A wet steam generator water-gas mixed sand filter backwashing system

A technology of wet steam generator and water-air mixing, which is applied in the direction of gravity filter, loose filter material filter, filter separation, etc., which can solve the problem that the intake pipe is easy to block, cannot move and discharge at multiple angles, and cannot carry out stirring and dredging. Gas and other problems to achieve the effect of improving efficiency and easy handling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

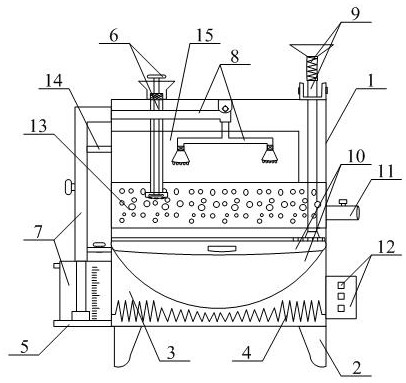

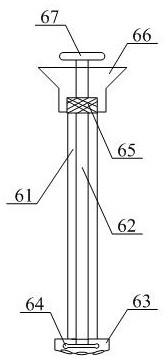

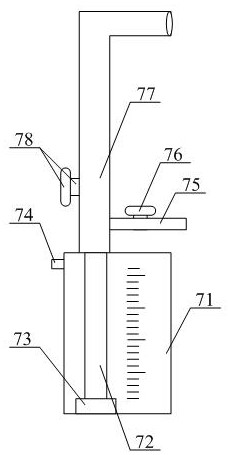

[0052] as attached figure 1 to attach Figure 6 shown

[0053] The invention provides a wet steam generator water-air mixed sand filter backwash system, which includes a wet steam generating box 1, supporting legs 2, a heating chamber 3, a heating wire 4, a supporting plate 5, a stirring gas entering pipe device 6, and a reverse Flush storage tank device 7, backwash nozzle structure 8, movable wet steam nozzle device 9, waste sand collection bucket structure 10, flushing water discharge pipe 11, control cabinet 12, sand filter layer 13, reinforcement rod 14 and backwash The warehouse 15, the supporting legs 2 are respectively bolted to the four corners of the lower surface of the wet steam generating box 1; the heating warehouse 3 is integrally arranged at the inner lower side of the wet steam generating box 1; 4. Horizontal screws are connected to the inner side of the heating chamber 3; the support plate 5 is transversely welded on the lower left side of the wet steam gene...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com