Brushless direct current motor

A brushed DC motor and linear segment technology, applied in the field of brushless DC motors, can solve the problems of high motor assembly process and cost, high magnetic steel processing technology cost, increased material cost, etc., and achieve low overall cost and processing material utilization rate. High, low vibration effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be further described in detail below with reference to the embodiments of the accompanying drawings.

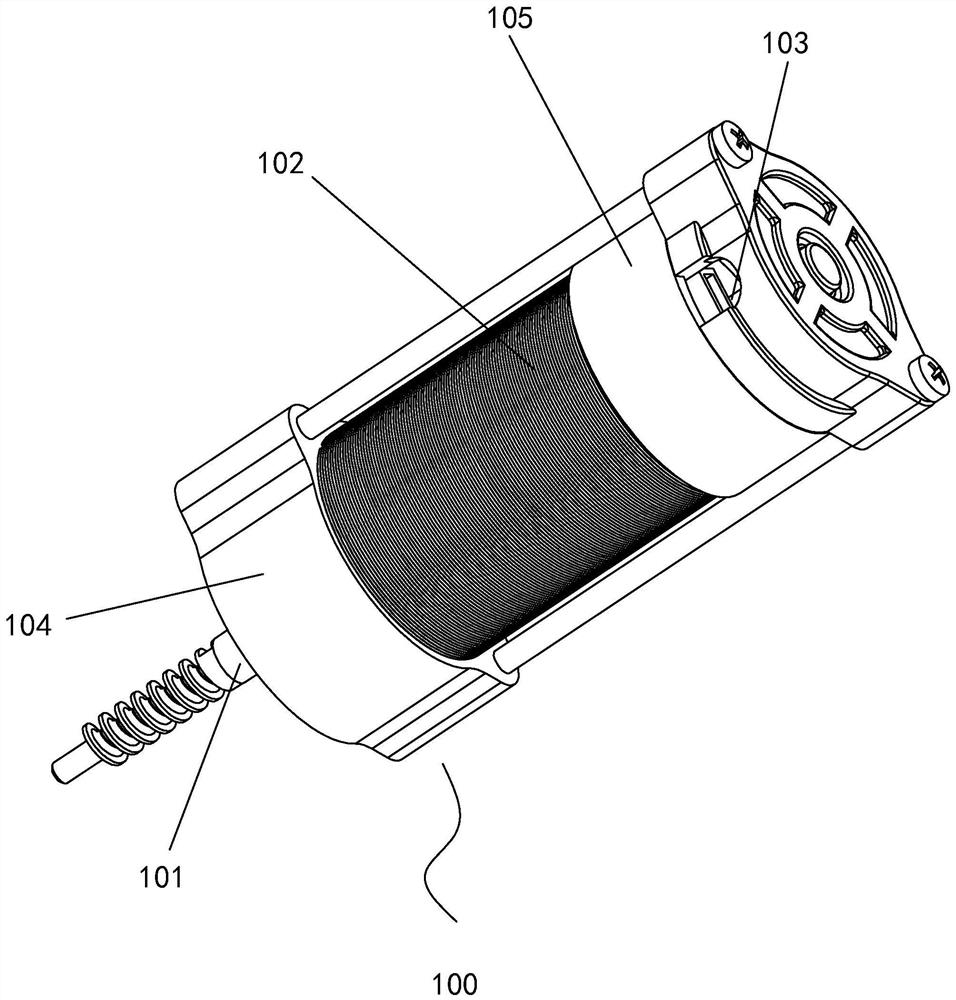

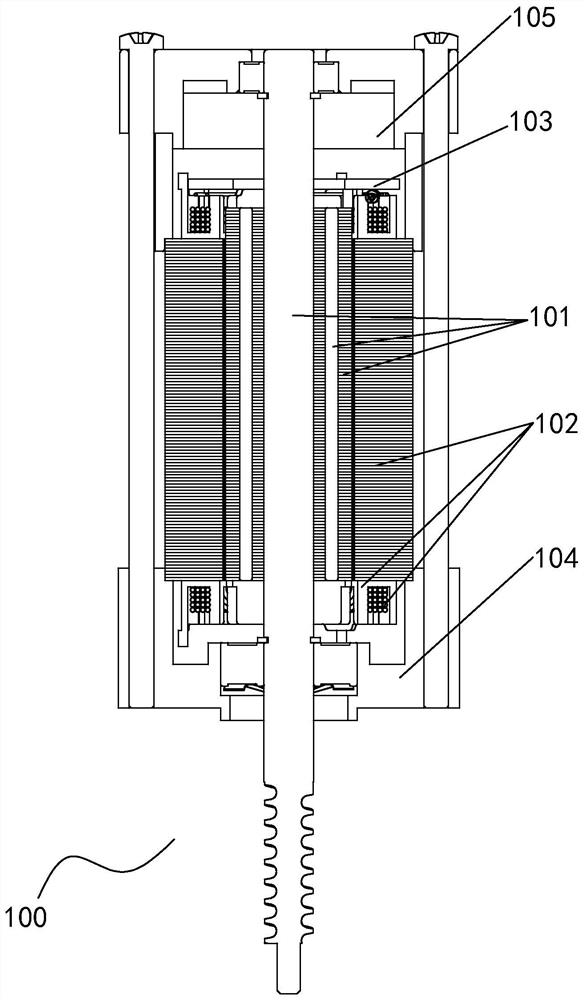

[0027] This example is figure 1 and 2 Shown is a brushless DC motor 100 , including a rotor 101 , a stator 102 , a Hall assembly 103 , a front end cover 104 and a rear end cover 105 . The rotor 101 includes a plurality of rotor punches 1, a rotating shaft, and a long-strip permanent magnet magnetic steel fixedly installed in the magnetic steel slot 1.1 of the rotor punch 1; the stator 102 includes a plurality of stator punches 2, an insulating frame and an armature winding.

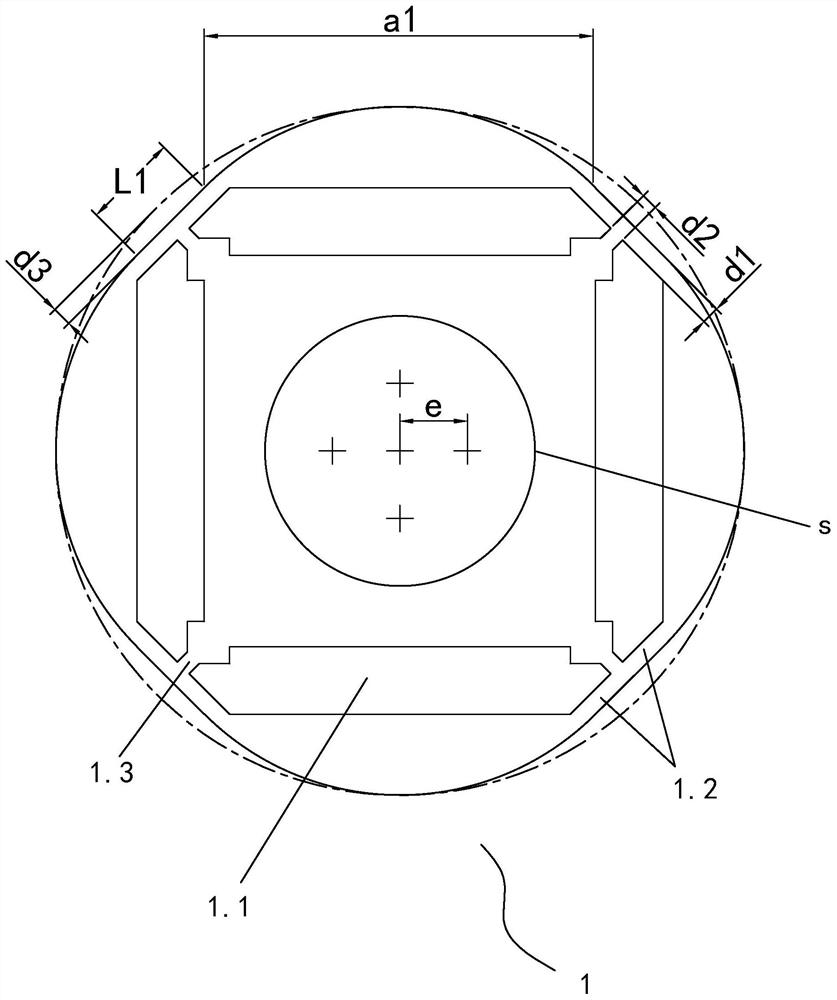

[0028] In this preferred embodiment, the rotor punching piece 1 of the rotor 101 is as image 3 As shown, there are 4 magnetic steel slots 1.1 evenly distributed around the circumference. The outer edge of the magnetic steel slot 1.1 and the magnetic isolation bridge 1.2 is the first straight line segment L1, and the first straight line segments L1 are connected by the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com