Concrete prefabricated box girder rapid hoisting appliance

A technology for concrete and box girders, applied in the direction of load hanging components, transportation and packaging, etc., can solve problems such as small contact area, broken strands of steel wire ropes, and potential safety hazards

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] In order to make the purpose, technical solutions and advantages of the embodiments of the present invention more clear, the technical solutions in the embodiments will be clearly and completely described below in conjunction with the drawings in the embodiments of the present invention. The following embodiments are used to illustrate the present invention , but not to limit the scope of the present invention.

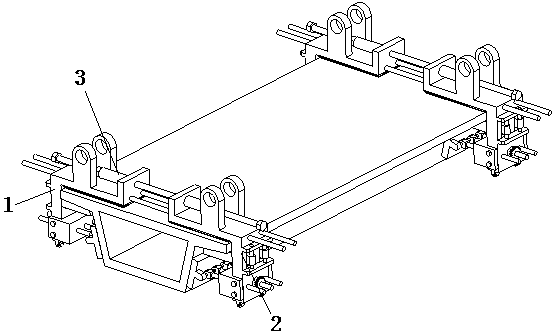

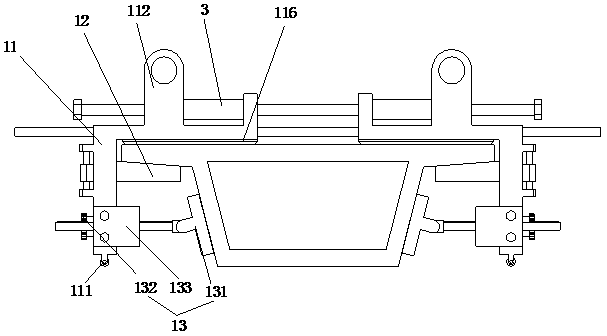

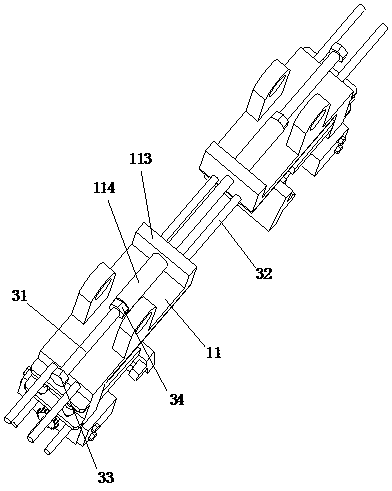

[0026] Such as Figure 1 to Figure 6 As shown, a kind of concrete prefabricated box girder rapid lifting spreader of the present invention comprises left hoisting device 1 and right hoisting device 2, and described left hoisting device 1 and right hoisting device 2 are provided with the adjustment of the distance between the two Device 3, the left lifting device 1 and the right lifting device 2 have the same structure and both include an L-shaped bracket 11, a first positioning mechanism 12 and a second positioning mechanism 13, and the first positioning mechan...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com