Laser engraving method for jewelry product and laser engraving jig for ringlike jewelries

A laser engraving and jewelry technology, applied in laser welding equipment, manufacturing tools, welding/welding/cutting items, etc., can solve the problems of unsophisticated patterns or patterns, not easy to fix, low output, etc., to improve laser burning speed, Exquisite appearance effect, the effect of improving output

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] In order to fully understand the technical content of the present invention, the technical solutions of the present invention will be further introduced and illustrated below in conjunction with specific examples, but not limited thereto.

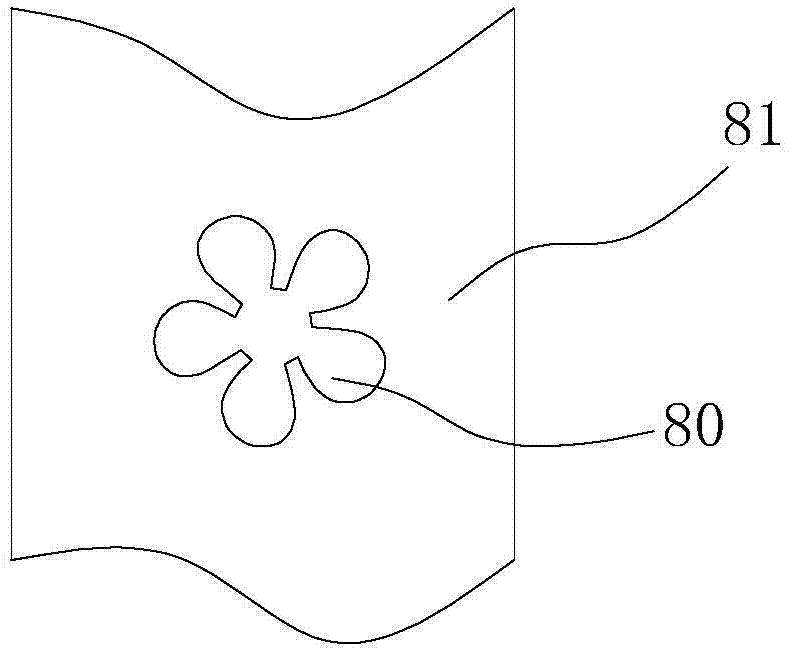

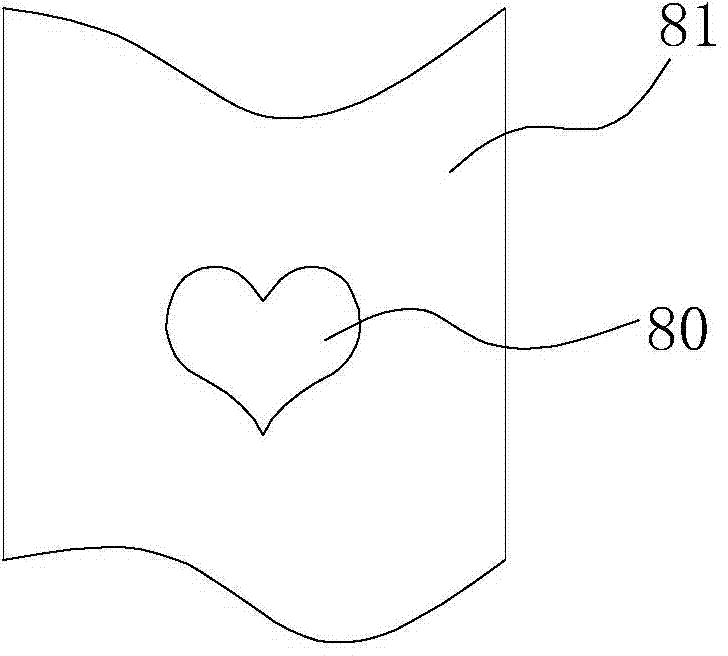

[0039] In the laser engraving method of jewelry products, the surface of jewelry products is first processed into a smooth mirror surface, and then laser burning is used to process the smooth surface according to the preset pattern area. The laser burning depth is 0.02-0.03mm ; The number of burns is at least 2 times. Among them, jewelry products are preferably platinum jewelry, because the smooth surface of platinum jewelry is bright in color, which can form a sharp contrast with the dark color of the burnt facet. In other embodiments, it can also be used in jewelry products such as gold.

[0040] When the engraved surface of the jewelry product is flat, the number of laser engravings shall be at least 4 times, including at least e...

PUM

| Property | Measurement | Unit |

|---|---|---|

| depth | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com