Feeding unit

一种进给装置、进给的技术,应用在传动装置、摩擦传动装置、皮带/链条/齿轮等方向,能够解决未公开等问题,达到前进和倒退准确、倒退方向正确、定位精度高的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

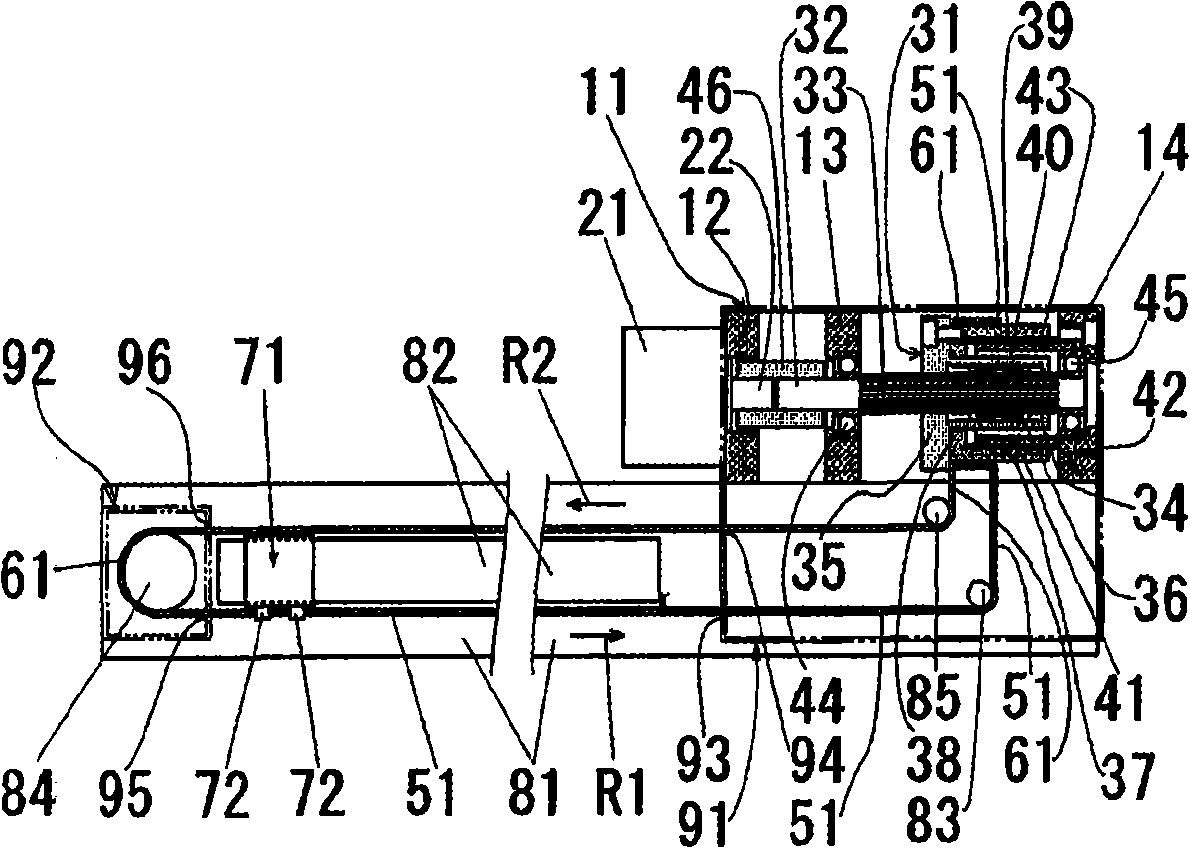

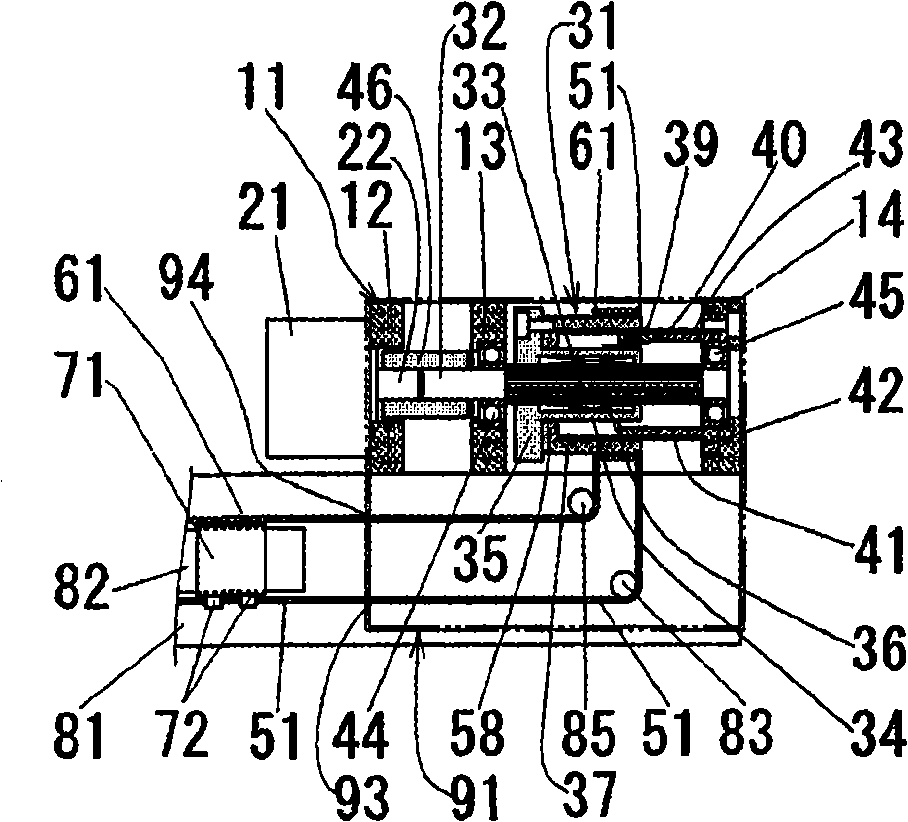

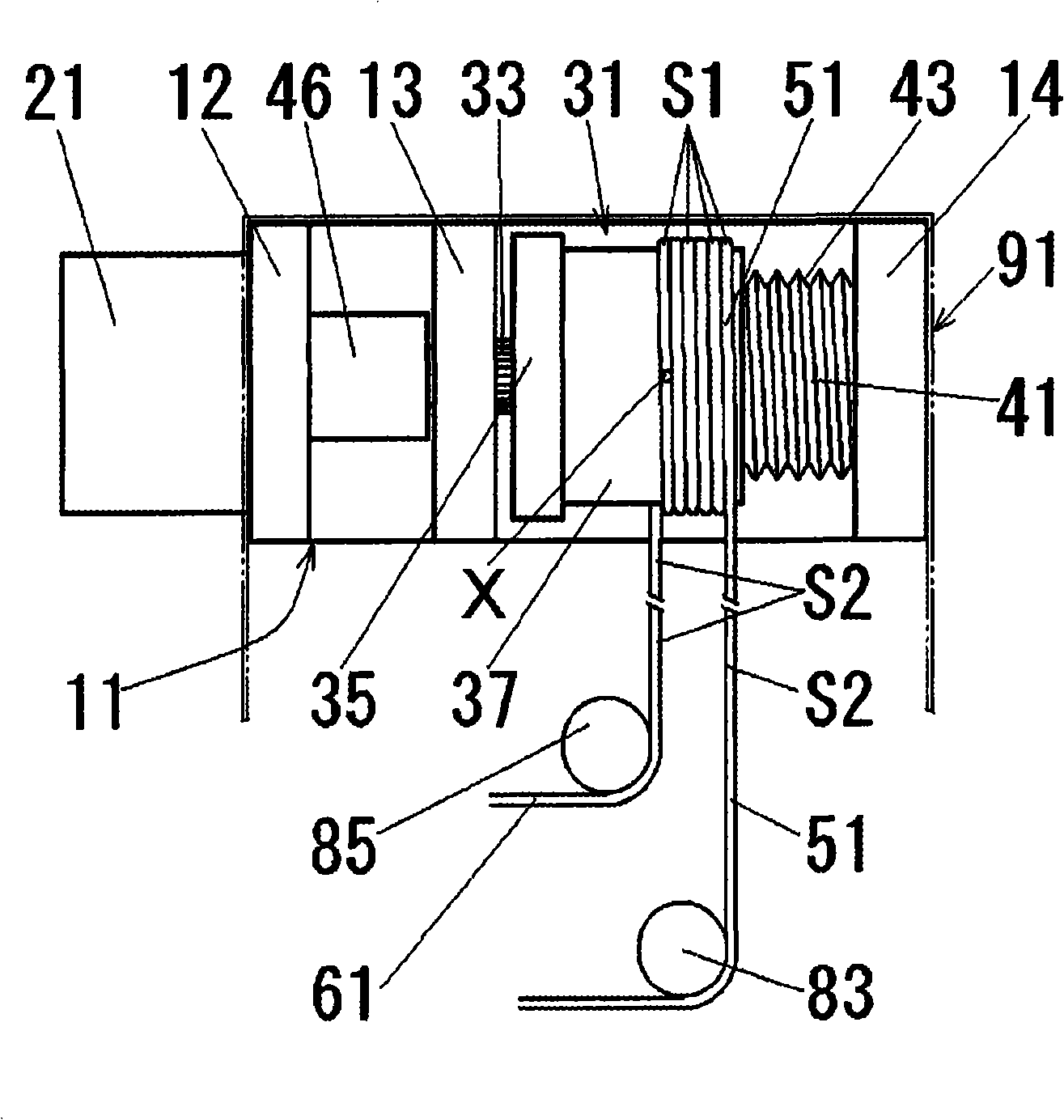

[0048] Several embodiments of the feeding device of the present invention will be described with reference to the drawings. exist Figure 1 ~ Figure 3 The feeding device of the first embodiment is shown in , and the feeding device is composed of a mounting table 11, a prime mover 21, and a front and back winder 31. body 51 and the linear body 61 for rewinding. In addition, reference numeral 71 denotes a reciprocating body, 81 denotes a base, 82 denotes a guide mechanism, and 83 to 85 denote pulleys.

[0049] The mount 11 is made of a material having excellent mechanical properties such as metal, synthetic resin, or composite material, and has a plurality of support walls 12 to 14 standing from the upper surface thereof.

[0050] The prime mover (motor) 21 is constituted by a known or well-known servo motor or pulse motor. The prime mover 21 has an output shaft 22 that rotates integrally with the motor rotor.

[0051] The forward and reverse winder 31 winds or unwinds the l...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com