Chicken house manure cleaning device

A technology for cleaning manure and chicken houses, applied in poultry cages or houses, applications, poultry industry, etc., can solve the problems of serious water consumption, large impact on chicken house environment, poor working environment, etc., to reduce the cost of manure cleaning, The hygienic environment is conducive to improving the effect of breeding income

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

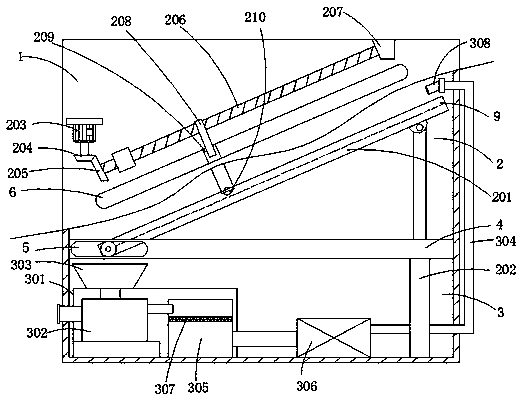

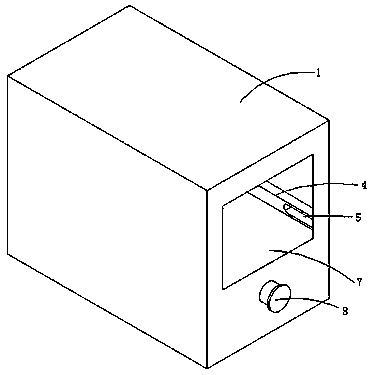

[0021] see Figure 1-2 , the present invention provides a technical solution: a chicken house manure cleaning device, including a chicken cage 1, a cleaning mechanism 2 and a flushing mechanism 3, and the cleaning mechanism 2 includes a bottom plate 201, a telescopic rod 202, a servo motor 203, a bevel gear 204, a pair of Bevel gear 205, screw mandrel 206, connection block 207, slide bar 208, connection plate 209 and cleaning roller 210, on the side wall of the inner cavity of chicken coop 1, be fixedly connected with side plate 4, the left side of side plate 4 is provided with sliding plate. Slot 5, telescopic rod 202 is fixedly connected to the bottom of the inner cavity of the chicken cage 1, one end of the bottom plate 201 is slidably connected to the chute 5 through a rotating shaft, and the other end is hinged on the top of the telescopic rod 202, and the servo motor 203 is fixedly connected to the chicken cage 1, the bevel gear 204 is installed on the output end of the ...

Embodiment 2

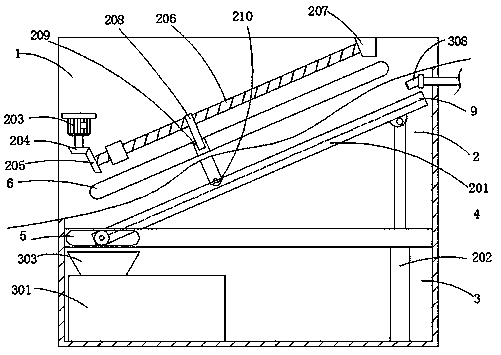

[0030] refer to image 3 Shown, embodiment 2 is different from embodiment 1 in that:

[0031] The nozzle 308 is supplied with water through an external water source, which can maintain the maximization of the manure cleaning intensity, and is suitable for situations where there is a lot of accumulation of chicken manure.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Rotation angle | aaaaa | aaaaa |

| Rotatable angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com