Safe and easily-opened metal packaging container

A metal packaging and container technology, applied in packaging, transportation and packaging, bottle/container caps and other directions, can solve the problems of shortened product shelf life, large opening force, deformation of container anti-theft ring, etc. The effect of solving poor sealing and improving safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

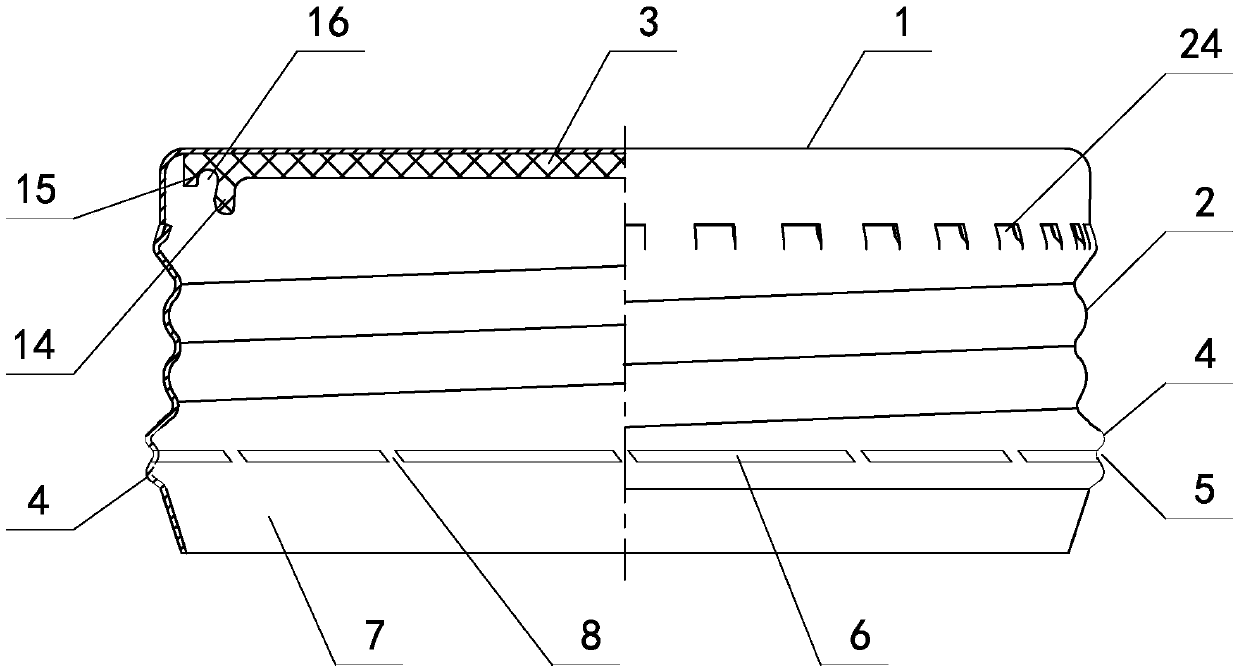

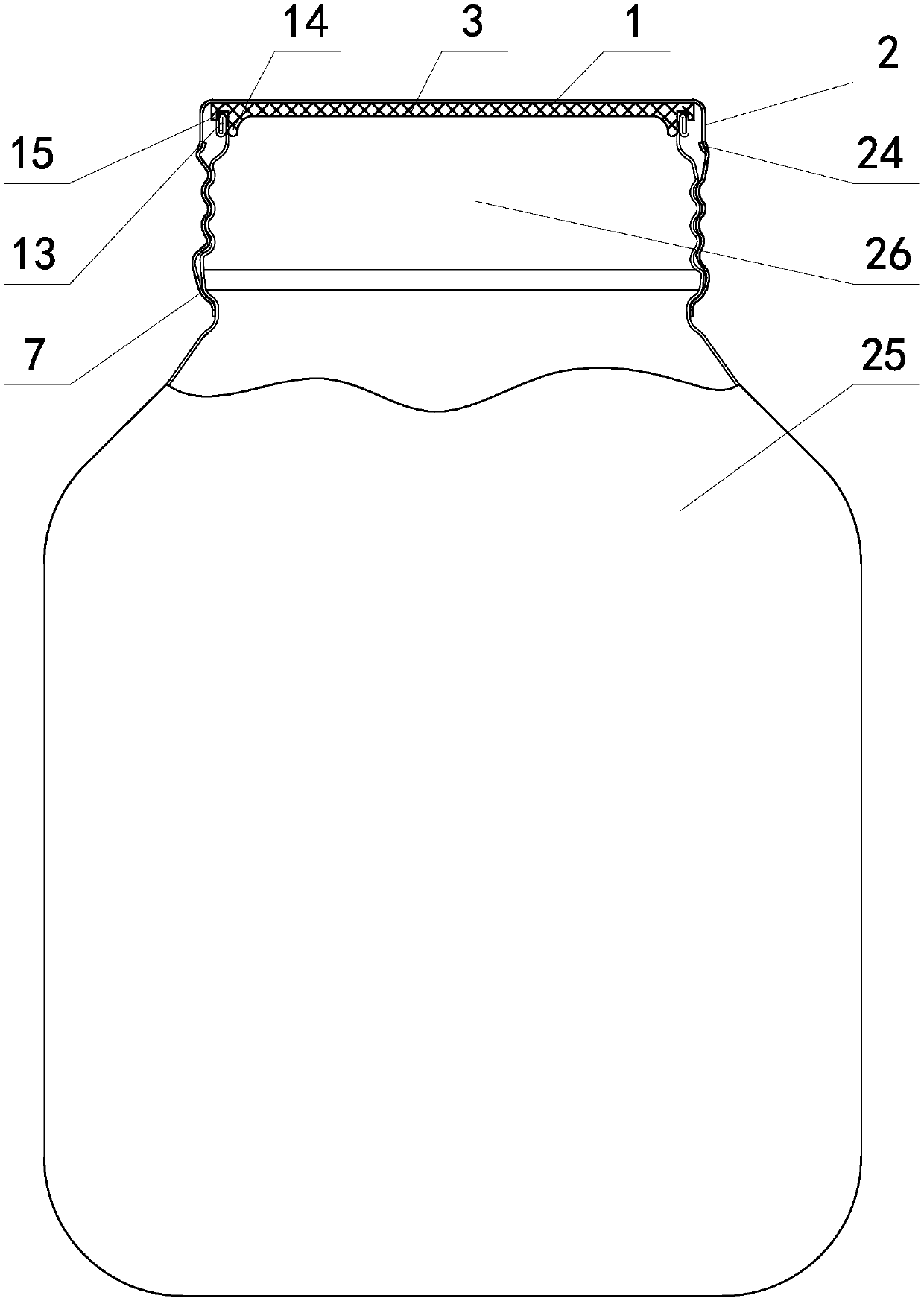

[0035] exist figure 1 figure 2 In the shown embodiment 1, a safe and easy-to-open metal packaging container includes a container body 25 and a twist-off lid. A cylindrical container opening 26 is formed on the packaging container, and external threads are formed on the outer wall of the container opening. The twist-off cover includes a cover top 1 and a cover wall 2 extending downward from the outer edge of the cover top. The lower surface of the cover top is provided with a gasket 3, and the outer periphery of the gasket extends downward integrally. The inner sealing ring 14 abutting against the inner wall of the container mouth rim 13 and the outer sealing ring 15 abutting against the outer wall of the container mouth rim form a downwardly opening sealing groove 16 between the inner sealing ring and the outer sealing ring. The container body is composed of a single layer of metal material, and the rim of the container mouth is made of four layers of metal material folded....

Embodiment 2

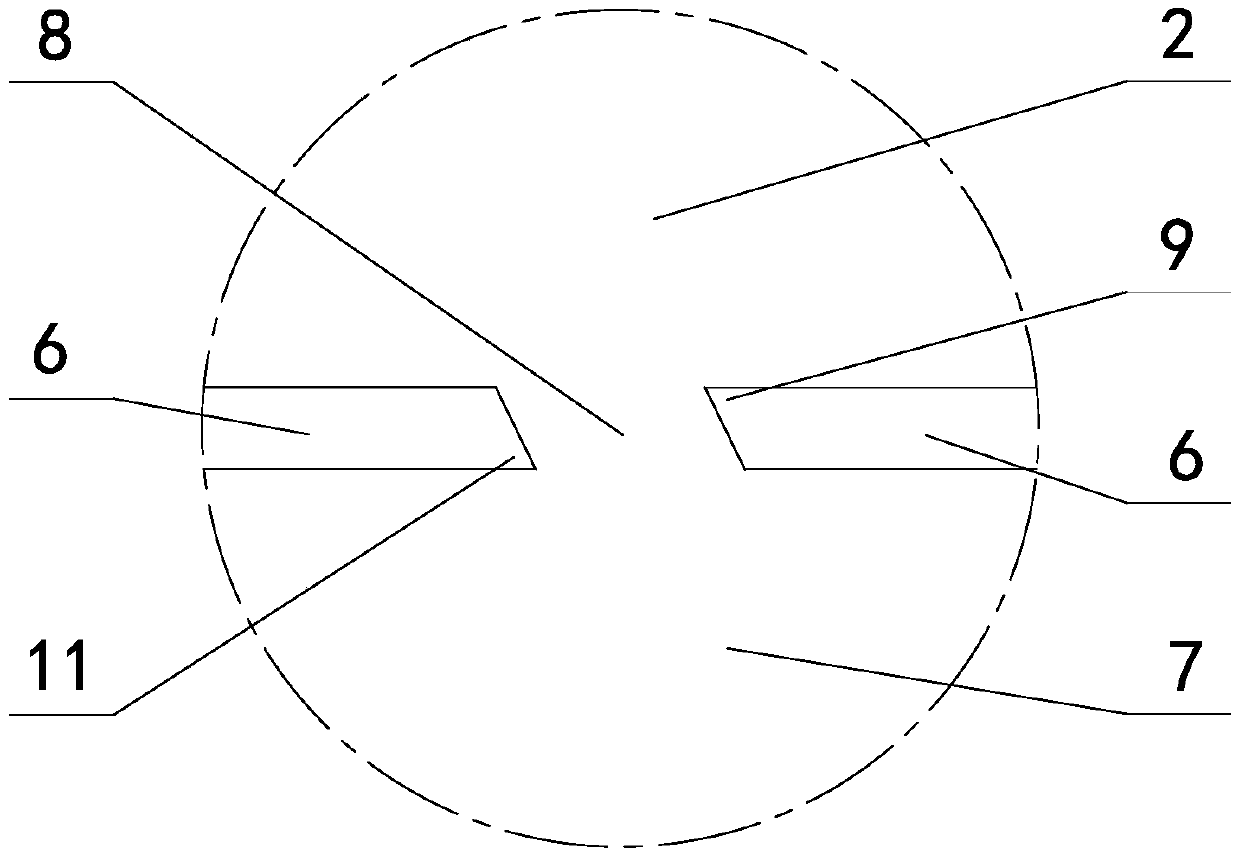

[0037] exist Figure 4 In the shown embodiment 2, the connection between the bridging and the upper acute angle is formed with an upper pre-slit 10, the upper pre-slit extends along the circumference of the cover wall and its opening communicates with the slit, and the upper pre-slit is formed on the periphery of the cover wall. The upward length is 15% of the bridging width; the connection between the bridging and the lower acute angle forms a lower pre-split 12, which extends along the circumference of the cover wall and its opening communicates with the slit, and the lower pre-split is in the cover. The circumferential length of the wall is 70% of the upper pre-slit length, and the rest are the same as in Example 1.

Embodiment 3

[0039] exist Figure 5 In the shown embodiment 3, the top surface of the sealing pad corresponding to the upper and lower sides of the sealing groove is provided with a material holding tank 17. The center line of the section coincides, the opening width of the container is 60% of the width of the sealing groove, and the depth of the container is 45% of the opening width of the container; the lower end of the outer surface of the inner sealing ring is provided with a guide arc edge 19 The upper edge of the guiding arc edge is connected with the lower edge of the interference ring. In this embodiment, the height of the cross-section of the inner seal ring is greater than the height of the cross-section of the outer seal ring, and the lower part of the outer surface of the inner seal ring is provided with an interference ring 18 (the left part of the dotted line in the figure), and the interference ring and the bottom of the seal groove The distance between them is greater than...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com