Method for preventing spontaneous combustion of stored coal piles by covering coal piles by utilizing oxygen-insulating materials

A technology of oxygen isolation and coal piles, which is applied in fire rescue and other directions, can solve the problems of expensive wind barriers, difficulty in large coal piles, and large coal footprint, so as to prolong the period of spontaneous combustion, suppress spontaneous combustion of piles, and suppress penetration effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

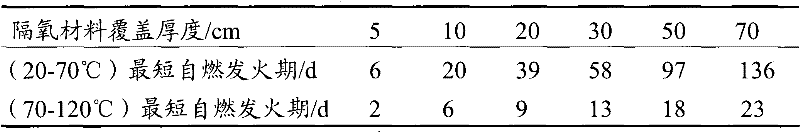

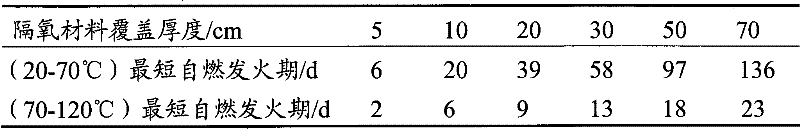

Embodiment 1

[0024] Embodiment 1: First, pulverize and sieve lump coal with a crusher to obtain pulverized coal less than 6mm as an oxygen barrier material; then use a belt conveyor to evenly cover the pulverized coal on the surface of the coal pile with a height of 1.8m from the ground to the coal pile, The covering thickness is 70cm (the particle size of the coal sample in the coal pile: 0-50mm; the size of the coal pile: the diameter of the bottom surface is 14.6m, and the total height of the coal pile is 4.6m); The damage shall be re-covered with pulverized coal in time, and at the same time, the low-temperature oxidation temperature of the coal pile and the symbolic gas concentration coupling measurement device shall be used to monitor whether the internal temperature of the coal pile exceeds 70°C and whether the standard gas concentration rises rapidly, so as to judge whether there is a possibility of spontaneous combustion in the coal pile The coal pile can be placed for 123 days wit...

Embodiment 2

[0025] Embodiment 2: first use a crusher to crush and sieve the waste cement slag filling material to obtain a <6mm oxygen barrier material; then use a belt conveyor to evenly cover the oxygen barrier material on the surface of the coal pile with a height of 1.8m from the ground to the coal pile, The covering thickness is 70cm (the particle size of the coal pile coal sample: 0-50mm; the size of the coal pile: the diameter of the bottom surface is 14.6m, and the total height of the coal pile is 4.6m); check the damage of the oxygen barrier material layer during the storage of the coal pile If there is any damage, it shall be covered with oxygen barrier material in time, and at the same time, the low-temperature oxidation temperature of the coal pile and the symbolic gas concentration coupling measurement device shall be used to monitor whether the internal temperature of the coal pile exceeds 70°C and whether the standard gas concentration rises rapidly, so as to judge whether th...

Embodiment 3

[0026] Embodiment 3: first crush and sieve lump coal with a crusher to obtain pulverized coal less than 13 mm as an oxygen barrier material; The thickness is 70cm (the particle size of the coal sample in the coal pile: 0-50mm; the size of the coal pile: the length of the bottom surface is 35m, and the total height of the coal pile is 13.5m); check the damage of the pulverized coal layer during the storage of the coal pile, and if there is any damage, timely Re-cover with pulverized coal, and at the same time use the low-temperature oxidation temperature of the coal pile and the symbolic gas concentration coupling measurement device to monitor whether the internal temperature of the coal pile exceeds 70°C and whether the standard gas concentration rises rapidly, so as to judge whether there is a possibility of spontaneous combustion in the coal pile; Coal piles can only be placed for 30 days without spontaneous combustion.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com