sheet metal cutter

A metal sheet cutting technology, applied in the direction of hand-held metal shearing equipment, metal processing equipment, shearing devices, etc., can solve the problems of not being straight enough, deformation, and fixed incision, and achieve simple operation, convenient use, and improved incision The effect of uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

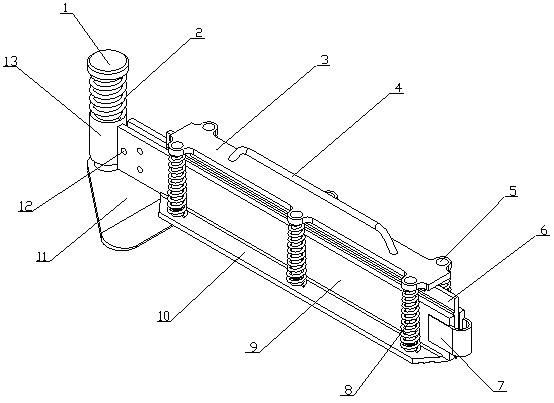

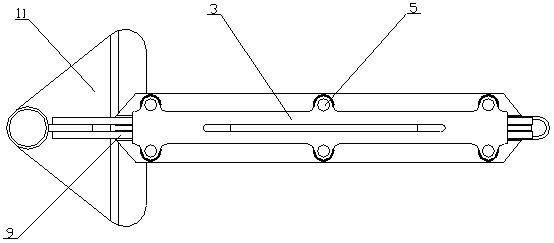

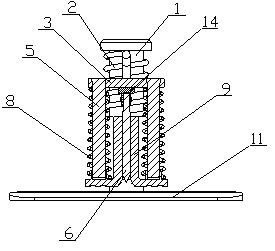

[0017] A kind of sheet metal cutter of the present invention is realized in this way, consists of guide post (1), return spring (2), driving plate (3), driving handle (4), sliding rod (5), cutting knife (6) , connecting arm (7), support spring (8), guide plate (9), pressure plate (10), base (11), connecting screw (12), guide sleeve (13), knife seat (14), fixed sleeve ( 15), press groove (16) and connecting plate (17), one end of the guide column (1) is vertically fixed on the base (11), and the other end of the guide column (1) is provided with a limiting plate, so The base (11) is an isosceles triangular plate structure, the bottom of the base (11) is a slope, the guide sleeve (13) is placed on the guide column (1), and the guide sleeve (13) can be rotated , the guide sleeve (13) is slidable, the return spring (2) is set on the guide column (1), one end of the return spring (2) is connected with the limit plate, and the return spring (2) The other end is connected with the g...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com