Camera decontamination optimization method of smoke stove system and smoke stove system

A camera and smoke stove technology, applied in image enhancement, image analysis, image data processing and other directions, to achieve the effect of optimizing shooting quality, improving shooting quality, and reducing the number of times

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

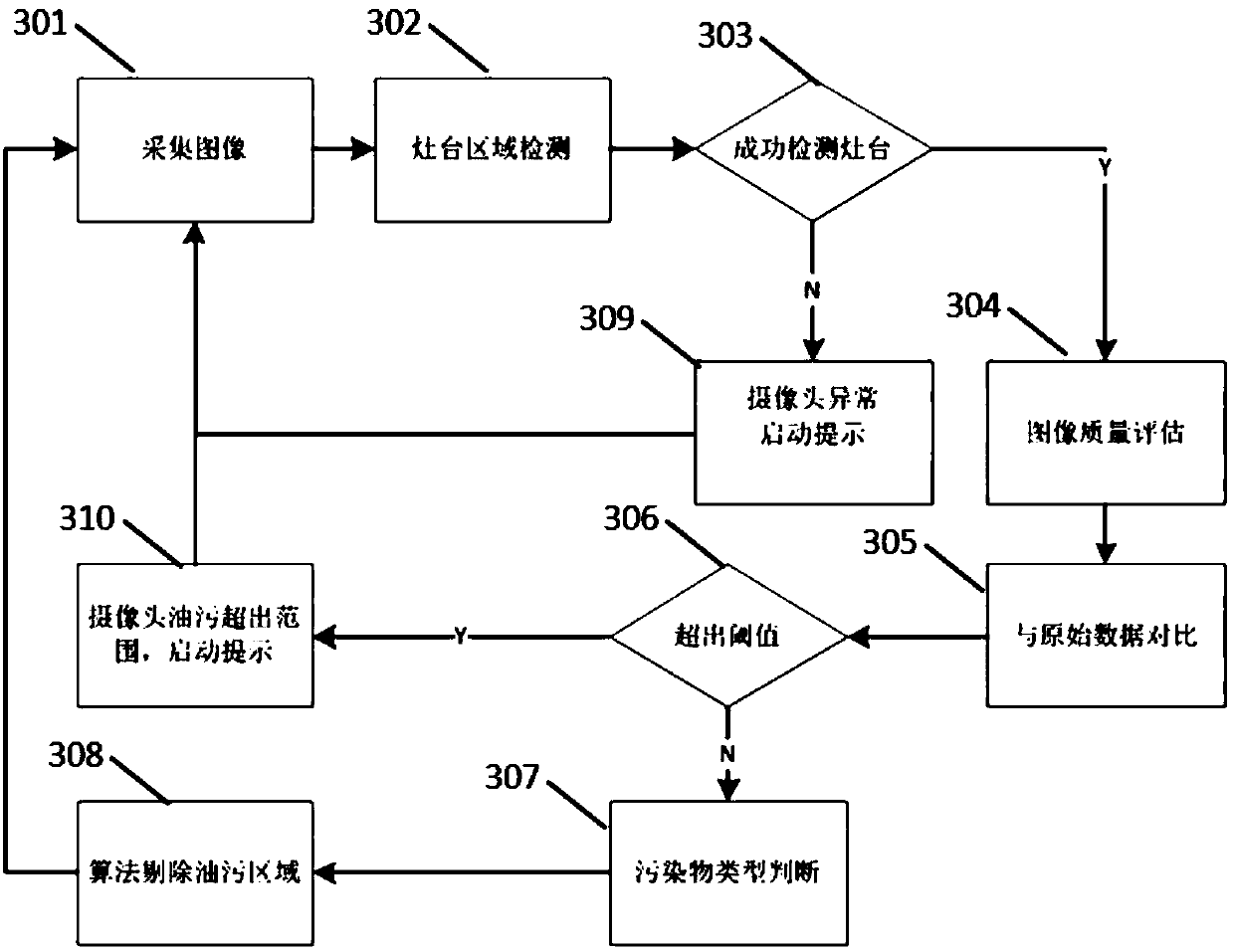

[0024] The technical solution provided by the present invention will be described in more detail below by means of the accompanying drawings and specific embodiments:

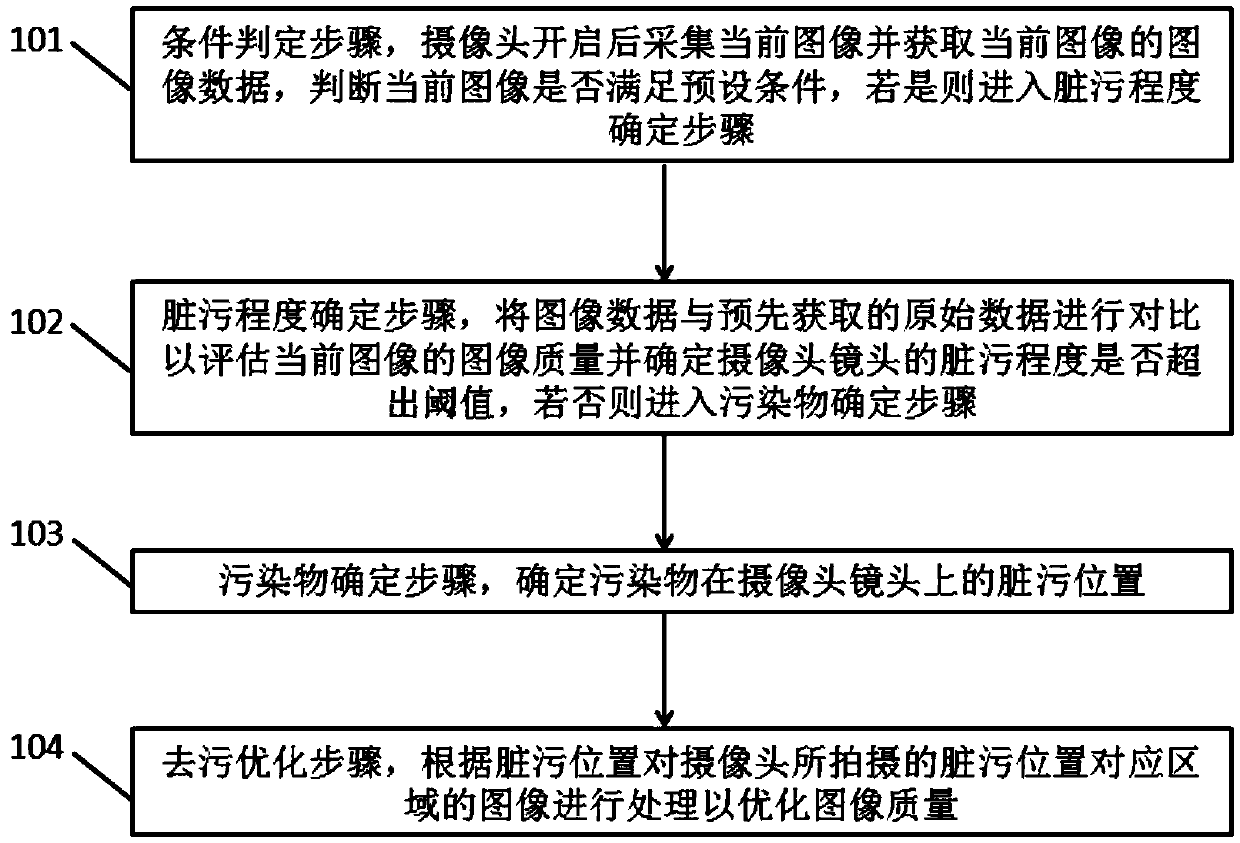

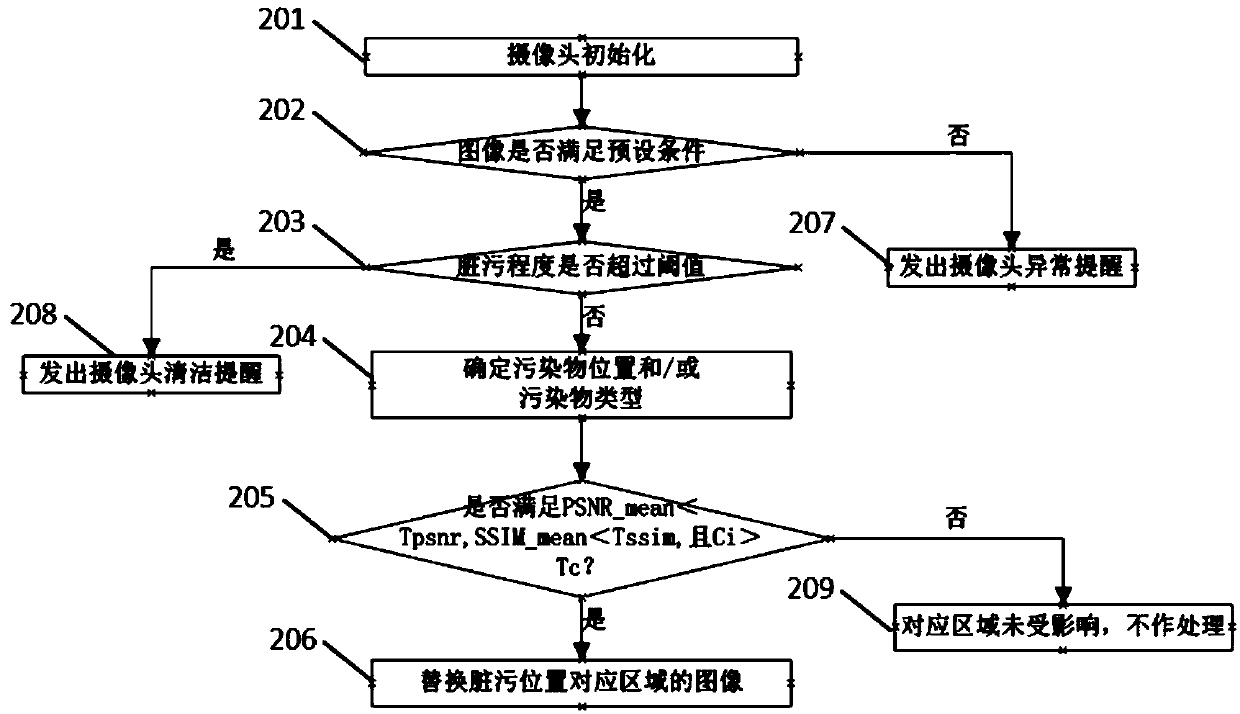

[0025] figure 1 A block diagram of the steps of one embodiment of the method of the present invention is disclosed. This embodiment discloses a camera decontamination optimization method for a smoke stove system, including:

[0026] Step 101: a condition determination step, after the camera is turned on, the current image is collected and image data of the current image is obtained, and it is judged whether the current image satisfies the preset condition, and if so, enters the step of determining the degree of contamination;

[0027] Step 102: the step of determining the degree of dirt, comparing the image data with the pre-acquired raw data to evaluate the image quality of the current image and determine whether the degree of dirt of the camera lens exceeds a threshold, if not, enter the step of determining t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com