A template polishing equipment for electronic equipment appearance spraying

A technology for electronic equipment and appearance, which is applied in the field of template polishing equipment for electronic equipment appearance spraying, which can solve problems such as difficult collection of polishing liquid and inability to integrate template polishing operations, so as to save manual operations, improve recycling capabilities, and improve operation. efficiency effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

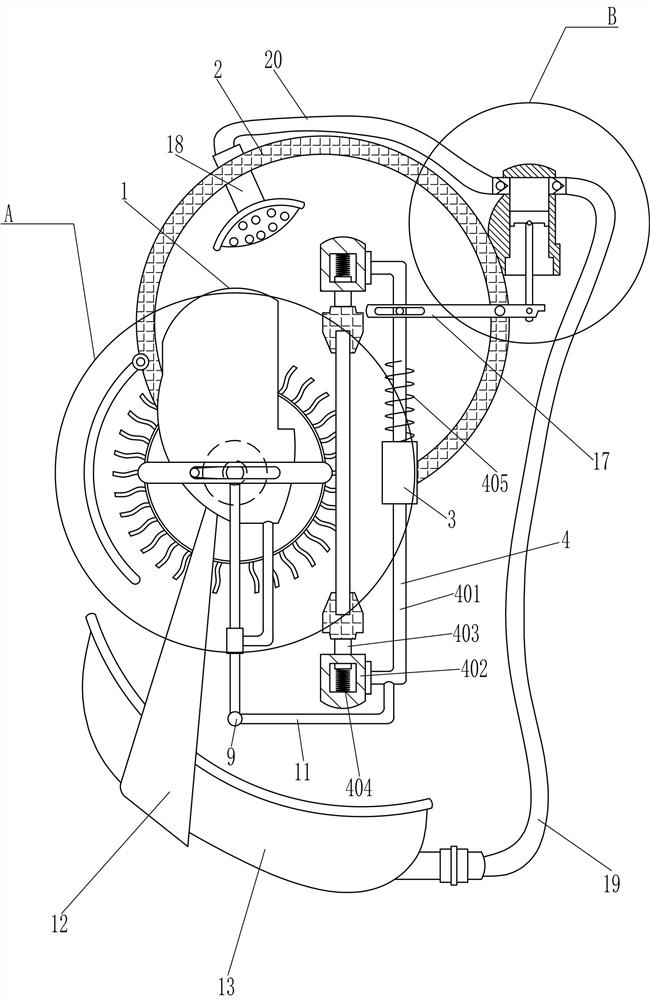

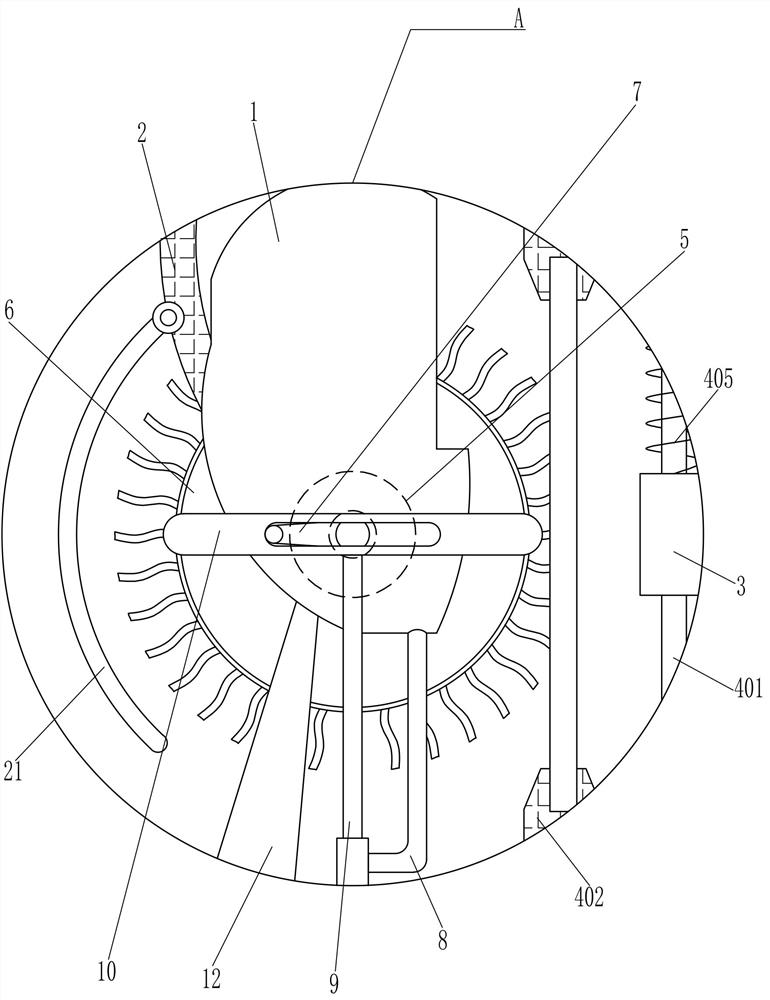

[0019] A template polishing equipment for electronic equipment appearance spraying, such as Figure 1-2 As shown, it includes a mounting plate 1, an arc frame 2, a guide sleeve 3, a clamping device 4, a biaxial motor 5, a brush wheel 6, a push rod 7, a guide frame 8, a T-shaped bar 9, and a first groove bar 10 , connecting rod 11, triangular plate 12 and arc-shaped basin 13, the top of the installation plate 1 is provided with an arc-shaped frame 2, the end of the arc-shaped frame 2 is provided with a guide sleeve 3, and the guide sleeve 3 is provided with a clamping device 4, behind the installation plate 1 There is a biaxial motor 5 on the side, the rear output shaft of the biaxial motor 5 is connected with a brush wheel 6, the front output shaft of the biaxial motor 5 is connected with a push rod 7, the bottom of the mounting plate 1 is provided with a guide frame 8, and the inside of the guide frame 8 Slidingly connected with a T-shaped bar 9, the top of the T-shaped bar 9...

Embodiment 2

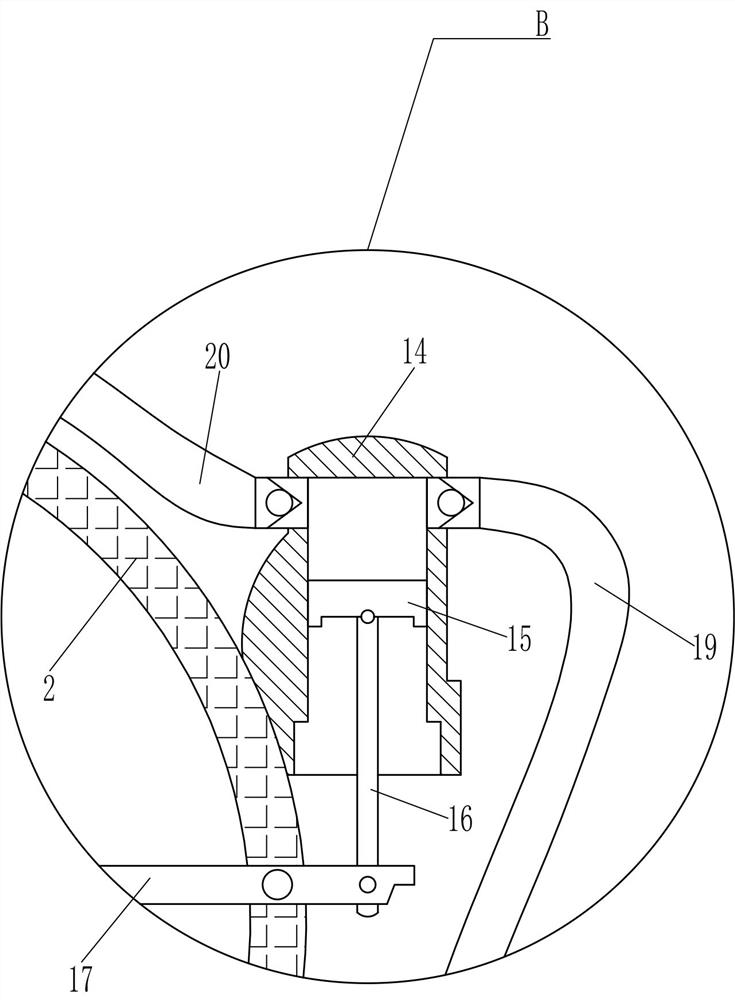

[0023] On the basis of Example 1, such as figure 1 and image 3 Shown, also comprise pump body 14, piston 15, rotating rod 16, the second groove bar 17, spray nozzle 18, liquid inlet pipe 19 and discharge pipe 20, arc frame 2 is provided with pump body 14, pump body 14 The inner sliding type is connected with the piston 15, the bottom of the piston 15 is connected with the rotating rod 16, and the front part of the arc frame 2 is connected with the second groove rod 17 in a rotating type, and one end of the second groove rod 17 is connected with the rotation rod 16 bottom. Connection, the upper part of the guide rod 401 is slidingly matched with the other side of the second groove rod 17, the upper part of the arc frame 2 is provided with a nozzle 18, the nozzle 18 is connected with a drain pipe 20, the drain pipe 20 is connected with the pump body 14, and the pump body The other side of 14 is connected with a liquid inlet pipe 19, and the end of the liquid inlet pipe 19 is c...

Embodiment 3

[0026] On the basis of Example 2, such as figure 2 As shown, an arc-shaped baffle 21 is also included, and one side of the arc-shaped frame 2 is rotatably connected to the arc-shaped baffle 21 .

[0027] Through the arc-shaped baffle 21 , the polishing fluid on the brush wheel 6 can be effectively diverted, thereby achieving the effect of preventing random splashing of the polishing fluid.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com