Vehicular headlamp

A technology for lamps and vehicles, which is applied in the direction of headlights, road vehicles, vehicle parts, etc., can solve the problem of increasing the number of parts, and achieve the effect of increasing the size and realizing the number of parts

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 approach

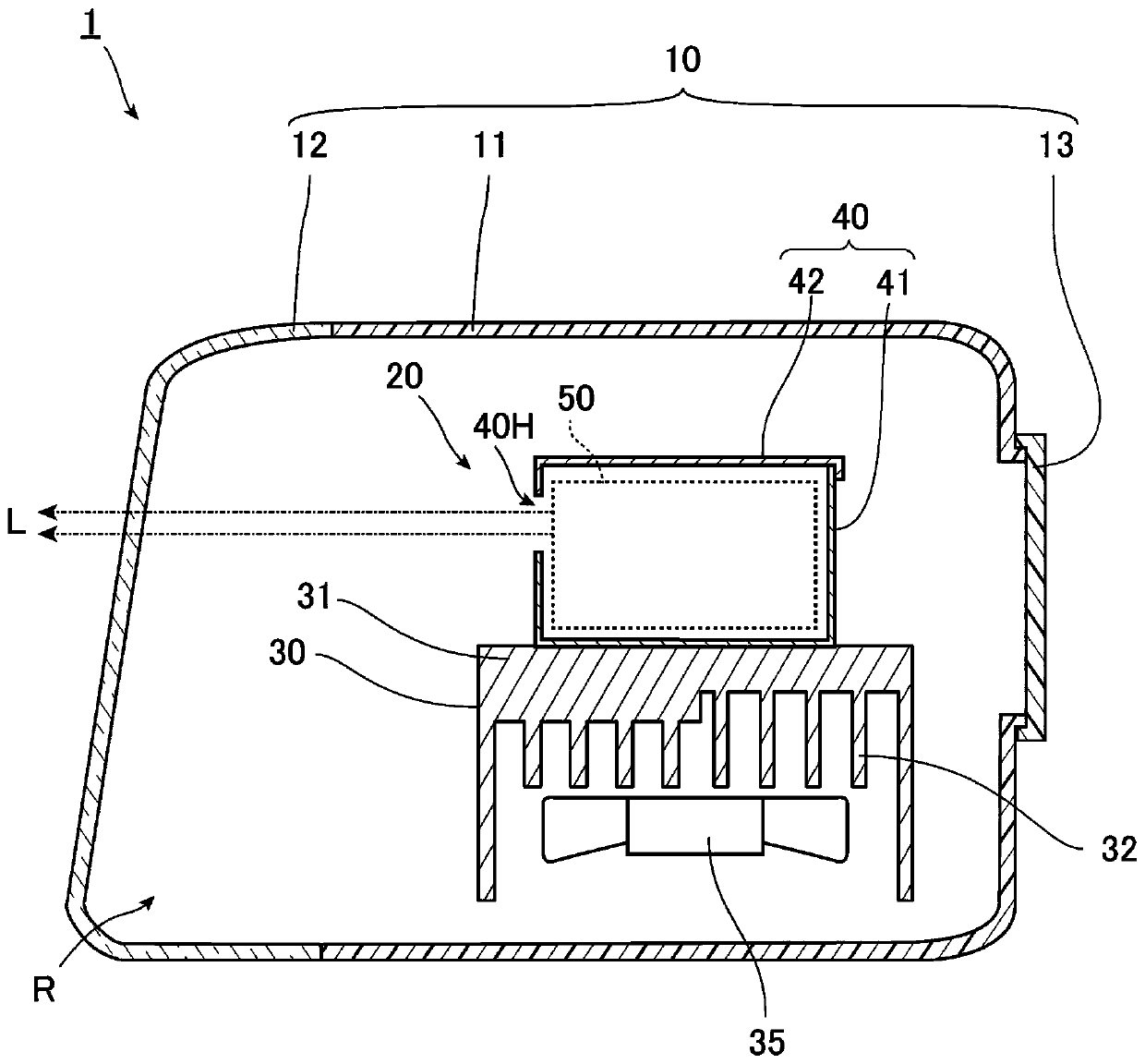

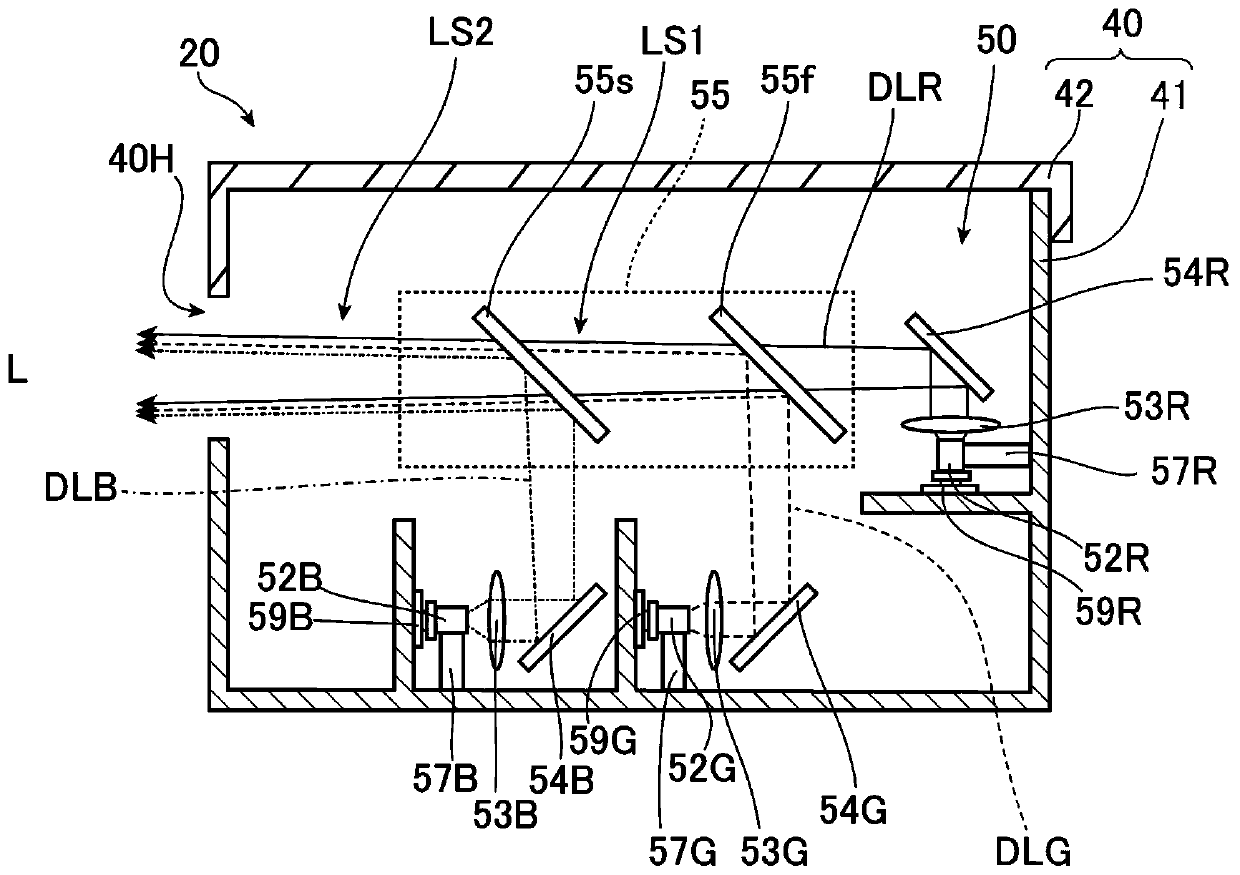

[0202] figure 1 It is a figure which shows an example of the vehicle lamp of this embodiment, and is a longitudinal cross-sectional view which shows typically the cross section of the up-down direction of the vehicle lamp. In this embodiment, the vehicle lamp is a vehicle headlamp 1. Such as figure 1 As shown, the vehicle headlamp 1 has a frame body 10 and a lamp unit 20 as main structures.

[0203] The frame body 10 has a lamp housing 11, a front cover 12, and a rear cover 13 as main structures. The lamp housing 11 has an opening at the front, and the front cover 12 is fixed to the lamp housing 11 in a manner of blocking the opening. In addition, an opening smaller than the front is formed in the rear of the lamp housing 11, and the rear cover 13 is fixed to the lamp housing 11 to close the opening.

[0204] The space formed by the lamp housing 11, the front cover 12 that closes the opening at the front of the lamp housing 11, and the rear cover 13 that closes the opening at the...

no. 2 approach

[0251] Next, a second embodiment of the present invention will be described. In addition, with regard to components that are the same or equivalent to those of the first embodiment, unless otherwise described, the same reference numerals are assigned and repeated descriptions are omitted.

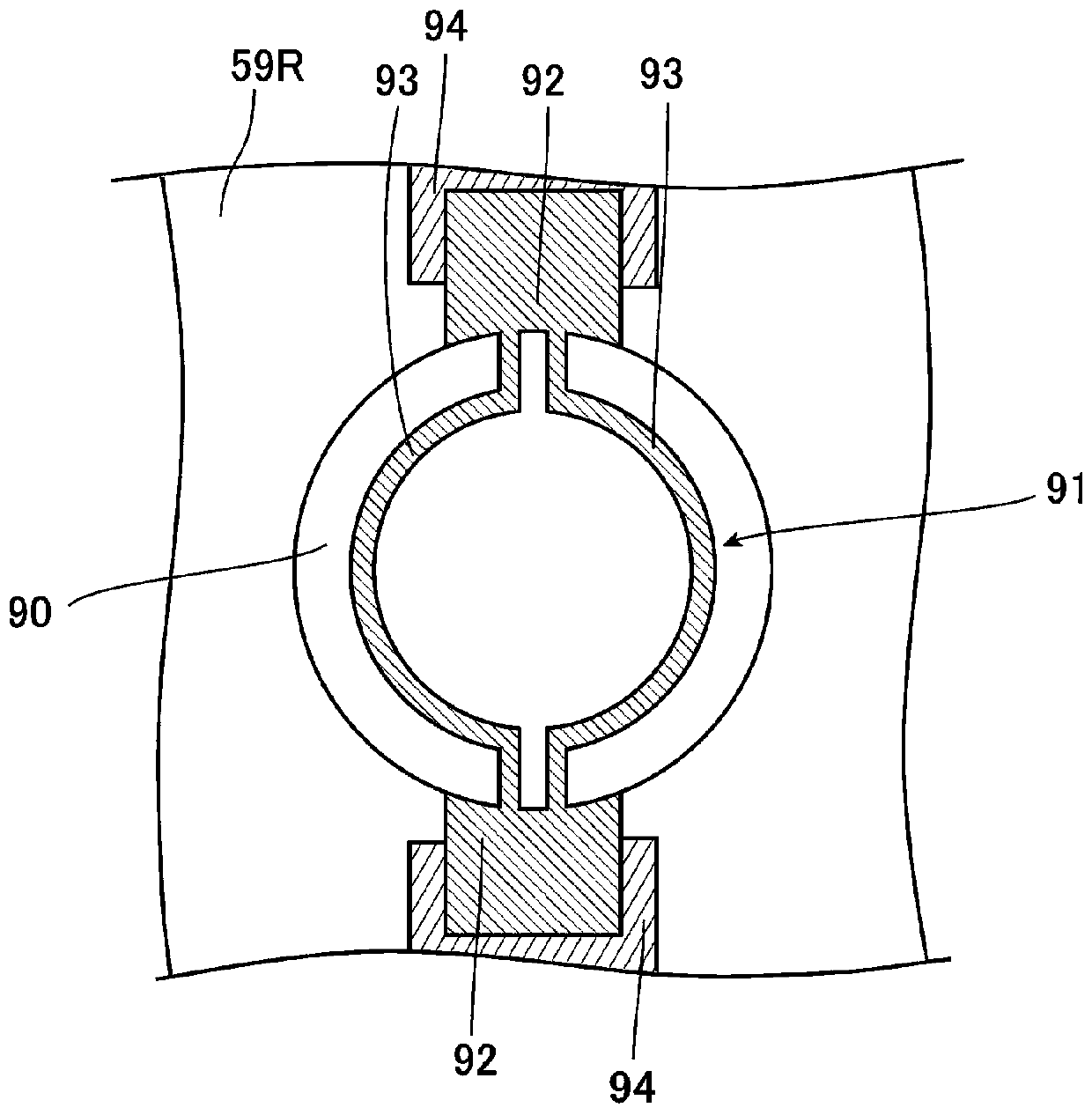

[0252] Figure 7 With figure 2 Similarly, a diagram showing the lamp unit 20 of the vehicle headlamp 1 according to the second embodiment of the present invention. Such as Figure 7 As shown, the lamp unit 20 of the second embodiment is different from the lamp unit 20 of the first embodiment in that the light sources 52R, 52G, and 52B are mounted on the base 41 of the housing 40 via elastic members. Specifically, the first light source 52R is mounted on the base 41 via a pair of elastic members 157R, the second light source 52G is mounted on the base 41 via a pair of elastic members 157G, and the third light source 52B is mounted on the base 41 via a pair of elastic members 157B. 41. In add...

no. 3 approach

[0255] Next, a third embodiment of the present invention will be described. In addition, with regard to components that are the same or equivalent to those of the first embodiment, unless otherwise described, the same reference numerals are assigned and repeated descriptions are omitted.

[0256] Figure 8 With figure 2 Similarly, a diagram showing the lamp unit 20 of the vehicle headlamp 1 of the third embodiment of the present invention. In addition, in Figure 8 In order to facilitate understanding, a part of the housing 40 is omitted and shown. Such as Figure 8 As shown, in the lamp unit 20 of the third embodiment, the number of phase modulation elements of the optical system unit 50 is one, and three phase modulation elements 54R, 54G, and 54B are used to form the first and second optical system units 50 The lamp unit 20 of the second embodiment is different. Hereinafter, the structure of the lamp unit 20 of the third embodiment will be described.

[0257] In this embodim...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com