Auxiliary bearing system suitable for magnetic levitation bearing-rotor system

A technology of magnetic suspension bearings and auxiliary bearings, which is applied to bearings, shafts, bearings, mechanical equipment, etc., can solve problems such as damage to the rotor system, small damping of auxiliary bearings, and serious consequences of falling, so as to avoid long-term beating and reduce impact loads. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be further explained below in conjunction with accompanying drawing

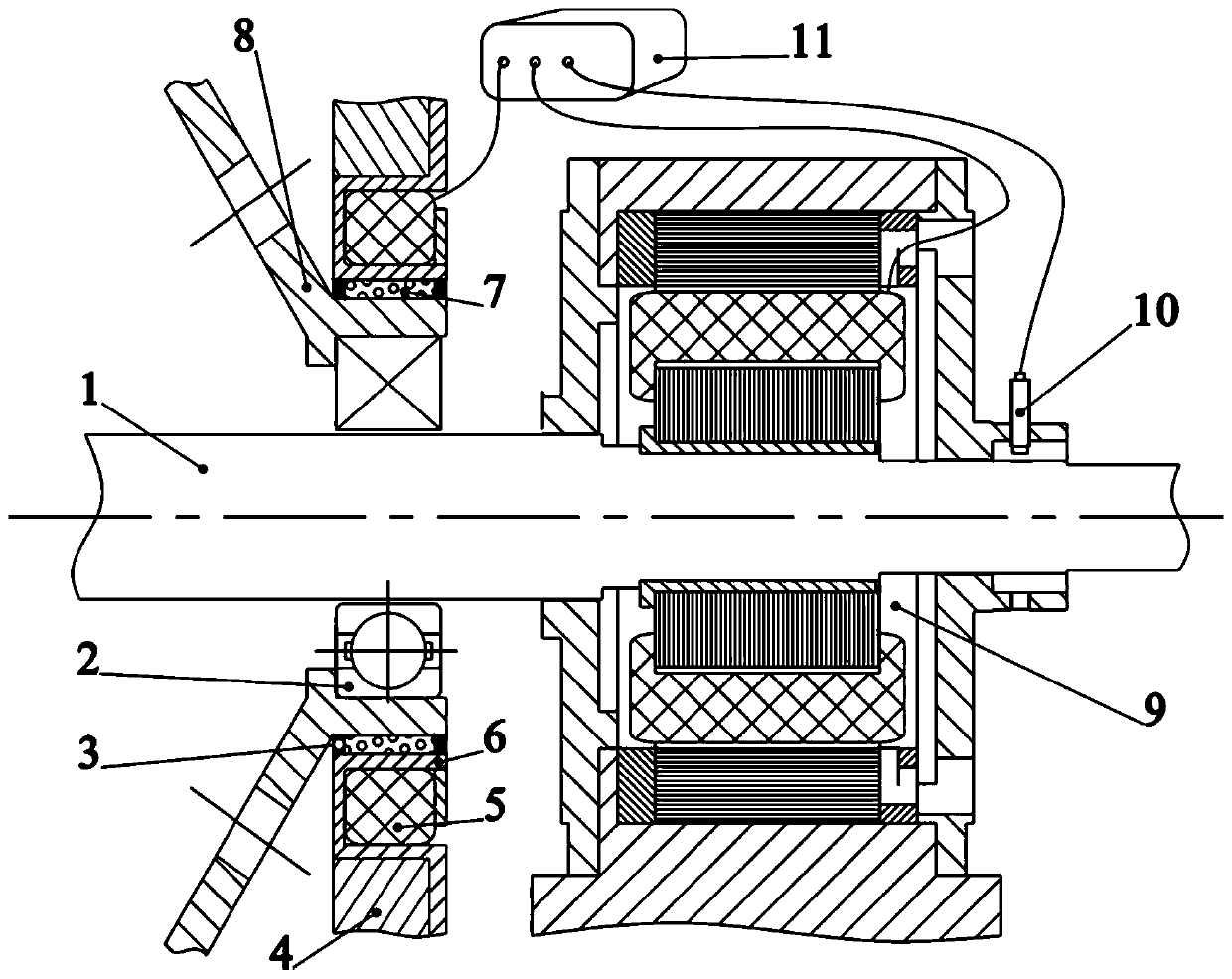

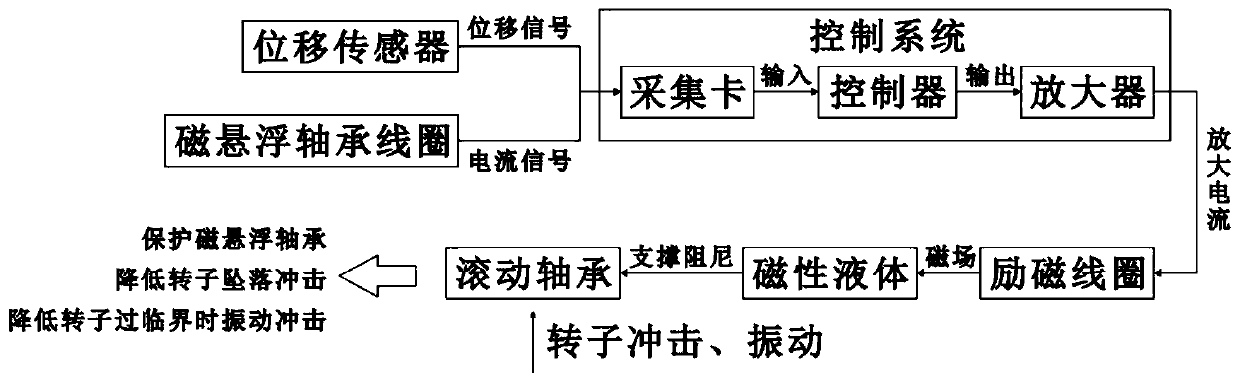

[0023] Such as figure 1 As shown, it is a structural schematic diagram of the auxiliary bearing system provided by the present invention, the system includes a rolling bearing (2), an elastic support (8) for supporting the rolling bearing, a controllable oil film (7) formed by a magnetic liquid, an excitation coil (5 ), the coil holder (6) made of non-magnetic material and fixed coil, the elastic seal (3) and the control device (11); the rolling bearing (2) is installed on the elastic support (8), and the inner ring of the bearing directly bears the rotor The impact of falling, and support the rotor to rotate after the rotor falls; the excitation coil (5) is wound on the coil frame (6), and the gap between the coil frame (6) and the elastic support (8) is filled with magnetic liquid to form a Control the oil film (7), and the two ends of the oil film are sealed by elastic s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com