Improved Stretch Bending Machine

A stretch-bending machine and an improved technology, applied in the field of metal profile stretch-bending, can solve the problems of single function, small scope of application, and most profile stretch-bending, etc., and achieve the effects of simple operation process, simple structure and low transformation cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The technical solutions in the embodiments of the present invention are clearly and completely described below in conjunction with the drawings in the embodiments of the present invention. It should be understood that the specific embodiments described here are only used to explain the present invention, and are not intended to limit the protection scope of the present invention.

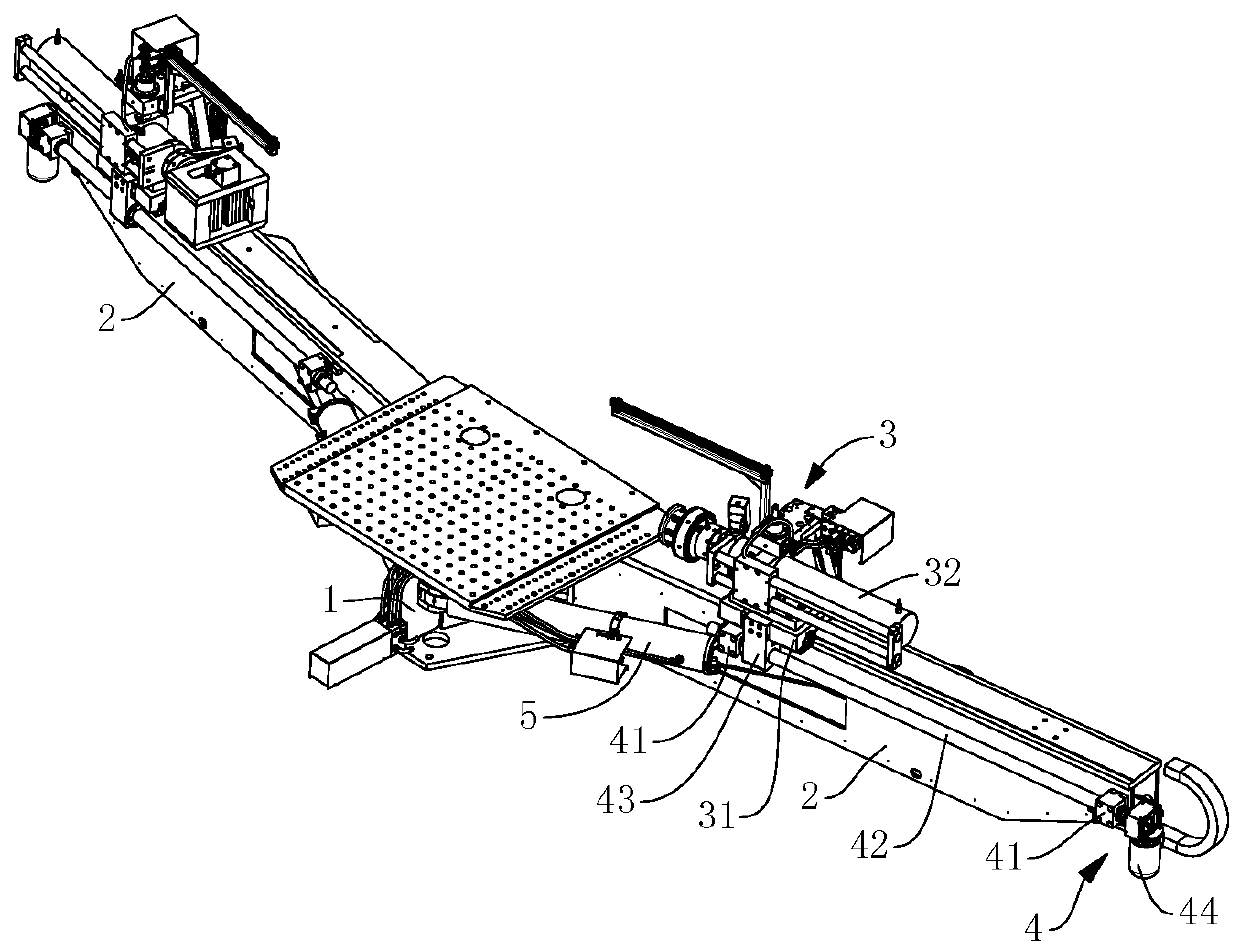

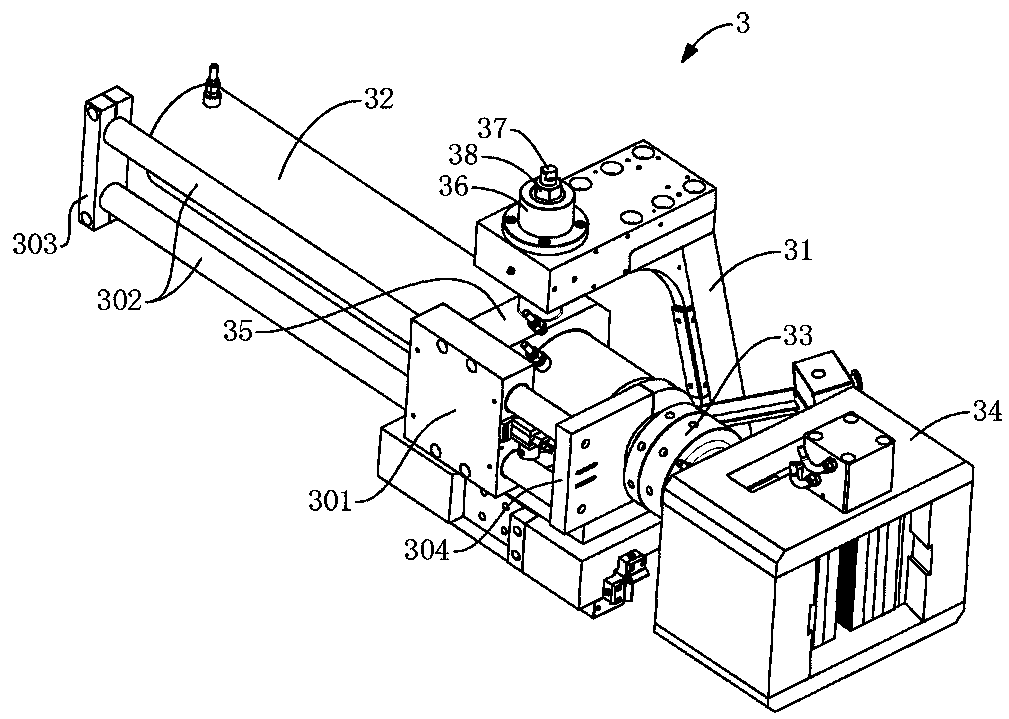

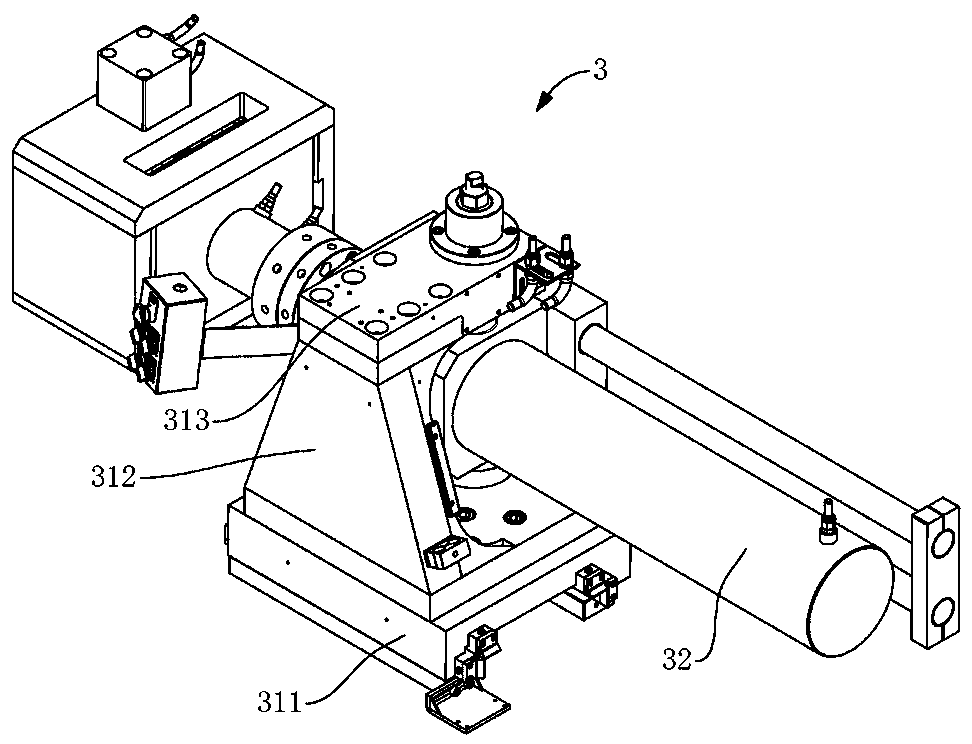

[0031] see Figure 1 to Figure 5 , the present invention provides an improved stretch bending machine, which includes a machine base 1, a rotating arm 2 and a stretching mechanism 3. Both sides of the machine base 1 are rotatably provided with rotating arms 2, and each rotating arm 2 is provided with Stretching mechanism 3, stretching mechanism 3 comprises support base 31, stretch drive cylinder 32, collet connecting seat 33, chuck 34, lift seat 35, top cover 36, lift screw rod 37 and lift nut 38, support base 31 sets On the pivoting arm 2, the stretching drive cylinder 32 is mounted on the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com