A device and method for measuring radial flow oil-water relative permeability of conglomerate full-diameter core

A relative permeability and full-diameter core technology, which is applied to the field of radial flow oil-water relative permeability measurement devices for conglomerate full-diameter cores, can solve the problems of small core size, poor representativeness of small cores, and large measurement errors, and facilitate installation and disassembly, simple structure design, small experimental error

Active Publication Date: 2022-06-03

CHINA UNIV OF PETROLEUM (EAST CHINA) +1

View PDF0 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0003] (1) Due to the small size of the core, the three-dimensional radial seepage process of the formation near the actual wellbore cannot be simulated, which affects the use of test results

[0004] (2) The particle size of conglomerate cores varies greatly, and the representativeness of small cores is poor. It is difficult to obtain suitable representative cores with conventional core holders, and the availability of test results is poor

[0005] (3) The amount of saturated oil in the conventional core is small, and the measurement error is large, and the plane displacement equation is usually used to process the experimental data, so the actual applicability of the relative permeability curve obtained by the final calculation is poor

[0006] (4) Conventional relative permeability tests are based on small cores and one-dimensional linear steady seepage, but the calculation and data processing methods for two-phase radial seepage relative permeability are not yet mature

[0007] It can be seen that the permeability test on standard small cores cannot meet the needs of conglomerate core relative permeability testing and oilfield production. It is necessary to develop a full-diameter core holder for conglomerate and its supporting equipment, and it is necessary to improve the conglomerate oil-water Processing Method of Test Data of Radial Flow Two-phase Relative Permeability

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 1

[0178] (1) The full-diameter core holder is vertically installed on the core holder fixing frame, and the liquid outlet of the upper end cap is upward. Will

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Login to View More

Abstract

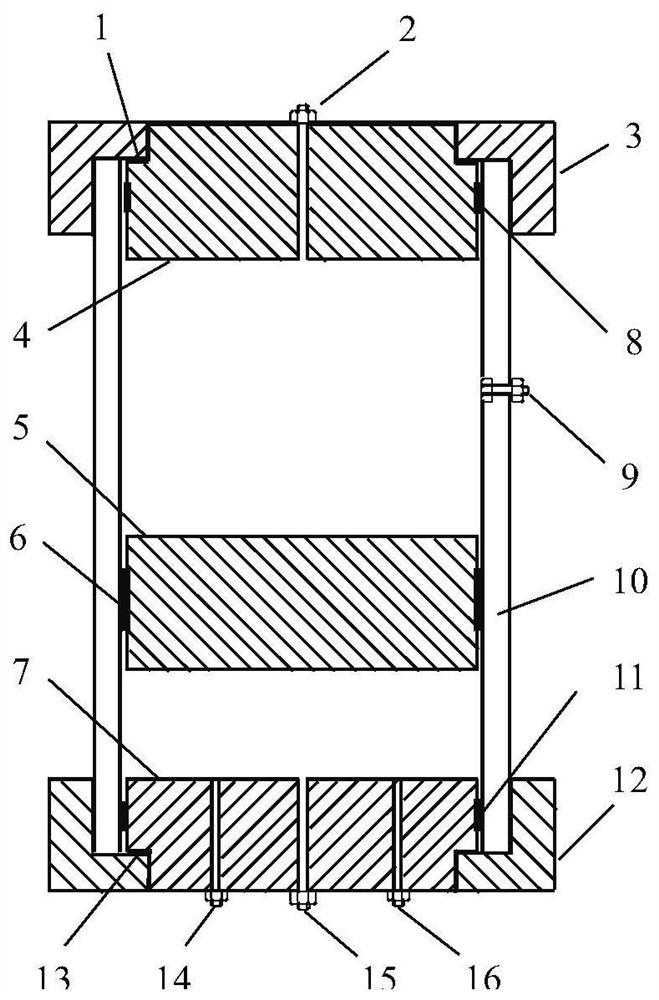

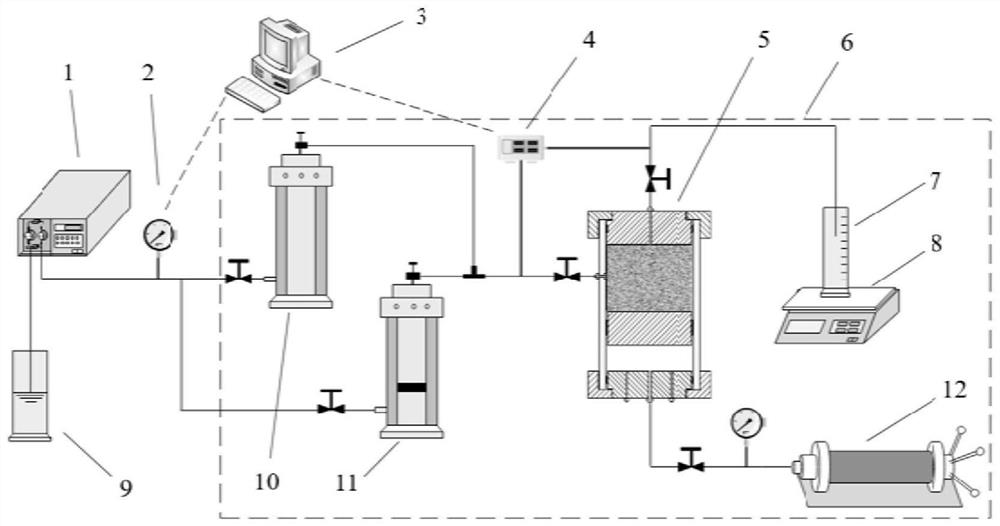

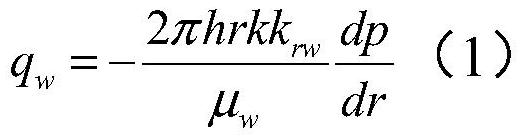

The invention discloses a device and method for measuring the radial flow oil-water relative permeability of a conglomerate full-diameter core, including an experimental device for measuring the radial flow oil-water relative permeability of a conglomerate full-diameter core, an experimental process and an experimental data processing method. It can accurately simulate the radial seepage process of oil and water near the wellbore under formation temperature and pressure, and realize the determination of the relative permeability of oil and water in radial seepage of conglomerate full-diameter cores. The experimental devices include: vacuum pumping system, pressure supply system, simulated reservoir module and production fluid metering system. The experimental process includes: full-diameter core pre-treatment, core absolute permeability measurement, core vacuum and saturated water, oil flooding water core saturated oil, water flooding oil unsteady state method oil-water relative permeability measurement experiment. The data processing is based on the calculation method of the full-diameter core radial flow oil-water relative permeability curve derived from Darcy's formula, B-L radial seepage equation, and flow function G.

Description

A device and method for measuring the relative permeability of oil and water in radial flow of conglomerate full-diameter cores technical field The invention belongs to conglomerate oil reservoir core oil-water two-phase relative permeability measurement technical field, comprising a kind of conglomerate full straight Radial core radial flow oil-water relative permeability measuring device and method. Background technique Oil-water two-phase relative permeability is one of the basic parameters of oil and gas field development, and it is used for oil reservoir development scheme formulation, Understanding the seepage of oil and water in the reservoir has important guiding significance and is a parameter that must be measured. At present, the core oil-water relative The measurement of permeability is mainly for sandstone cores. The cores used for measurement are mostly core columns with a diameter of 2.5cm. dimensional linear flow. The diameter of the core holder com...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Patents(China)

IPC IPC(8): G01N15/08G01N1/28

CPCG01N15/0826G01N1/286

Inventor 孙仁远陈宇靳军刘冬冬寇根曹刚孙业恒陈昊天吕道平周波周伟王子强

Owner CHINA UNIV OF PETROLEUM (EAST CHINA)

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com