Sealing structure used for eight-way valve of regenerative heat exchanger

A sealing structure and heat exchanger technology, which is applied in the directions of multi-way valves, lift valves, valve devices, etc., can solve the problems of leaking regenerative heat exchangers, eight-way valves, component wear, assembly errors, etc., and achieve the sealing effect Decrease, easy to manufacture, simple structure effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] Hereinafter, the present invention will be specifically introduced with reference to the drawings and specific embodiments.

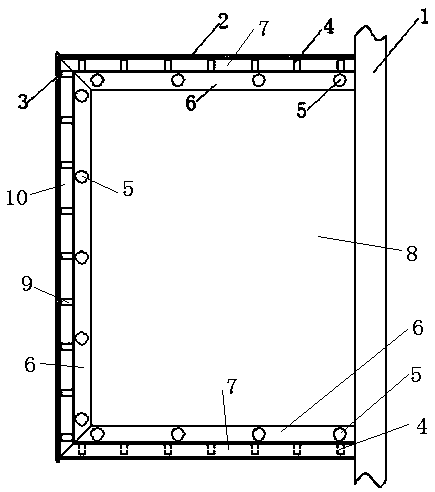

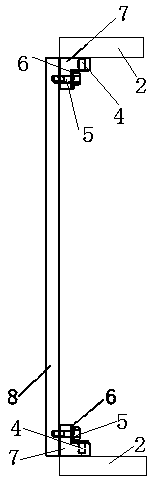

[0018] A sealing structure for an eight-way valve of a regenerative heat exchanger, comprising a rotating shaft 1. The upper and lower ends of the rotating shaft 1 are both provided with valve covers 2, and the two valve covers 2 are far away from the rotating shaft. A valve body 3 is arranged between one end of the shaft, and the valve cover 2 and the valve body 3 are arranged vertically.

[0019] The valve body 3 and the rear side of the valve cover 2 are vertically provided with a baffle 8; the connection between the valve cover 2 and the baffle 8 is provided with a first sealing strip 7; the valve body 3 and the baffle 8 are connected A second sealing strip 10 is provided at the place.

[0020] The first sealing strip 7 is provided with a first inclined surface on the side away from the rotating shaft 1, and both ends of the second sealing strip 10...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap