Product information binding method

A product information and product identification technology, applied in data processing applications, instruments, calculations, etc., can solve problems such as garbled codes and incomplete code reading information, and achieve the effect of avoiding incomplete code reading information or garbled codes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

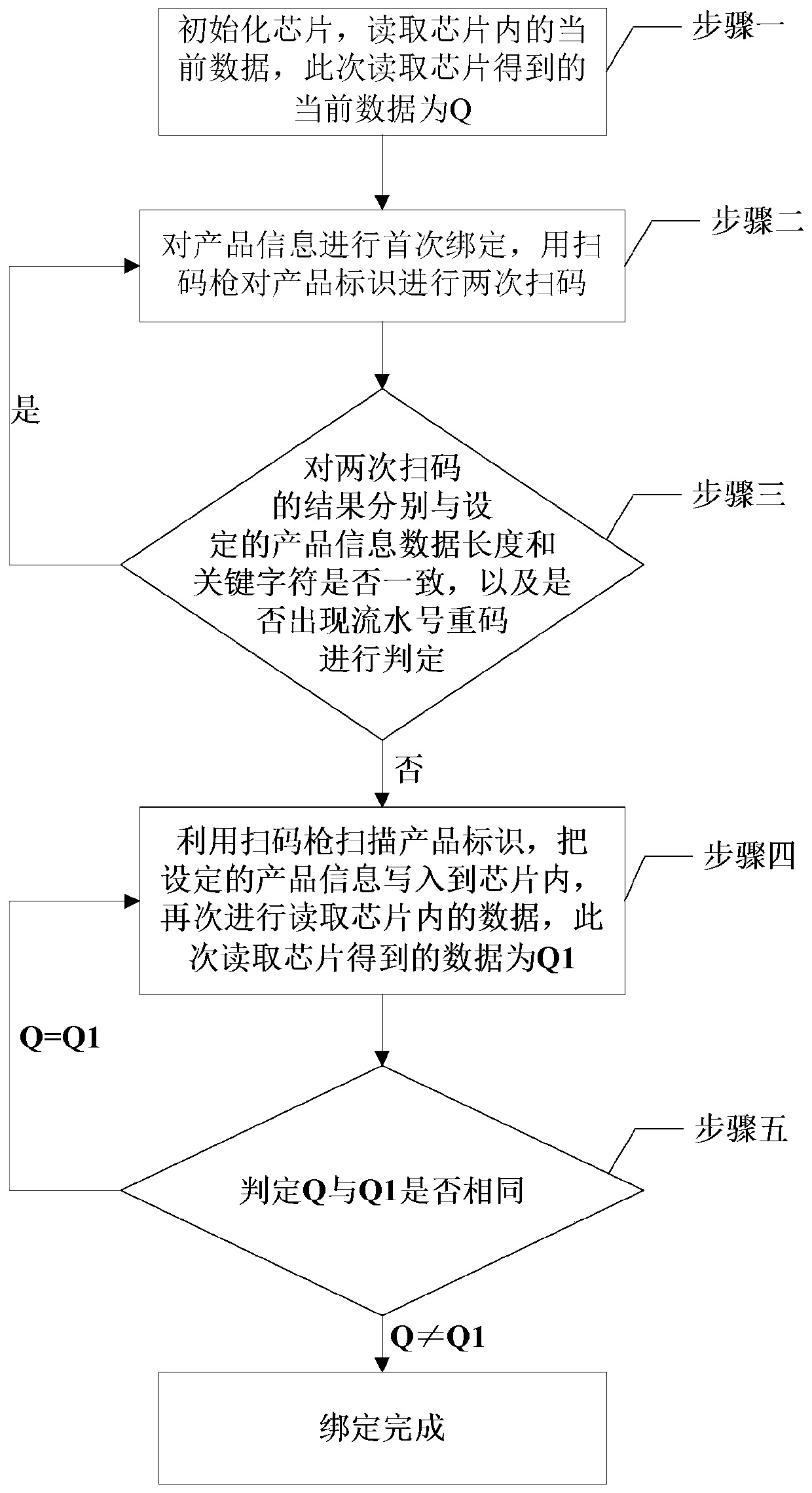

[0013] Specific implementation mode one: combine figure 1 Describe this implementation mode, a product information binding method described in this implementation mode is implemented by a chip:

[0014] Step 1. Initialize the chip and read the current data in the chip. The current data obtained by reading the chip this time is Q; prepare for the subsequent write product information check;

[0015] Step 2. Bind the product information for the first time, and scan the product logo twice with a code scanning gun; in order to achieve the reliability of product information entry, scan the code twice to prevent the personnel from operating too quickly and causing the data to be lost;

[0016] Step 3. Determine whether the results of the two code scans are consistent with the set product information data length and key characters, and whether there is a repeated serial number; if any judgment information does not conform to the set data, return to step 2; otherwise It is considered ...

specific Embodiment approach 2

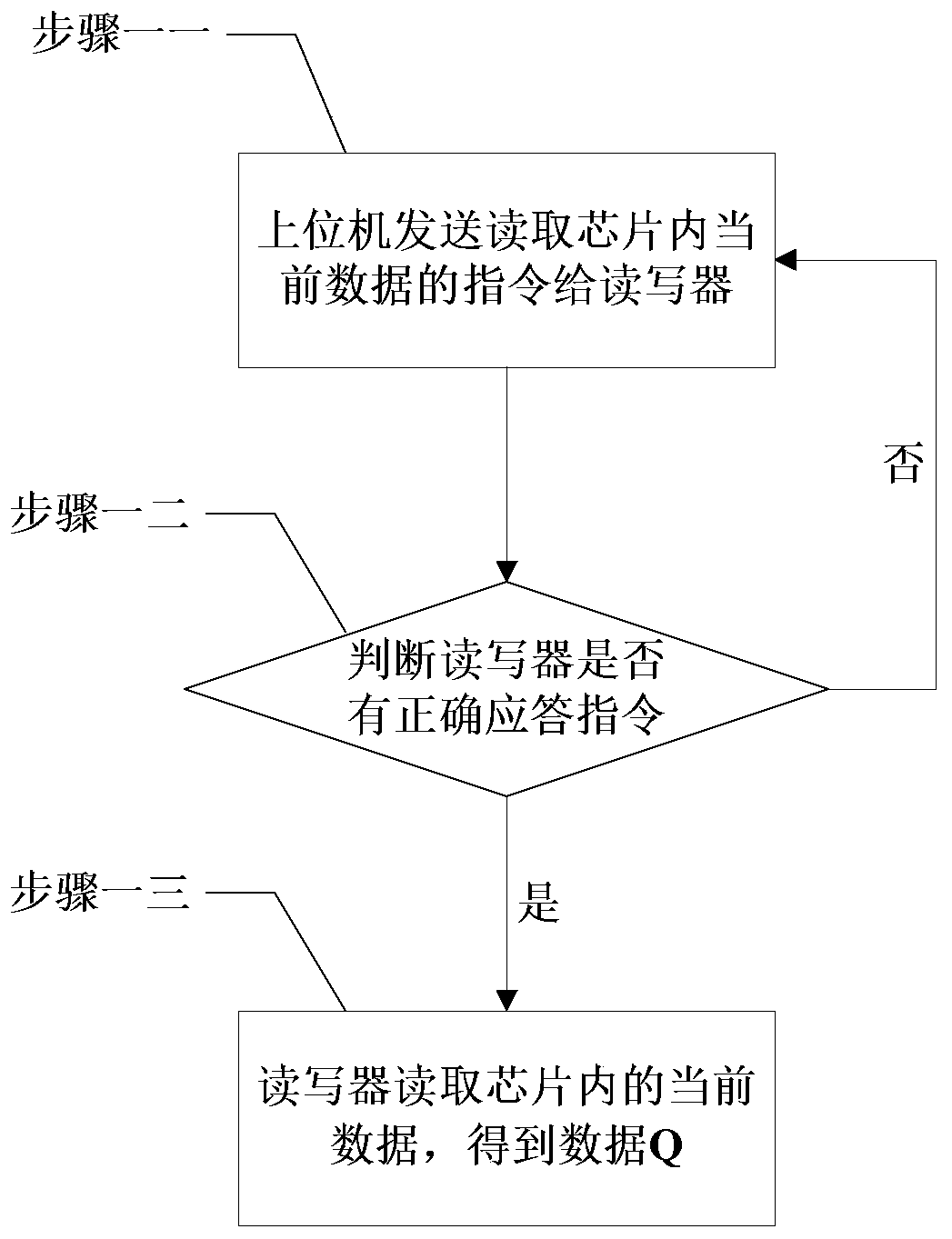

[0020] Specific implementation mode two: combination figure 1 Describe this embodiment. This embodiment is to further limit the product information binding method described in Embodiment 1. In this embodiment, the data in the chip is read before the product information is bound in step 1. The specific steps to read the data in the chip before binding the product information are as follows:

[0021] Step 11, the host computer sends an instruction to read the chip data to the reader;

[0022] Step 12, determine whether the reader has a correct response command; if the reader has a correct response command, then perform step 13; otherwise, perform step 11;

[0023] Step 13: The reader / writer reads the data in the chip to obtain data Q.

[0024] In this embodiment, the response time of the reader is 50ms; the number of times the host computer sends the command to read the chip data to the reader is less than 3 times, otherwise it will prompt that the reading fails, and check whe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com