An Adaptive High Performance Bridge Plug

A self-adaptive, bridge plug technology, applied in wellbore/well components, earthwork drilling, sealing/isolation, etc., can solve the problems of high application cost, failure of seat seal, high manual operation requirements, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

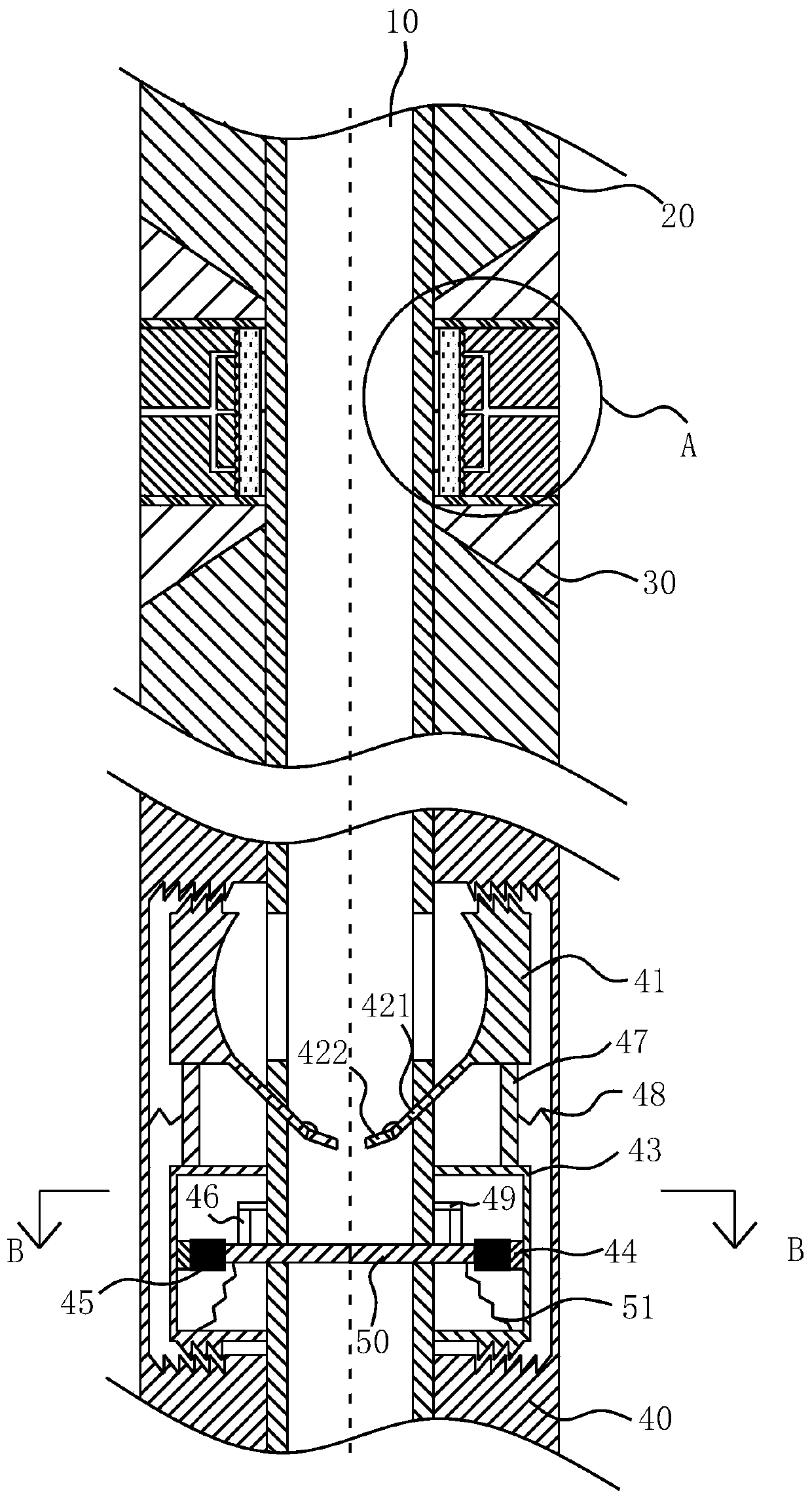

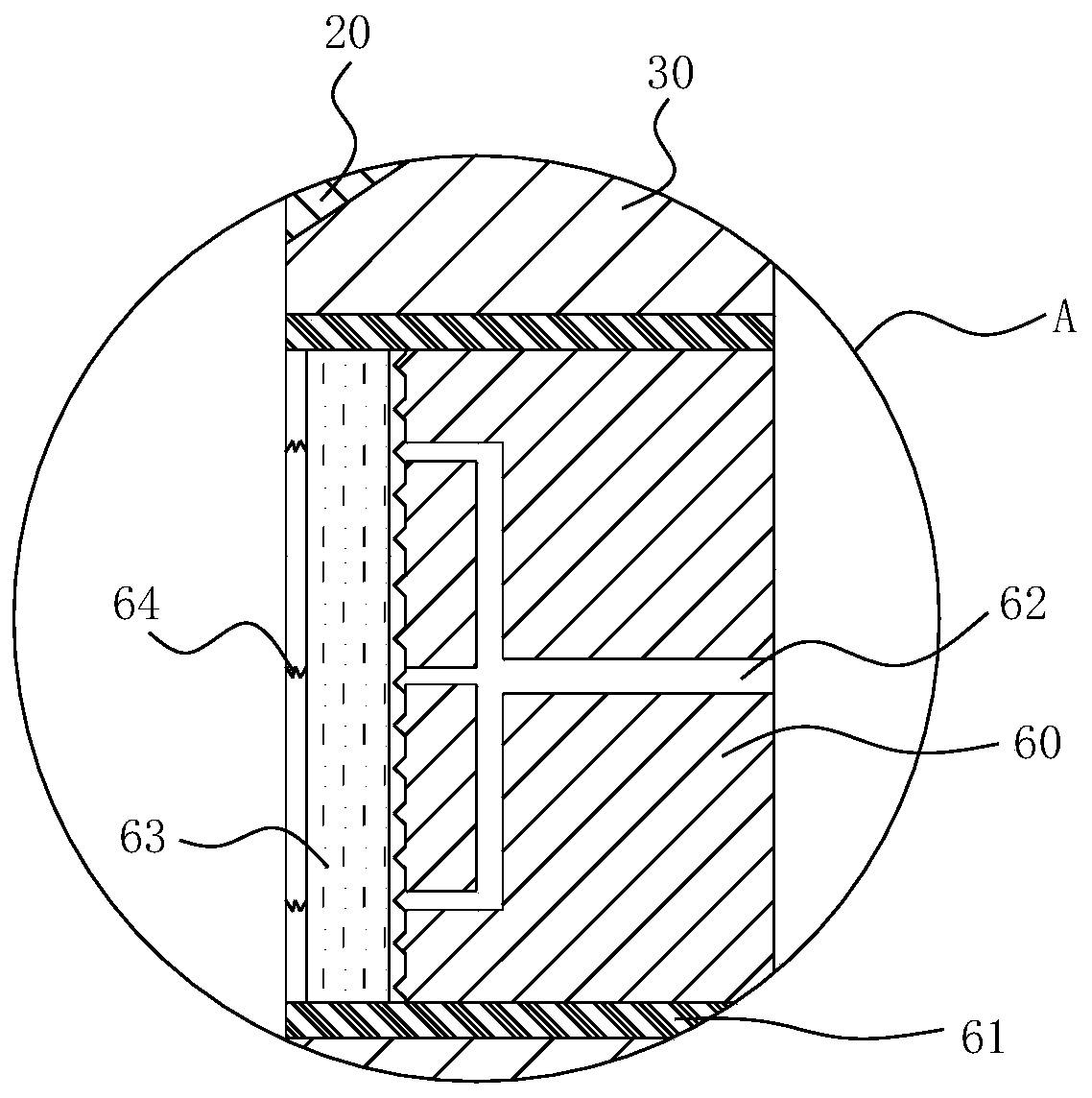

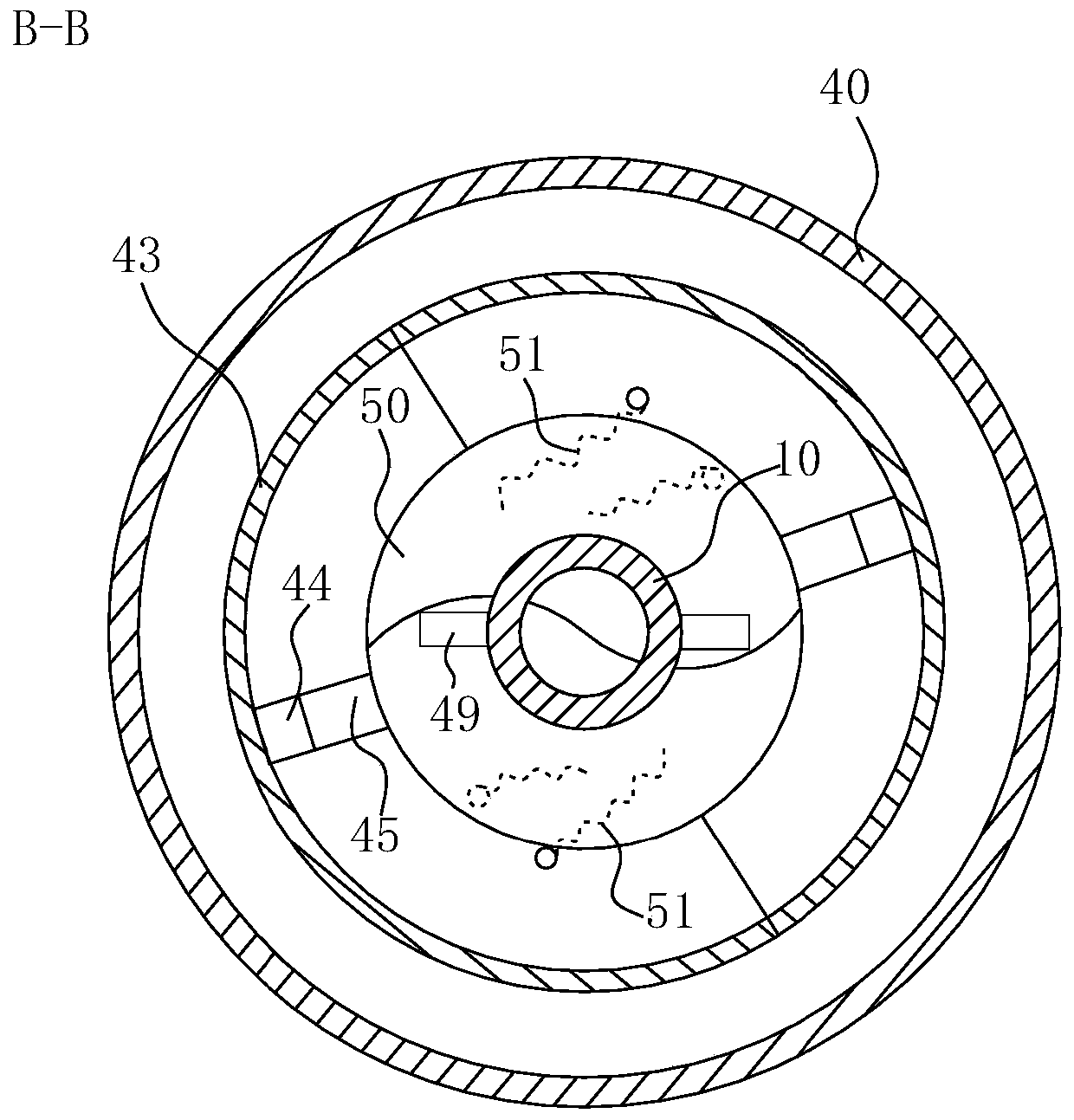

[0024] like figure 1 , 2 As shown in , 3, the present invention provides a bridge plug that can realize self-adaptation. It should be noted that the structures of the upper and lower joints and limit sleeves required by the bridge plug are all mature existing technologies, and those skilled in the art can choose to install them according to their needs, and do not involve the improvement points of the present invention, so they will not be described in detail. . The bridge plug of the present invention includes a central tube 10, and a rubber cartridge assembly is set outside the central tube 10. The rubber cylinder assembly includes an inverted trapezoidal compressed rubber cylinder 30 with a small inner side and a larger outer side. Outside the central tube 10, the compressed rubber cylinder 30 is provided with wedge-shaped extruding parts 20 matching the shape of the compressed rubber cylinder 30. . The material of the compressed rubber cylinder 30 is a rubber material ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com