A material transfer device

A technology of transmission device and transmission unit, which is applied in the directions of transportation and packaging, conveyor objects, etc., can solve the problems of weak stability and poor synchronization, and achieve the effect of strong stability, good stability and reduced operation difficulty.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

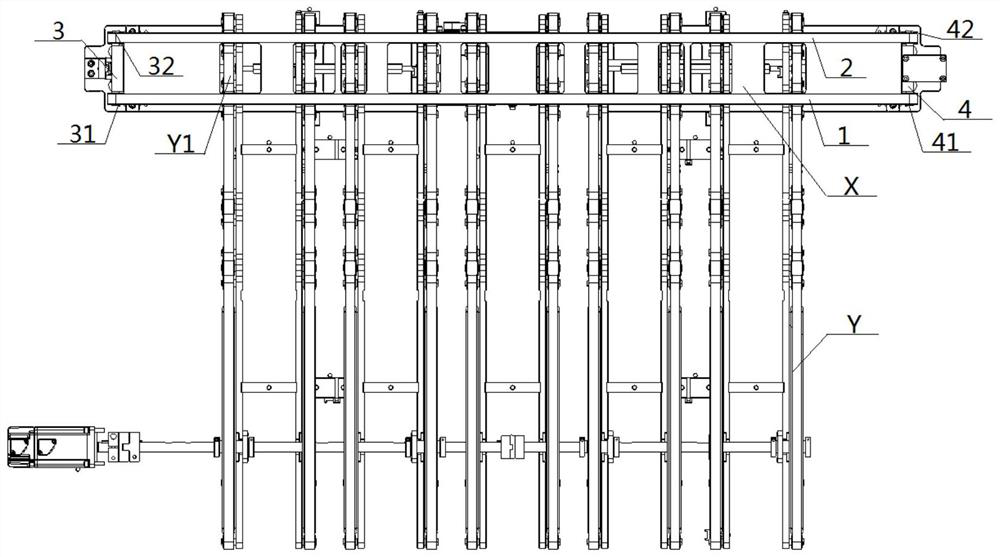

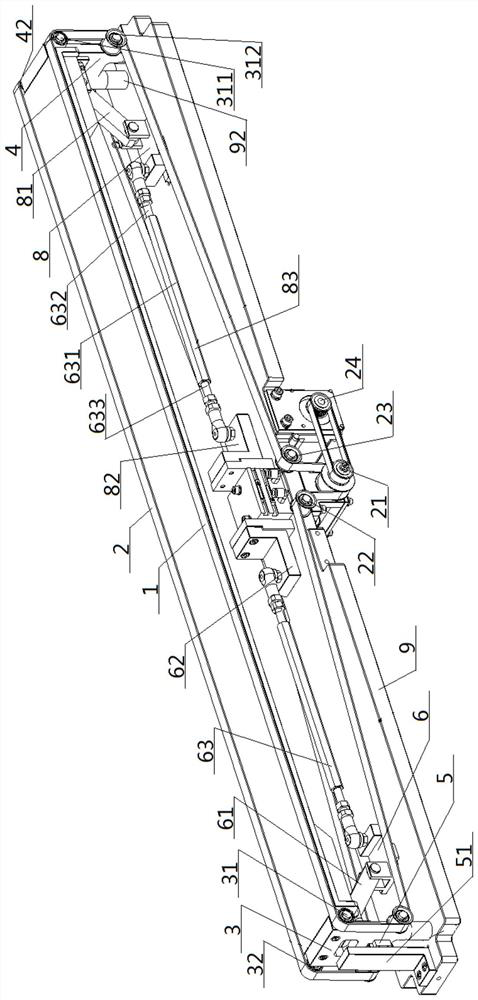

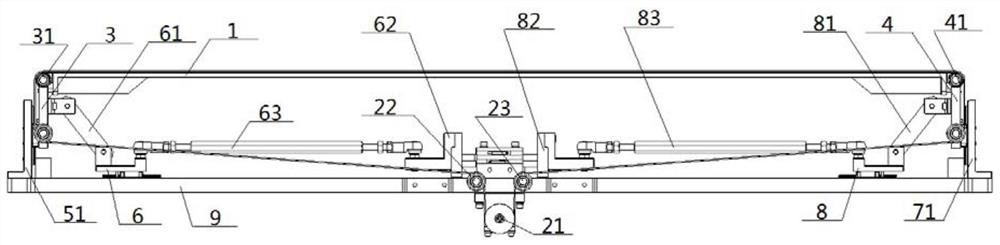

[0058] A material distribution transmission device, comprising a lifting transmission unit X and at least one piece transmission unit Y, the transmission direction of the lifting transmission unit X is different from the transmission direction of the piece transmission unit Y, and one end of the piece transmission unit Y Near the transmission surface of the lifting transmission unit X is set, the other end of the slice transmission unit Y is set away from the transmission surface of the lifting transmission unit X, and the transmission surface of the lifting transmission unit X includes a front conveyor belt 1 and a rear conveyor belt 2; The transmission unit X includes a front conveyor belt 1, a rear conveyor belt 2, a left support frame 3 and a right support frame 4, and the two ends of the front conveyor belt 1 are wound around the outer sides of the left front belt drive structure 31 and the right front belt drive structure 41 respectively. , the two ends of the rear convey...

Embodiment 2

[0064] Basic content is the same as embodiment 1, the difference is:

[0065] The left front belt driving structure 31 , the left rear belt driving structure 32 , the front belt driving structure and the right rear belt driving structure 42 are all upper rollers 311 and lower rollers 312 which are arranged up and down.

Embodiment 3

[0067] Basic content is the same as embodiment 1, the difference is:

[0068] The left horizontal drive mechanism 62 and the right horizontal drive mechanism 82 are any of the following:

[0069] The first type: the left horizontal drive mechanism 62 and the right horizontal drive mechanism 82 are each an air cylinder, motor or hydraulic cylinder;

[0070] The second type: the left horizontal drive mechanism 62 and the right horizontal drive mechanism 82 are the left and right output ends of the air gripper;

[0071] The third type: the left horizontal drive mechanism 62 and the right horizontal drive mechanism 82 are the left and right output ends of the double-rod cylinder.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com