An intermittent manual mushroom stone chipping machine

A kind of mushroom stone, intermittent technology, applied in the field of intermittent manual mushroom stone chipping machine, can solve the problems of low hitting efficiency, complicated operation, long time consumption, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

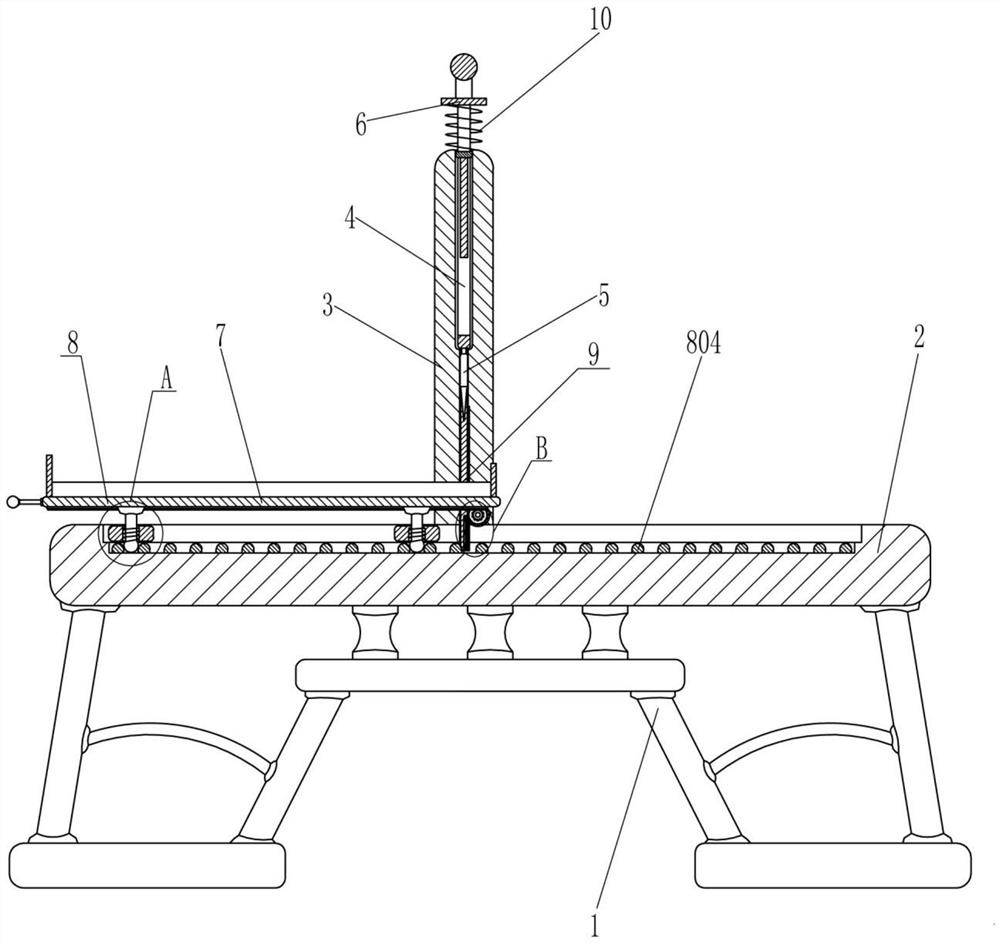

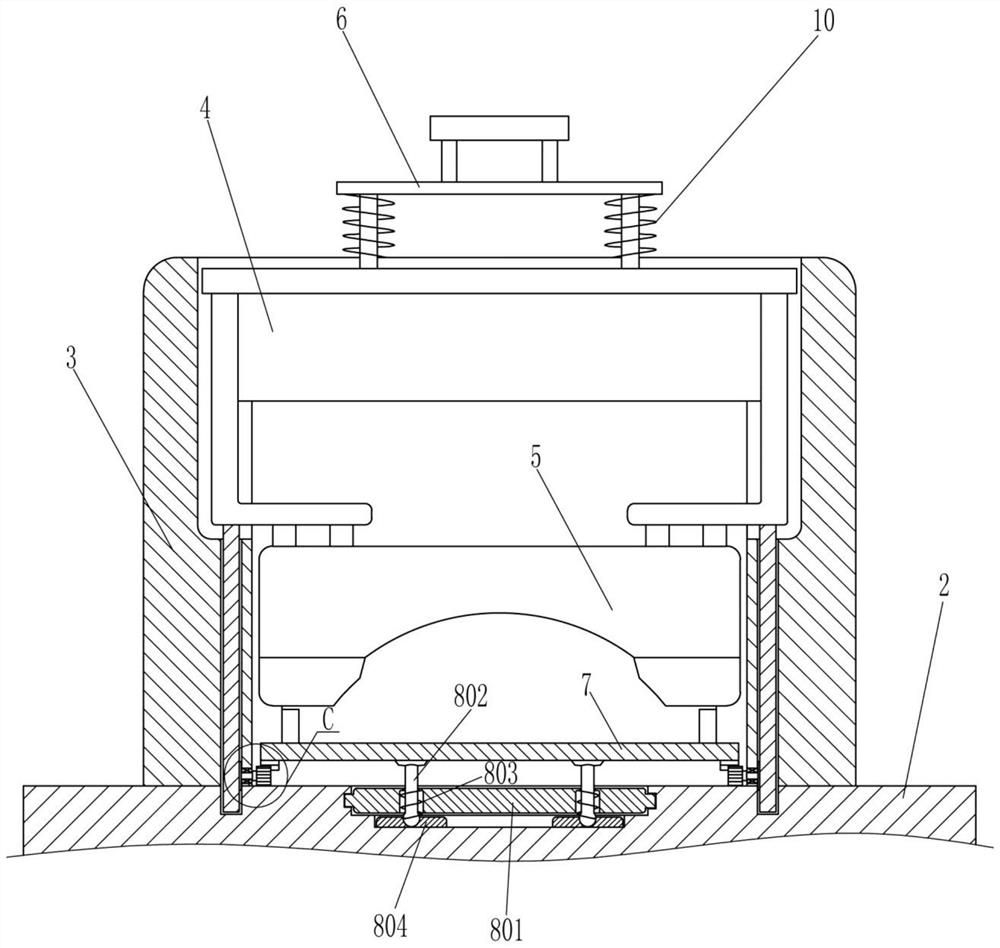

[0019] An intermittent manual mushroom stone chipping machine, such as Figure 1-2 As shown, it includes a bracket 1, a base 2 and an installation frame 3. The bracket 1 is installed at the bottom of the base 2, and the installation frame 3 is arranged in the middle of the top of the base 2. The installation frame 3 is connected to the installation frame 3 by welding, and also includes There are sliding frame 4, knocking knife 5, grip 6, sliding plate 7 and positioning mechanism 8, sliding type is provided with sliding frame 4 in the installation frame 3, the bottom of sliding frame 4 is connected with knocking knife 5, and sliding frame 4 top is provided with There is a handle 6, and a positioning mechanism 8 is arranged on one side of the base 2, the positioning mechanism 8 is connected with a sliding plate 7, and the left side of the sliding plate 7 is connected with a push rod, and the positioning mechanism 8 is used for positioning the sliding plate 7.

[0020] Place the ...

Embodiment 2

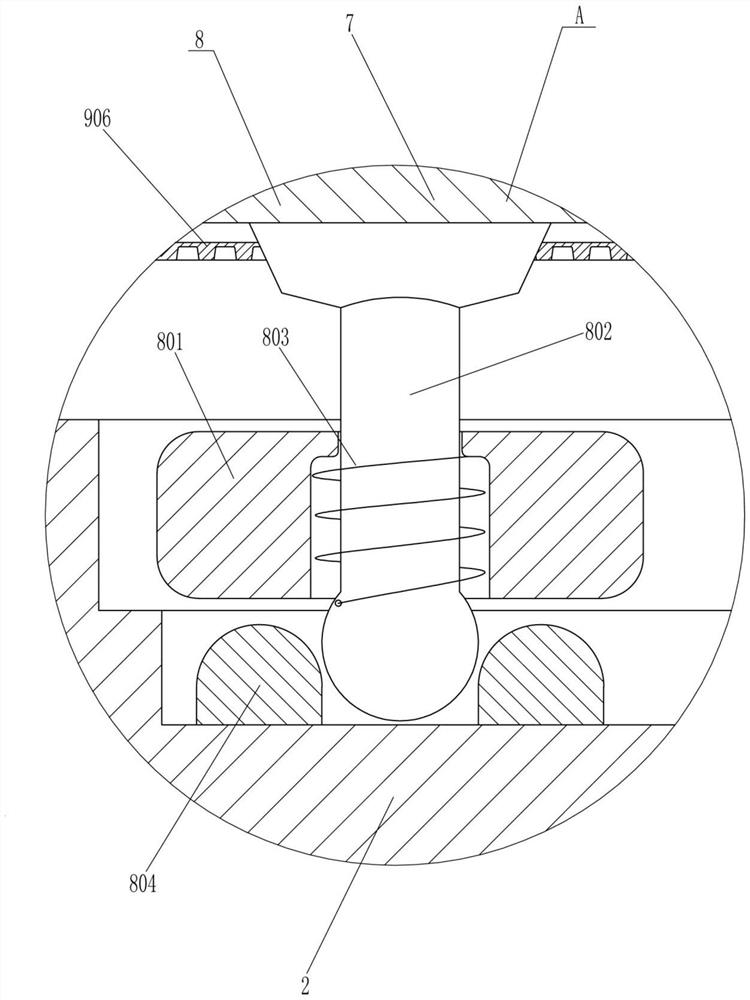

[0024] On the basis of Example 1, such as Figure 4-5 As shown, transmission device 9 is also included, and transmission device 9 includes transmission rod 901, second spring 902, ratchet rack 903, ratchet gear 904, transmission gear 905 and transmission rack 906, and the front and rear sides of slide frame 4 There is a chute in the installation frame 3, and the front and rear sides of the bottom of the sliding frame 4 are connected with a transmission rod 901. The transmission rod 901 is connected with the sliding frame 4 by welding, and the lower right part of the transmission rod 901 has a groove. There are second springs 902 evenly spaced inside, and a ratchet bar 903 is connected between the ends of the second springs 902. The ratchet bar 903 is located in the groove, and a ratchet gear is installed in the installation frame 3 on the right side of the ratchet bar 903. 904, ratchet gear 904 and ratchet bar 903 transmission cooperation, ratchet gear 904 front side connects ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com