Method for generating and outputting process control plans in batches based on TeamCenter

A technology of control planning and process control, applied in calculation, instrumentation, electrical digital data processing, etc., can solve the problems of consuming time and energy of engineers, inconsistency of plan report templates, and non-standard control plan preparation, so as to improve work efficiency and facilitate Human-computer interaction, the effect of improving the accuracy of documents

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

[0049] In order to clearly and completely describe the technical solution of the present invention and its specific working process, in conjunction with the accompanying drawings, the specific implementation of the present invention is as follows:

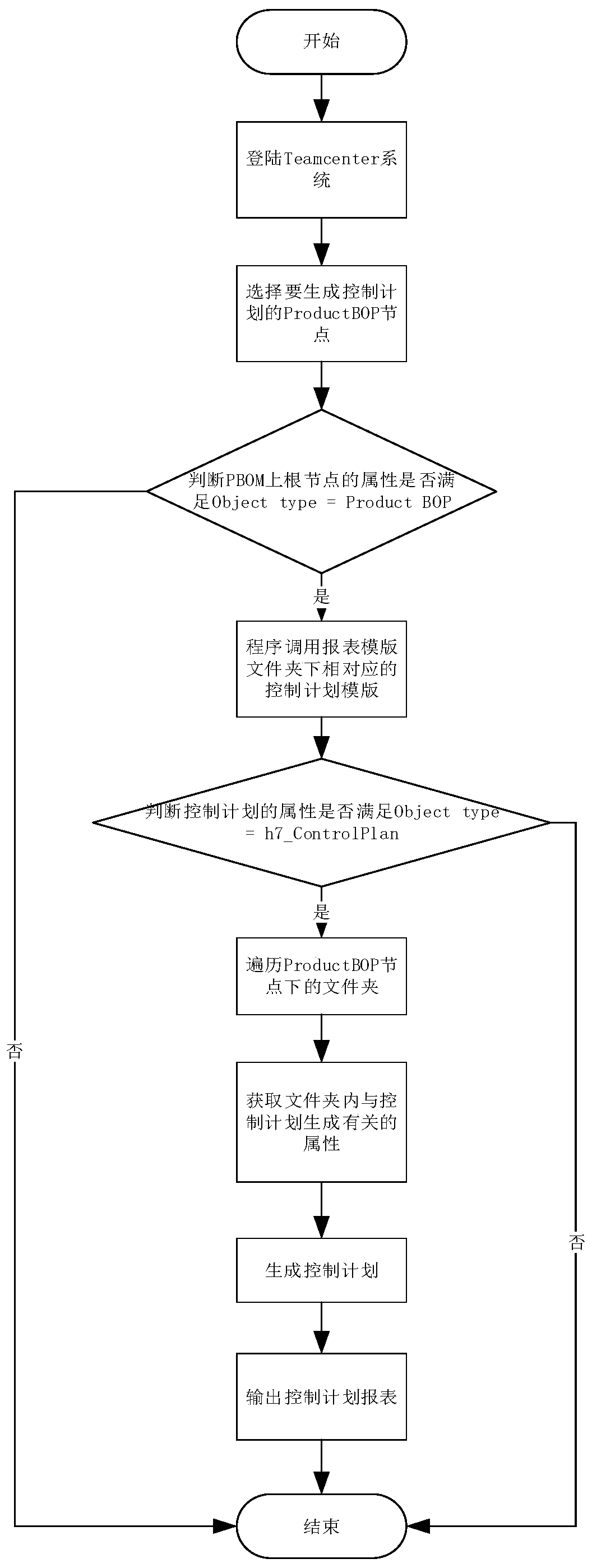

[0050]The invention provides a method for generating and outputting process control plans in batches based on TeamCenter. The method reads the attributes of Product BOP (Product Bill Of Process) and MBOM (Manufacturing Bill Of Material) in the TeamCenter system. ) properties, generate and output a control plan in Microsoft Excel format. Such as figure 1 As shown, the specific process of the method is as follows:

[0051] Step 1: Log in to the TeamCenter system;

[0052] 1.1 Initialize the Teamcenter log file;

[0053] 1.2 The program automatically calls the configuration file tcm.properties in the same directory;

[0054] 1.3 Login username and password verification logic:

[0055] Read the TCM_TC_URL, TCM_TC_USER, TCM_TC_PASS...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap