An easy-to-operate component pin bending device

A bending device and component technology, applied in the field of component pin bending, can solve the problems of unreachable use, cumbersome operation procedures, and different bending degrees, and achieve the effect of consistent curvature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

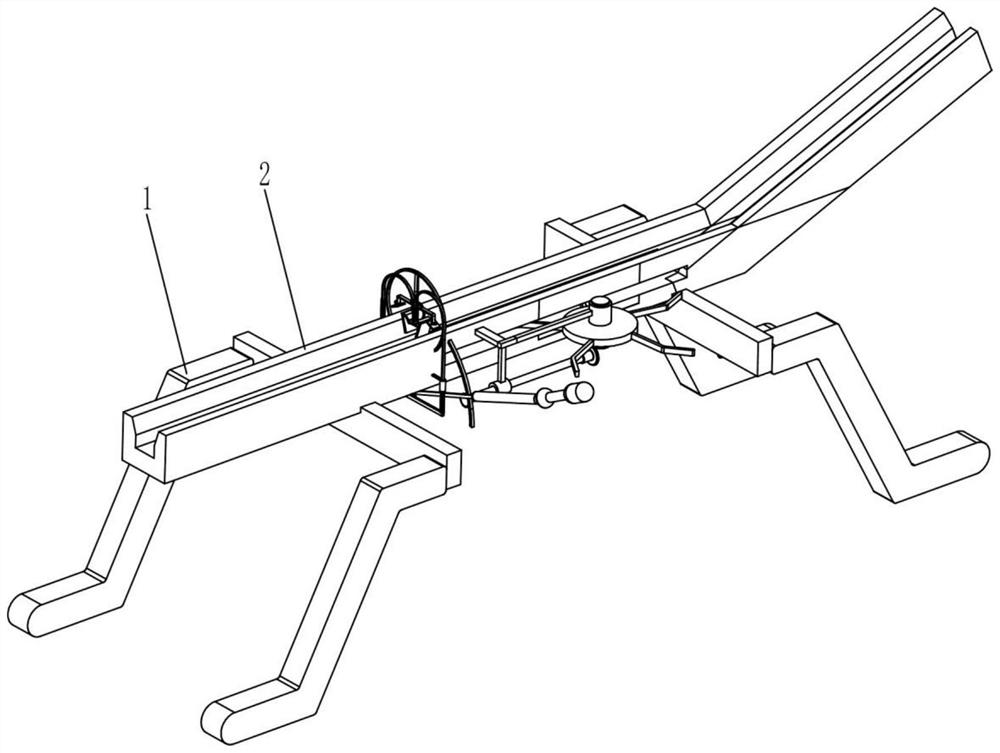

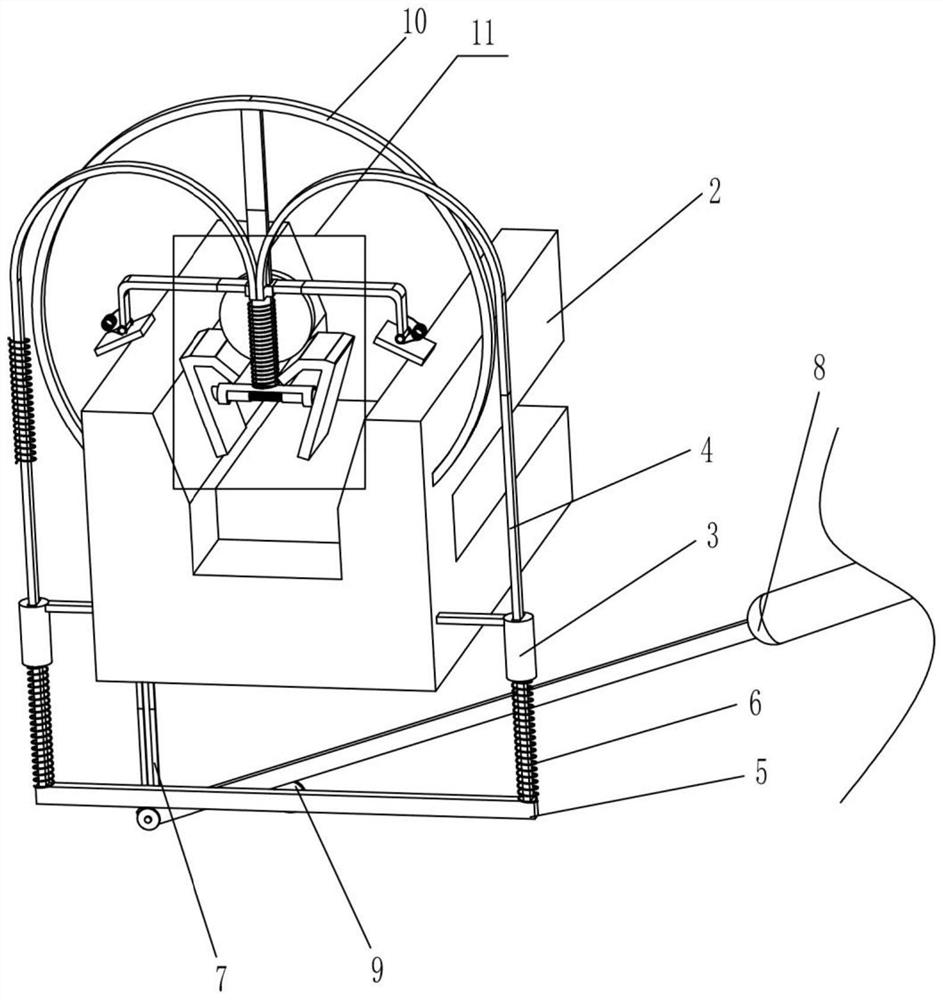

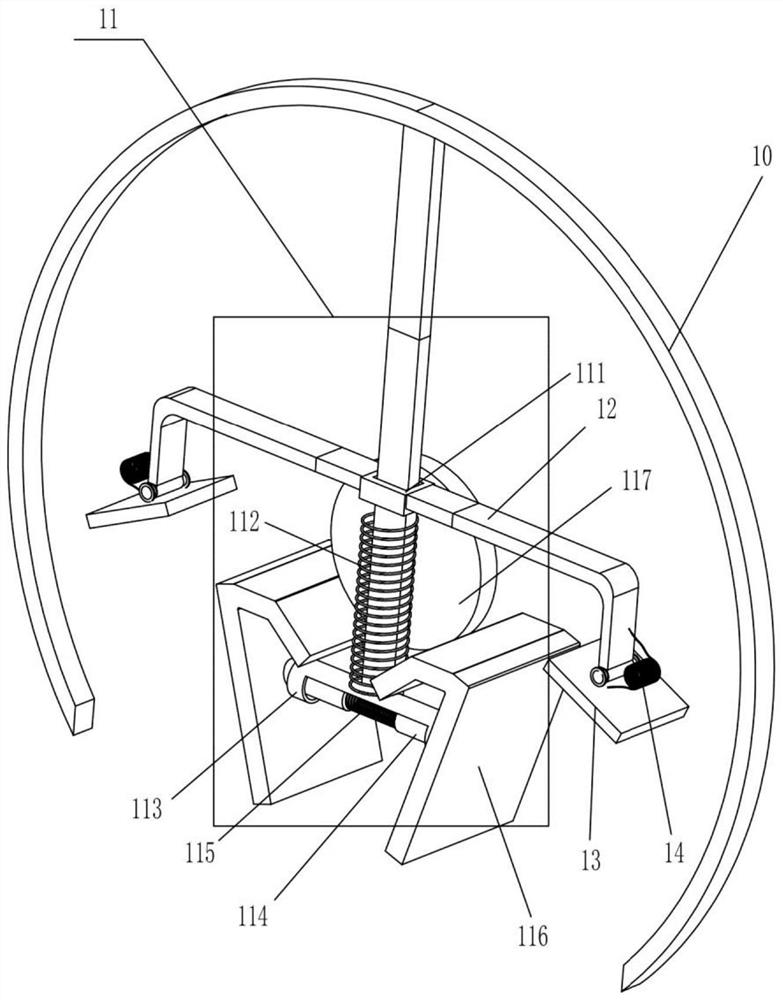

[0019] An easy-to-operate component pin bending device, as shown in 1-3, includes a fixed frame 1, and the upper ends of several fixed frames 1 for supporting functions are fixed by bolts and provided with slide plates 2 for sliding component pins , specifically six fixed frames 1, the outer side of the slide plate 2 is fixedly provided with an arc-shaped support plate 10 and two sliding sleeves 3 are symmetrically installed, and the front side of the arc-shaped support plate 10 is provided with an extruding part 11, The two sliding sleeves 3 are provided with moving rods 4, and the lower ends of the two moving rods 4 are connected by a connecting plate 5, and the upper ends of the two moving rods 4 are fixedly connected and connected with the extruding part 11. A vertical arm 7 is arranged on the outer bottom side of the slide plate 2, and the lower end of the vertical arm 7 is connected to a swing arm 8 through a rotating column. The roller 9 in contact with the bottom side,...

Embodiment 2

[0021] An easy-to-operate component pin bending device, as shown in 1-4, includes a fixed frame 1, and the upper ends of several fixed frames 1 for supporting functions are fixed by bolts and provided with slide plates for component pins to slide 2. Specifically, there are four fixed frames 1. The outer surface of the slide plate 2 is fixedly equipped with an arc-shaped support plate 10 and two sliding sleeves 3 for guiding functions are symmetrically installed. The front side of the arc-shaped support plate 10 is set There is an extruding part 11 for bending, and the two sliding sleeves 3 are provided with a moving rod 4 that can move up and down, and the lower ends of the two moving rods 4 are connected by a connecting plate 5, and the two moving rods 4 The upper ends are fixedly connected and connected with the extruding part 11, a vertical arm 7 is arranged on the bottom side outside the slide plate 2, and the lower end of the vertical arm 7 is connected to a swing arm 8 in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com