Chamfering equipment

A chamfering and equipment technology, applied in metal processing equipment, measuring/indicating equipment, metal processing machinery parts, etc., can solve the problems of low work efficiency and inability to ensure 100% accuracy of workpieces, and achieve the effect of improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0051] The chamfering equipment provided in this embodiment is used for automatic precision detection and automatic chamfering treatment of rod-shaped metal parts. Wherein, optionally, the rod-shaped metal piece is a rod-shaped metal piece processed by a silver-brightening process, specifically, the rod-shaped metal piece is a steel rod processed by a silver-brightening process.

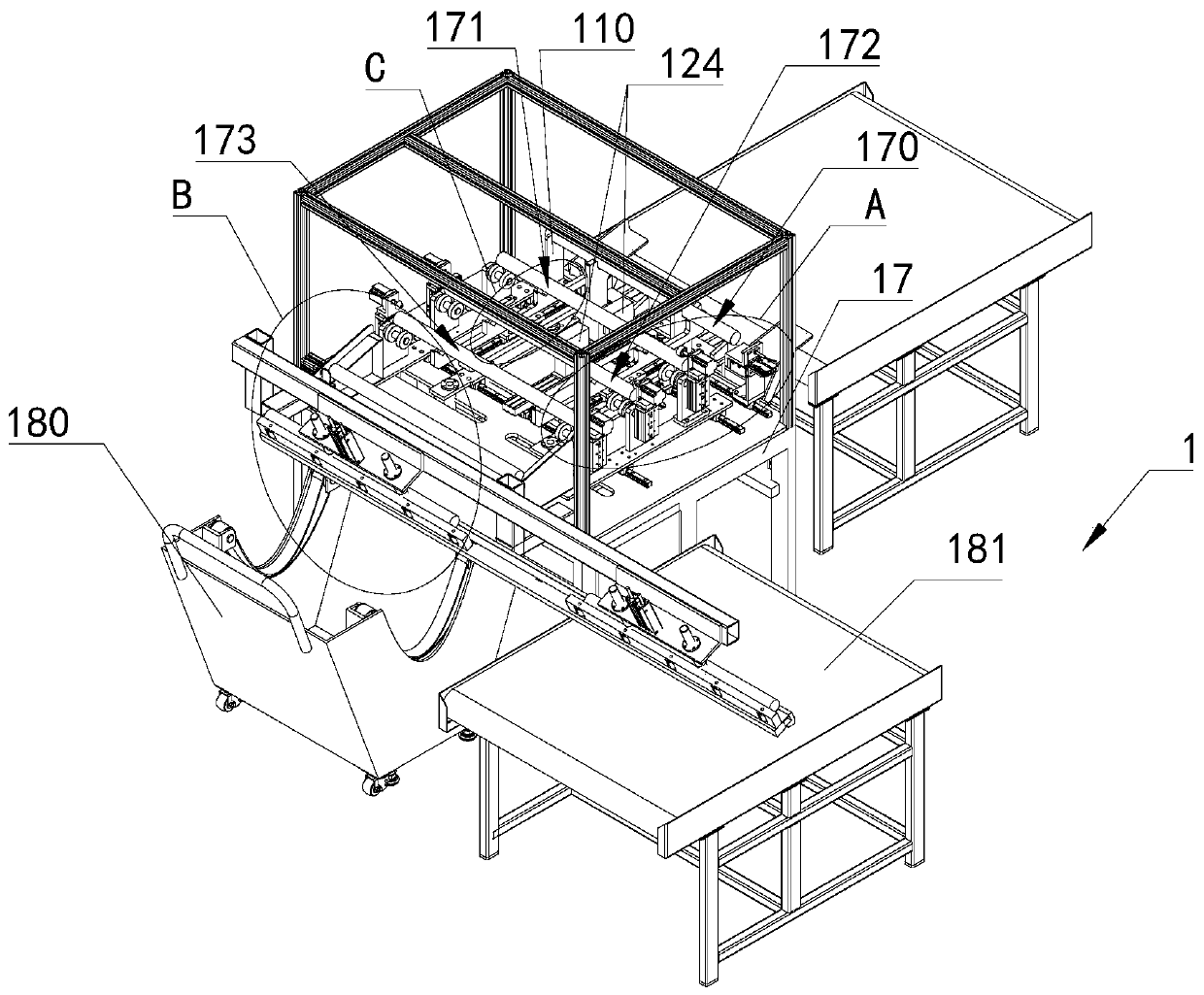

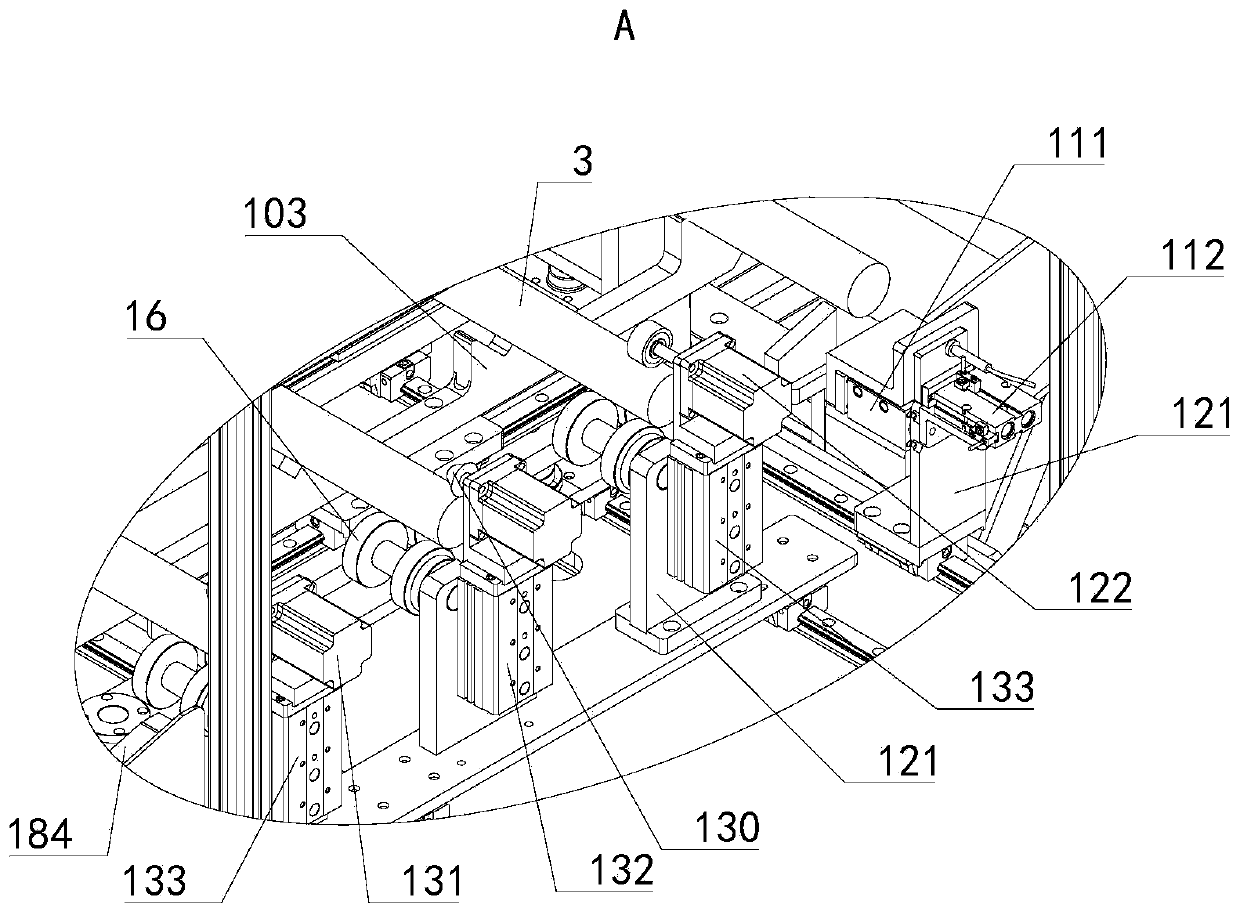

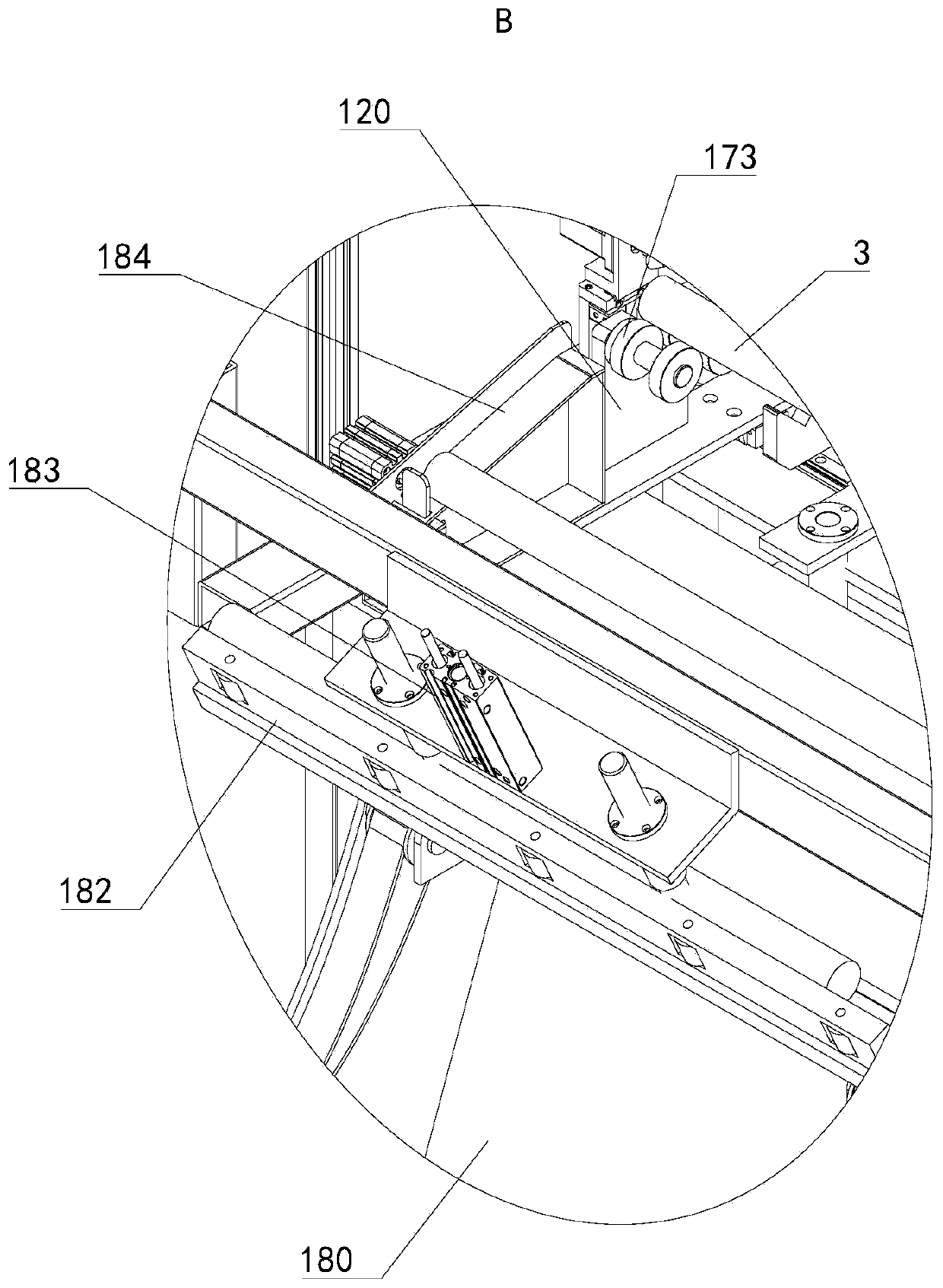

[0052] see Figure 1 to Figure 5 As shown, the chamfering equipment 1 provided in this embodiment includes a transmission mechanism, a controller 15 and a precision detection mechanism and a chamfering mechanism arranged in sequence.

[0053] The transmission mechanism can move the rod-shaped metal piece 3 from the precision detection mechanism to the chamfering mechanism, so that the two ends of the rod-shaped metal piece 3 can be chamfered through the chamfering mechanism, and the direction from the precision detection mechanism to the chamfering mechanism is the transmission The transport directi...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap