Large-scale high-speed rotary equipment cylinder contour measurement model based on multi-offset errors

A technology for measuring model and offset error, which is applied in measuring devices, complex mathematical operations, instruments, etc., can solve the problems affecting sensor probe offset error, influence, contour measurement influence, etc., so as to improve the accuracy of ultra-precision measurement and avoid The effect of flaws in principle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

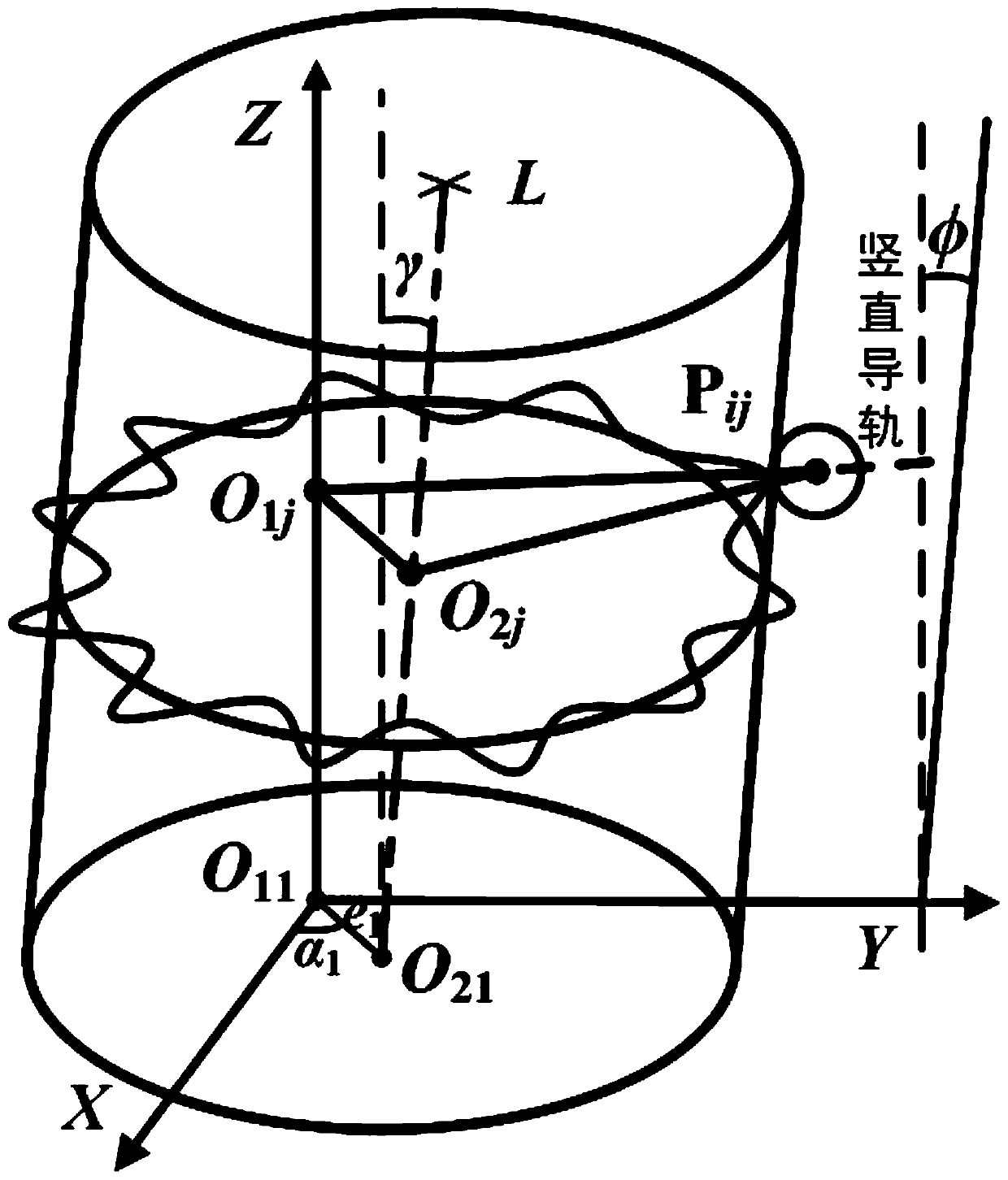

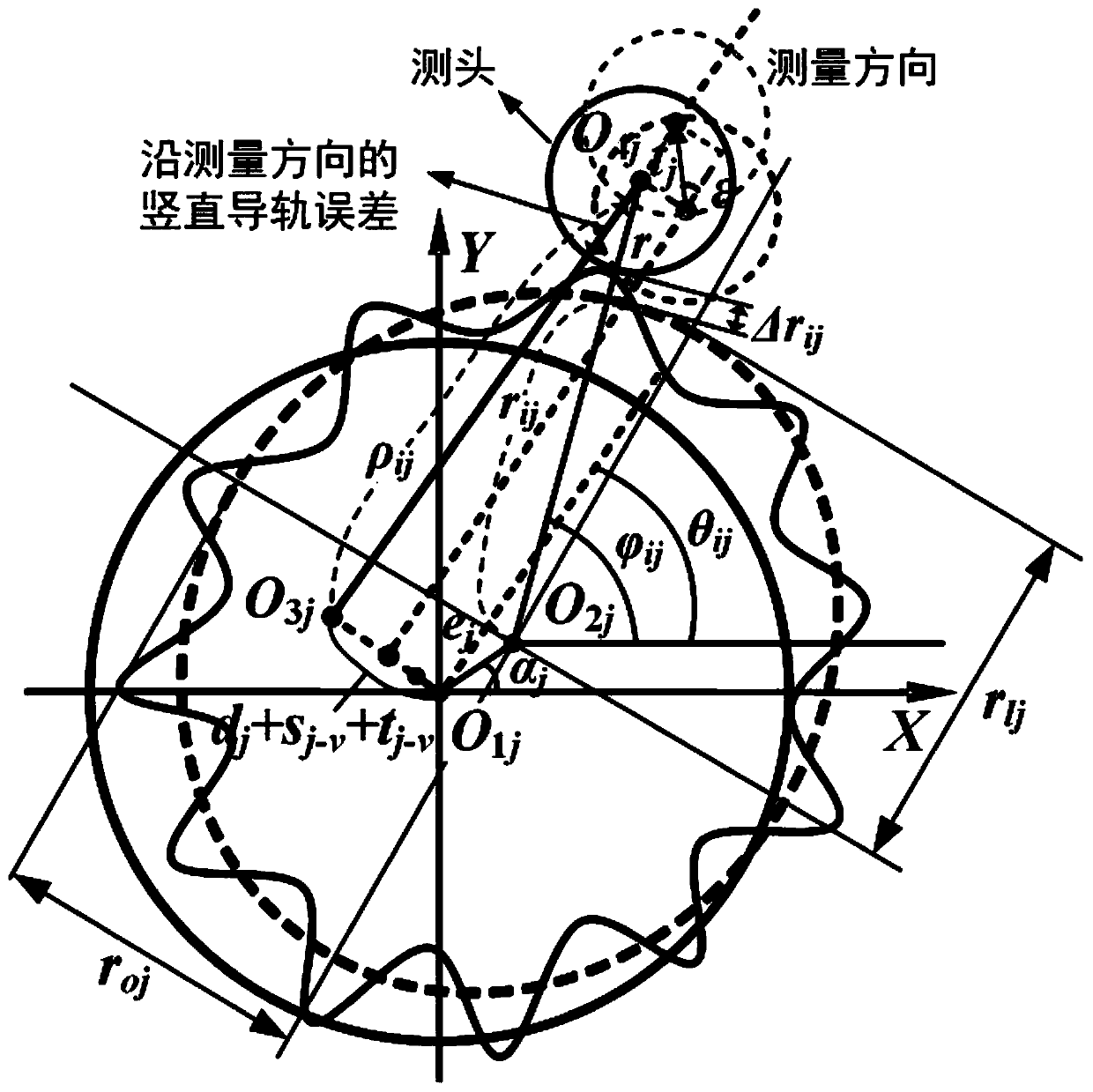

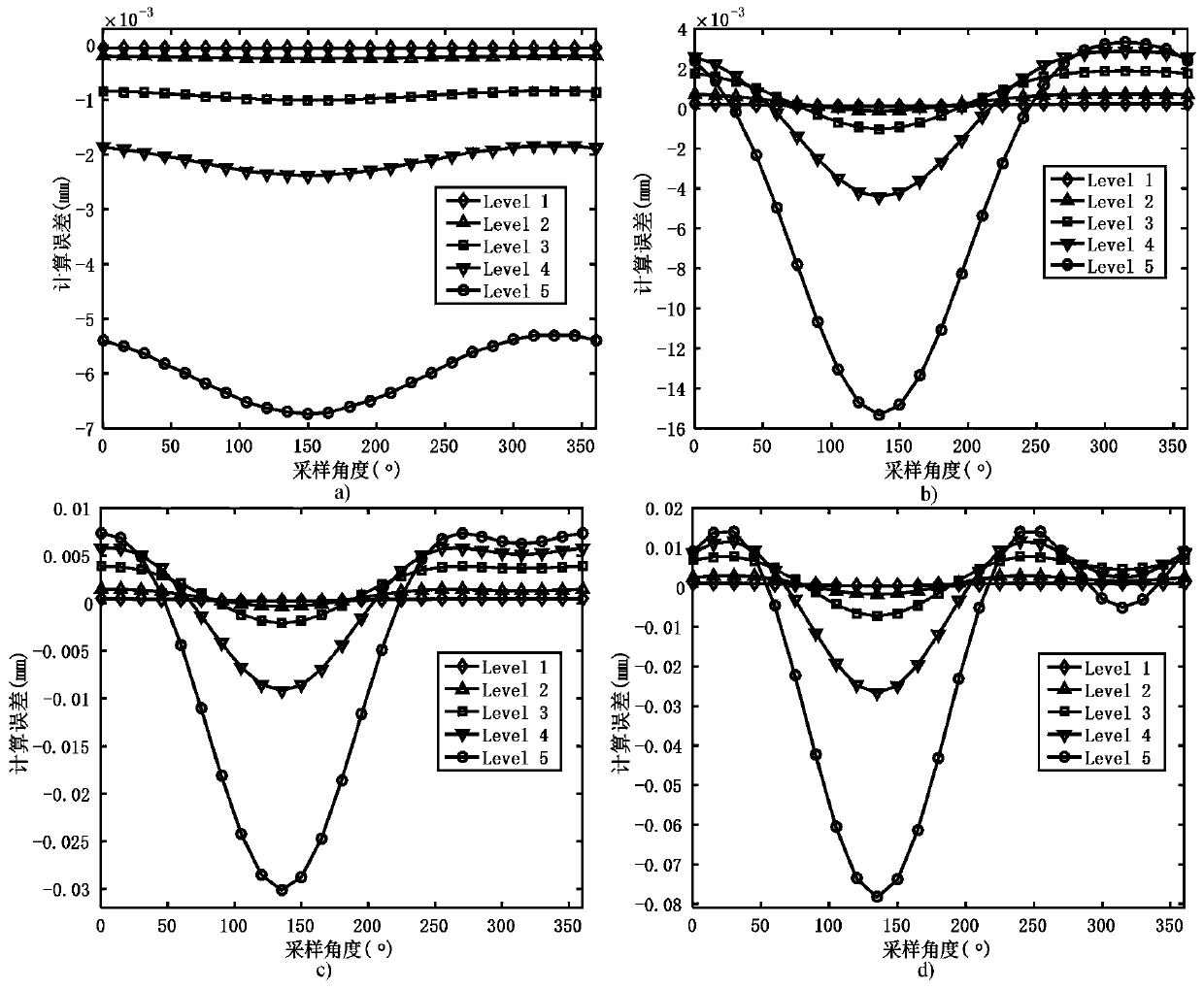

[0030] A cylindrical profile measurement model for large-scale high-speed rotary equipment based on multiple offset errors. The measurement model includes seven offset error components, which are the eccentric error (α, e), which is the difference between the center of the base surface of the test piece and the center of rotation of the turntable. Deviation, geometric axis tilt error γ, sensor head offset error d j (j=1,2,...,p, p is the number of sampling sections), the sensor ball radius r, the sensor head rod tilt error The tilt error w of the axis of the horizontal guide rail and the tilt error φ of the axis of the vertical guide rail, the measurement model at different height sections of the cylindrical profile is:

[0031]

[0032] In the formula, ρ ij ——From the i-th (i=1,2,…,n, n is the number of sampling points of each section) measuring point of the jth section on the cylindrical contour of the test piece to the instantaneous measurement center O 3j distance; Δr ...

Embodiment 2

[0046] Such as figure 1 , figure 2 Shown is the seven-offset error cylinder profile measurement model proposed by the present invention, which improves the cylinder profile measurement model by introducing a new error source on the basis of the two-parameter cylinder profile measurement model. The geometric center of the base surface of the tested piece O 21 Impossible and turntable center of rotation O 11 The overall eccentricity error (α, e) is introduced due to complete coincidence; when there is an angle γ between the geometric axis of the test piece and the rotary axis of the turntable, it will not only bring about the secondary eccentricity of the sections at different heights, but also make each section ellipse; the sensor The measuring line does not pass through the measuring center of gyration O 1j The probe offset error caused by d j It will also affect the measurement results, causing the sensor to measure not relative to the measurement center of rotation O 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com