Rotor and motor

A rotor and permanent magnet technology, applied in the field of rotors and motors, can solve the problems of permanent magnet magnetization process influence, easy deviation, high precision, etc., achieve the effect of optimizing the pole arc coefficient, simplifying the magnetization process, and improving the magnetization structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] In order to facilitate the understanding of the present invention, the present invention will be described more fully below with reference to the associated drawings. Preferred embodiments of the invention are shown in the accompanying drawings. However, the present invention can be embodied in many different forms and is not limited to the embodiments described herein.

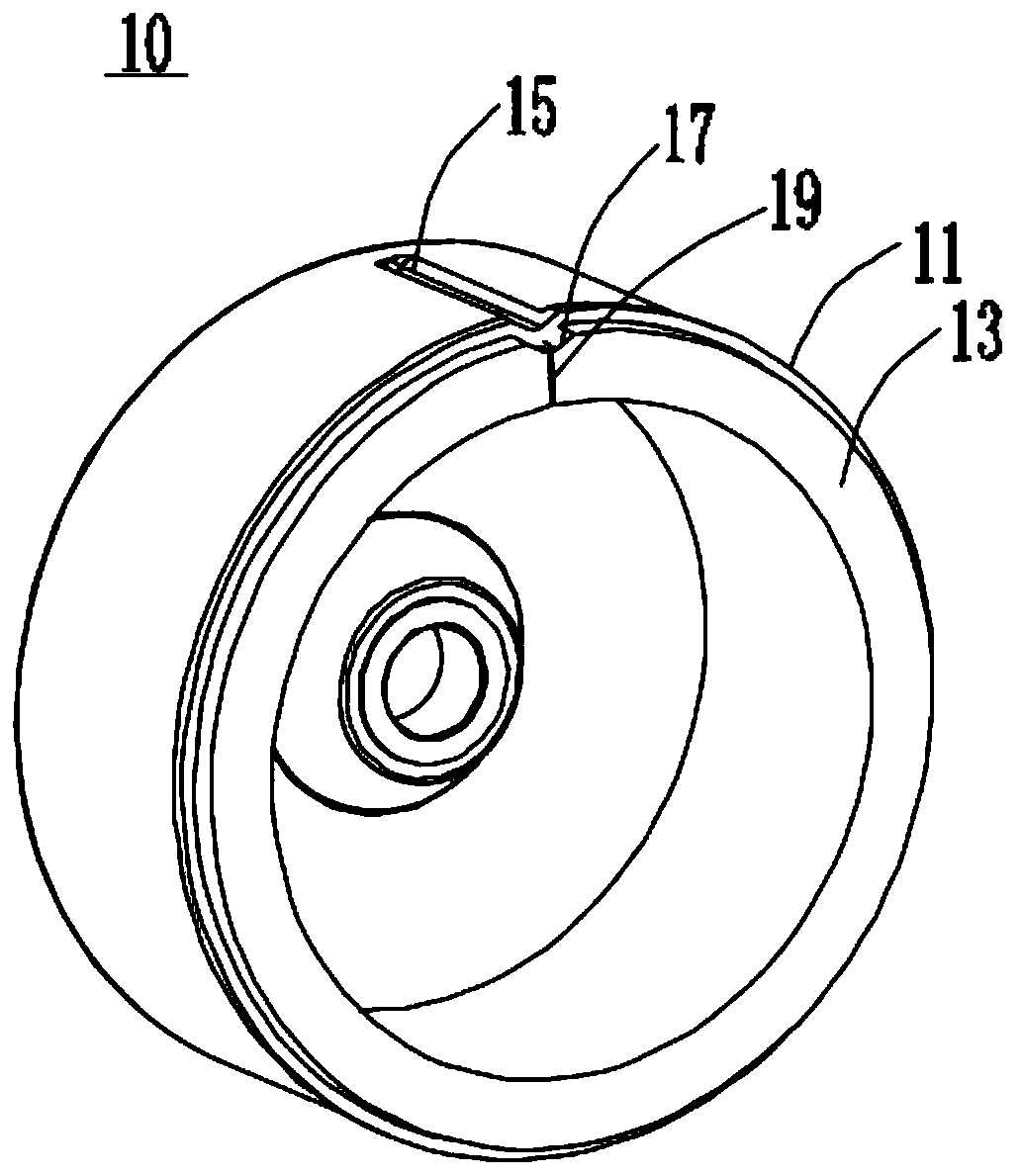

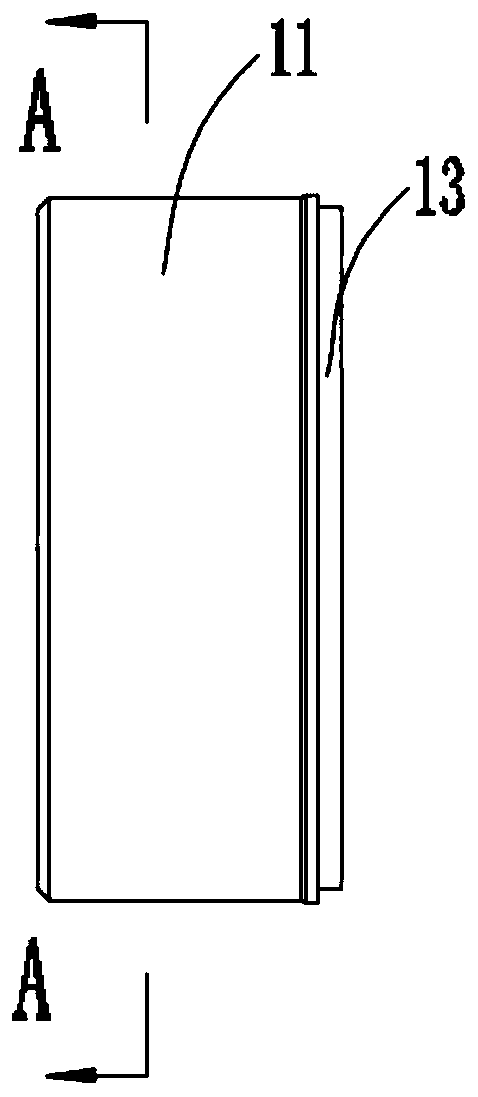

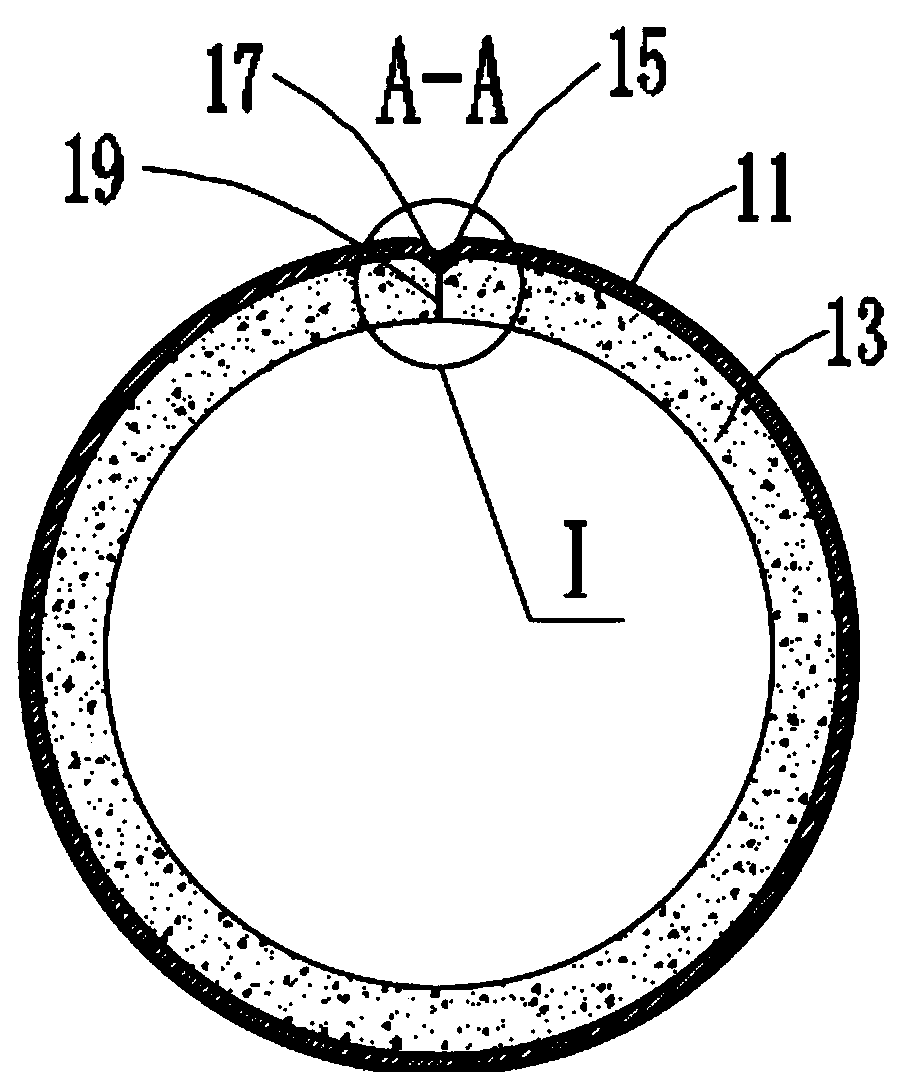

[0036] Such as Figure 1-6 As shown, a rotor 10 includes a rotor casing 11 and a permanent magnet 13 sleeved inside the rotor casing 11. The rotor casing 11 is provided with a concave portion 15 that is concave toward its center, and the permanent magnet 13 is provided with a concave portion that is concave toward its center. The groove 17, the concave part 15 is matched with the groove 17.

[0037] Wherein, the permanent magnet 13 is provided with a splicing seam 19, and the splicing seam 19 is located at the groove 17. When the recessed part 15 cooperates with the groove 17, the deviation angle of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com