Lining double-arch masonry structure in mouth area of horizontal converter

A converter mouth and masonry structure technology, applied in the direction of furnace, furnace components, lining repair, etc., can solve the problems of low lining strength, short service life, etc., achieve good structural strength, improve service life, dimensional accuracy and structure high intensity effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

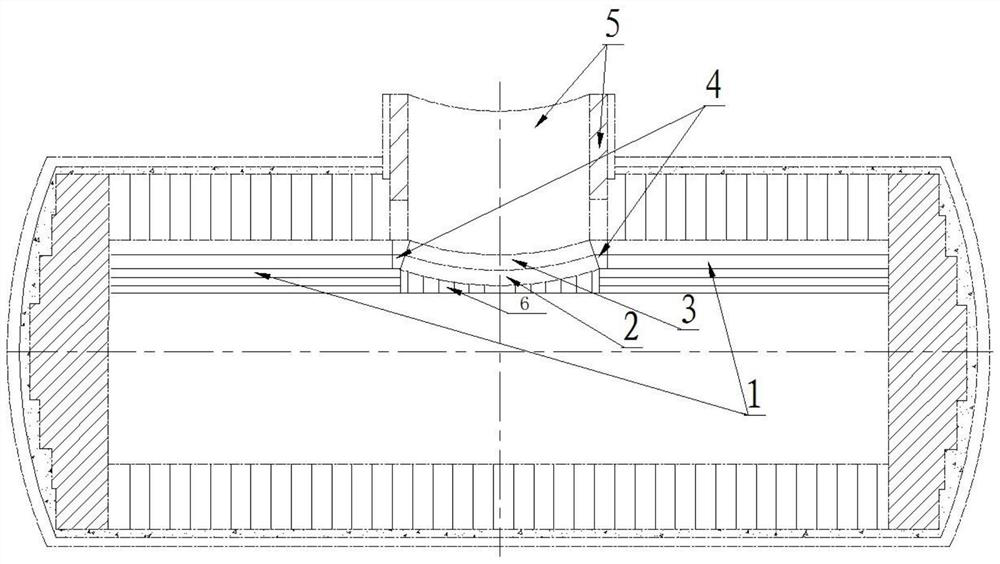

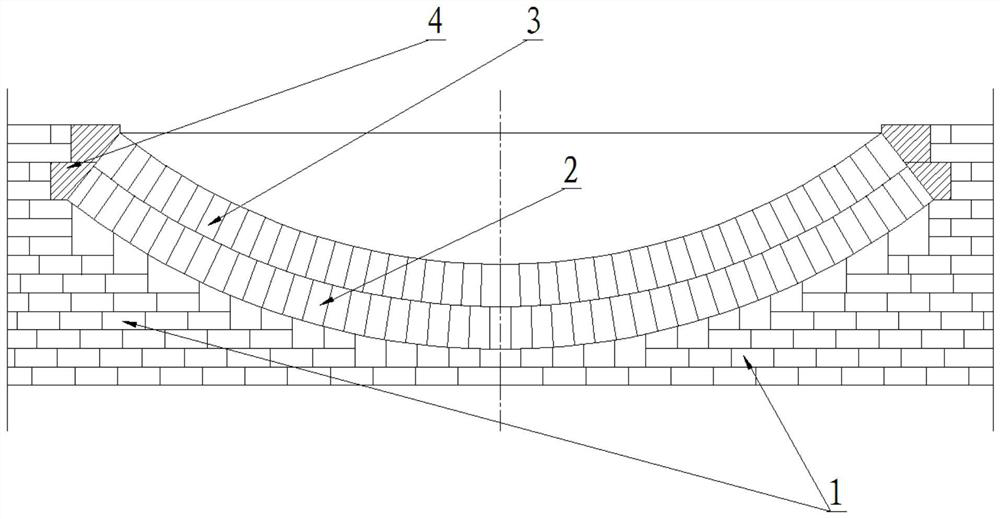

[0011] see Figure 1-2 , a double-arch masonry structure lining the furnace mouth area of a horizontal converter according to the present invention, comprising an inner ring arch 2 and an outer ring arch 3, the outer ring arch 3 is built at the bottom of the furnace mouth 5 of the horizontal converter, and the inner ring arch 2 is built on the bottom of the outer ring arch 3, and the inside of the horizontal converter body passes through a plurality of cylinder bricks 1 to build the circumferential cylinder brick layer, and both the inner ring arch 2 and the outer ring arch 3 pass through multiple cylinder brick layers. Two lock bricks 4 are connected by masonry; the bottom of the inner ring arch 2 is built with a plurality of cylinder bricks 1 to build a transition brick layer 6, and the bottom of the transition brick layer 6 is flush with the inner surface of the circumferential cylinder brick layer. The transition brick layer 6 is connected with the circumferential cylind...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com