POS machine battery electric leakage detection device and POS machine production line

A leakage detection, POS machine technology, applied in the direction of measuring device, measuring electricity, short-circuit test, etc., can solve the problems of time-consuming, labor-intensive, high labor cost, and achieve the effect of improving detection efficiency, reducing labor cost and convenient operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

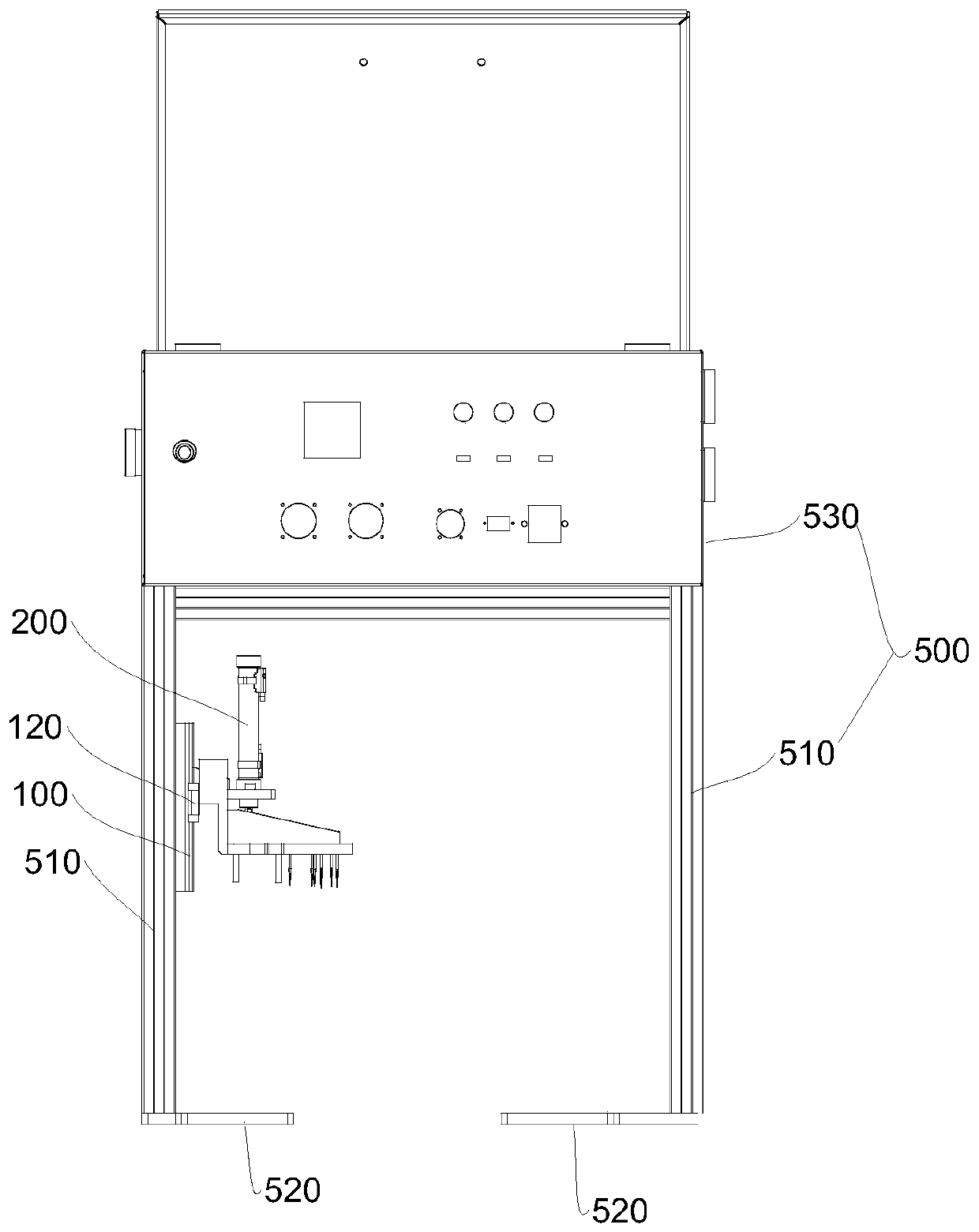

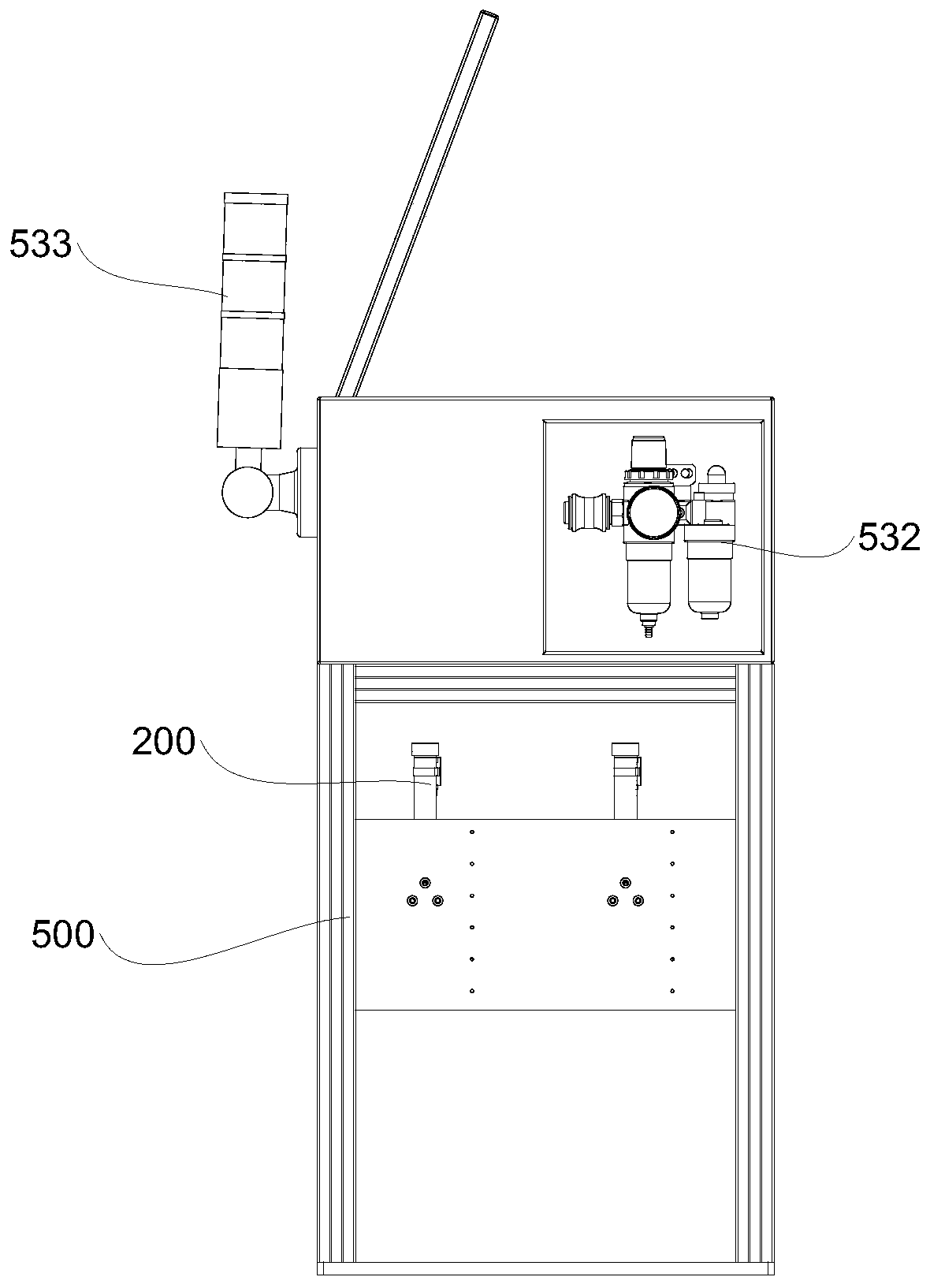

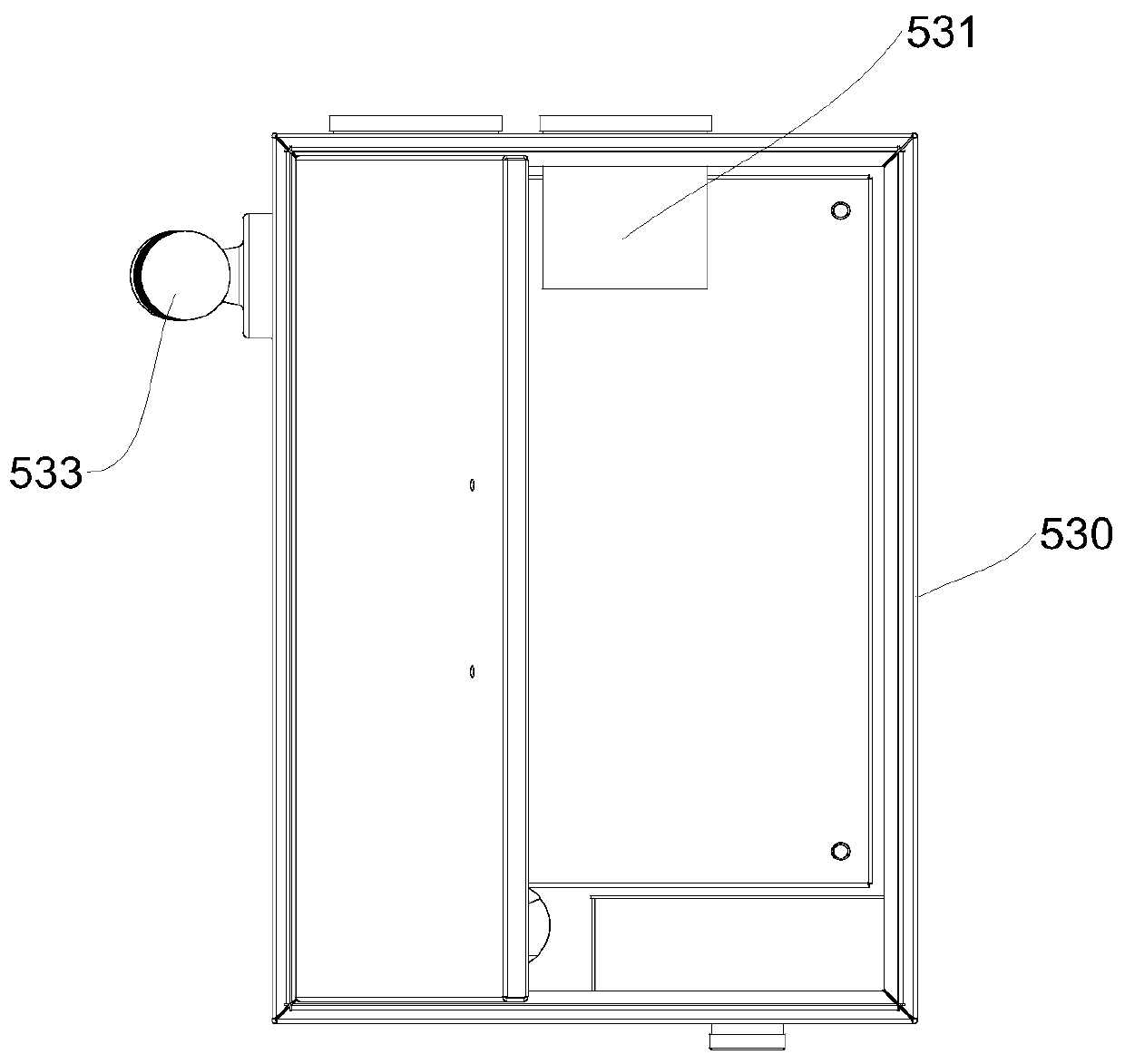

[0038] see Figure 1 to Figure 5 As shown, this embodiment provides a battery leakage detection device for a POS machine, which includes a fixing plate 100 , a driving mechanism 200 and a leakage detection mechanism 300 .

[0039] Wherein, the driving mechanism 200 is installed on the fixed plate 100 , and the fixed plate 100 is provided with a guide rail 110 . Leakage detection mechanism 300 includes probe card 320 and probe 310, and probe card 320 is connected with drive mechanism 200, and drive mechanism 200 is used for driving probe card 320 to move directionally along guide rail 110, so that probe 310 faces or stays away from POS The semi-finished product of the POS machine moves, and the probe 310 is used to contact the circuit board of the semi-finished POS machine.

[0040] It can be understood that the driving mechanism 200 is a component used to drive the probe plate 320 to drive the probe 310 to move. Since the movement of the probe 310 is generally one-dimensional...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com