Fluid reactor

A technology for reactors and fluids, applied in fluid mixers, chemical/physical/physicochemical nozzle reactors, chemical liquid solidification, etc., can solve problems such as insufficient particle size distribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

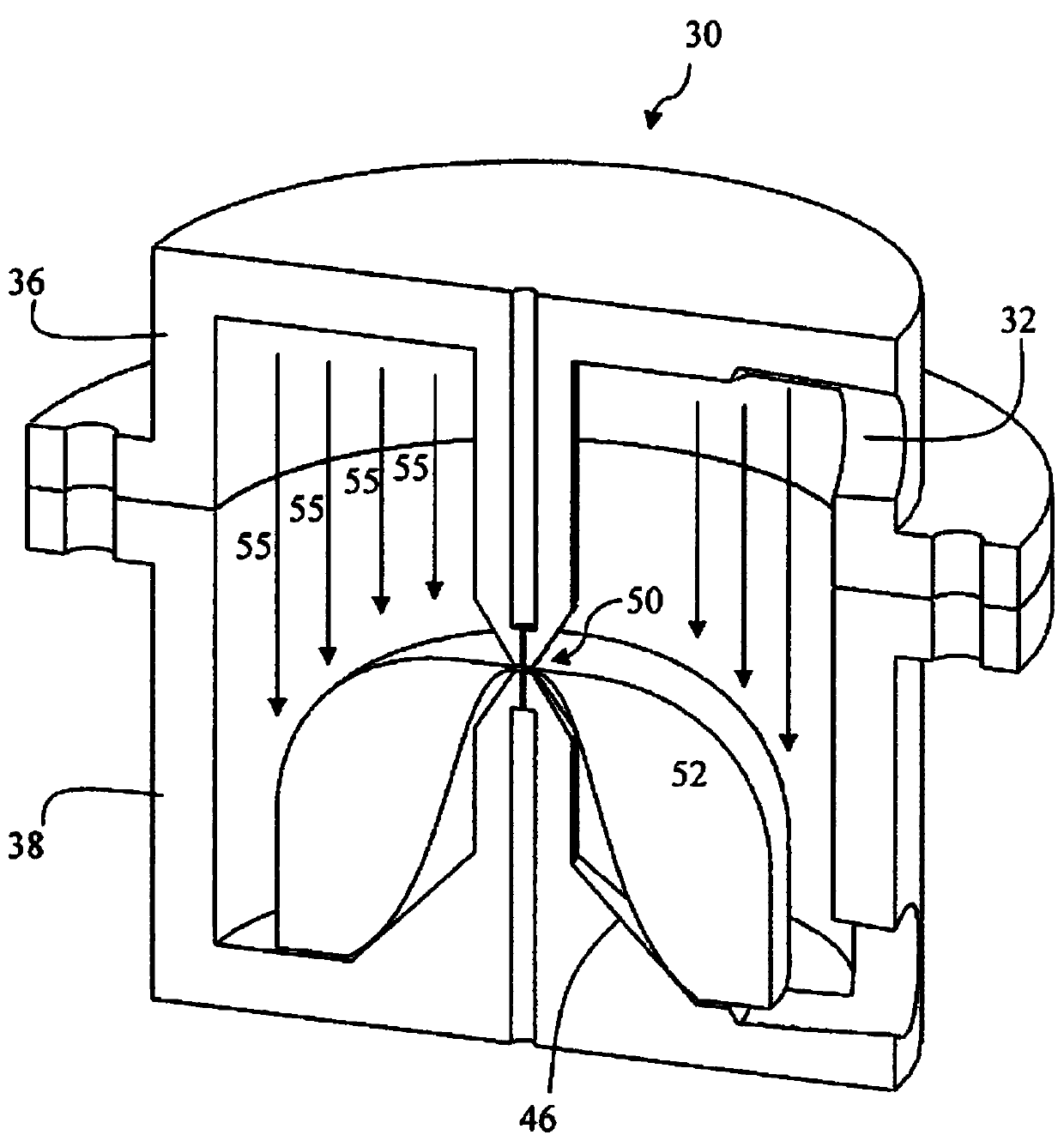

[0013] In the context of the present invention, "collinear" refers not only to angles of 0° (same direction) or 180° (opposite directions), but also includes some deviations from this interaction angle that can be seen in practice. The term "collinear" herein is intended to include interaction angles of -10° to +10°, ie 170° to 190°.

[0014] In the context of the present invention, "collinear" not only means that two interacting jets or nozzles are aligned or located on the same axis, but actually includes possible displacement deviations on either side of the jet or nozzle axis. Ideally, the two jets should overlap 100%, ie the two jets or nozzle axes are aligned. However, the term "collinear" also includes overlapping ratios of 50% and above, 70% and above. The degree of this overlap also depends on the jet profile of the free jet coming out of the nozzle. Those skilled in the art are aware of the relationship therein.

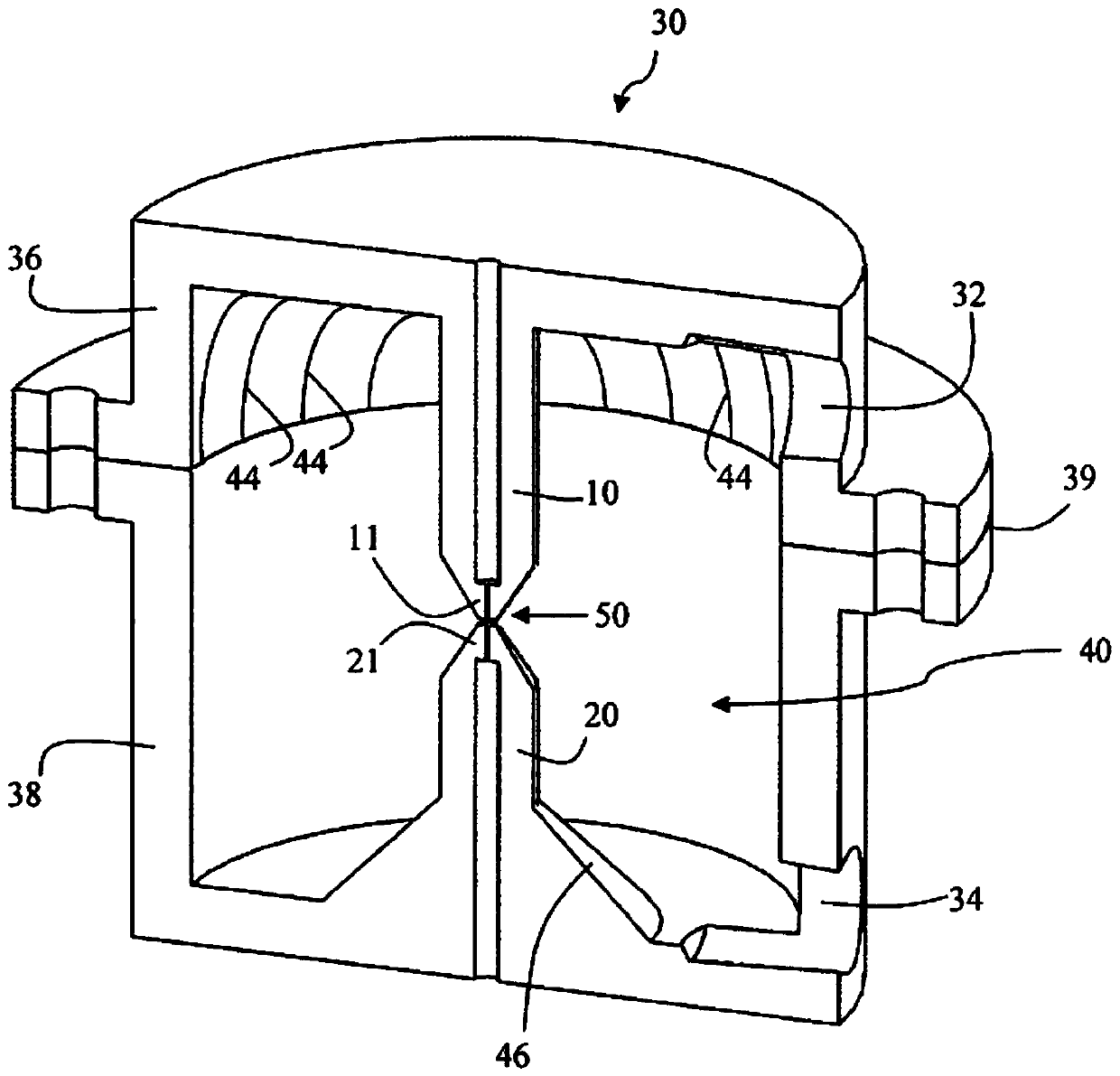

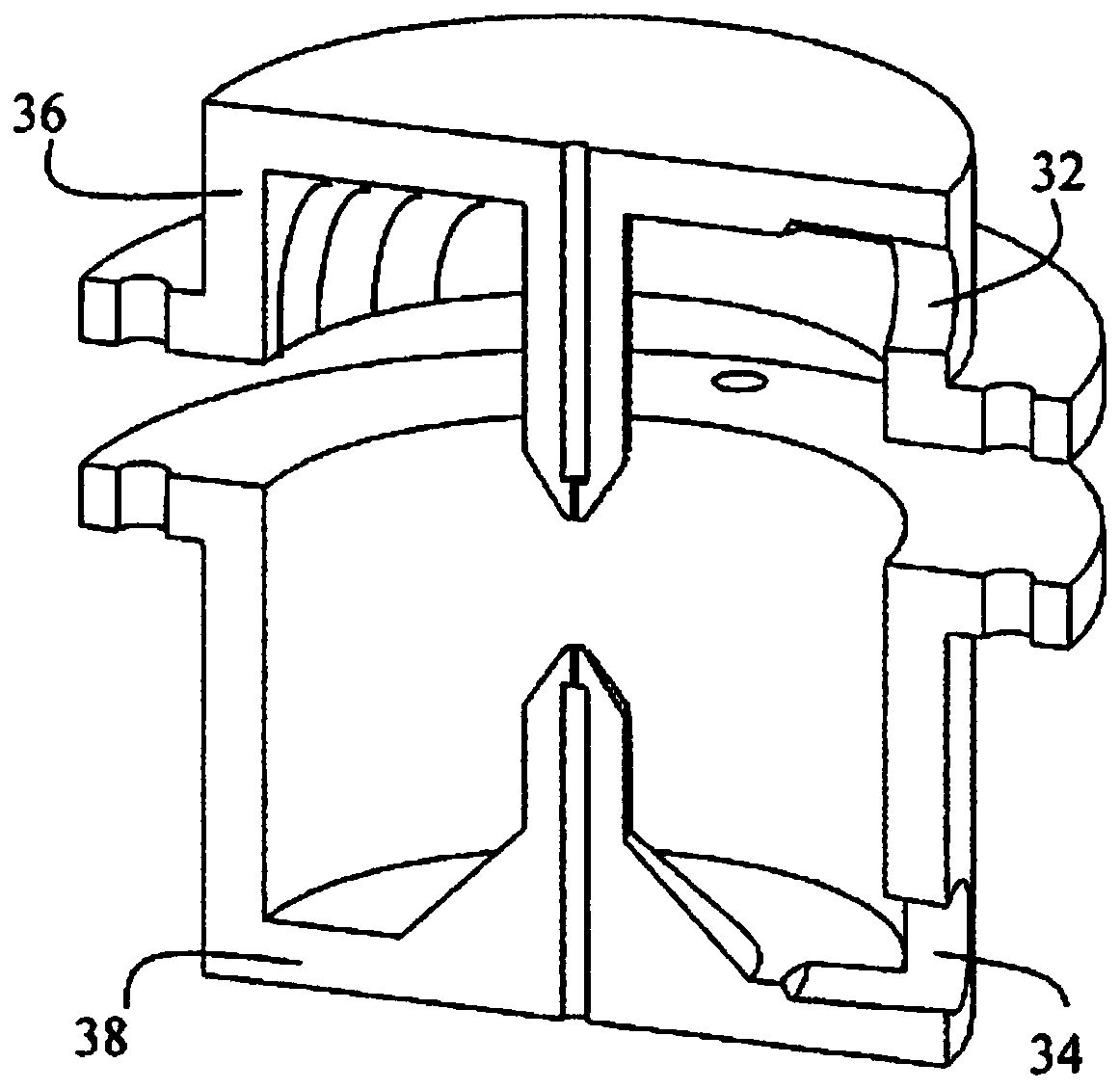

[0015] In the following, specific embodiments of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com