Automatic loading method and device

An automatic, car technology, applied in the direction of electrical program control, program control in sequence/logic controller, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

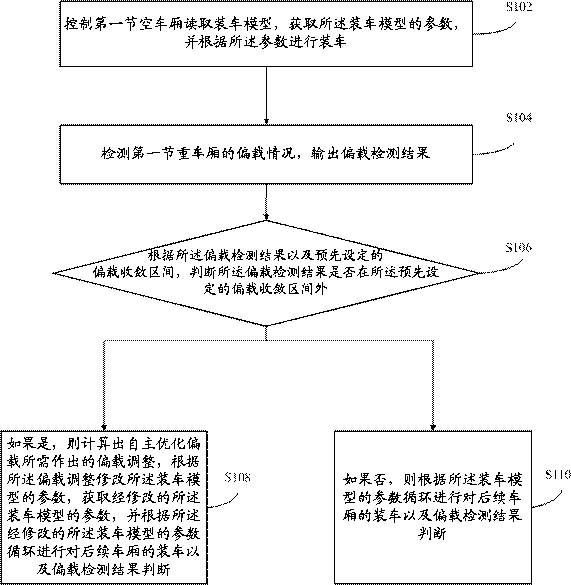

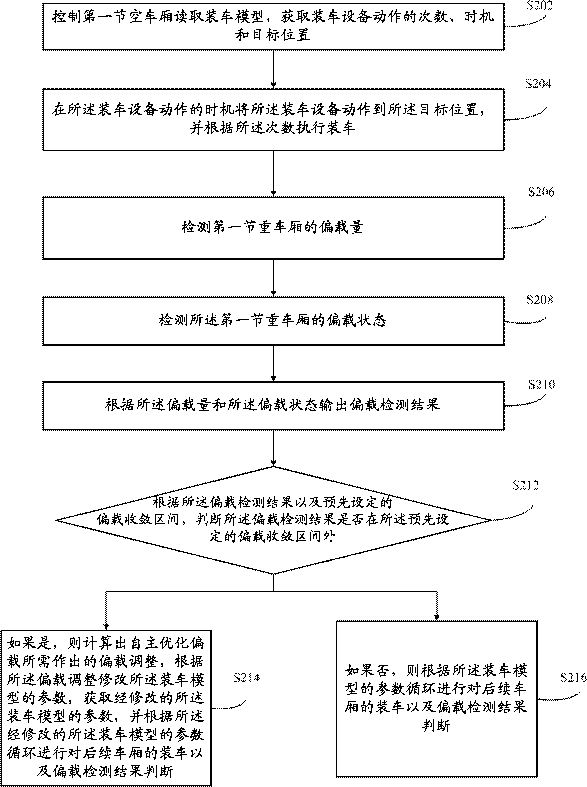

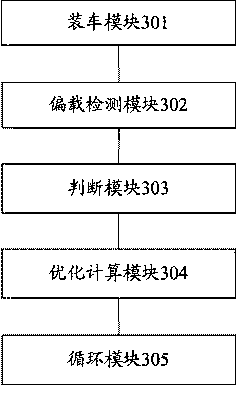

Method used

Image

Examples

example

[0074] 1), loading equipment: telescopic loading chute

[0075] 2) Loading model: see Table 1 for a sample table.

[0076] Table 1 Loading model (sample form)

[0077] frequency 1 2 3 4 5 Timing of device action 180 219 237 250 173 The target position of the device action 2396 3209 2980 2769 2396

[0078] The timing of the device action: the position where the car travels

[0079] The target position of the equipment action: the height of the loading chute from the rail surface

[0080] 3), automatic loading control

[0081] According to the loading model, the automatic loading control module controls the telescopic loading chute to reach the position of 2396 when the carriage reaches the position of 180; then, when the carriage reaches the position of 219, controls the telescopic loading chute to reach the position of 3209; according to this method, it is executed sequentially After the actions set in the loading model, the automatic...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com