Upper air inlet combustor

A burner and ring gas technology, applied in the direction of burners, gas fuel burners, combustion methods, etc., can solve the problems of affecting gas combustion conditions, insufficient gas combustion, easy to produce yellow flames, etc., and achieve short and stable flames and uniform flame, reducing the effect of kinetic energy loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

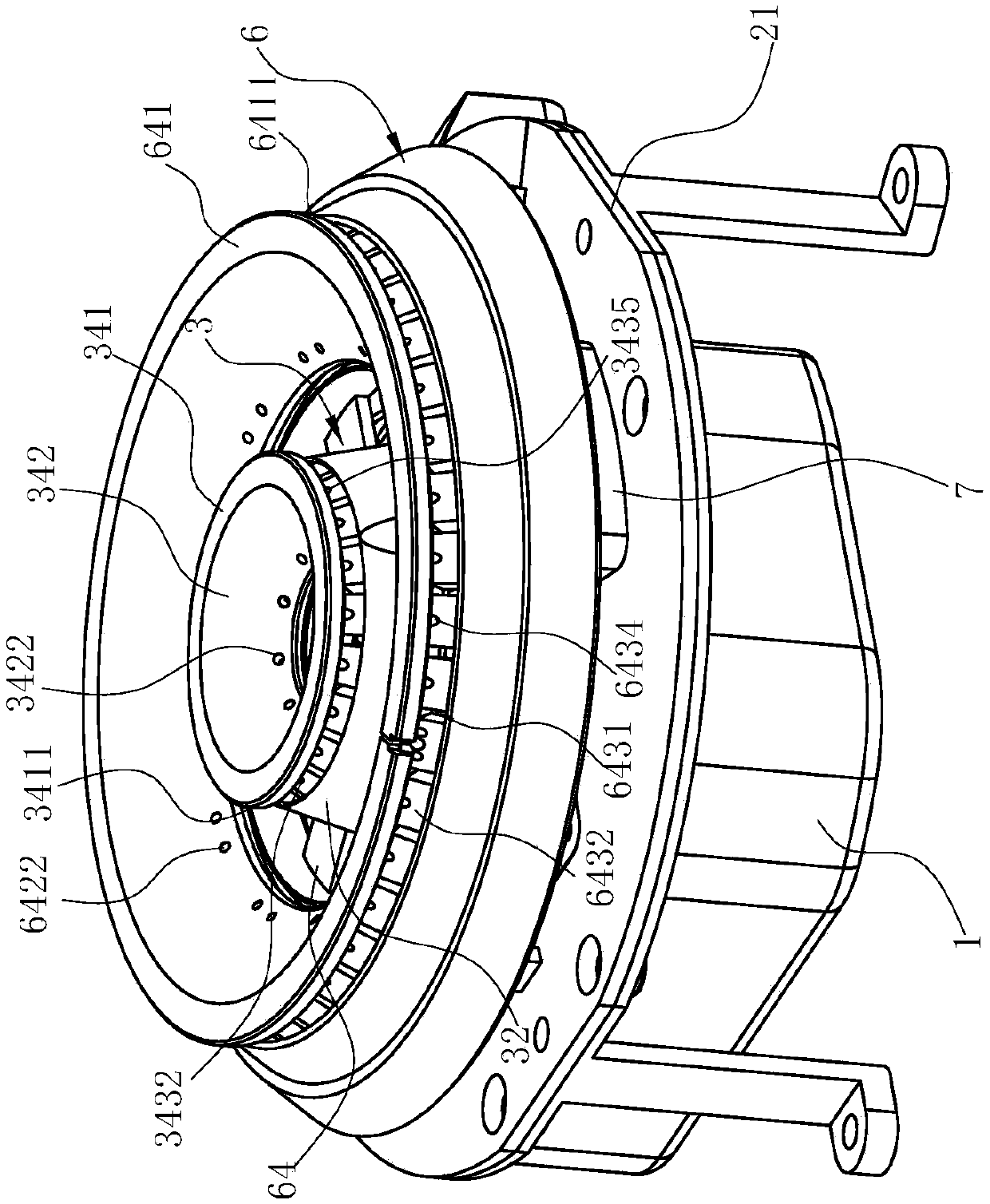

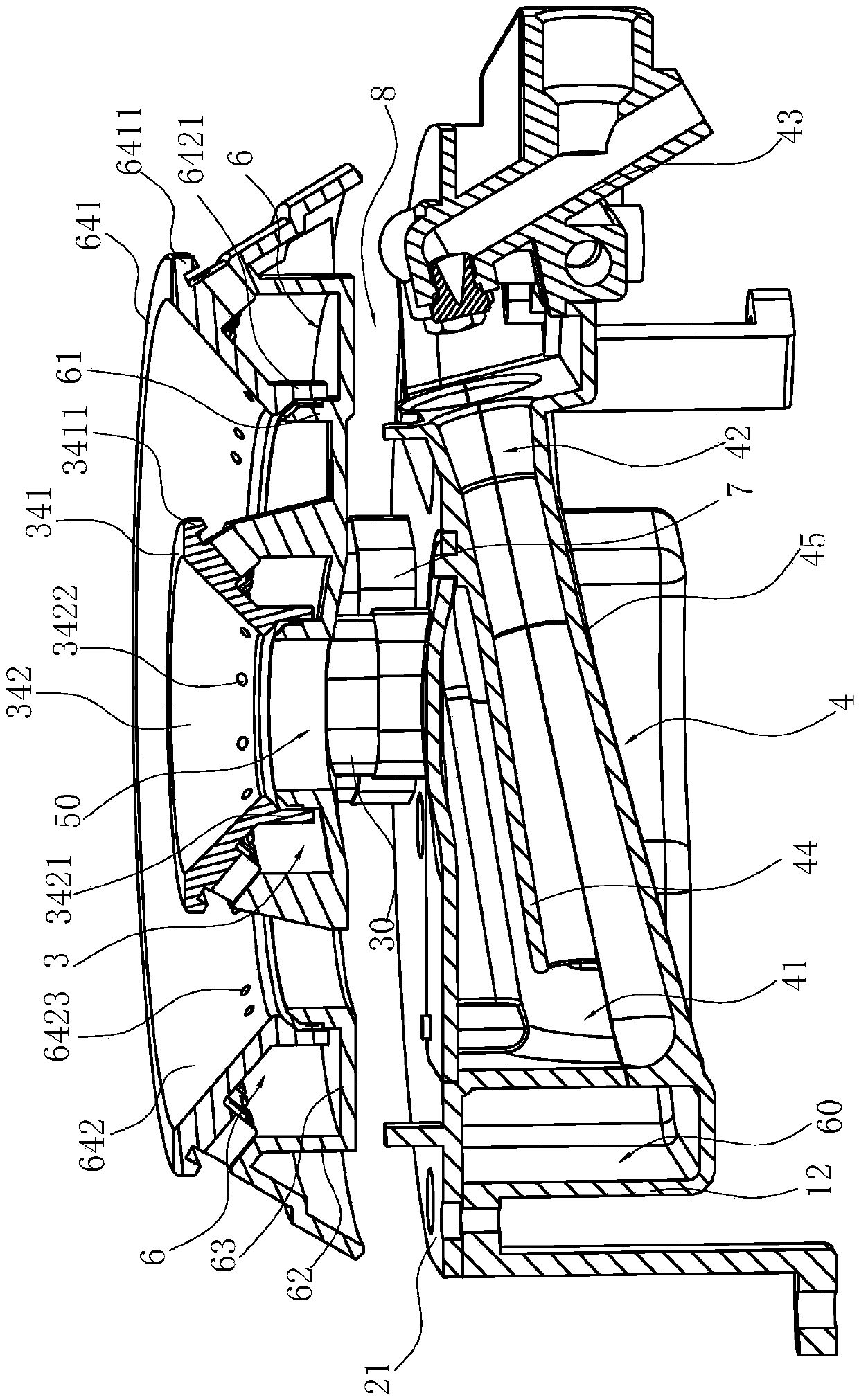

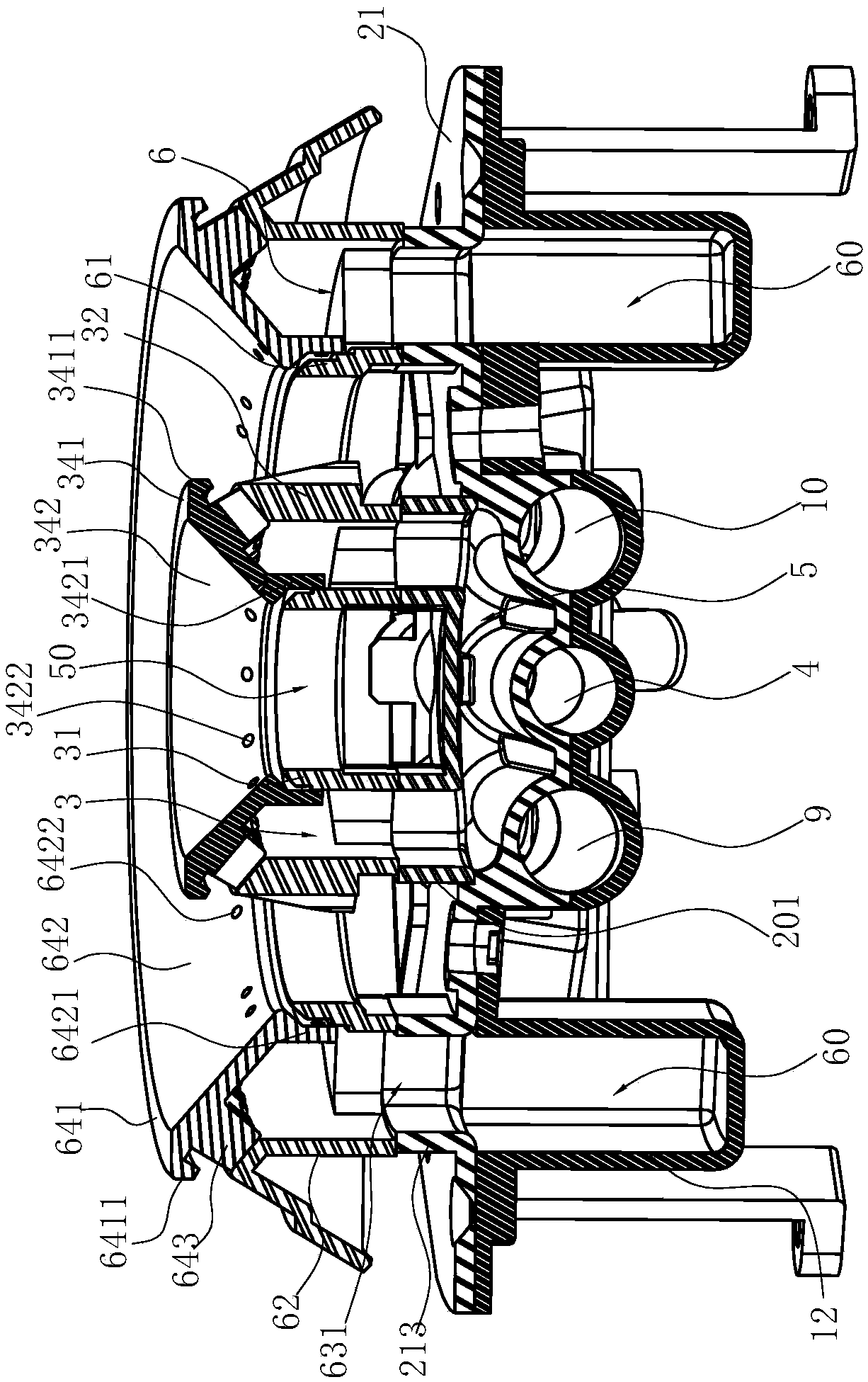

[0040] Such as Figure 1-11 As shown, it is the best embodiment of the present invention, the upper air intake burner can be applied to the traditional upper air intake burner and can also be applied to the Italian Sabaf burner such as Europe, including a base 1, which has The first concave cavity 11 located in the center; the connecting body 2 arranged on the base 1, the connecting body 2 includes a plate body 21, and the central position of the plate body 21 corresponds to the first concave cavity 11 and has a vertical inner ring gas Channel 211 and the inner ring gas mixing chamber 3 arranged above the inner ring gas channel 211. The inner ring gas mixing chamber 3 of this embodiment includes an annular inner ring wall surface 31 and an outer ring wall surface 32 arranged concentrically at intervals and connecting The bottom wall 33 of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com