Manual clamping mechanism for battery module

A clamping mechanism and battery module technology, which is applied in the directions of load hanging components, transportation and packaging, etc., can solve the problems that the clamping mechanism cannot realize the workpiece and the space is small.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The following will clearly and completely describe the technical solutions in the embodiments of the present invention with reference to the accompanying drawings in the embodiments of the present invention. Obviously, the described embodiments are only some, not all, embodiments of the present invention.

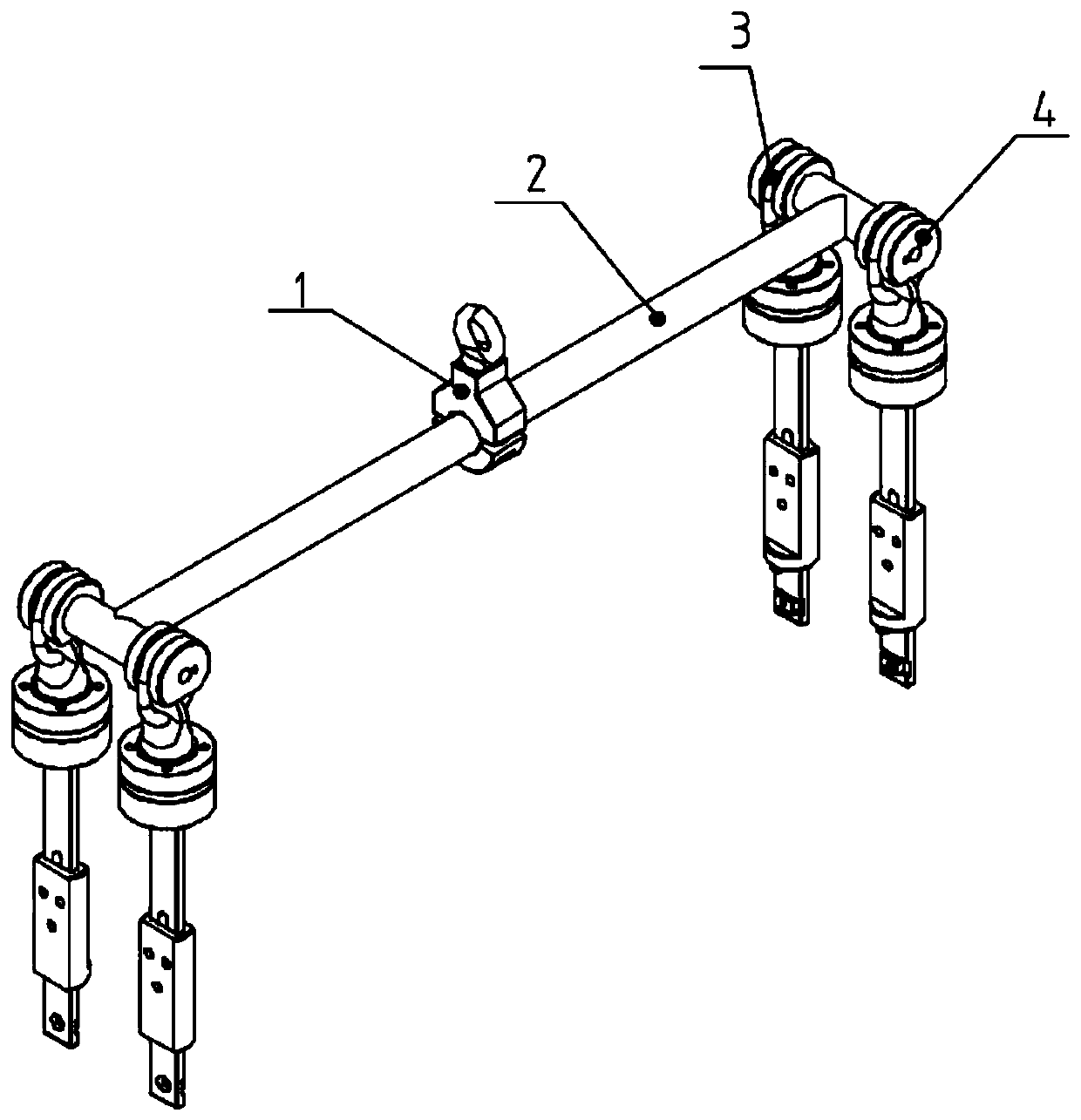

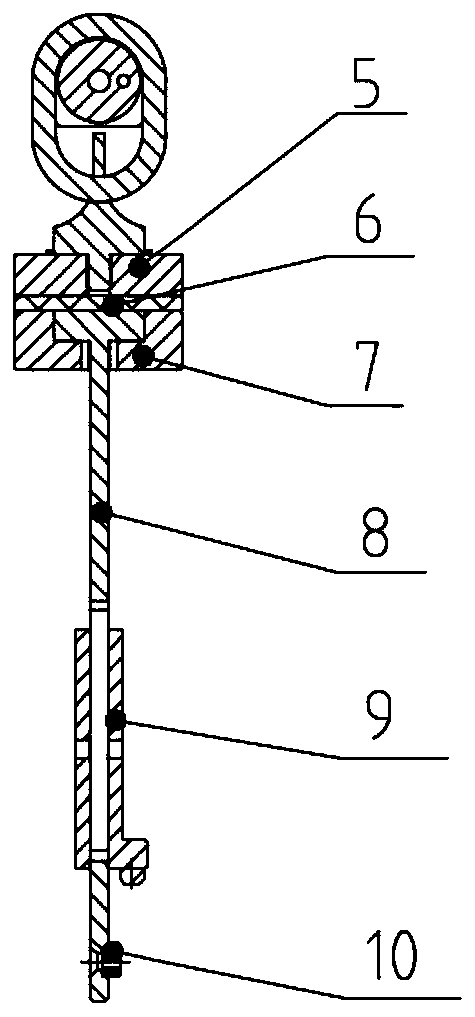

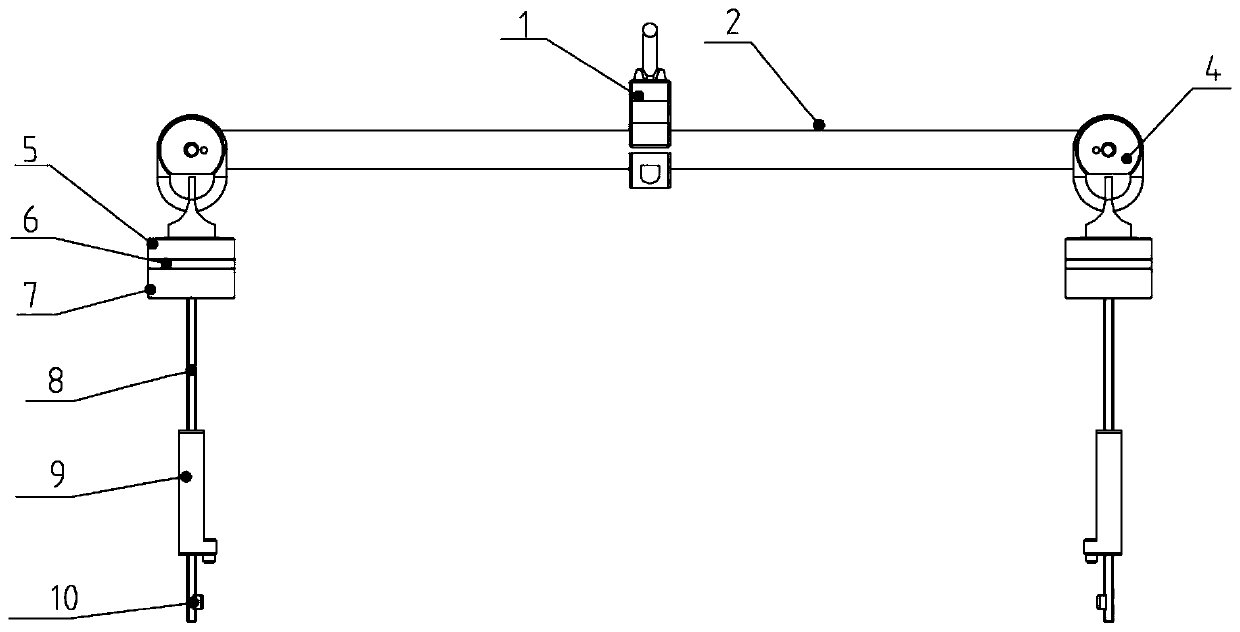

[0022] Such as Figure 1 to Figure 4 As shown, a battery module manual clamping mechanism provided by the present invention includes a hanging beam 2 and jaws 12. Both ends of the hanging beam 2 are respectively connected to the first connecting rod 11 and the second connecting rod 13. The first Two groups of jaws 12 are respectively installed on the connecting rod 11 and the second connecting rod 13, the two groups of jaws 12 on the first connecting rod 11 and the two groups of jaws 12 on the second connecting rod 13 are oppositely arranged, and the jaws 12 Including the universal lifting point 3, the universal lifting point 3 is fastened on the connecting rod throu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com