Environment-friendly reflective cloth and preparation method thereof

An environmentally friendly and reflective technology, applied in optics, optical components, and devices for coating liquid on the surface, can solve the problems of environmental hazards, complex processes, and high energy consumption, and achieve faster operation speed, lower energy consumption, and improved production. efficiency effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

[0031] Example 1:

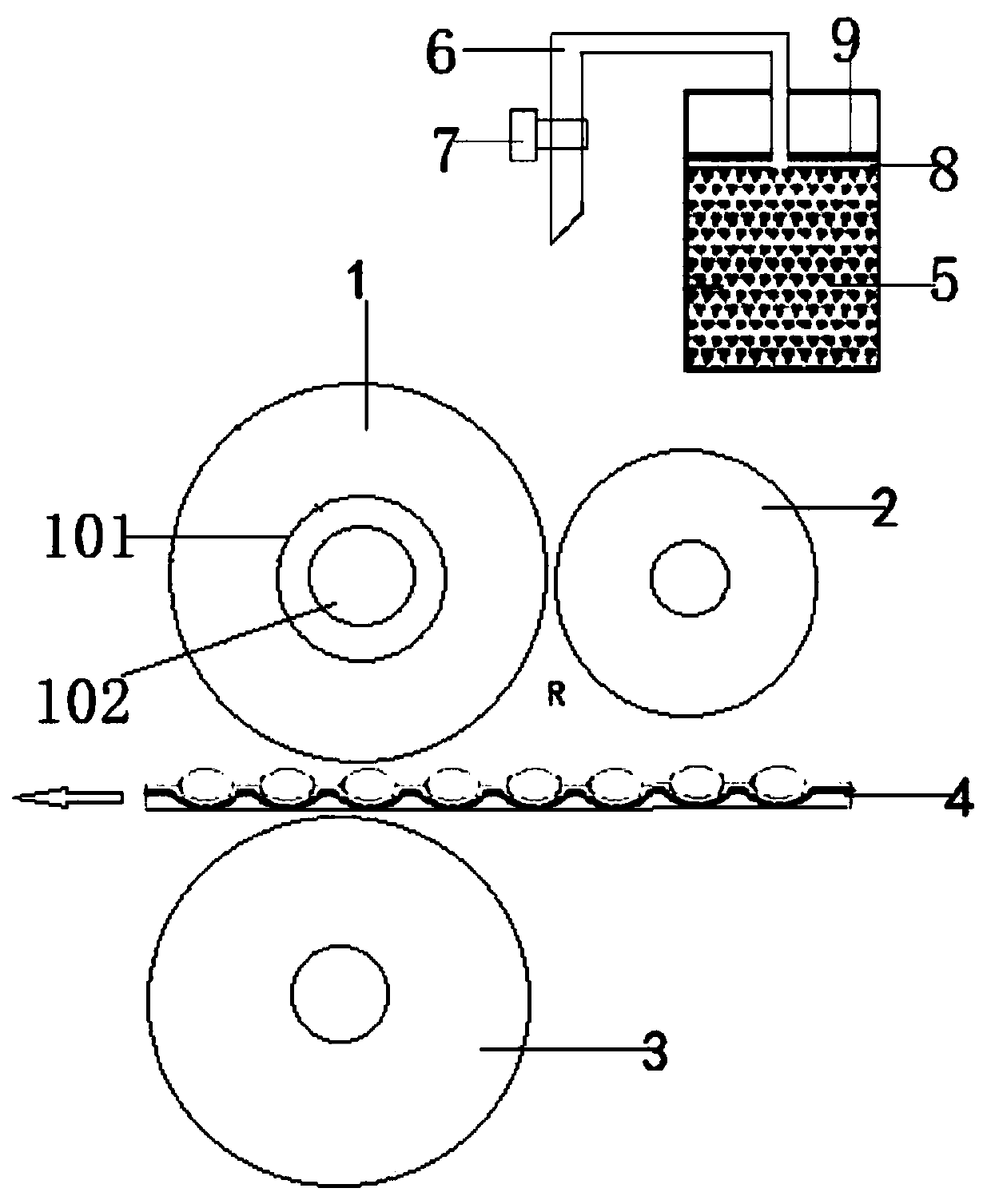

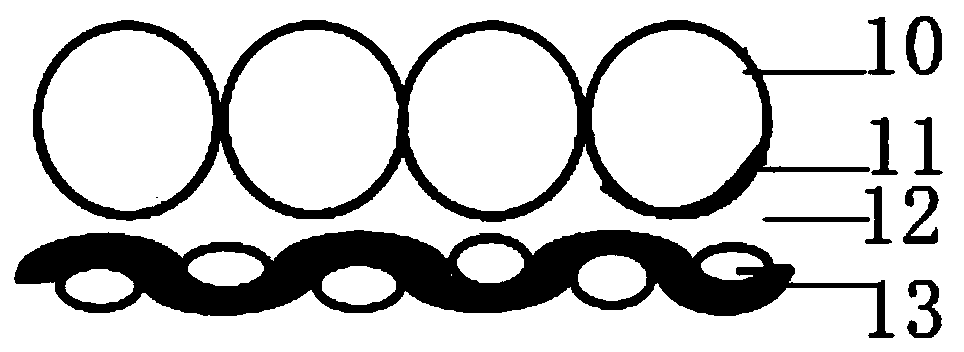

[0032] Such as figure 1 , figure 2 As shown, this patent provides an environmentally friendly reflective fabric, which includes a glass microbead layer 10, a reflective layer 11, an adhesive layer 12, and a base fabric layer 13 from top to bottom; the adhesive layer 12 is a polyurethane layer; The reflective layer is a 1200 mesh aluminum powder coating, the thickness of the reflective layer is 20nm; the base fabric layer is made of flat and smooth polyurethane coated taffeta; the glass beads are glass beads with a refractive index of 1.93 and a particle size of 400 -500 mesh, roundness is greater than or equal to 95%.

[0033] At the same time, this embodiment also provides a method for preparing an environmentally friendly reflective cloth. In the gluing process of the reflective material, polyurethane solid glue is used. The roller is compounded with the base fabric and peeled off to obtain a reflective fabric; the gluing device includes a glue tank 5, a fi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com