Injection structure of polymer molding mold

A technology for forming molds and polymers, which can be applied to home appliances, other home appliances, and household components. It can solve the problems of seepage of raw materials, difficulty in processing, and difficulty in ensuring tightness between piercing holes, so as to reduce the amount of waste and reduce seepage. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

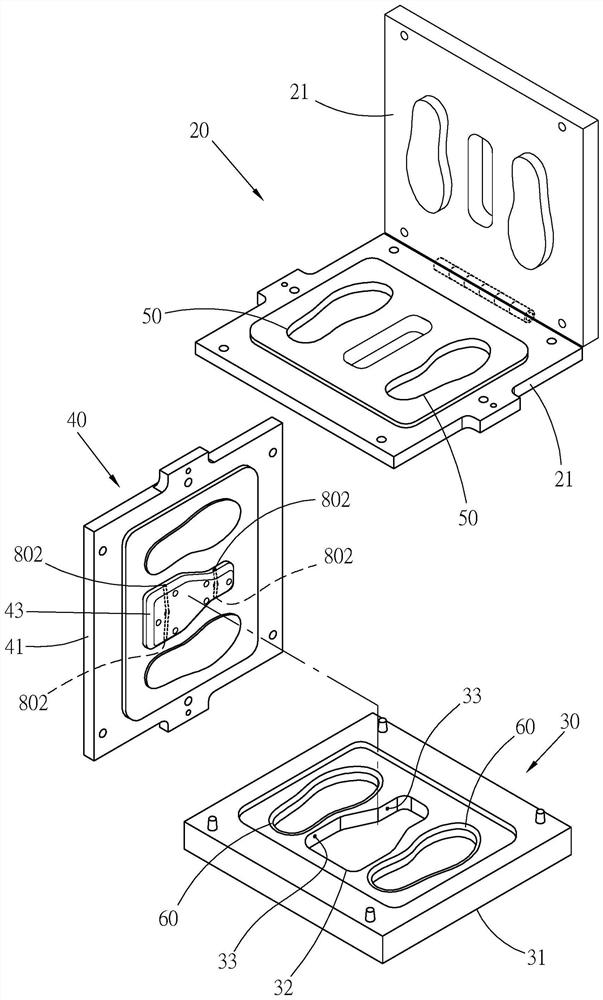

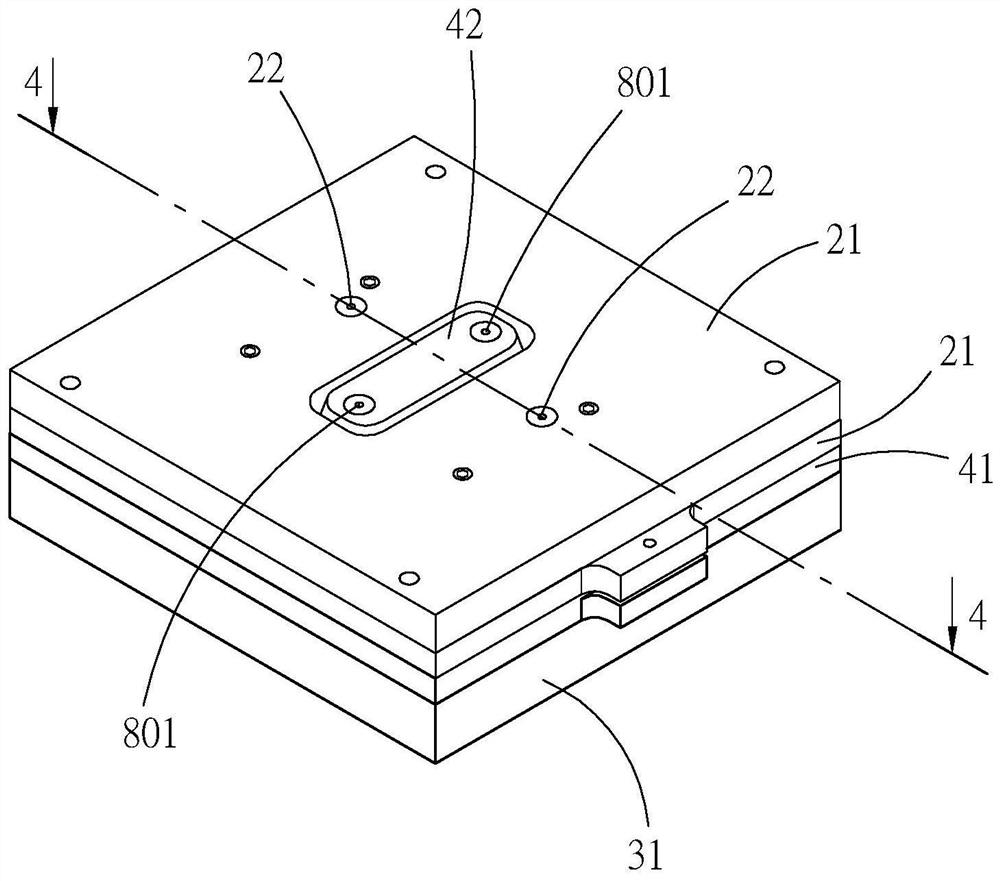

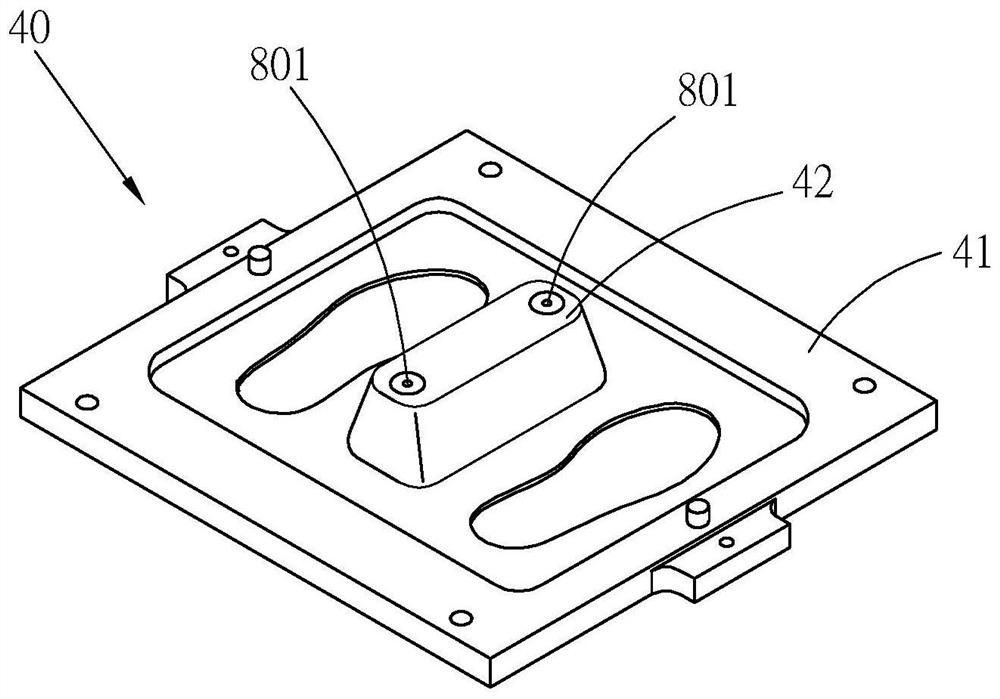

[0033] see Figure 1 to Figure 3 As shown, in a preferred embodiment of the present invention, the injection structure 10 of the polymer article molding mold provided mainly includes a first mold portion 20, a second mold portion 30, and a third mold portion 40. , two mold chambers 50 at the proximal end, two mold chambers 60 at the distal end, a channel 70 and two flow channels 80 .

[0034] First, the prior art in this embodiment will be described in which multiple layers of molds are stacked on top of each other and a mold chamber is formed therebetween. That is, the first mold portion 20 has two plate-shaped first mold bodies pivotally connected to each other. 21; the second mold part 30 has a plate-shaped second mold body 31 with an appropriate thickness, and is located below the first mold part 20; the third mold part 40 has a plate-shaped third mold with an appropriate thickness The body 41 is between the first mold part 20 and the second mold part 30; the proximal mol...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com