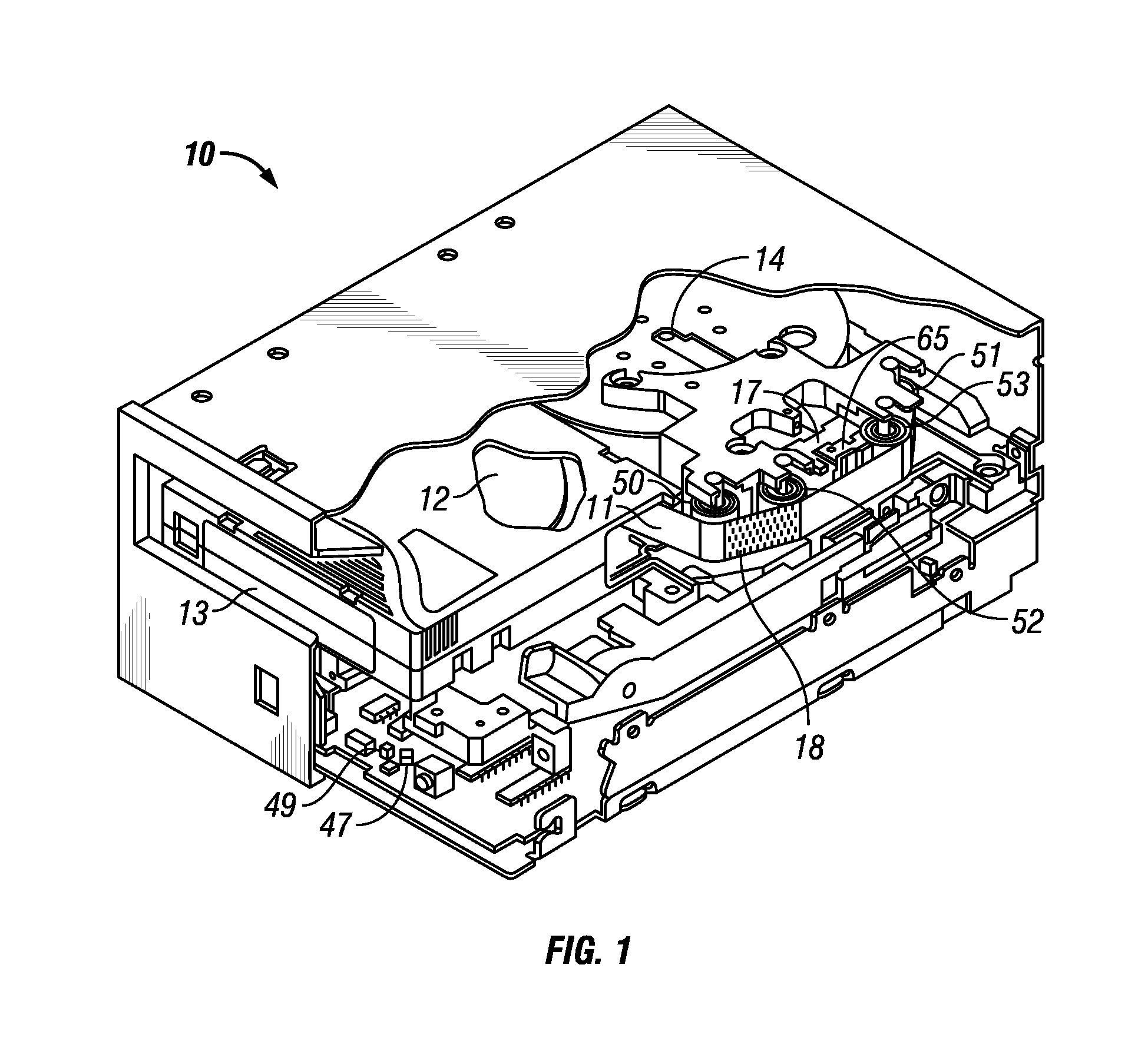

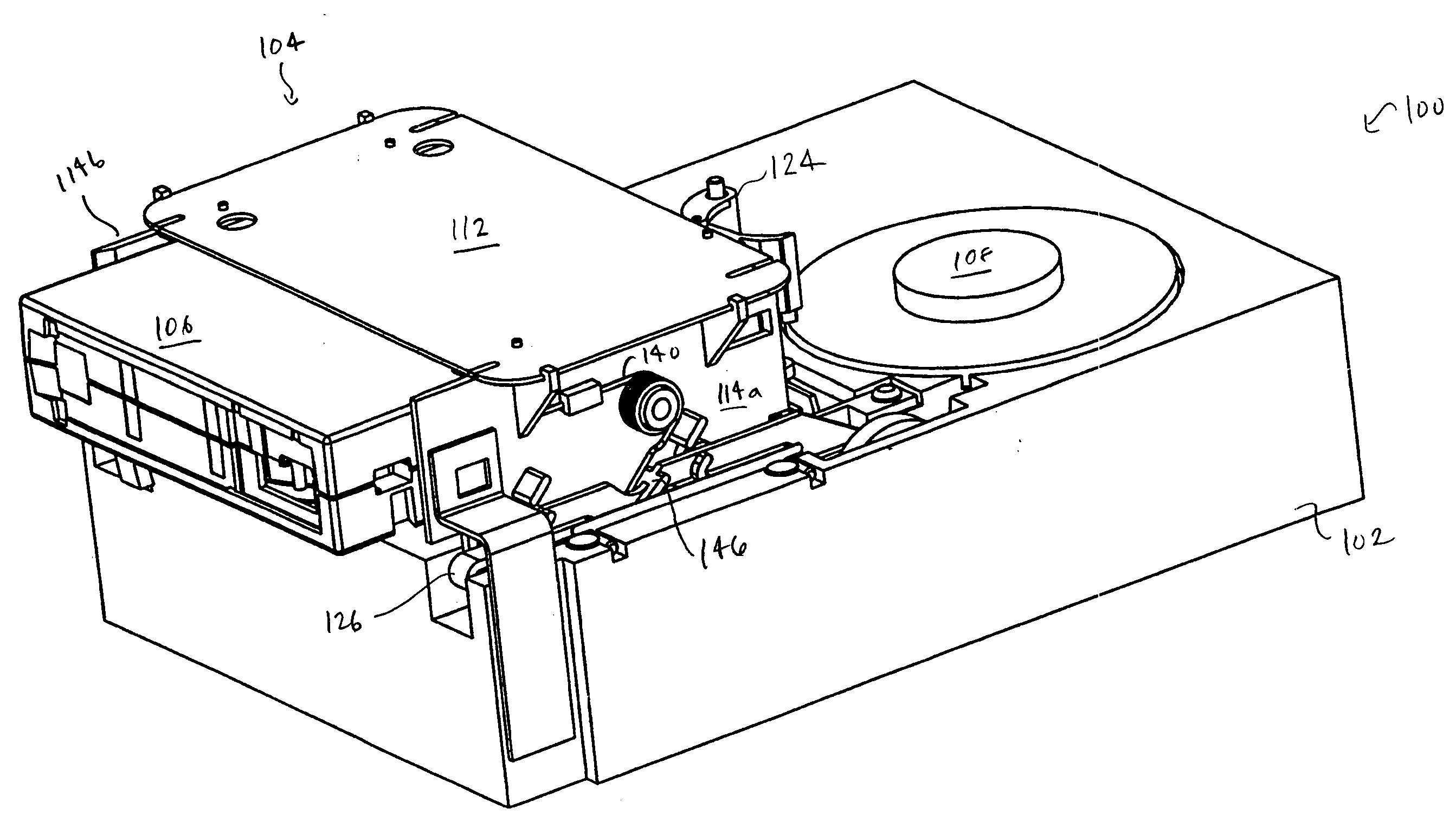

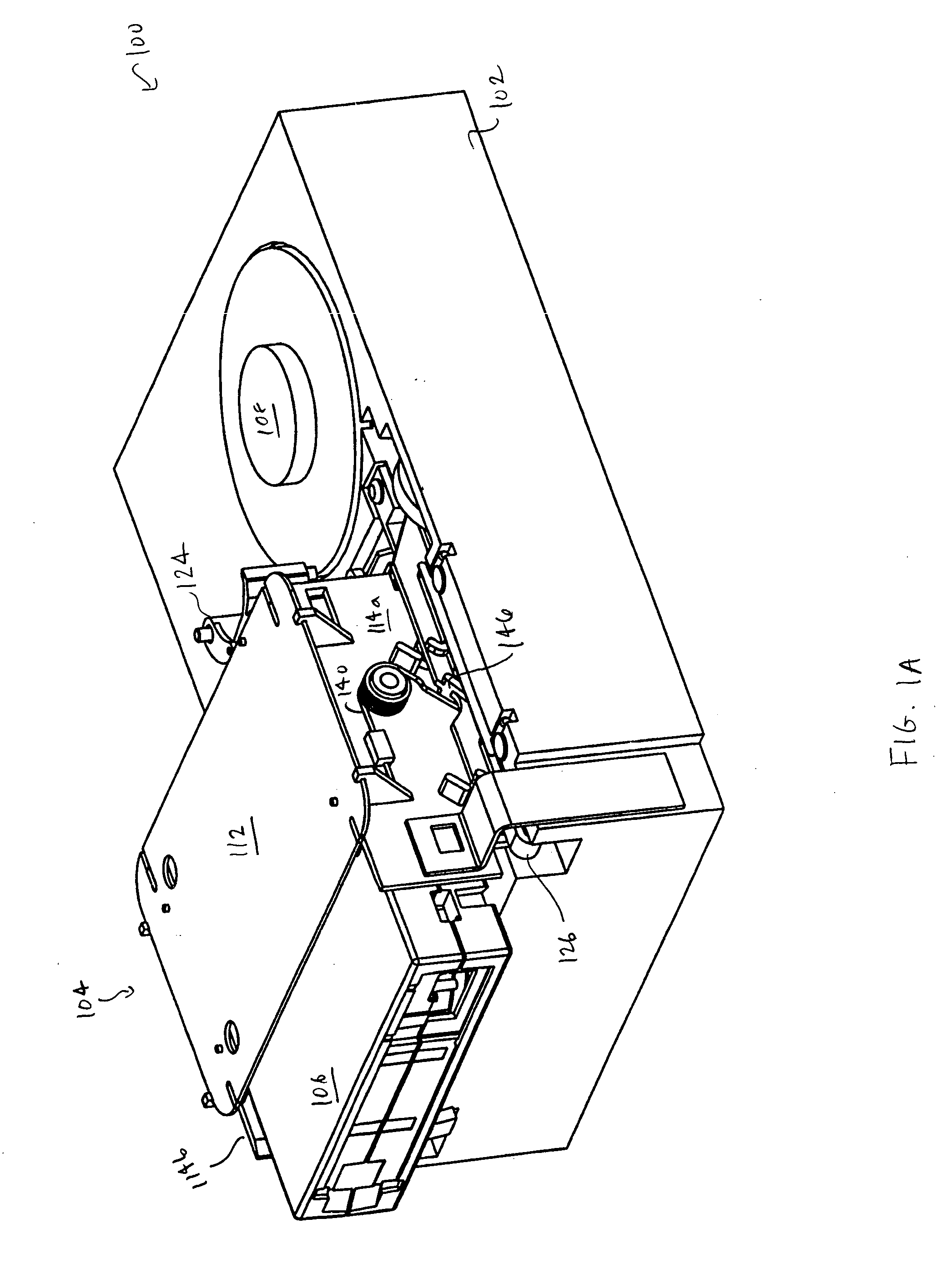

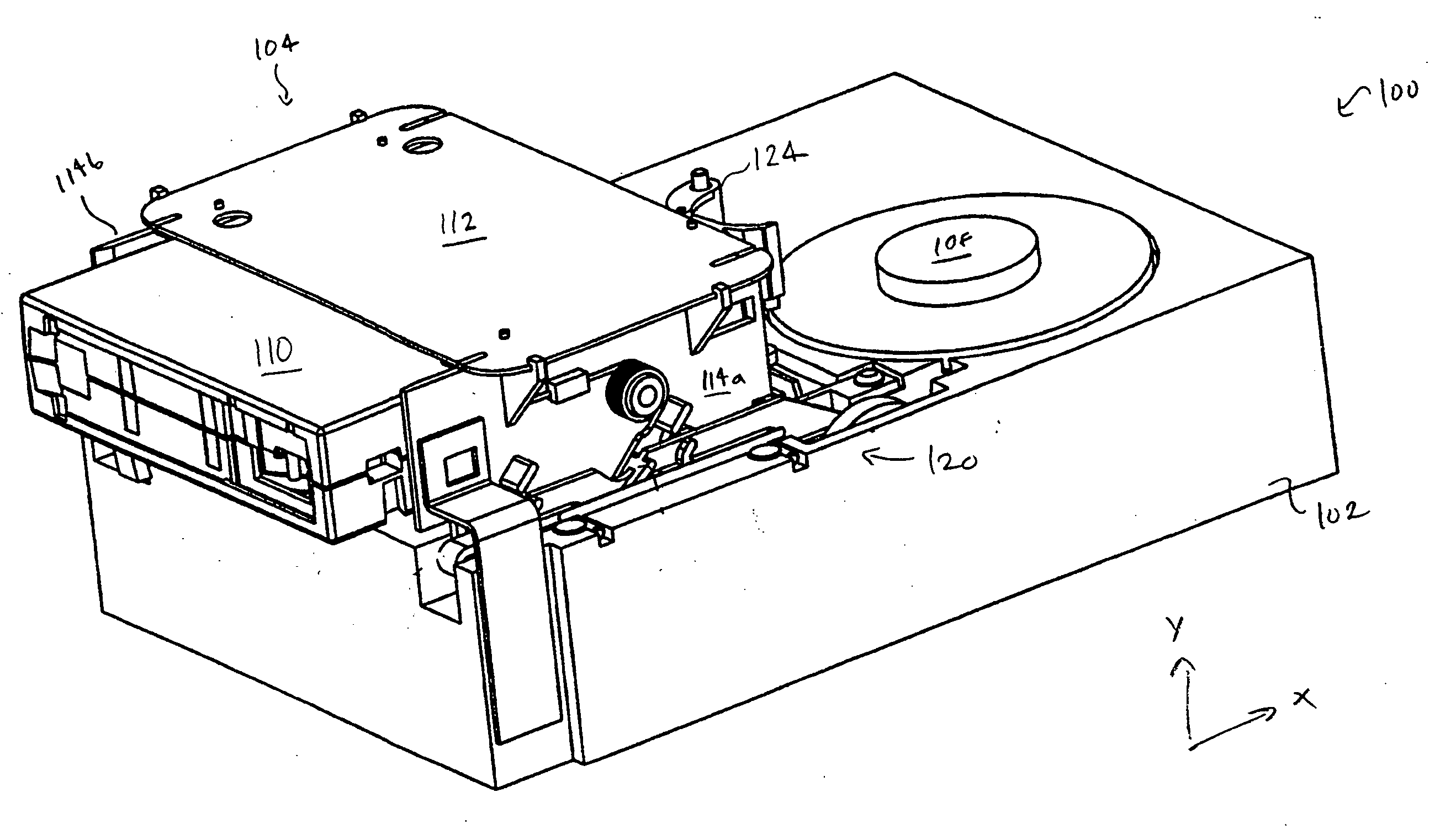

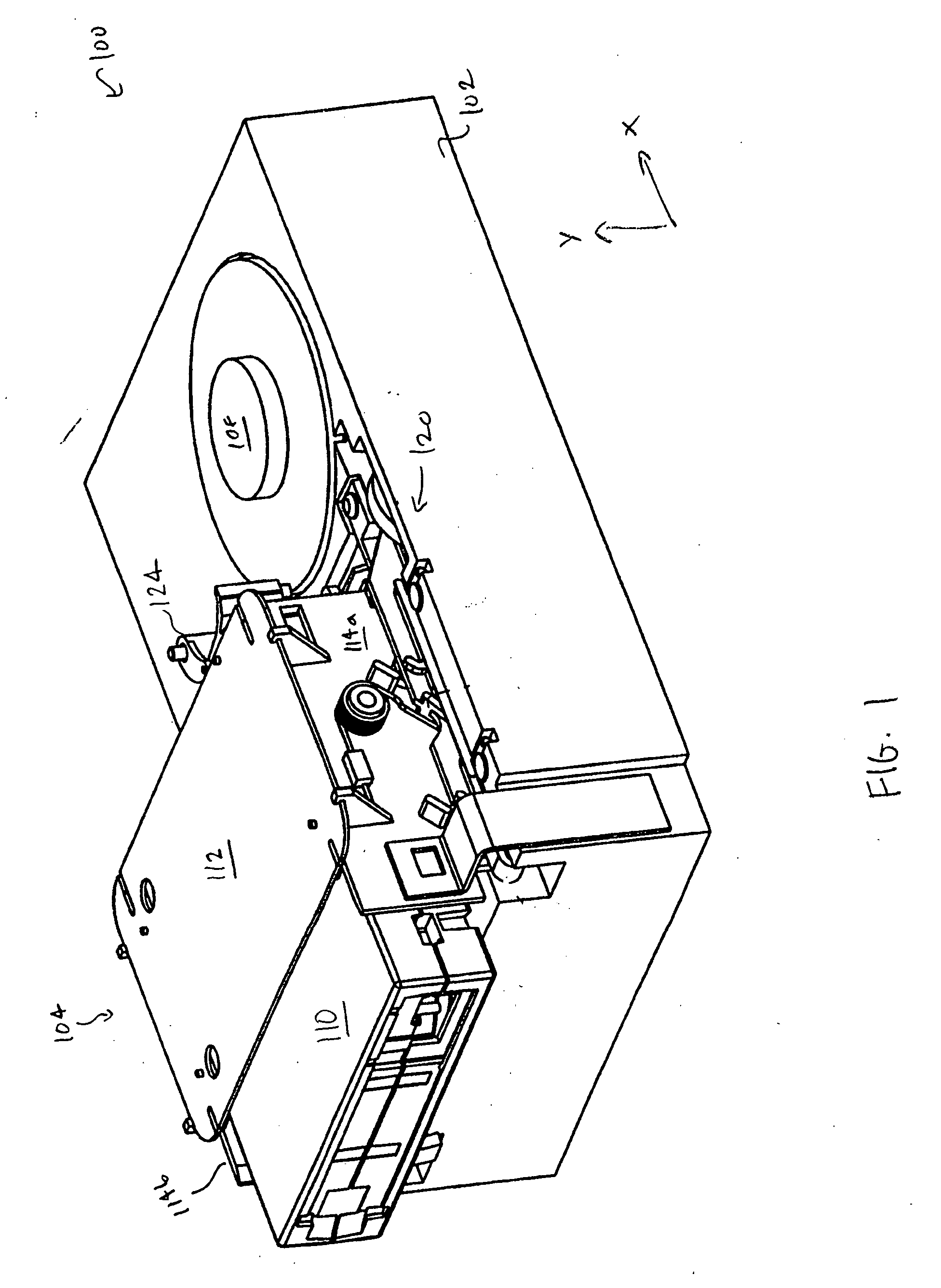

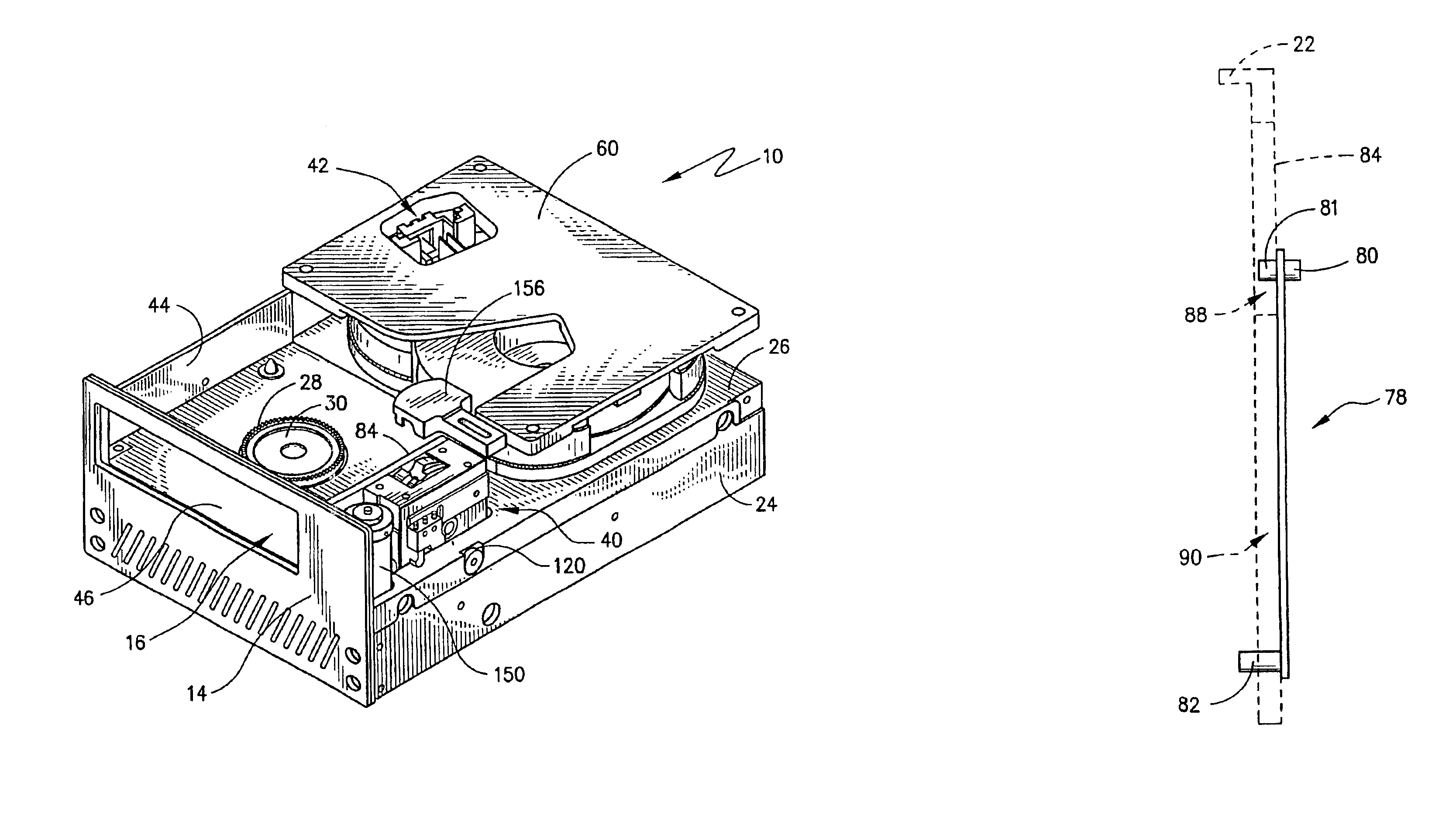

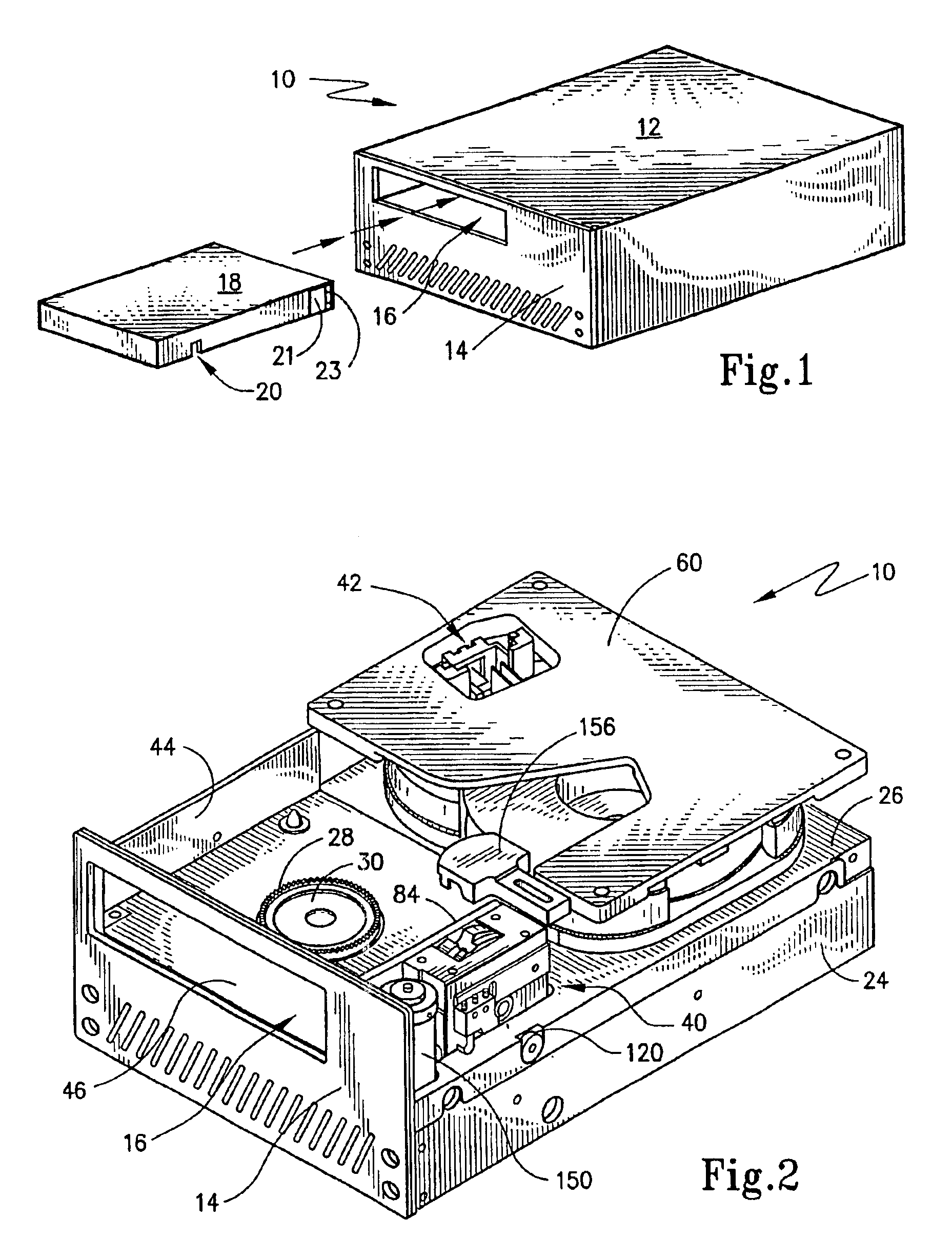

Tape cartridge docking apparatus for read/write recording assemblies and method therefor

InactiveUS6876512B2Simple processReduce manufacturing costRecord information storageMagazines/cassettes storageMode controlMagnetic tape

A docking apparatus and method is used in a read / write recording assembly (10) and includes a bay structure, such as a sub-frame (50), adapted to receive a tape cartridge (18) The sub-frame (50) is disclosed to pivot relative to the assembly's main frame. A pawl element (78) is controlled by a cam assembly (40) in a first mode so as to move from an advanced position to a withdrawn position thereby to move the cartridge (18) from a received / extended position to a received / retracted position. The cam assembly (40) also mounts the cartridge (18), for example, by pivoting the sub-frame (50) relative to the main frame. Driving the cam assembly (40) in a second mode reverses this operation. The cam assembly (40) may use a single rotatable cam element (72) to accomplish the loading and mounting of the cartridge (18), and a suitable drive actuates the cam assembly (40).

Owner:SEGWAY SYST

Video cassette recorder

InactiveUS7420766B2Minimized in sizeRecord information storageAnalogue recordingVideocassette recorderEngineering

Owner:SAMSUNG ELECTRONICS CO LTD

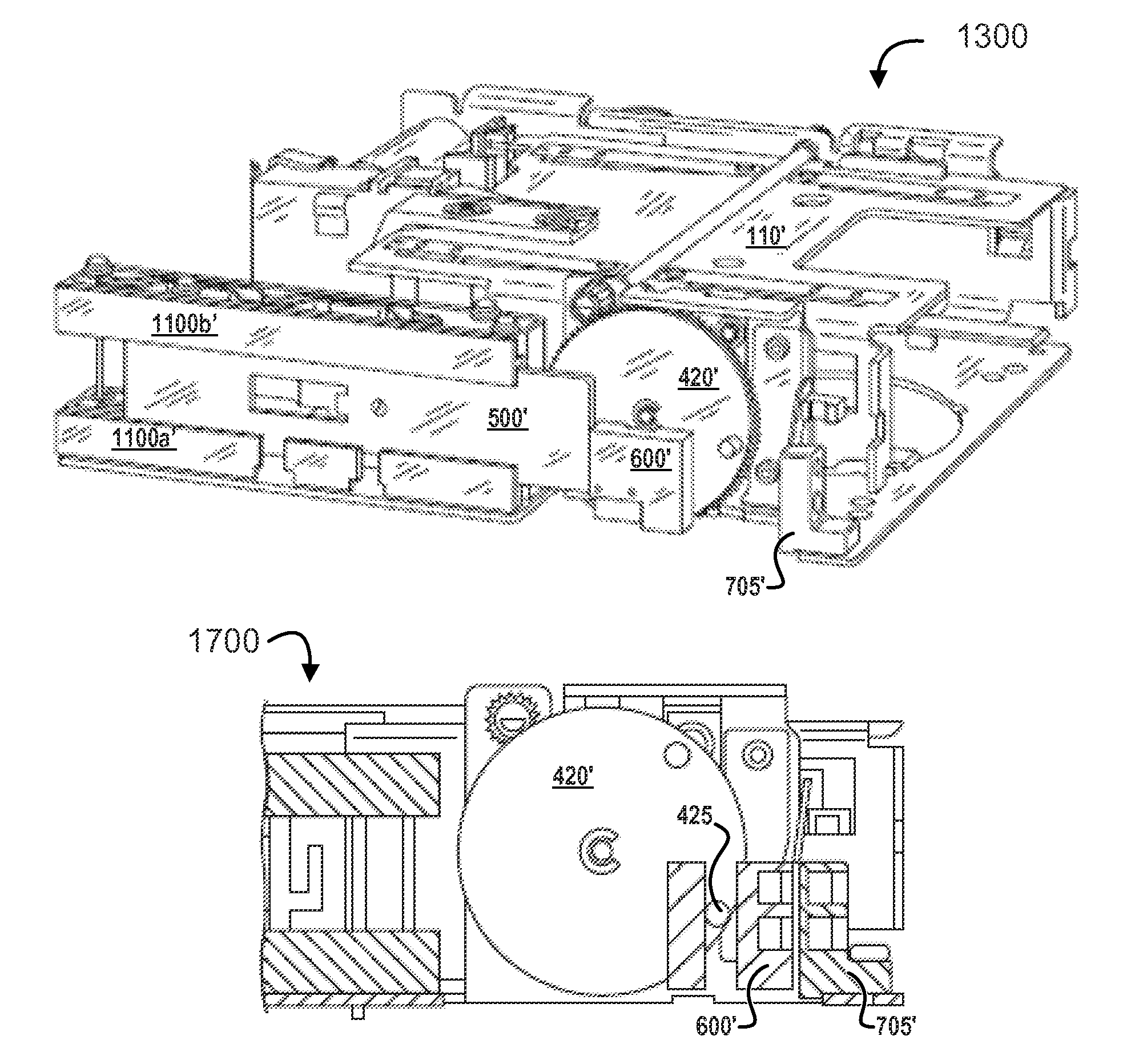

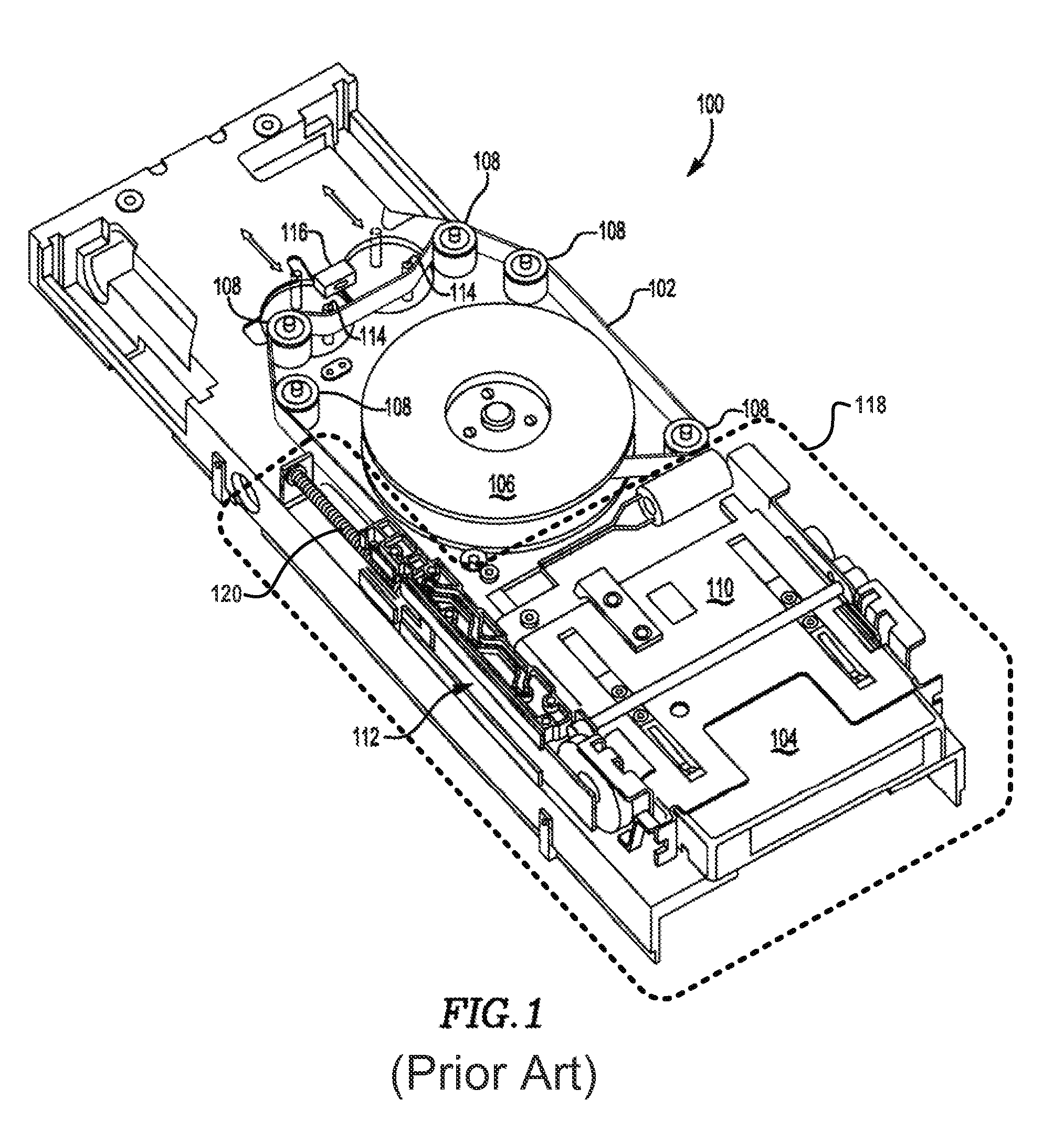

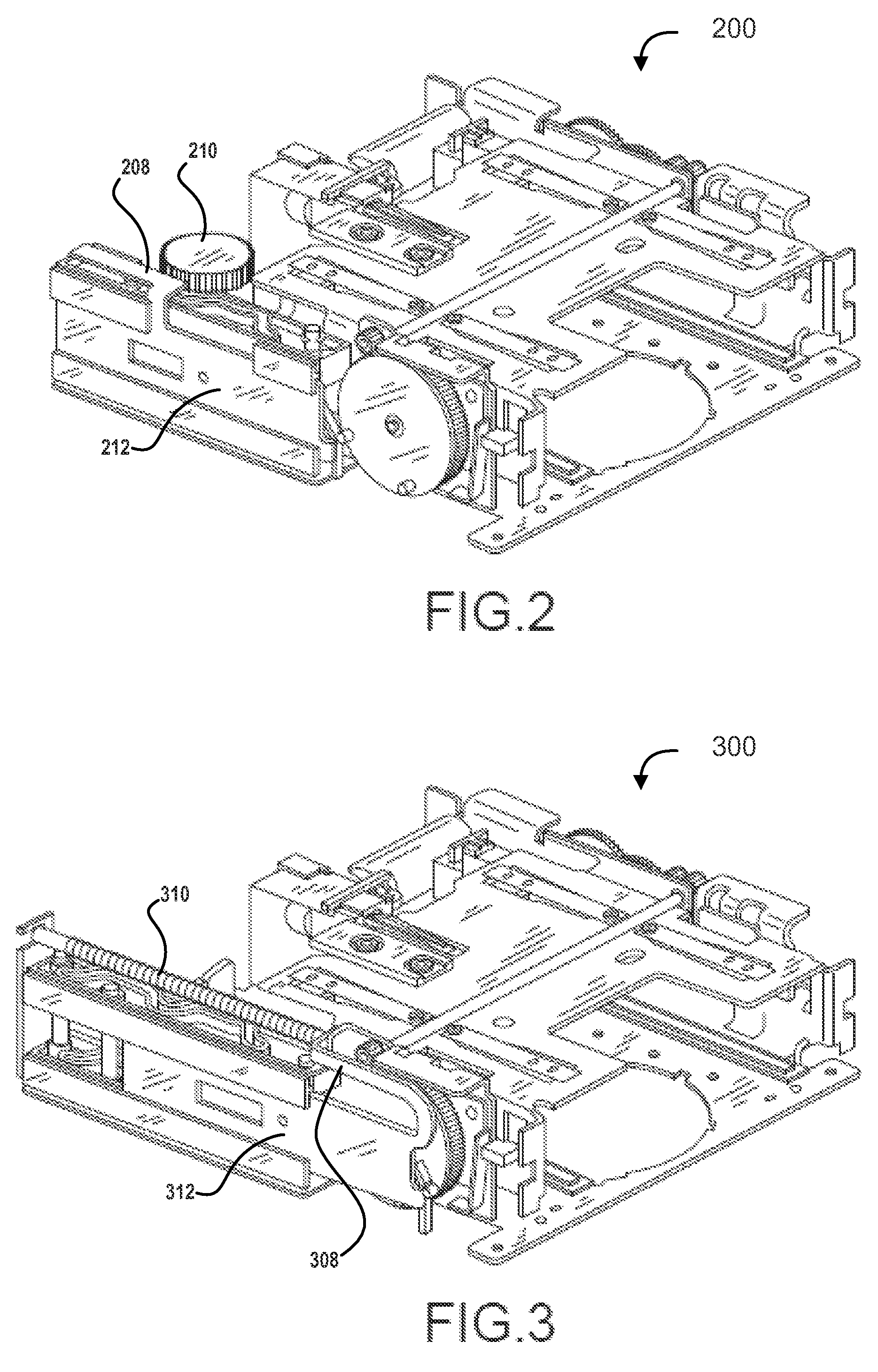

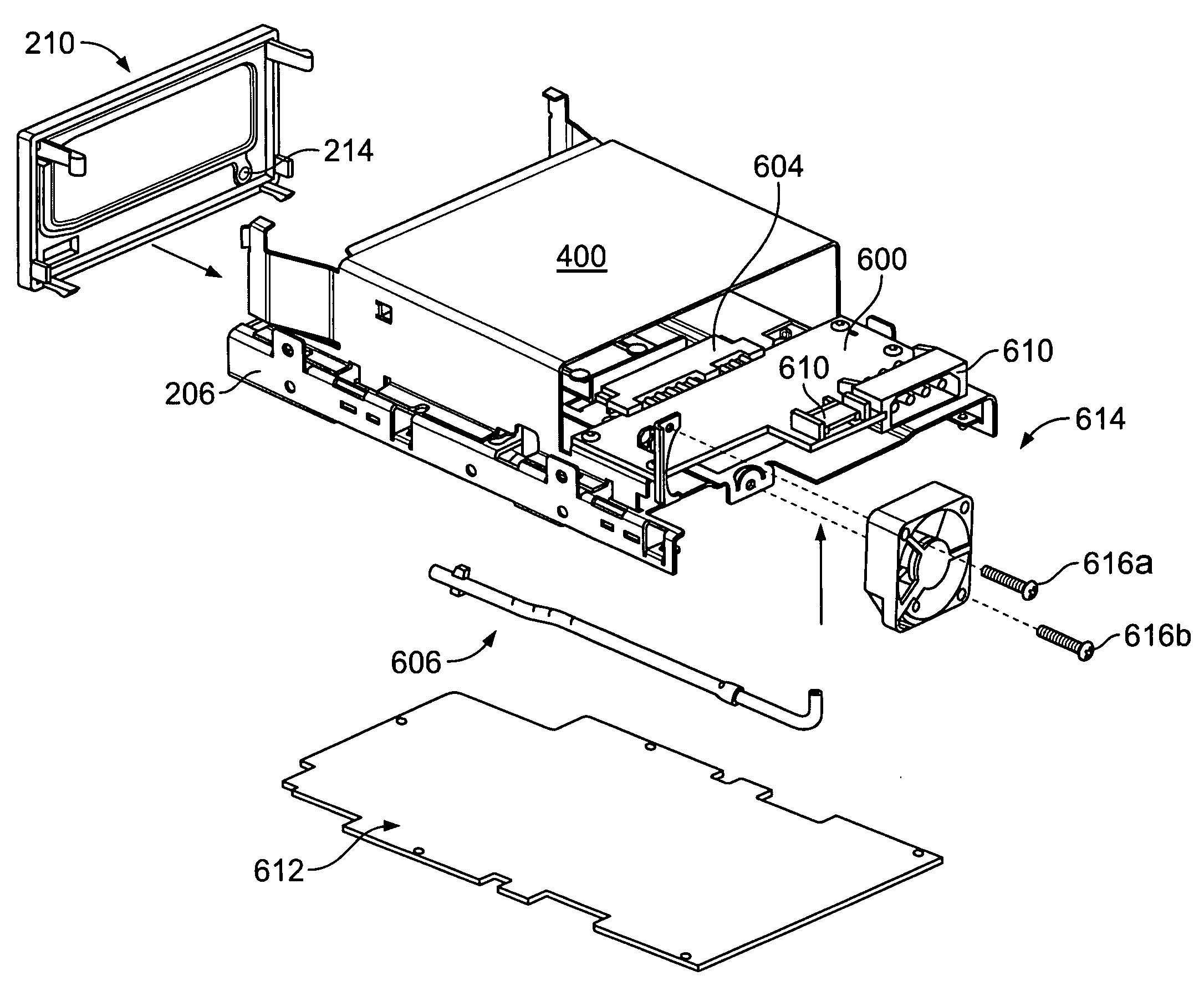

Buckling mechanism for a tape drive loader

ActiveUS9171566B2Reduced footprintReduce torqueMechanical apparatusRecord information storageMagnetic tapeEngineering

Embodiments include systems and methods for buckling in a loader assembly of a tape storage drive. Some implementations translate driving forces of an elevator of the loader assembly into driving forces that act on a pusher plate of a buckling mechanism in both buckling and unbuckling directions. For example, a plate interface can couple the pusher plate with the elevator in a manner that translates rotational motion of the elevator's drive gear into a lateral driving force that drives the pusher plate between its home and buckling positions. Certain implementations also include a home holding mechanism for removably securing the pusher plate in the home position when the elevator is in its unloaded position.

Owner:ORACLE INT CORP

Cartridge carrier

A cartridge carrier has a base having a recessed plate, a top surface, and a bottom surface, an interposer board coupled to the base at the top surface, a motorized eject mechanism coupled to the interposer board and the base, a slider plate coupled to the base at the bottom surface and the motorized eject mechanism, and a .button bar coupled to the base at the bottom surface, the button bar having a switch tab to contact the motorized eject mechanism.

Owner:QUANTUM CORP

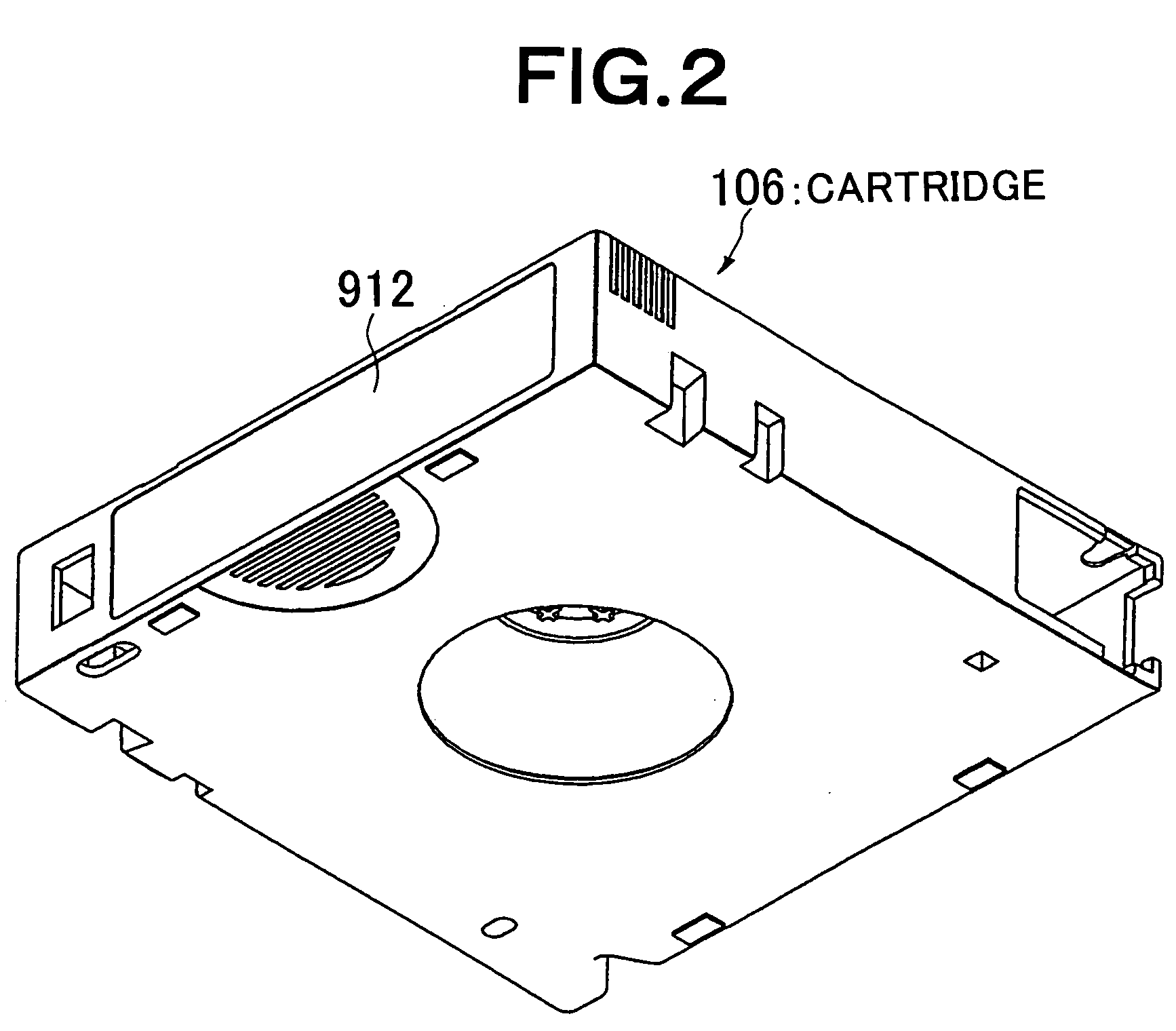

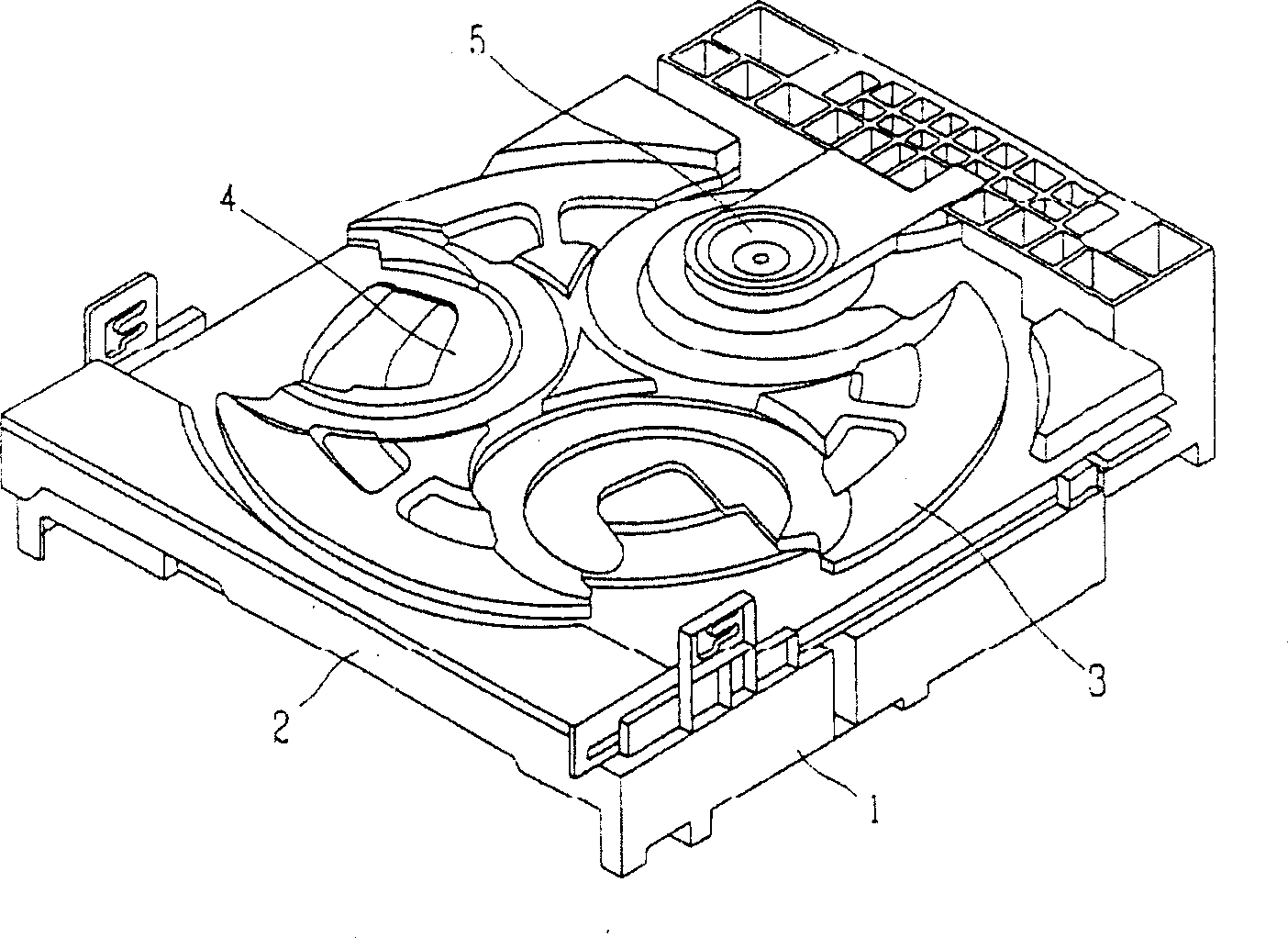

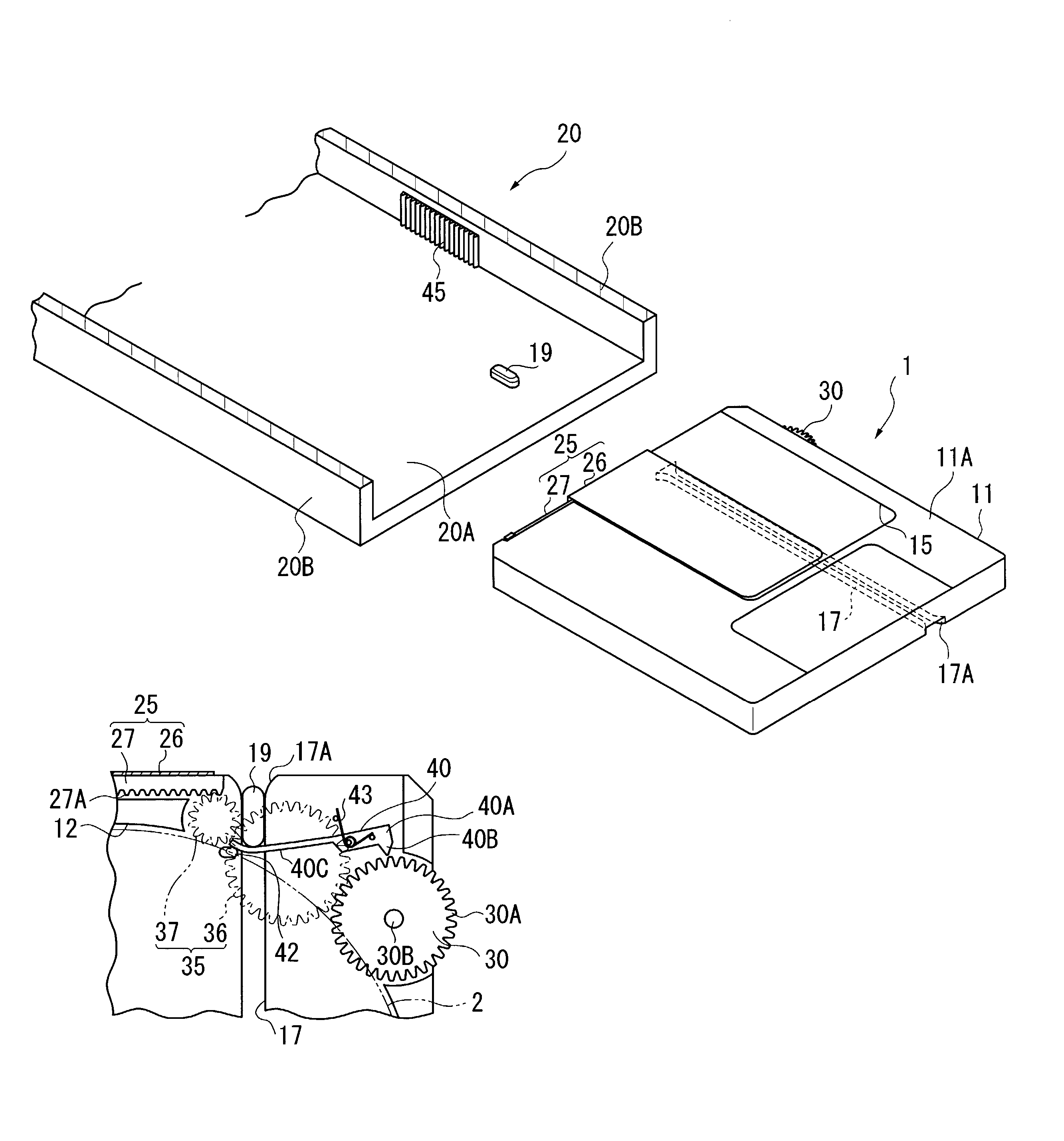

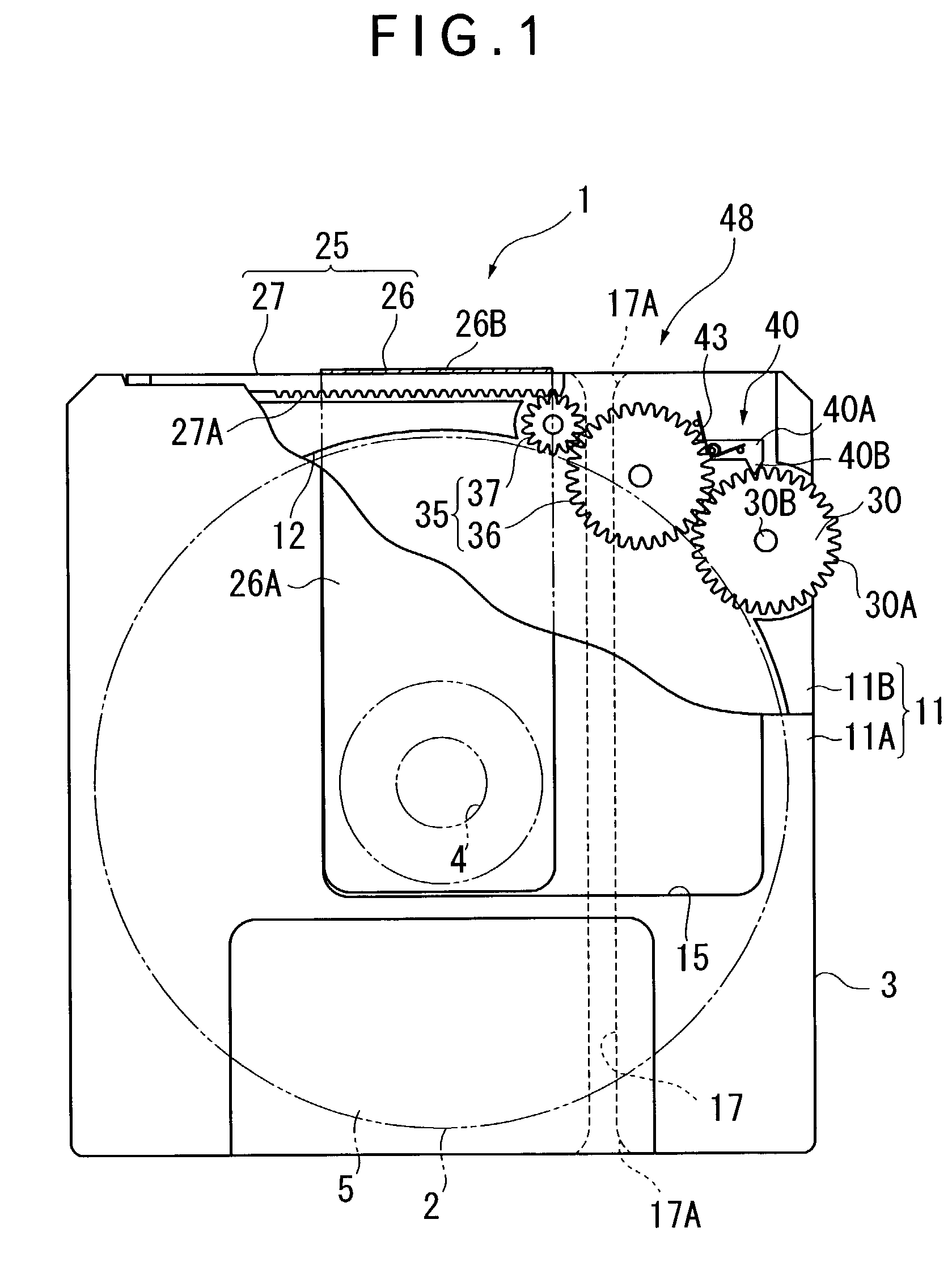

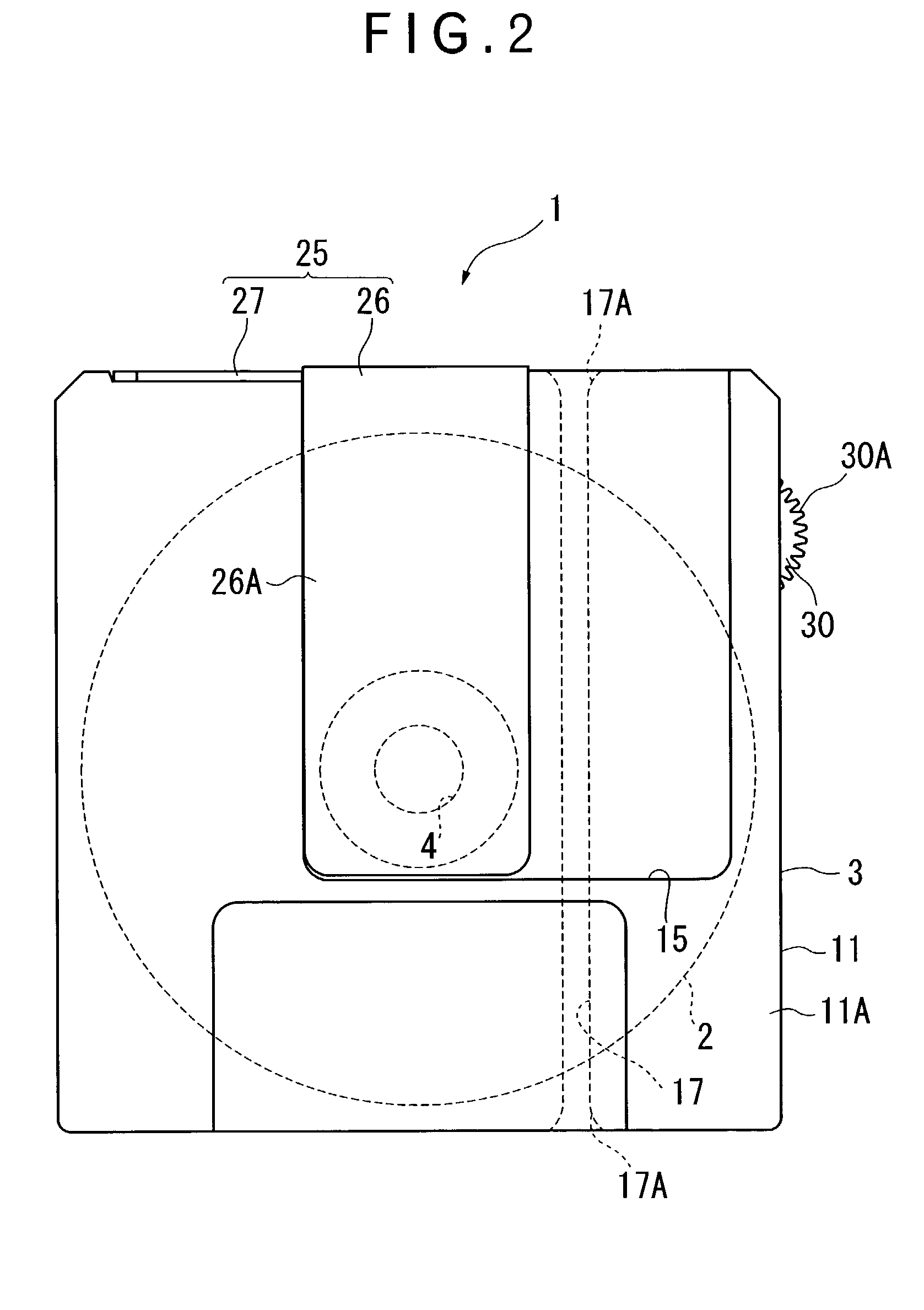

Disk cartridge with shutter regulator, disk device and shutter opening/closing mechanism

InactiveUS7111313B2Simple constitutionRecord information storageFlat record carrier containersEngineeringMagnetic disks

A disk device 1 comprising a disk cartridge 3 and a disk 2 accommodated therein. The disk cartridge 3 includes a body case 11: opened with a window for exposing a recording surface 5 of the disk 2; and provided with a shutter 26 to be moved in a manner capable of opening / closing the window. The body case 11 is provided with: a rotating body 30 in a gear shape having an outer peripheral surface exposed to the exterior of the body case; and transmission 35 for transmitting the rotation of the rotating body 30 to the shutter 26. Provided in a disk driving apparatus for recording a piece of information into or reproducing the information from the disk 2 are: a guiding rib; and an operation rack along the disk inserting direction. Provided on an outer surface of the body case 11 is an operational-position determining groove. 17 in a recessed groove shape along the inserting direction of the disk device 1 and near the rotating body 30, and the rotating body 30 is engaged with the operation rack while engaging the groove 17 with the guiding rib so as to conduct the positioning, to thereby open / close the shutter 26.

Owner:PIONEER CORP

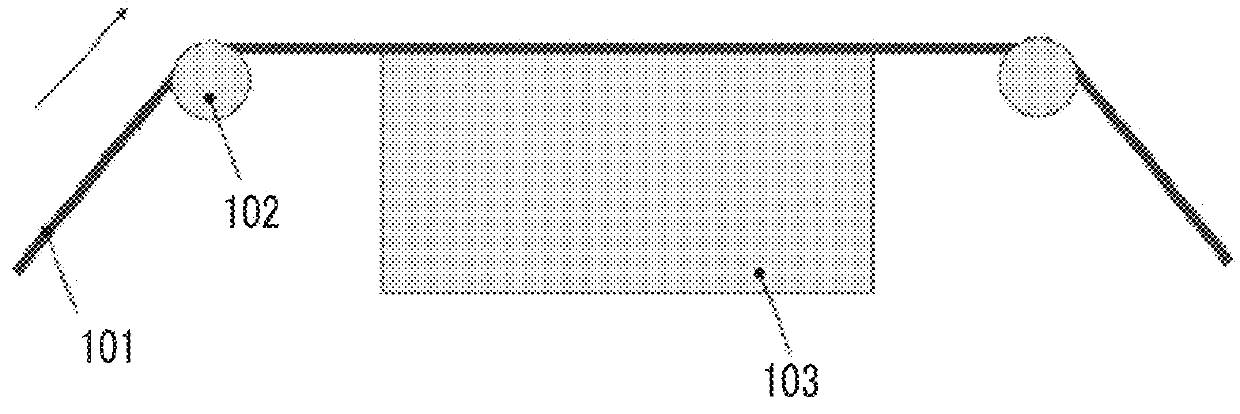

Tape guide mechanism of magnetic recording reproducing device

InactiveUS20050094310A1Simple structureImprove design flexibilityRecord information storageAnalogue recordingMagnetic tapeEngineering

A tape guide mechanism in a magnetic recording and reproducing apparatus is provided; the magnetic recording and reproducing apparatus includes a movable chassis 1 having a tape guide arm member 30 on which a tape guide 31 is erected and a pair of reels stands thereon and a fixed chassis 2 having a magnetic rotary head thereon, in which the movable chassis 1 moves to one position of said fixed chassis 2 to perform loading and unloading of a cassette and when moves to the other position, tape loading of taking out a magnetic tape from the reel of the loaded cassette to be wound around the magnetic rotary head is performed, wherein after completing the tape loading, the tape guide 31 is fixed to a predetermined position by a guide receiving member 40 that is provided on the fixed chassis 2 to receive the tape guide 31, and in the middle of the tape guide 31 traveling to said predetermined position, the tape guide arm member 30 is made to move along a groove 2a provided in the fixed chassis 2 to determine the position in the chassis plane direction and is guided and moved by the projections 36 provided on the lower surface of the tape guide arm member 30 to determine the position in the height direction.

Owner:SONY CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com