High-voltage bushing flange spinning device and spinning method

A high-pressure sleeve and flange technology, applied in the field of spinning forming equipment, can solve the problems of long cycle and cumbersome process, and achieve the effect of convenient operation, fast and simple process, and easy to place and take out.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

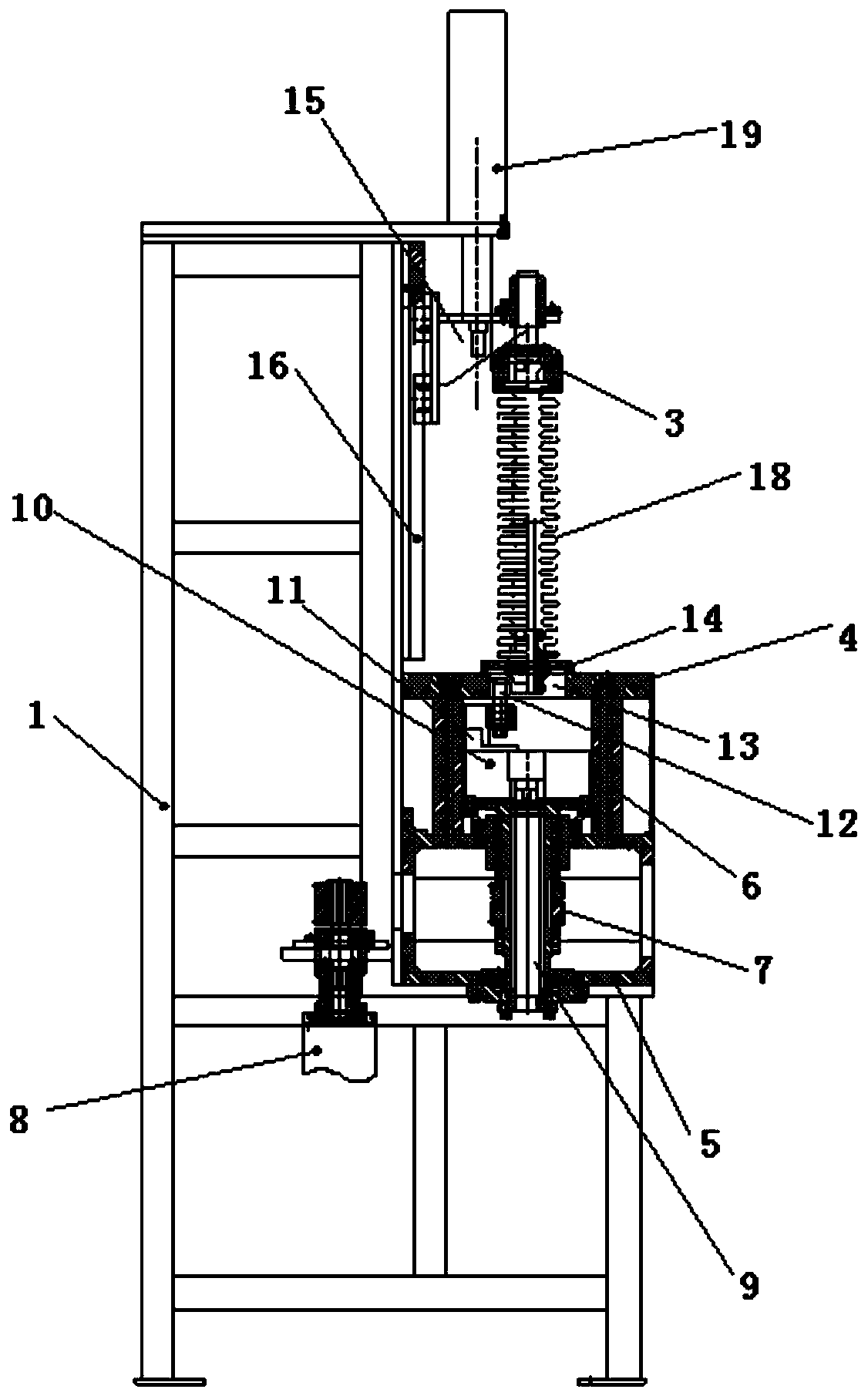

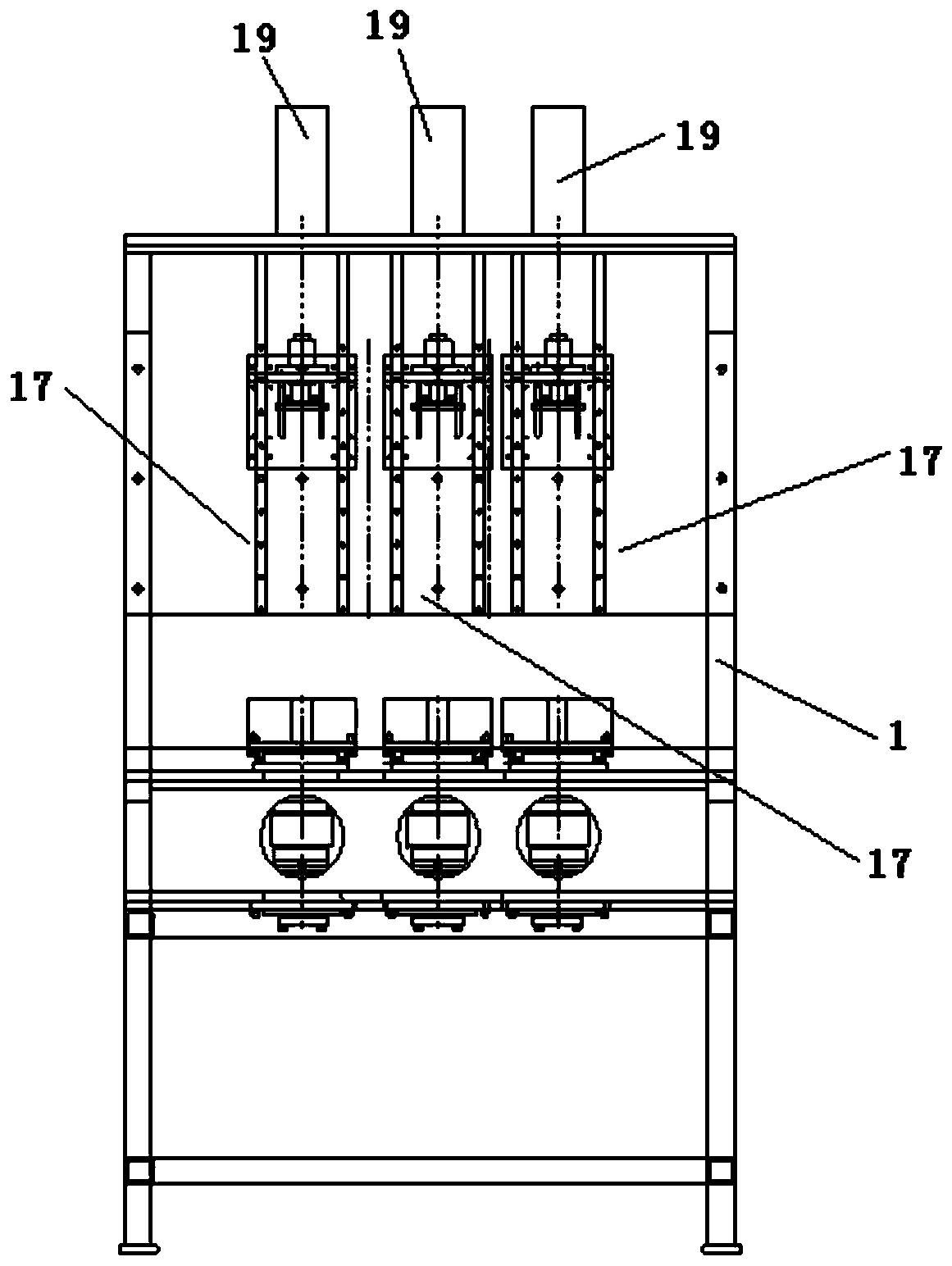

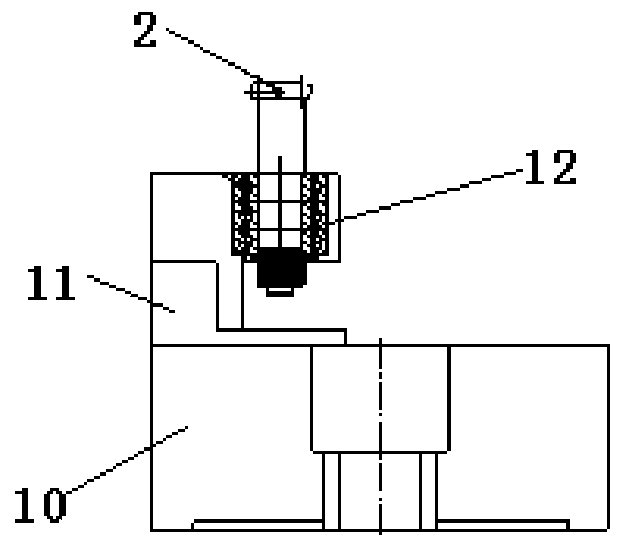

[0036] like figure 1 and figure 2 , a high-voltage bushing flange spinning device, including a frame 1 and three sets of spinning mechanisms 17 arranged on the frame 1, and the three sets of spinning mechanisms are arranged side by side. The spinning mechanism 17 includes a cylinder 19 installed on the frame 1; the cylinder 19 drives the top assembly 3 to move up and down, the top assembly 3 is installed on the sliding bracket 15, and the sliding bracket 15 cooperates with the slide rail 16 fixed on the frame 1 , The sliding bracket 15 is installed on the output end of the cylinder 19 . A panel 4 is provided below the top assembly 3 , a spindle box 5 is provided below the panel 4 , and the panel 4 is connected to the spindle box 5 through a column 6 . A through hole 13 is opened on the panel 4, and a hollow positioning bracket 14 is erected above the through hole 13, and the center of the through hole 13 and the center of the tip assembly 3 are located on the same straight ...

Embodiment 2

[0038] A high-voltage bushing flange spinning device includes a frame 1 and a group of spinning mechanisms 17 arranged on the frame 1 , and the spinning mechanism 17 is located in the middle of the frame 1 . The spinning mechanism 17 includes a cylinder 19 installed on the frame 1; the cylinder 19 drives the top assembly 3 to move up and down, the top assembly 3 is installed on the sliding bracket 15, and the sliding bracket 15 cooperates with the slide rail 16 fixed on the frame 1 , The sliding bracket 15 is installed on the output end of the cylinder 19 . A panel 4 is provided below the top assembly 3 , a spindle box 5 is provided below the panel 4 , and the panel 4 is connected to the spindle box 5 through a column 6 . A through hole 13 is opened on the panel 4, and a hollow positioning bracket 14 is erected above the through hole 13, and the center of the through hole 13 and the center of the tip assembly 3 are located on the same straight line. The bottom of frame 1 is p...

Embodiment 3

[0040]A high-voltage bushing flange spinning device includes a frame 1 and two sets of spinning mechanisms 17 arranged on the frame 1 , and the spinning mechanisms 17 are located in the middle of the frame 1 . The spinning mechanism 17 includes a cylinder 19 installed on the frame 1; the cylinder 19 drives the top assembly 3 to move up and down, the top assembly 3 is installed on the sliding bracket 15, and the sliding bracket 15 cooperates with the slide rail 16 fixed on the frame 1 , The sliding bracket 15 is installed on the output end of the cylinder 19 . A panel 4 is provided below the top assembly 3 , a spindle box 5 is provided below the panel 4 , and the panel 4 is connected to the spindle box 5 through a column 6 . A through hole 13 is opened on the panel 4, and a hollow positioning bracket 14 is erected above the through hole 13, and the center of the through hole 13 and the center of the tip assembly 3 are located on the same straight line. The bottom of frame 1 is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com