Skeleton connecting method of thermoplastic polymer ship

A technology of thermoplastic polymers and connection methods, which is applied to ships and other directions, can solve problems such as construction difficulties, local structural deformation, and dimensional deviations, and achieve the effects of reducing construction difficulty and cost, halving welding hours, and improving construction accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0038] A kind of skeleton connection method of polyethylene (PE) fishing boat, the steps are as follows:

[0039] Step one, right Image 6 Among the four types of components (keel 1, side girder 2, hatch coaming bottom plate 3, floor plate 4) that constitute the frame of this type of fishing boat involve staggered and connected positions, and positioning gaps are processed respectively; among them:

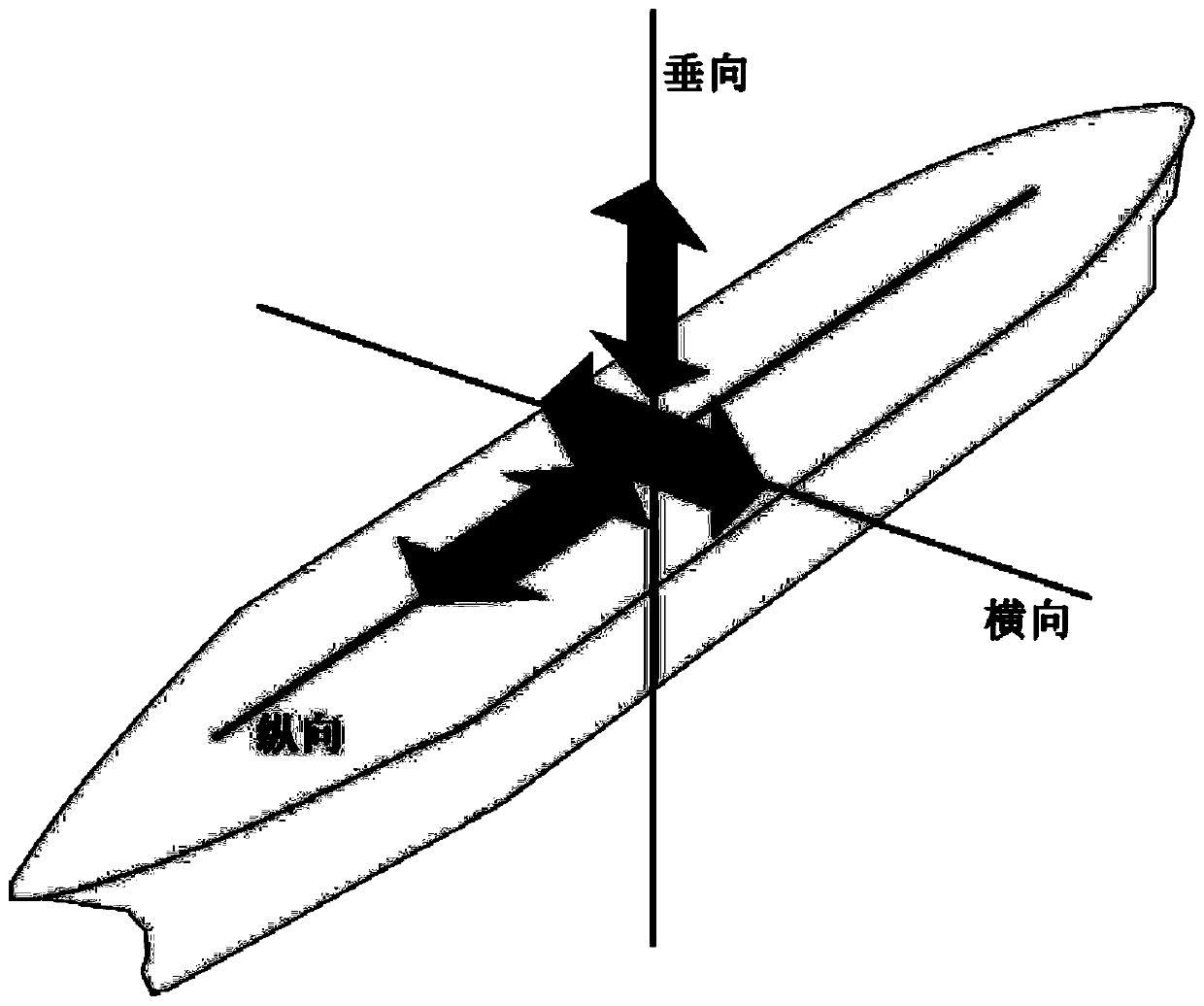

[0040] a) The keel 1 and the side girder 2 are longitudinal members, and the joints with the floors 4 are of equal height, and the gaps face inward;

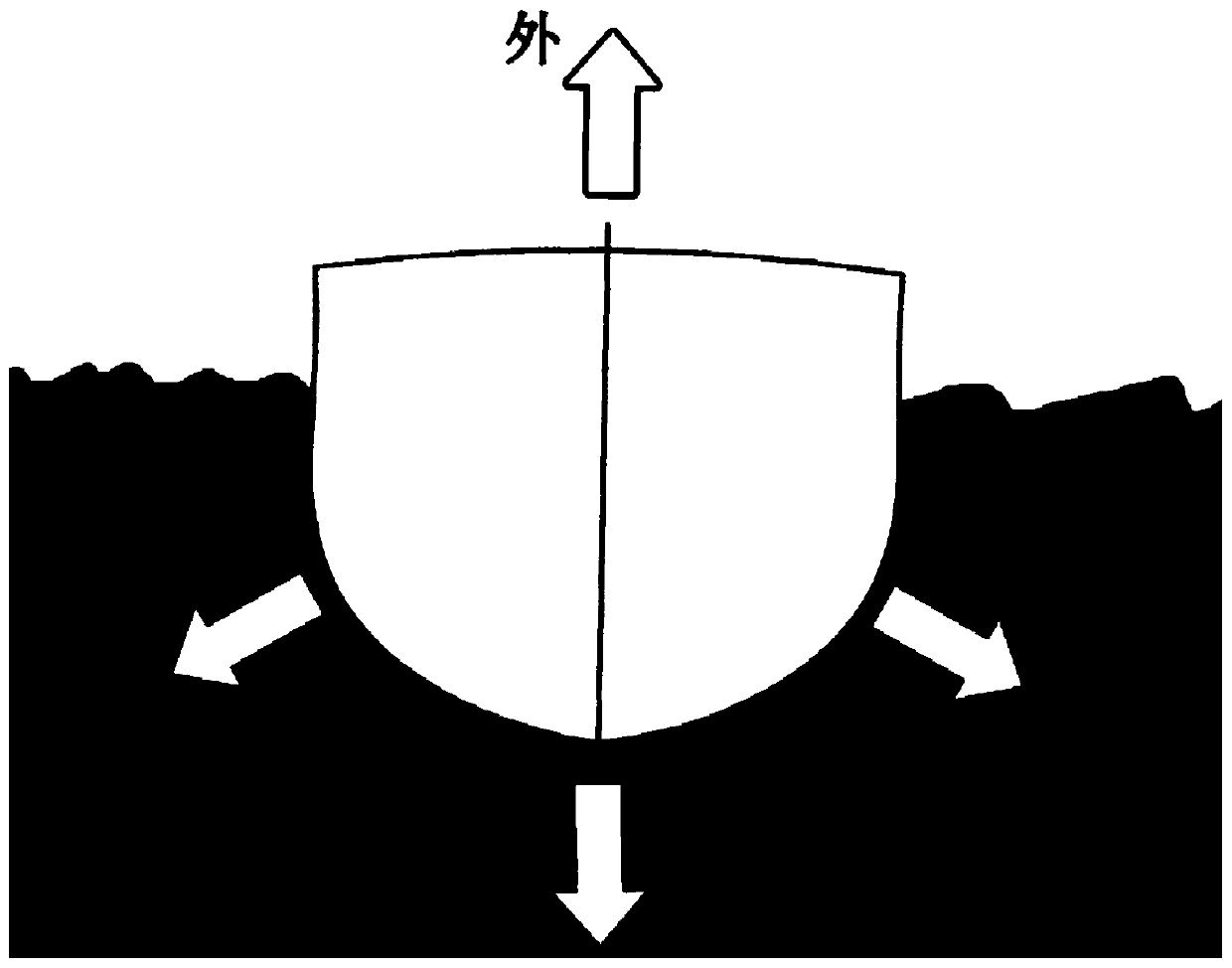

[0041] b) The height of the bottom plate 3 of the hatch coaming is greater than the height of the floor plate 4 at the joint, then according to Figure 4 , to determine the gap orientation;

[0042] c) The notch orientation of floor plate 4 is determined after the notch orientation of keel 1, side girder 2 and hatch coaming floor 3 are determined;

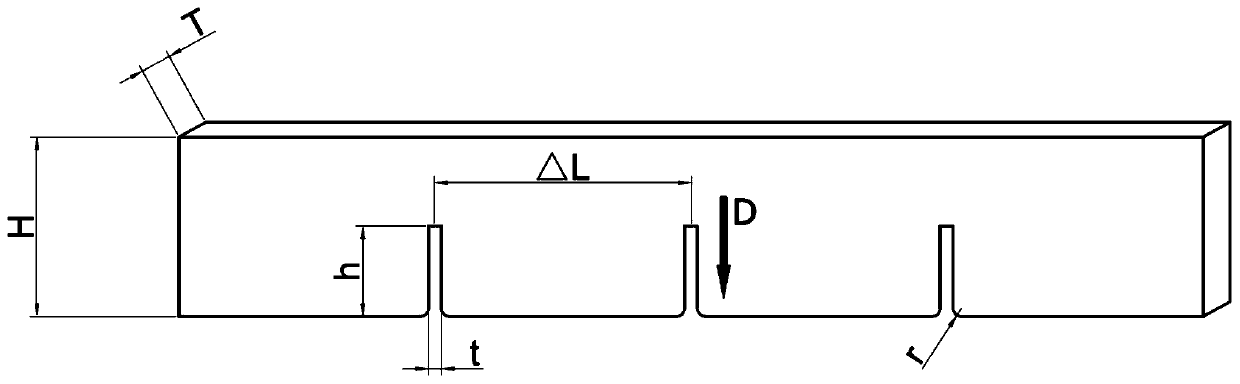

[0043] d) Calculate the various geometric parameters of the gap according to the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com