Patents

Literature

68results about How to "Obtain intuitively" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Medical information visualization method and device

ActiveCN103793611AEasy accessObtain intuitivelySpecial data processing applicationsPersonalizationUsability

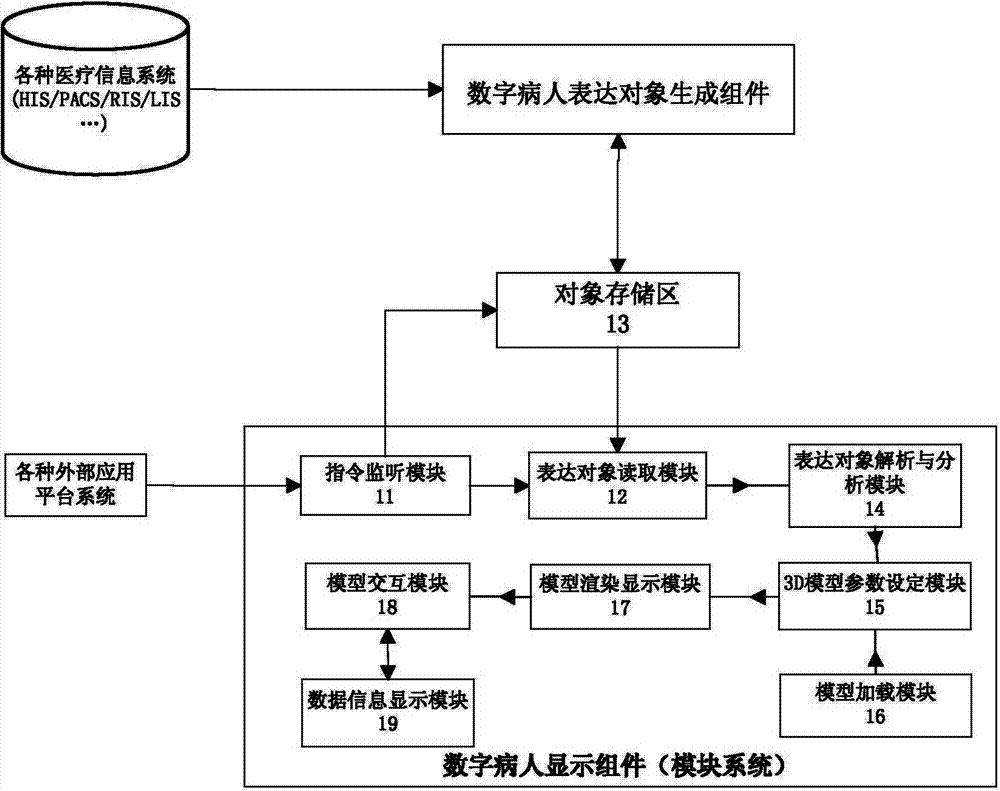

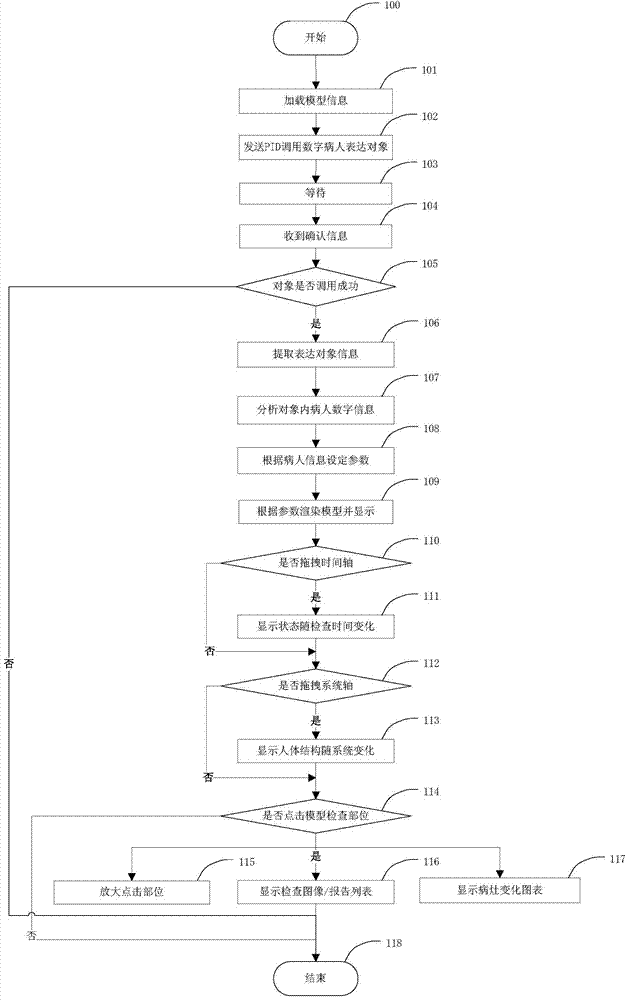

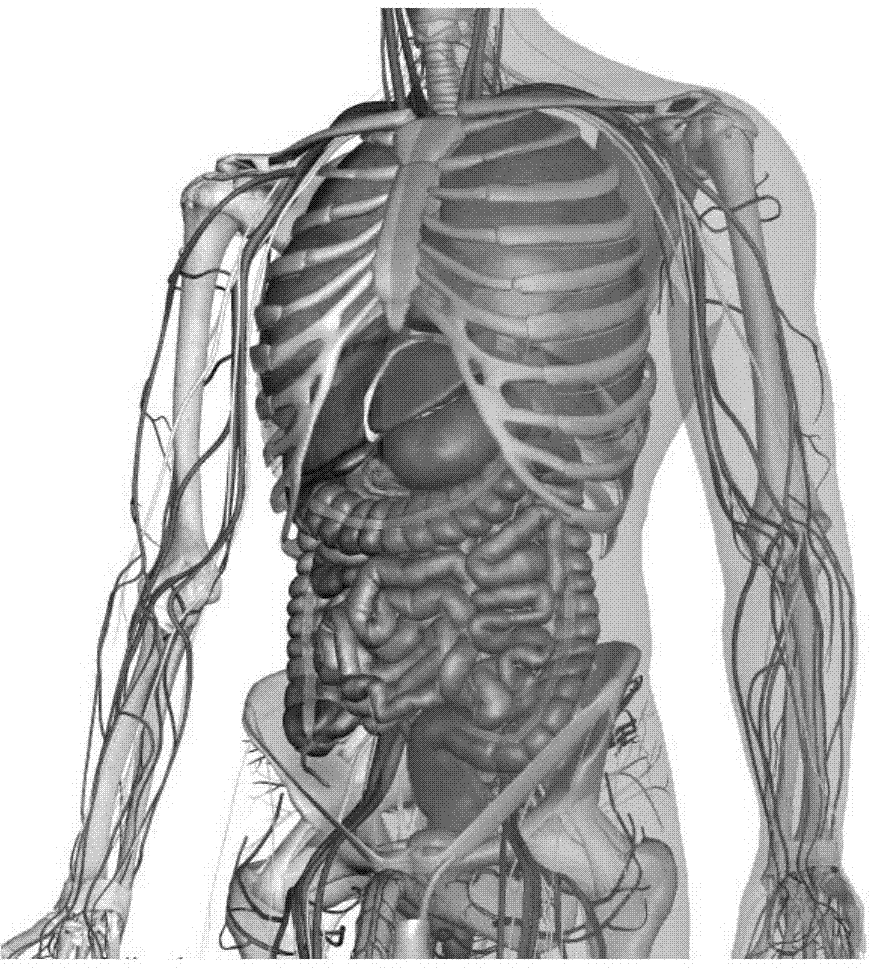

The invention relates to a medical information visualization method and device. The method includes the steps of loading a human model through 3D drawing software, converting patient information stored in a medical information system to structured medical information, and finally loading the medical information onto the human model. The medical information visualization device receives an instruction of a user and selects a displayed organ, a subclinical organ and / or the corresponding medical information according to the instruction of the user so that integration expression and visualized display of various types of digital medical information of patients can be achieved. The medical information visualization device can be integrated with various types of medical application platform systems. According to the medical information visualization method and device, materials such as clinical medical data, images and medical examination reports of the patients can be fully utilized; because of the visualization function, the recognition degree of non-medical staff on the health conditions of the patients can be improved, the intellectualization and personalization of user interfaces can be improved, the usability of the medical information of the patients can be improved, and the value chain and use efficiency of the medical information can be prolonged.

Owner:SHANGHAI INST OF TECHNICAL PHYSICS - CHINESE ACAD OF SCI

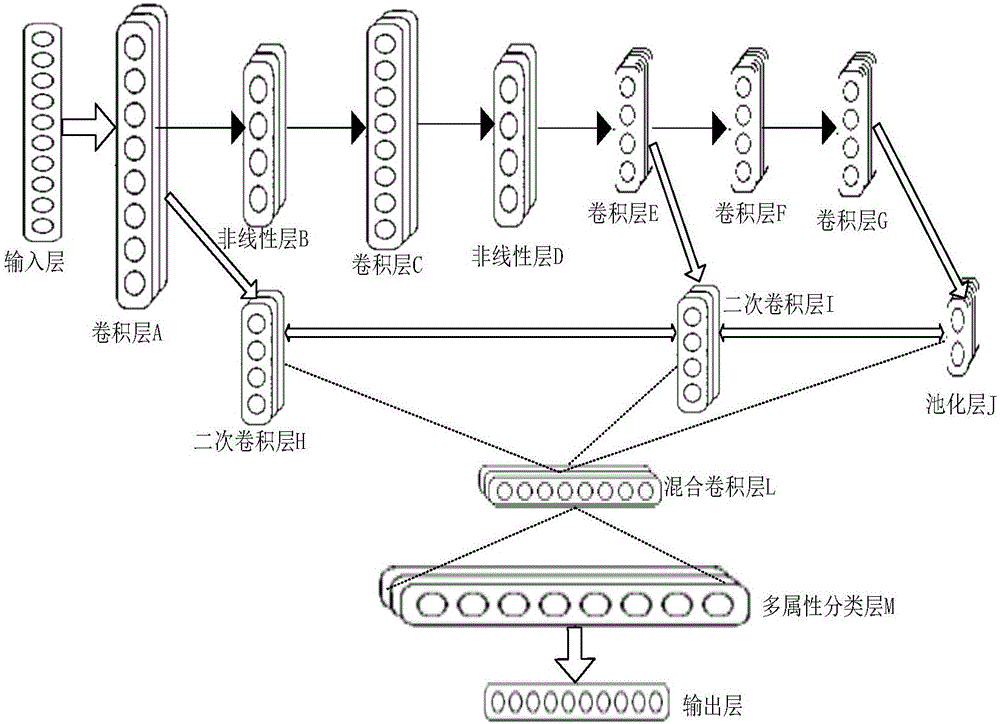

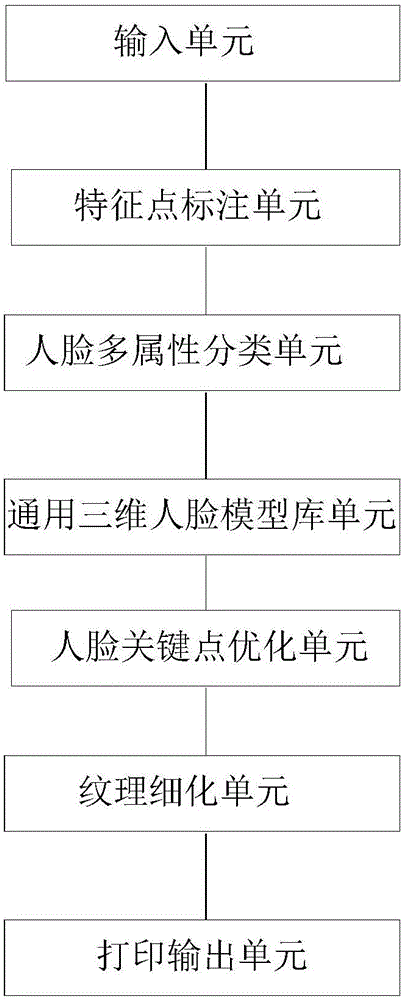

Three-dimensional face modeling method and three-dimensional face modeling printing device based on video streaming and face multi-attribute matching

ActiveCN106652025AImprove friendlinessLow costImage enhancementImage analysisPattern recognitionFace detection

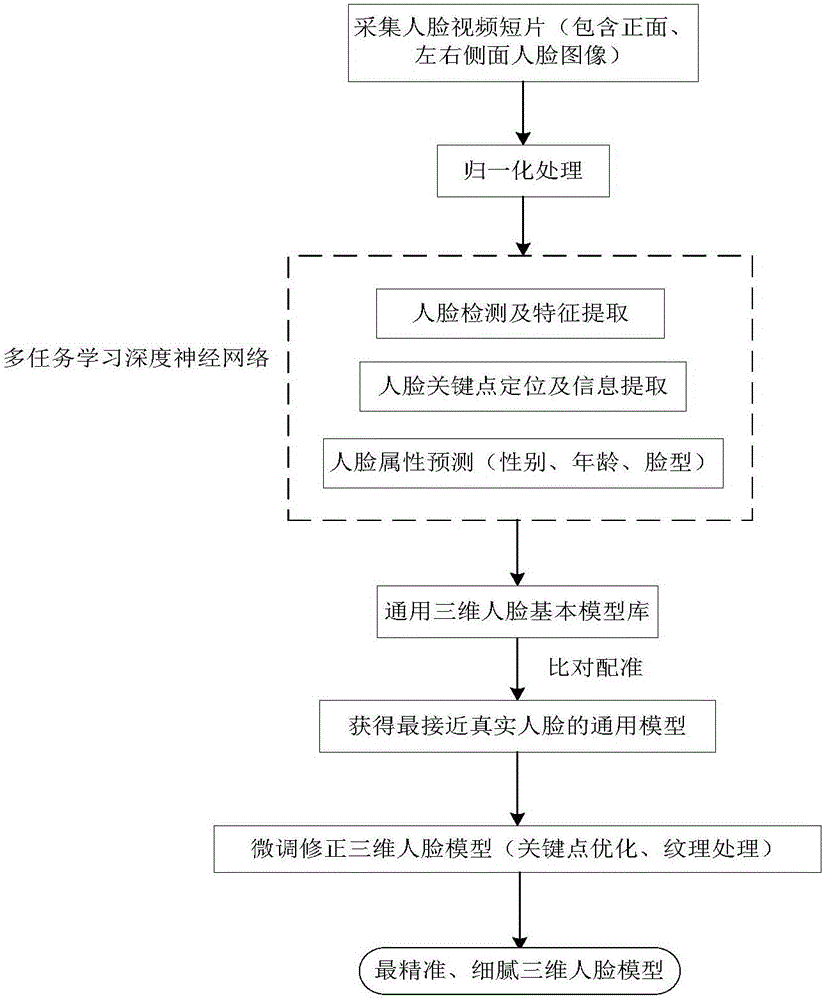

The invention discloses a three-dimensional face modeling method and a three-dimensional face modeling printing device based on video streaming and face multi-attribute matching. The method comprises the following steps that: establishing a universal three-dimensional face model library; through a pre-trained multi-task learning deep neural network, carrying out face detection and face key point information extraction; and utilizing the pre-trained multi-task learning deep neural network to carry out face attribute analysis prediction, and combining face key point data with face attribute information to carry out coarse registration with the universal three-dimensional face model library to obtain a universal face model which is most similar to real-time acquisition. The printing device comprises an input unit, a feature point labelling unit, a universal three-dimensional face model library unit, a face multi-attribute classification unit, a face key point optimization unit, a texture refining unit and a printing and outputting unit. The method and the printing device have the advantages of high accuracy, simple implementation way, good user friendliness, high automation degree and the like.

Owner:WUYI UNIV

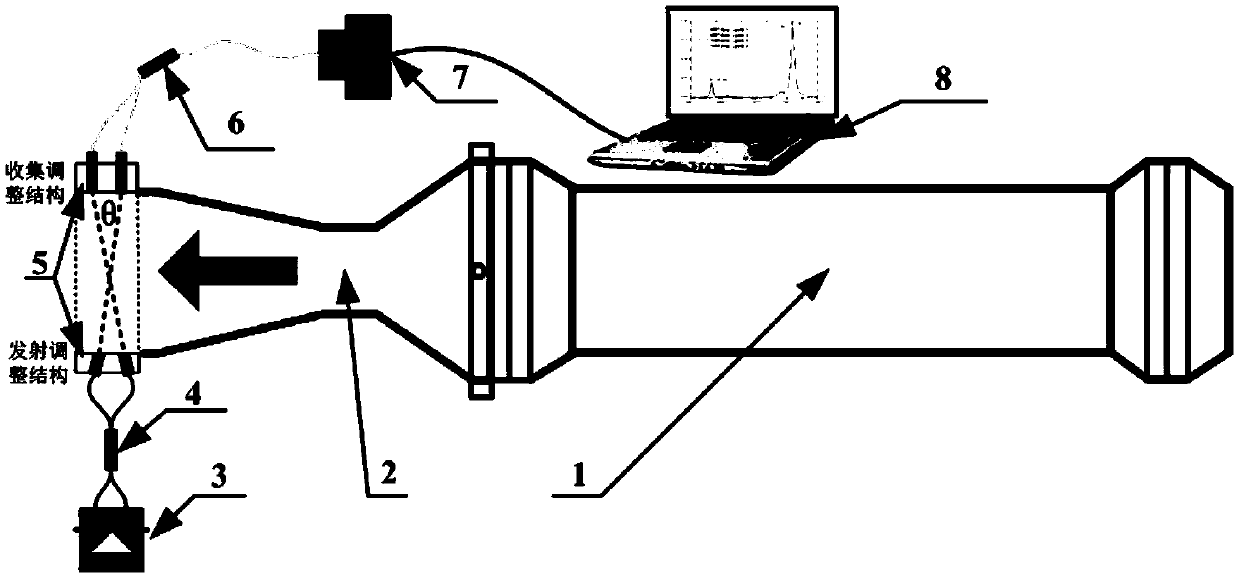

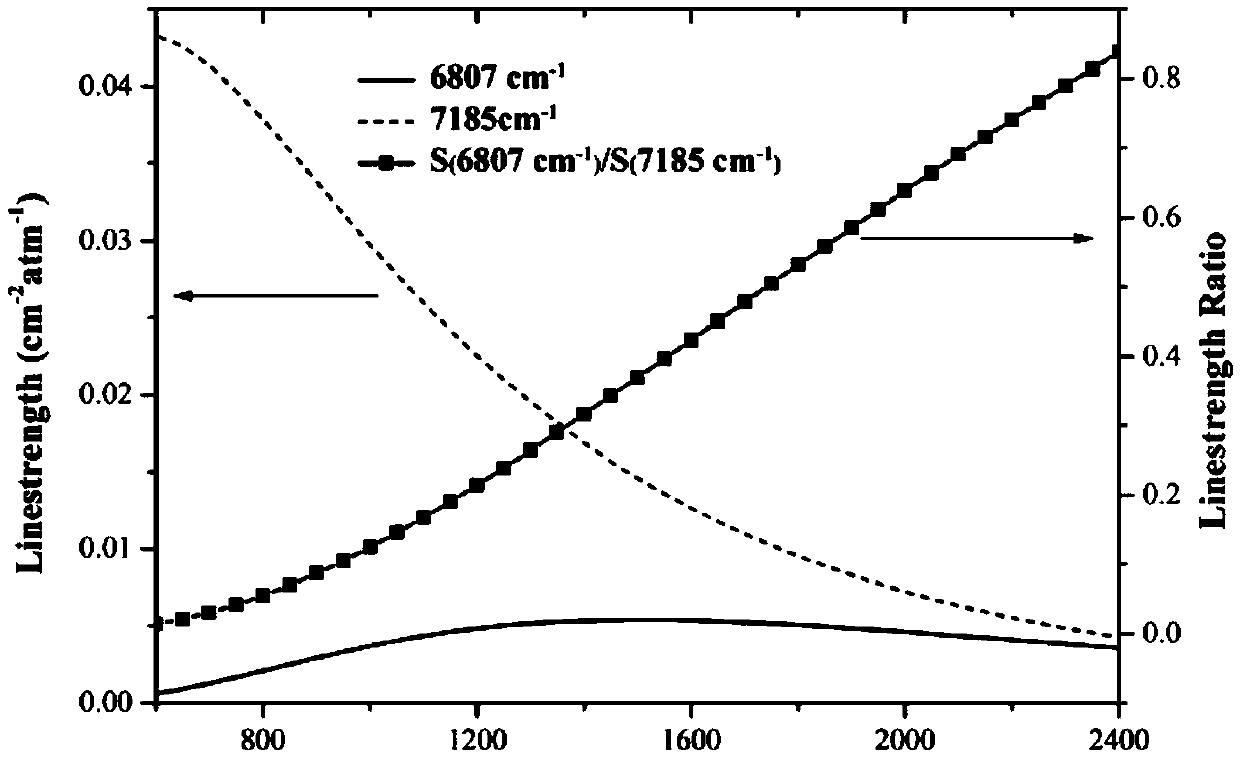

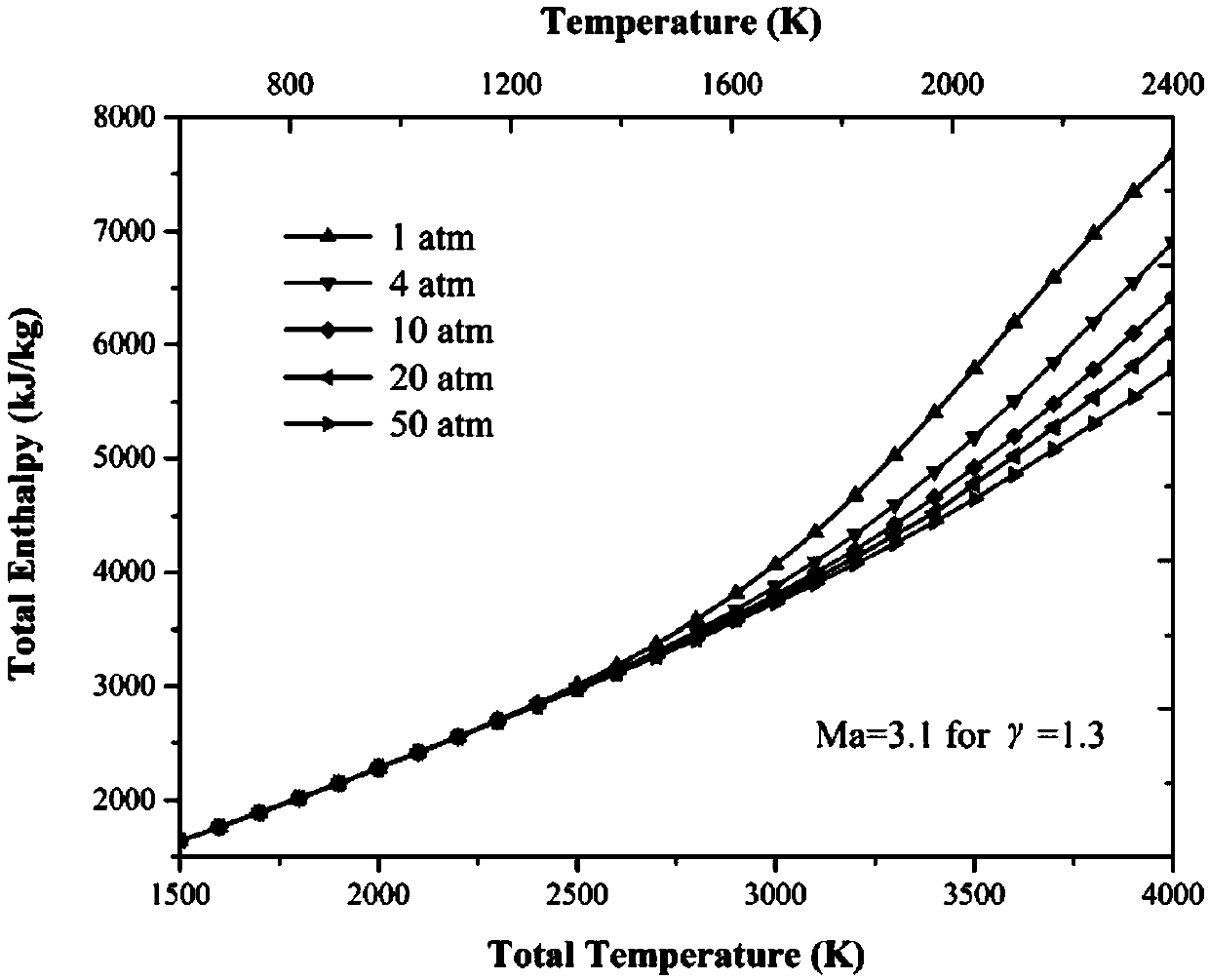

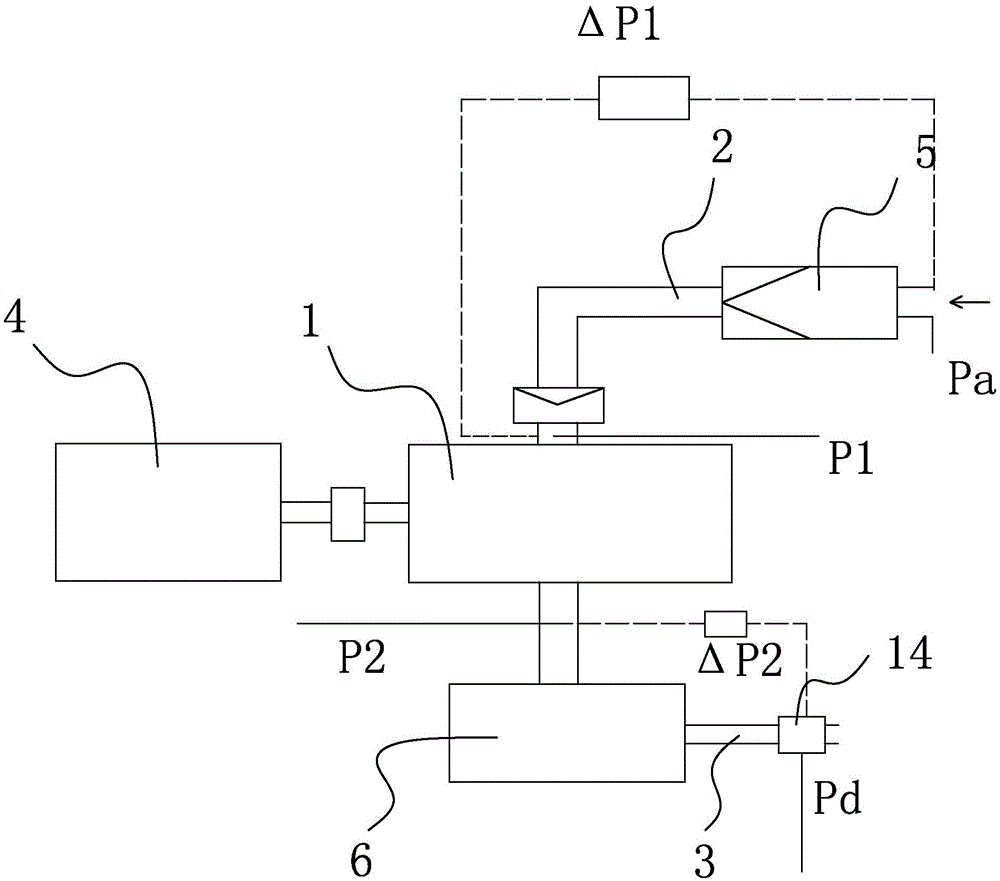

Low enthalpy arc heater airflow enthalpy diagnosis system and diagnosis method

ActiveCN109655227AObtain intuitivelyGet fastAerodynamic testingSimultaneous control of multiple variablesHeat balanceEngineering

The invention relates to a low enthalpy arc heater airflow enthalpy diagnosis system and diagnosis method. The method is characterized in that the near-infrared laser absorption spectrum diagnosis technology is utilized to directly measure flow field parameters of the free flow of an arc heater nozzle outlet, based on H2O double-wire temperature measurement, the airflow temperature and the velocity of the free flow of the arc heater nozzle outlet are obtained, in combination with the quantitative relationship among the heat balance airflow enthalpy, the temperature and the pressure, the totallocal airflow enthalpy at the nozzle outlet is obtained. The method is advantaged in that enthalpy measurement precision is improved, the method is applicable to measurement of the airflow enthalpy ofvarious types of low enthalpy arc heaters such as tubular, AC and long section heaters within the enthalpy range of 1500-7500kJ / kg; the method is a non-contact measuring method, interference on the flow field is avoided, the method does not depend on other measurement parameters and machining precision, accurate measurement of the flow field parameters can be realized, and the method can be usedas a powerful complement to enthalpy measurement methods in the prior art.

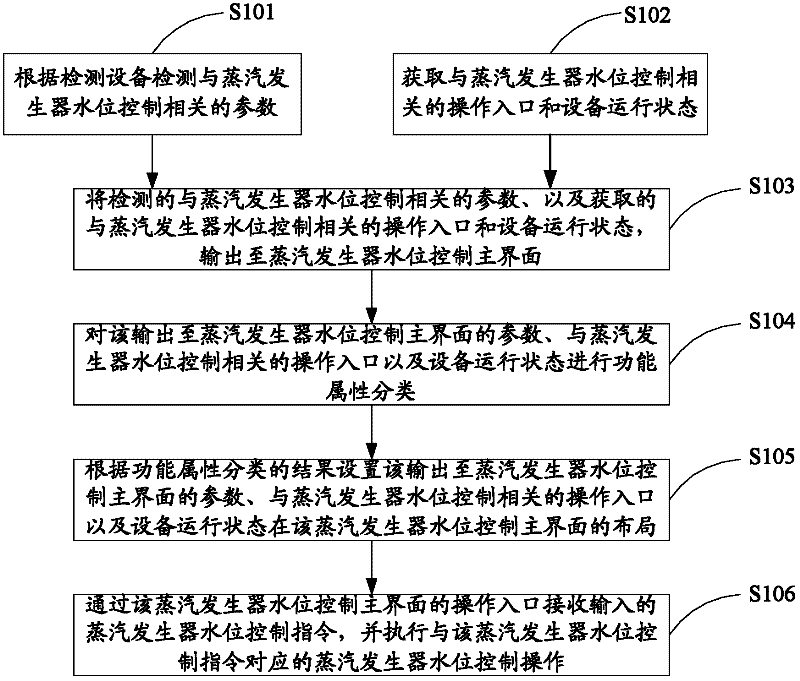

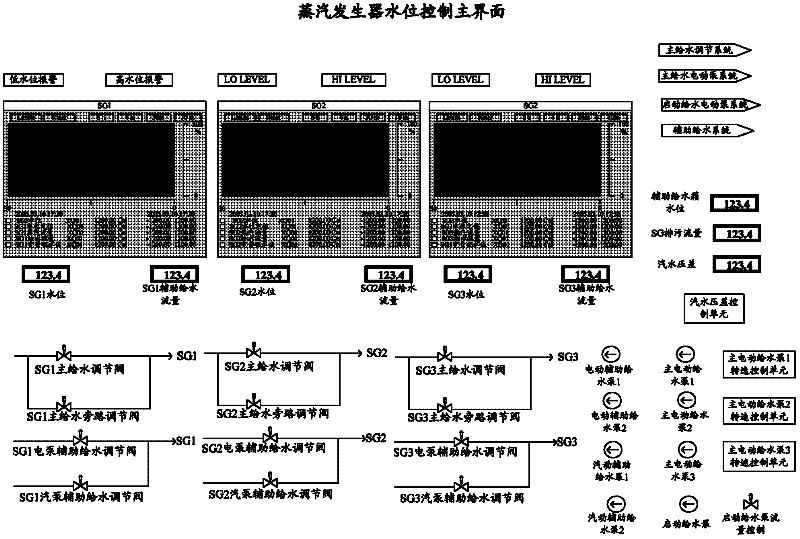

Steam generator water-level control method and device and nuclear power plant of nuclear power generating unit

ActiveCN102446566AObtain intuitivelyFull accessNuclear energy generationNuclear power plant controlNuclear powerNuclear engineering

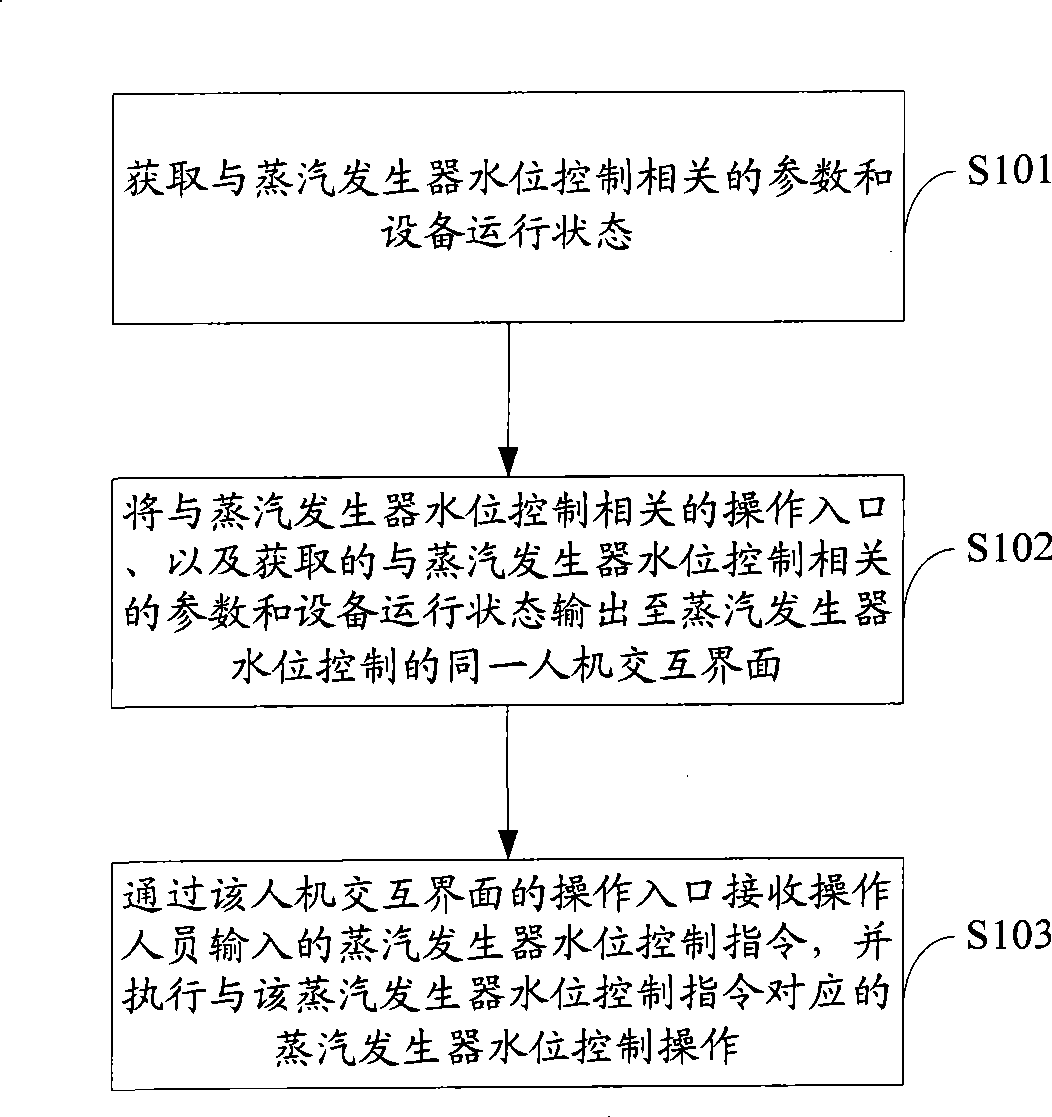

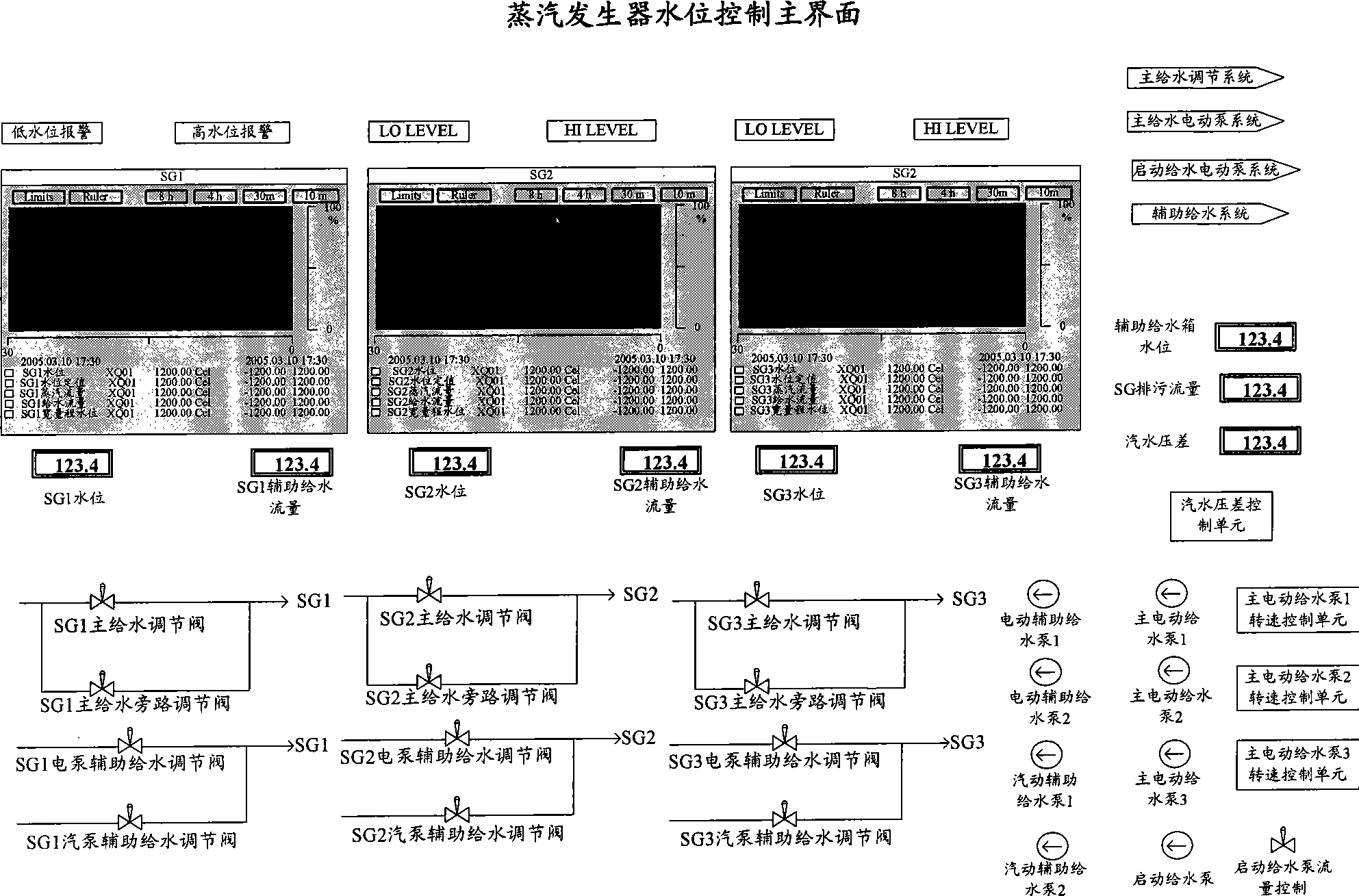

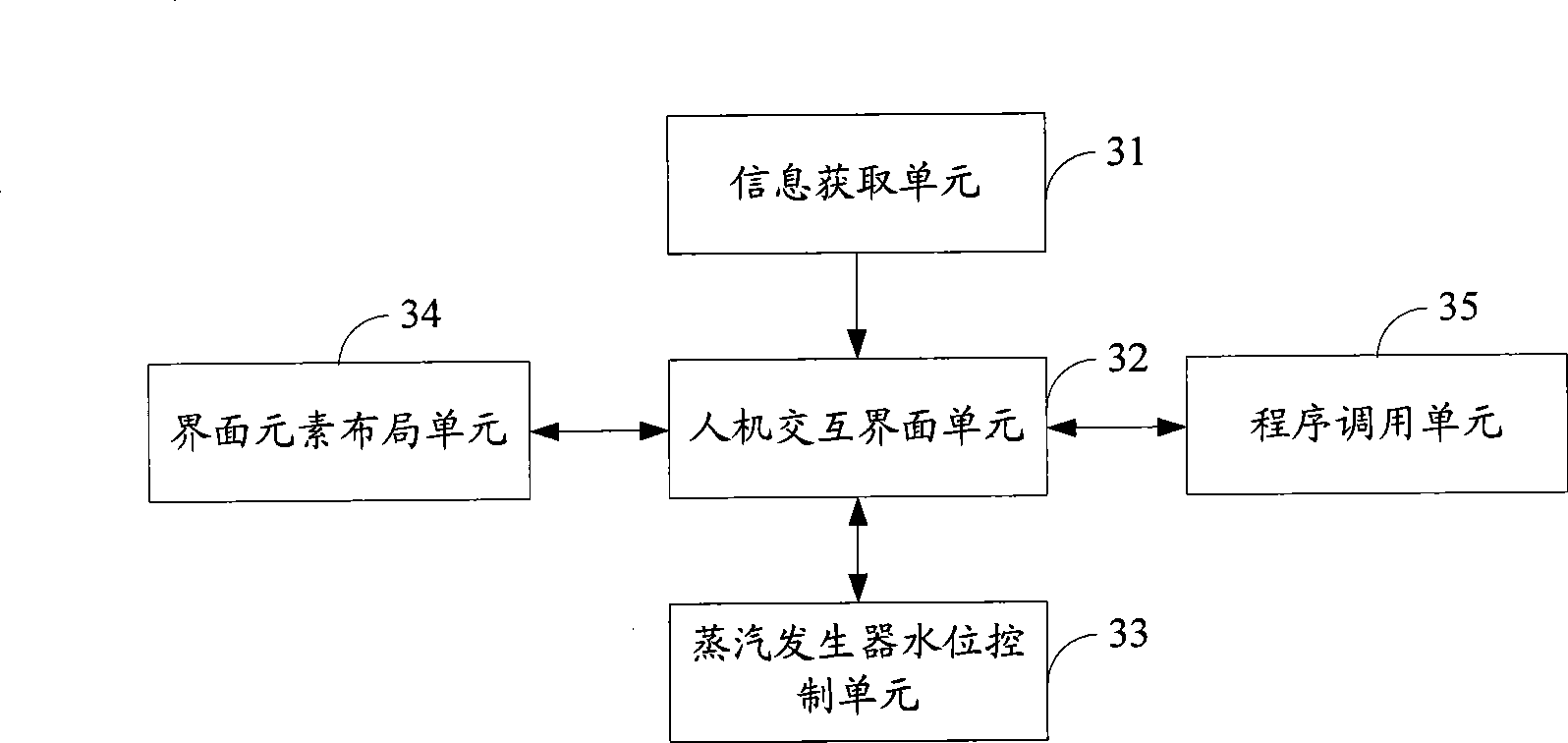

The invention is applied to the field of nuclear power control and provides a steam generator water-level control method, device and nuclear power plant of a nuclear power generating unit. The method comprises the following steps of: detecting a parameter associated with steam generator water-level control; obtaining an operation inlet and an equipment operating state associated with the steam generator water-level control; outputting the detected parameter and the obtained operation inlet and equipment operating state to a steam generator water-level control main interface; carrying out functional attribute classification on the detected parameter and the obtained operation inlet and equipment operating state; setting the layout of the steam generator water-level control main interface according to a result of the functional attribute classification; and receiving a steam generator water-level control command and executing the corresponding steam generator water-level control operation. In the embodiment, after the information associated with the steam generator water-level control is functionally classified, the steam generator water-level control main interface is laid out, so that an operator can quickly obtain the parameter in an overall way and realize quick interference.

Owner:GUANGDONG NUCLEAR POWER JOINT VENTURE +1

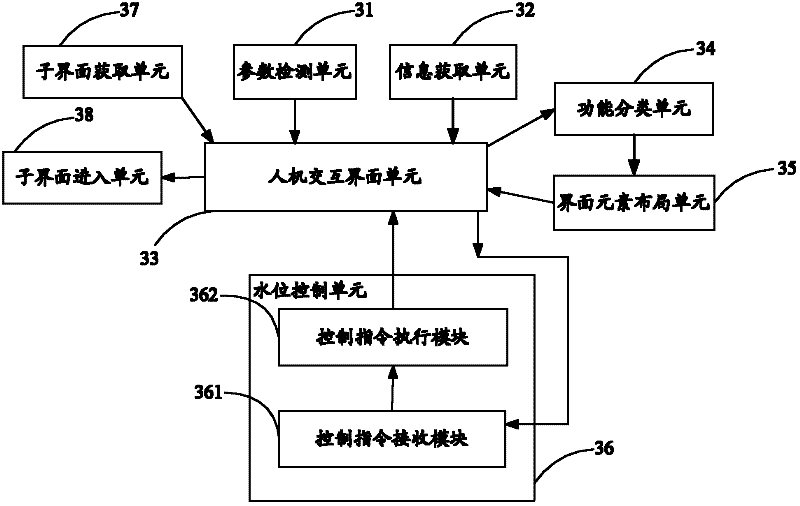

Nuclear power plant, water level control method and system for steam generator

InactiveCN101483078AObtain intuitivelyFull accessLevel controlPlant parameters regulationNuclear plantNuclear engineering

The invention is applied to the field of nuclear power control, which provides a nuclear power plant and steam generator water level control method and system thereof. The method includes the following steps: acquiring the parameter and equipment running status related to the steam generator water level control; outputting the operation entrance related to the steam generator water level control and the acquired parameter and equipment running status related to the steam generator water level control to a steam generator water level control main interface; receiving the input steam generator water level control instruction from the operations entrance of the steam generator water level control main interface, and executing the steam generator water level control operations corresponding to the steam generator water level control instruction. The inventive embodiment outputs the information related to the steam generator water level control to a same man-machine interactive interface, so that operators can intuitively, comprehensively and fast acquire parameters and judge the reason that the exceptional steam generator water level occurs, and rapid intervention can be realized by the man-machine interactive interface.

Owner:CHINA GENERAL NUCLEAR POWER CORP +1

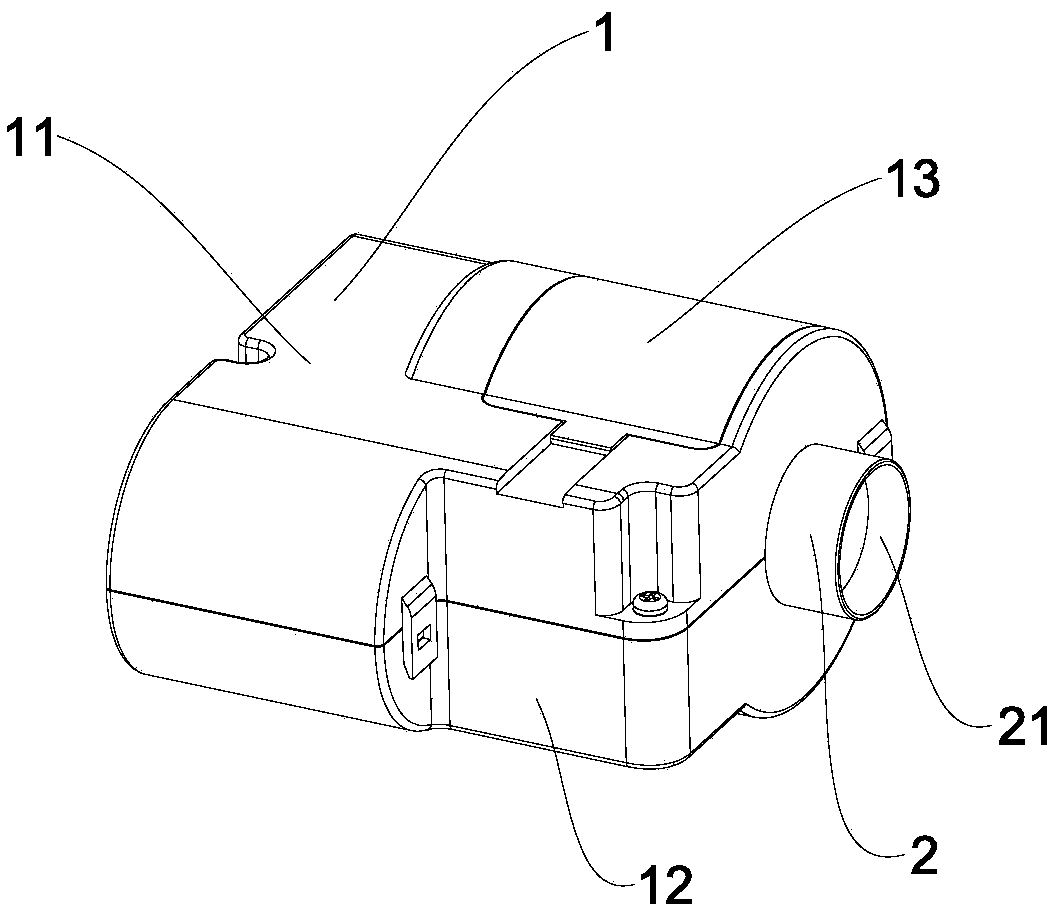

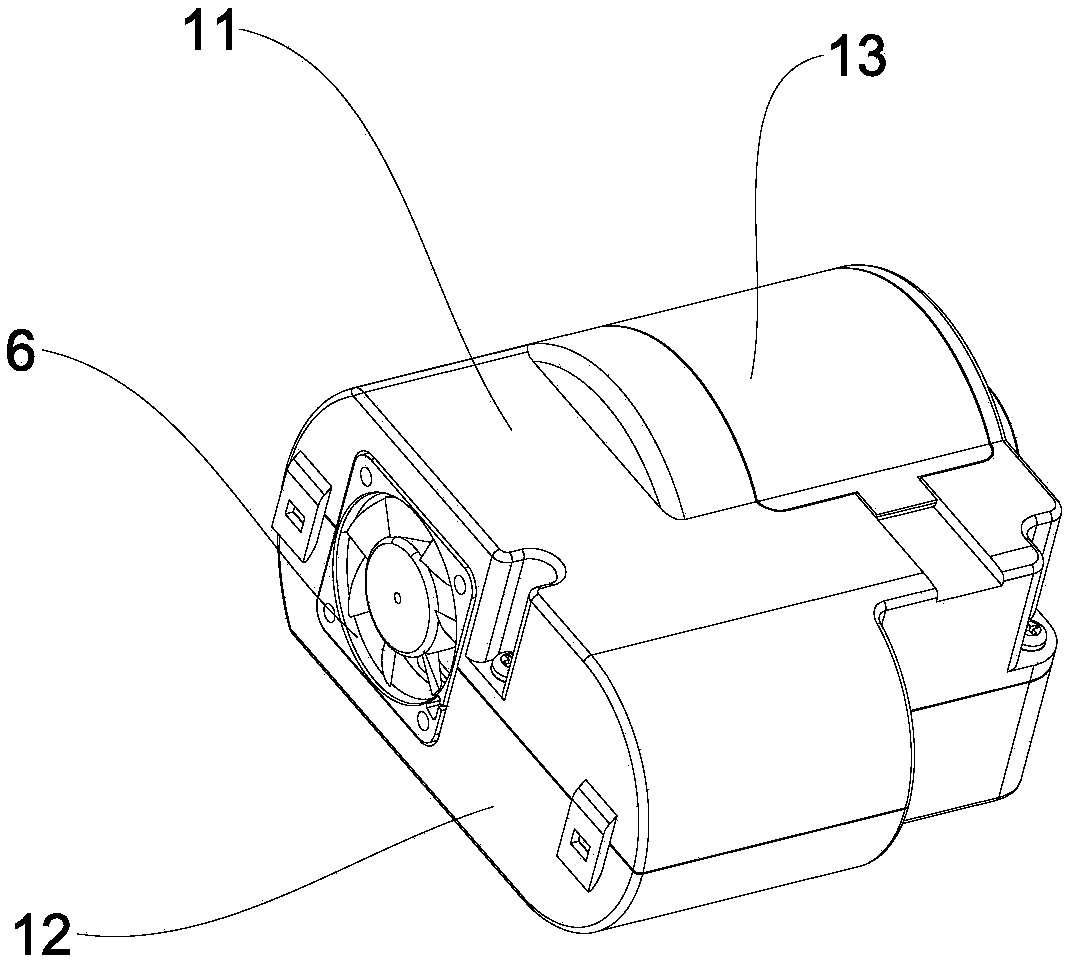

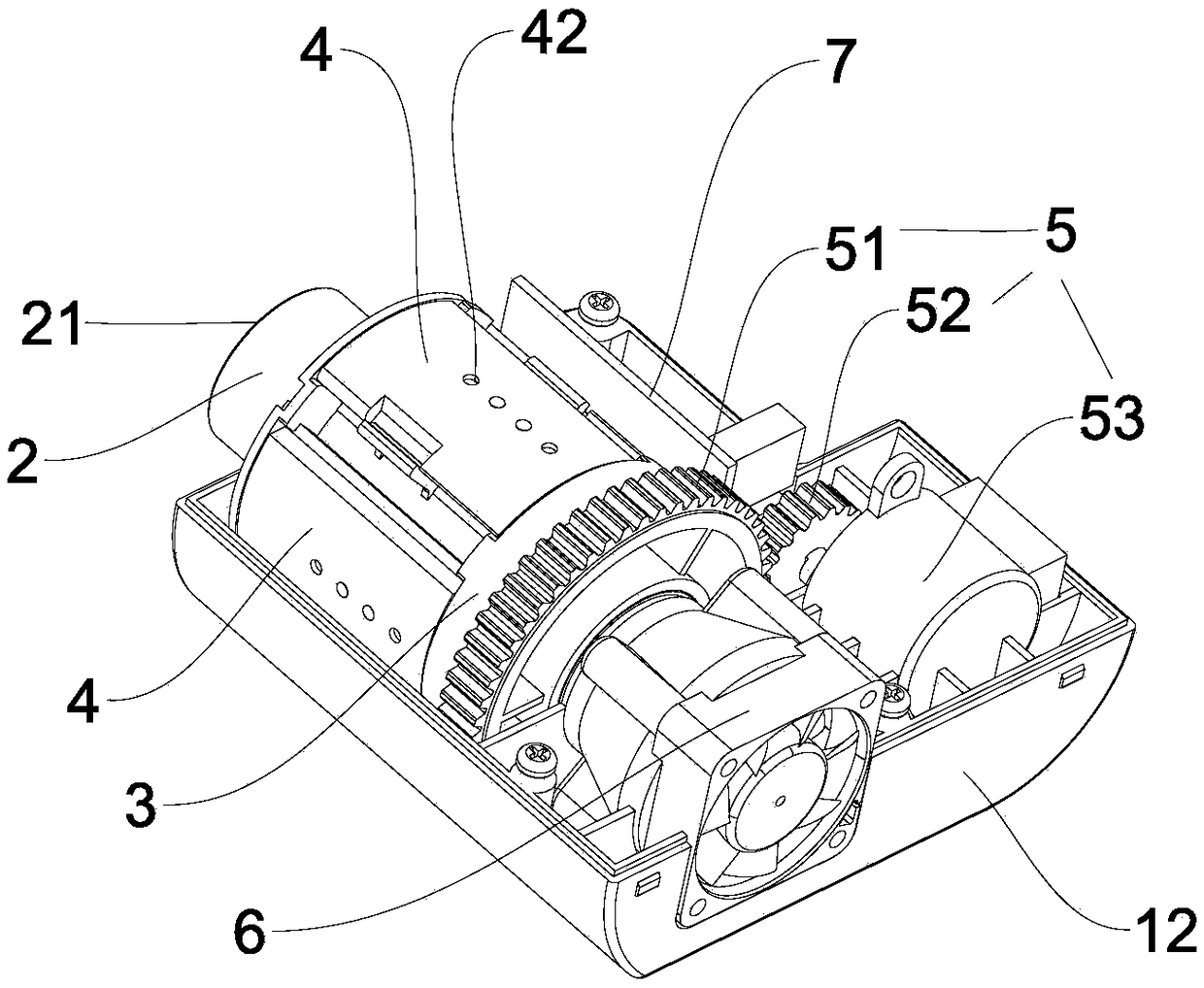

Perfume machine and automobile

The invention relates to the technical field of perfume devices, and discloses a perfume machine and an automobile. The perfume machine comprises an air guiding pipe, a rotating bracket and a plurality of perfume boxes, the rotating bracket drives the perfume boxes to rotate around the air guiding pipe, and perfume box air outlet holes of the perfume boxes are rotated to the air outlet positions and communicate with air outlet holes of the air guiding pipe. According to the perfume machine, the structure is simple, the perfume machine can be filled with the perfume boxes with a plurality of scent at the same time, and the demands of different crowds or the same person in different environments to different perfume scent can be met; and meanwhile switching operation of the perfume scent iseasy, and use is convenient.

Owner:KCLAMBER ELECTRIC TECH CORP

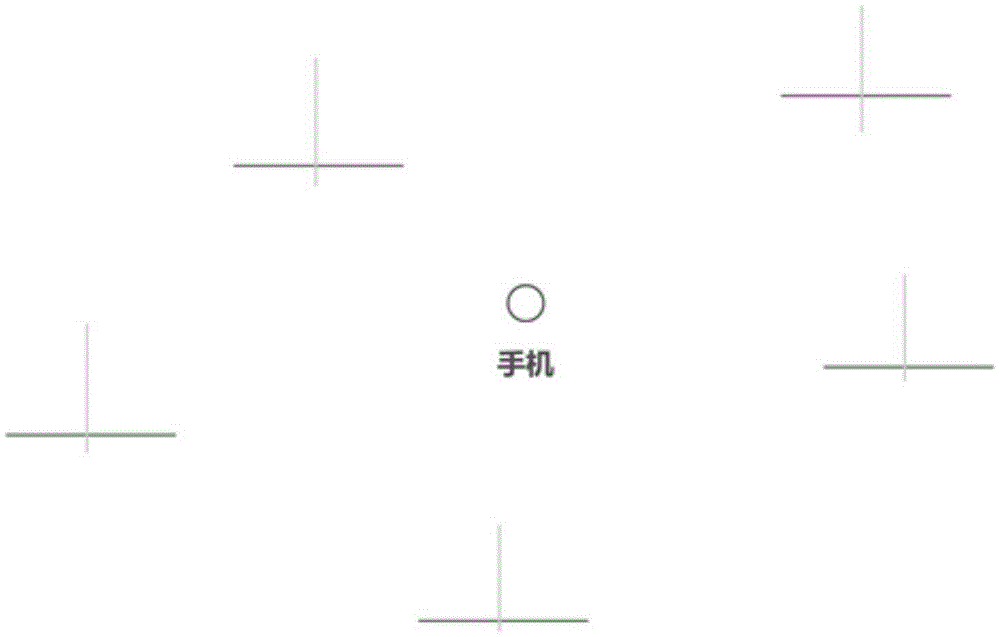

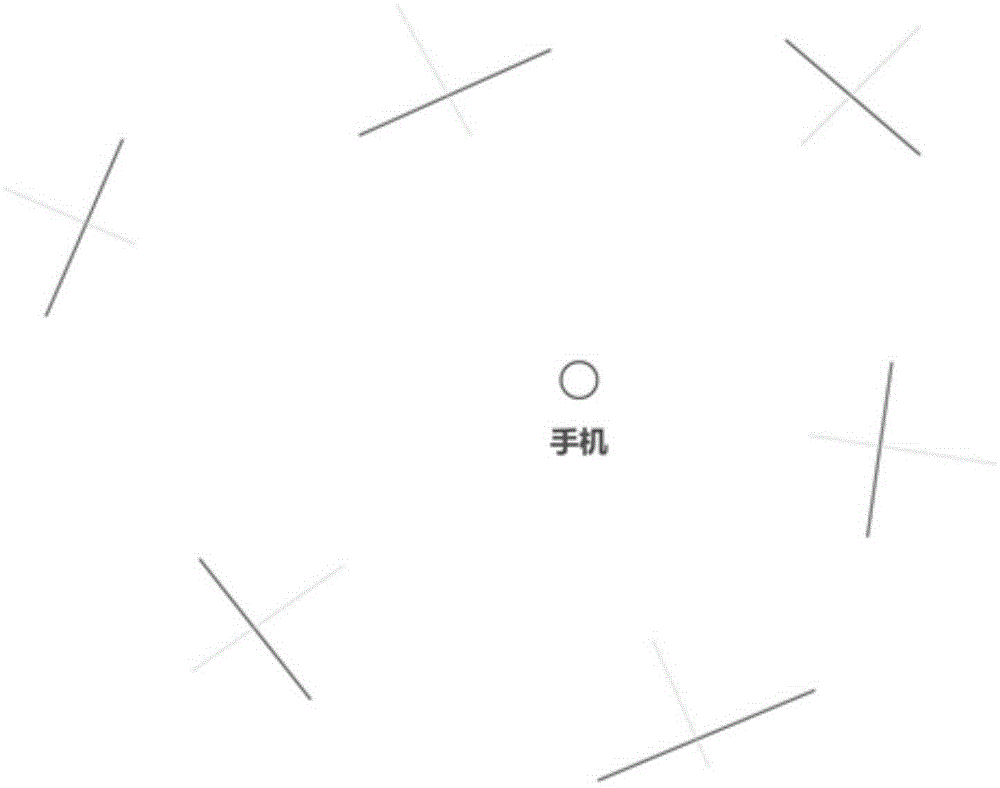

Geographic information display method based on augmented reality technology

ActiveCN105334525AObtain intuitivelyThe information displayed is rich and variedSatellite radio beaconingData displayThree-dimensional space

The invention relates to a geographic information display method based on the augmented reality technology. The method comprises the following steps: establishing a three-dimensional coordinate system of a mobile phone; mapping longitudes and latitudes of the mobile phone and a to-be-displayed feature into the three-dimensional coordinate system of the mobile phone; generating a rotation matrix of a rotation feature label according to the mobile phone coordinates and the feature coordinates in the three-dimensional coordinate system; and drawing the feature label and rotating the feature label to the plane normal direction of the feature label by utilizing the rotation matrix to point at the location of the mobile phone. Therefore, the method has the advantages that 1, information display is intuitive and convenient, geographic information can be directly superposed into a field scene by utilizing data display advantages of augmented reality, and the user can acquire information intuitively; and 2, information display content is various, the feature label can be accurately drawn in a virtual three-dimensional space directly on a screen according to the location coordinates of the feature by utilizing the augmented reality technology, and the user can determine the direction and distance of the feature directly through the label position.

Owner:吉奥时空信息技术股份有限公司

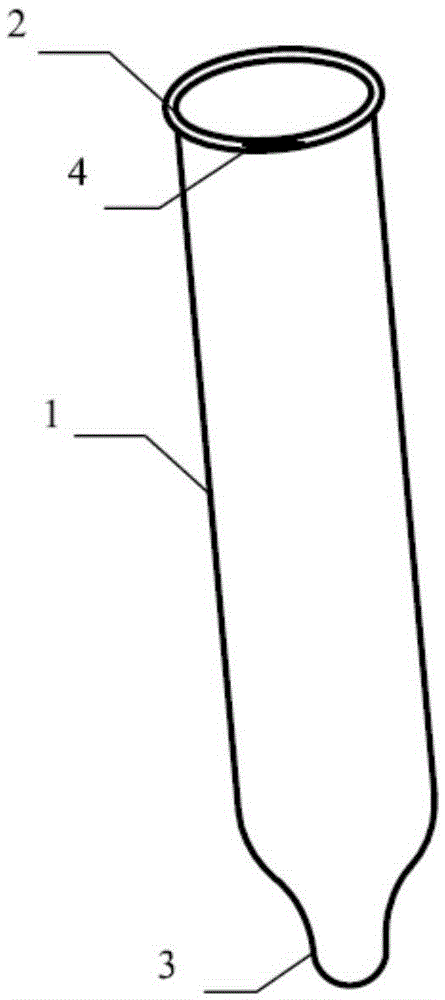

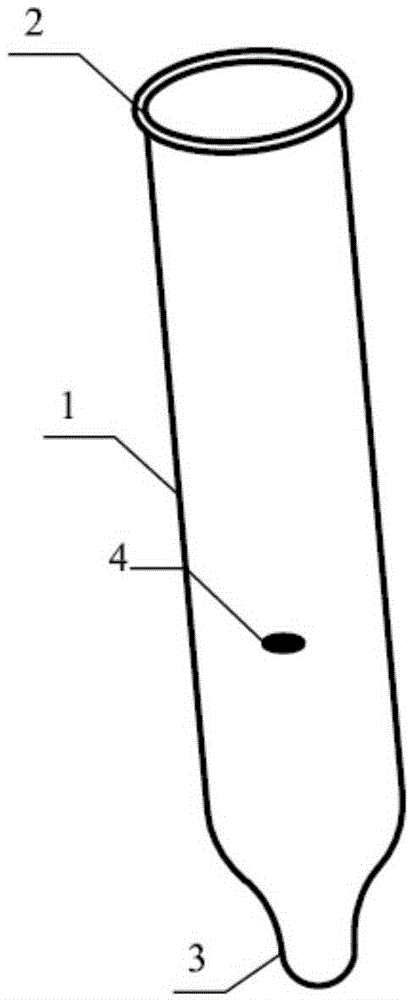

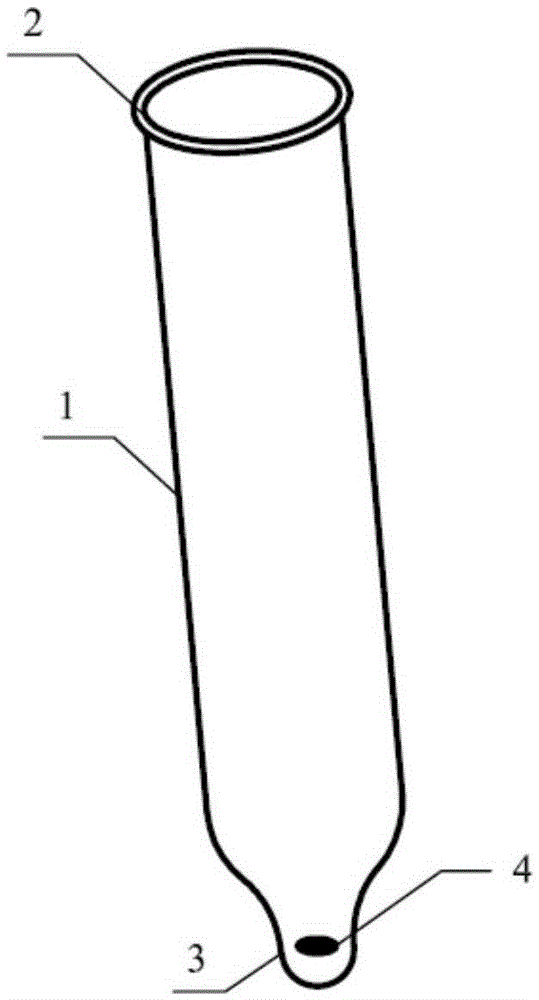

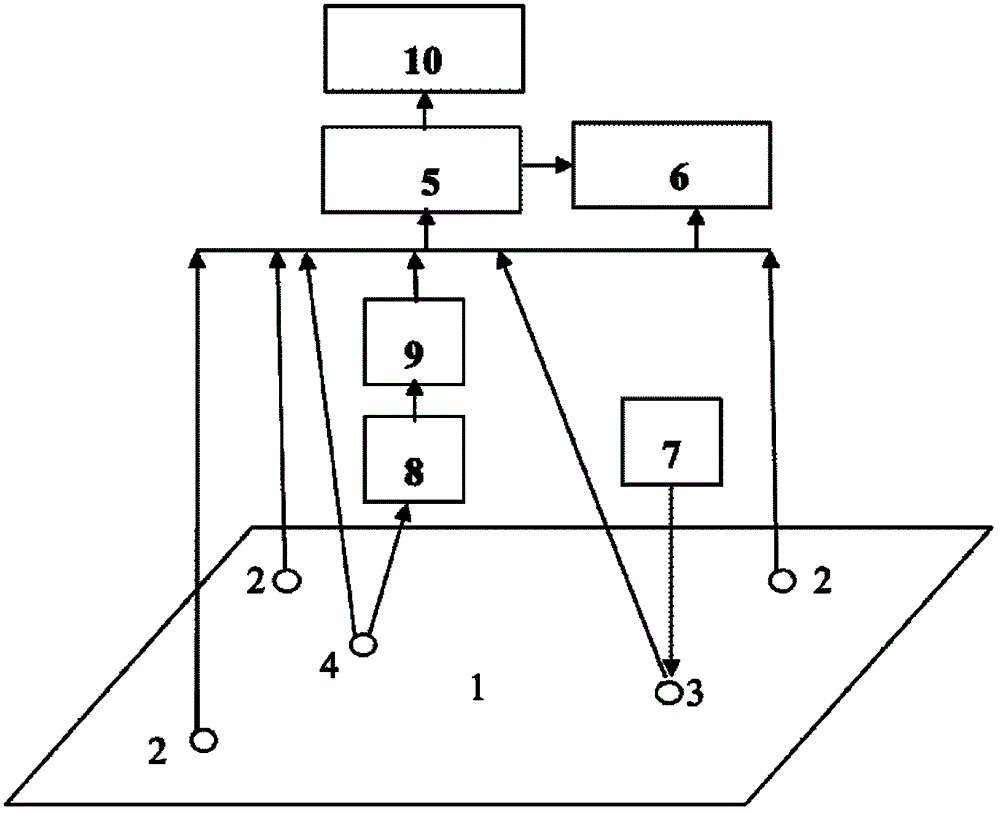

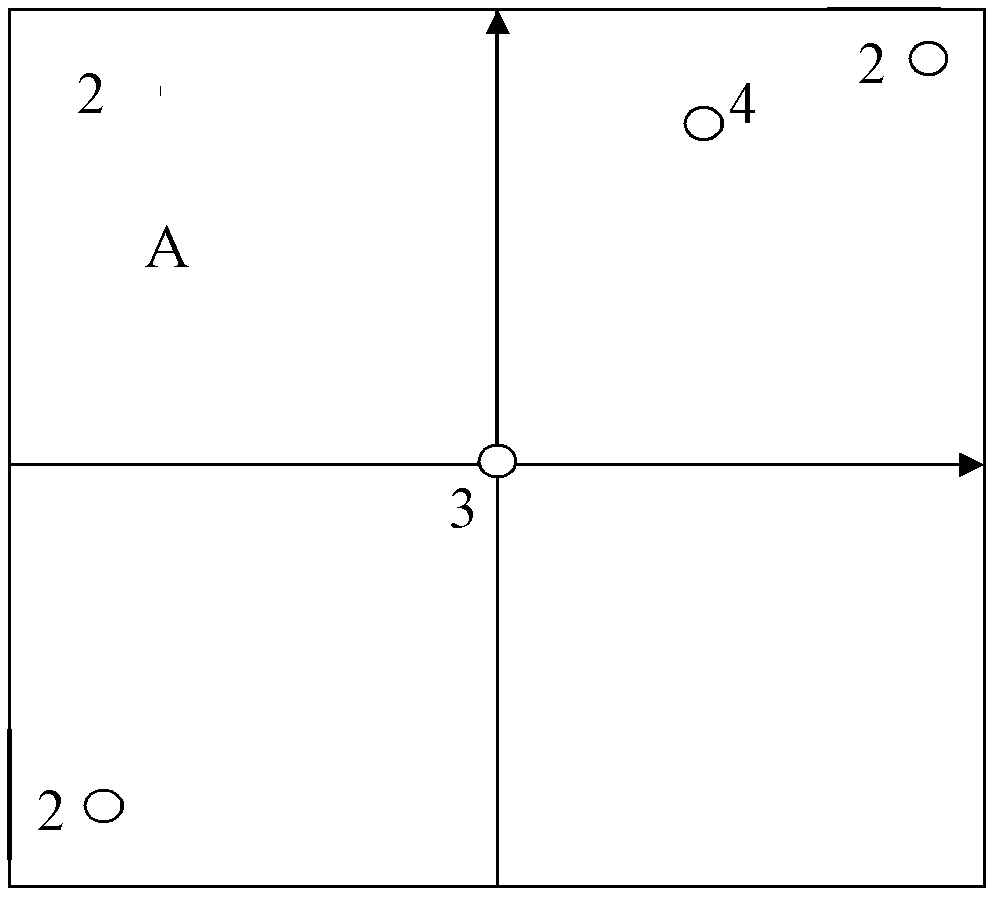

Condom with induction function, manufacturing method thereof and data collection system

InactiveCN105395305ARealize acquisitionGet it in real timeMale contraceptivesEvaluation of blood vesselsHuman bodyData acquisition

The invention discloses a condom with an induction function. The condom comprises a condom body. The condom body comprises a sleeve body (1), an open end (2) and a closed end (3) and is further provided with an induction element (4). The invention further provides a manufacturing method of the condom with the induction function. The manufacturing method comprises the steps that the induction element (4) is placed in the condom before forming or during forming or after forming, and the condom with the induction function is formed. The invention further provides a system for collecting human body sign and movement data. The system comprises an intelligent terminal and the condom with the induction function. According to the technical scheme, the human body sign and movement data can be collected and analyzed in real time; a user can adjust the body state according to the real-time human body sign and movement data after the condom is connected with the intelligent terminal for use.

Owner:陈汝霖 +1

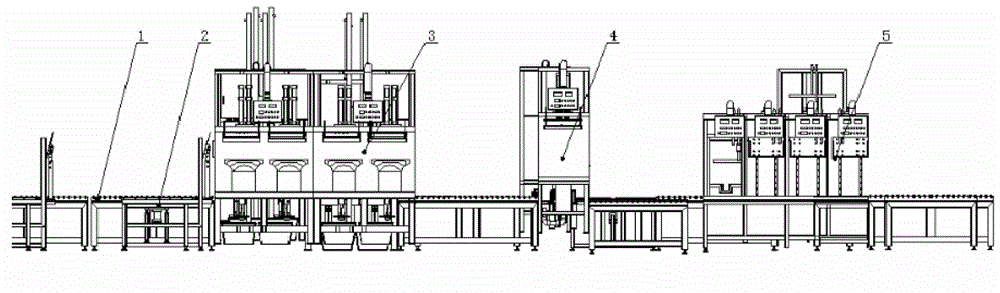

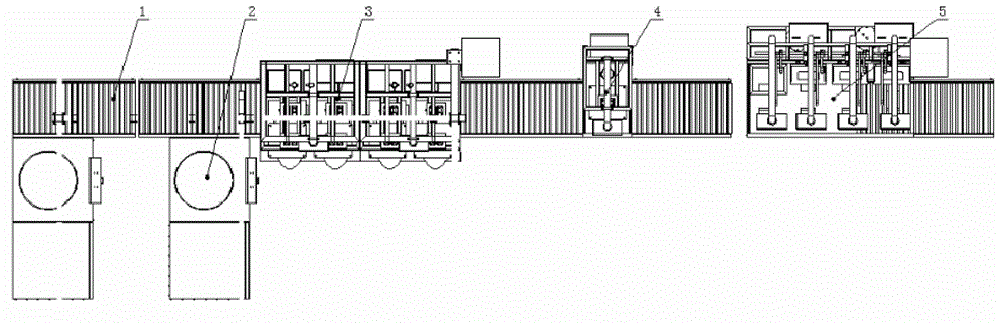

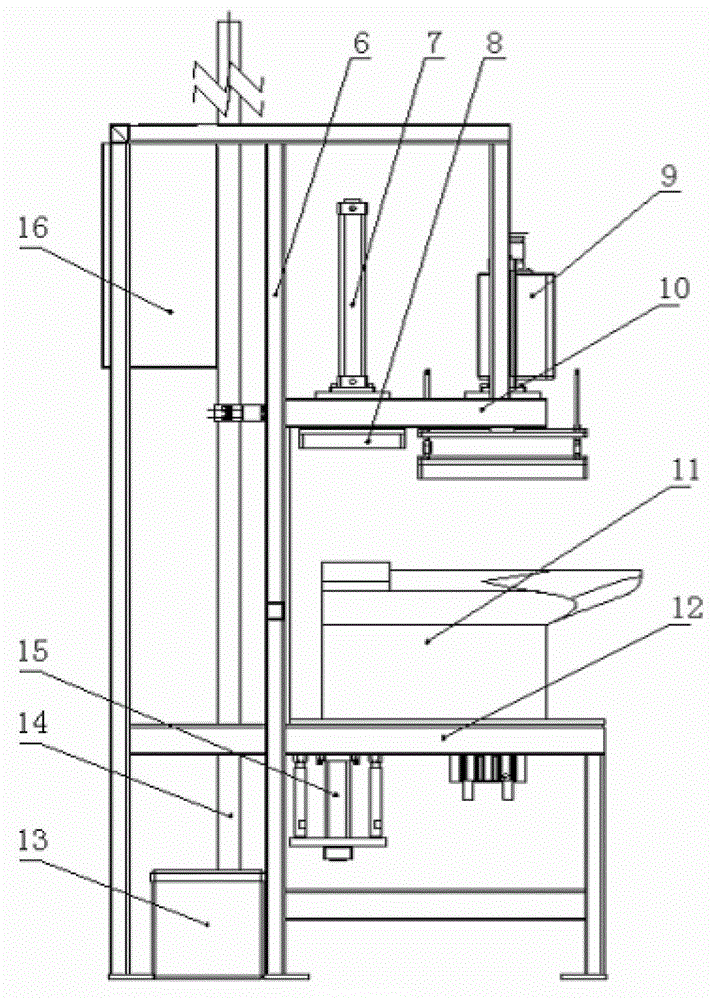

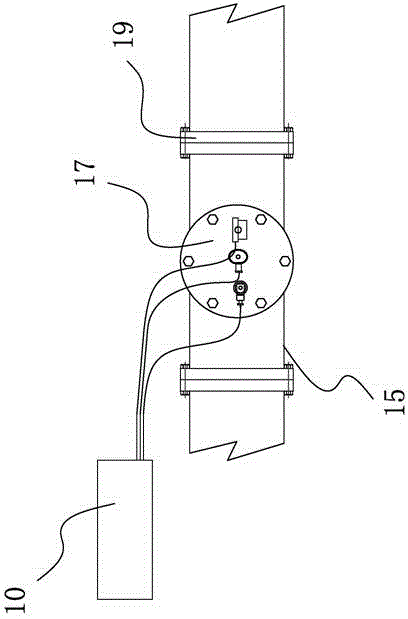

Ceramic sanitary appliance detection system

ActiveCN102865971AReduce equipment purchase costLow costFluid-tightness measurement using fluid/vacuumEngineeringAutomatic testing

The invention relates to a ceramic sanitary appliance detection system. The ceramic sanitary appliance detection system comprises a detection roller line, split-body water leakage inspection equipment, split-body air leakage inspection equipment and split-body washing equipment, wherein the middle of the detection roller line is sequentially connected with the split-body water leakage inspection equipment, the split-body air leakage inspection equipment and the split-body washing equipment. According to the ceramic sanitary appliance detection system, the structure is simple, in the design is scientific, the maintenance is convenient, rapid in the part replacement is rapid, the cost is saved, the efficiency is effectively improved through automatic detection and control in the whole process, the detection result can be obtained visually, and a prompt alarm is given in case of inconformity, so that the degree of accuracy of the detection result is ensured.

Owner:天津杰科同创科技发展有限公司

Air compressor efficacy instrument and efficacy calculating method thereof

ActiveCN105090003AEasy to adjustAdjust in timePump testingPositive-displacement liquid enginesEngineeringAir compressor

The invention belongs to the technical field of energy conservation and emission reduction and relates to air compressor detection, in particular to an air compressor efficacy instrument and an efficacy calculating method thereof. The technical problem that the design in the prior art is not reasonable enough and the like is solved. The efficacy instrument comprises a temperature sensor, a pressure sensor and a flow sensor, wherein the temperature sensor, the pressure sensor and the flow sensor are respectively connected with a central processor used for calculating the efficacy of the air compressor, and an input device used for inputting parameters is connected to the central processor. The air compressor efficacy instrument and the efficacy calculating method thereof have the advantages that the design is reasonable, and the structure is simple; and the efficacy of the air compressor can be conveniently, rapidly and visually obtained so as to timely regulate the air compressor, thereby effectively saving energy consumption and promoting the air compressor to lie in the optimum work state.

Owner:浙江联核动力科技有限公司

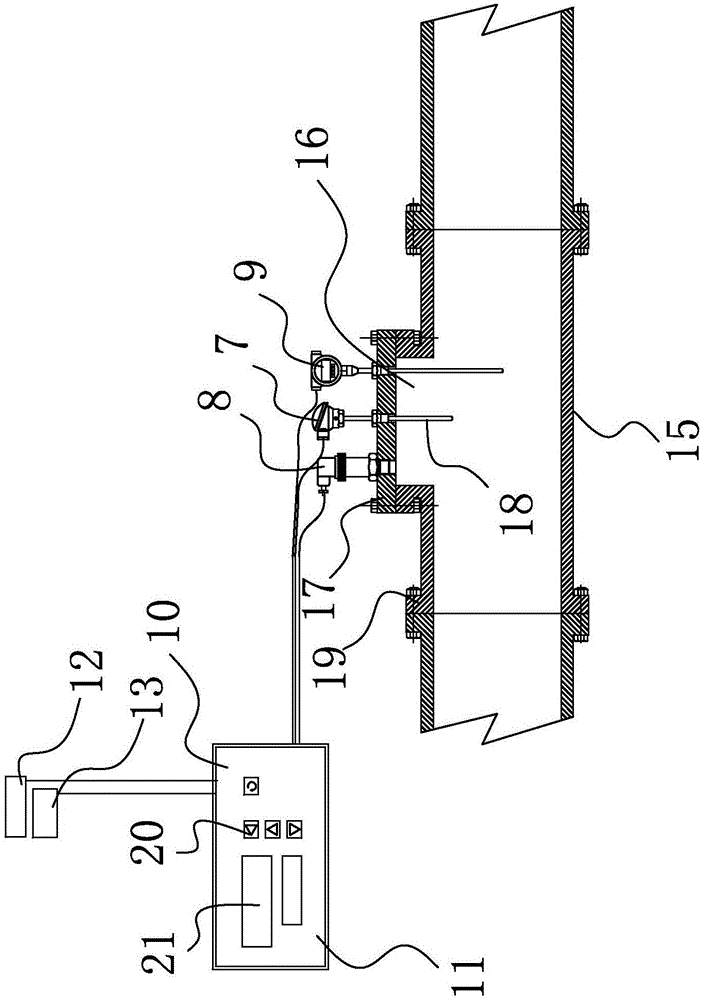

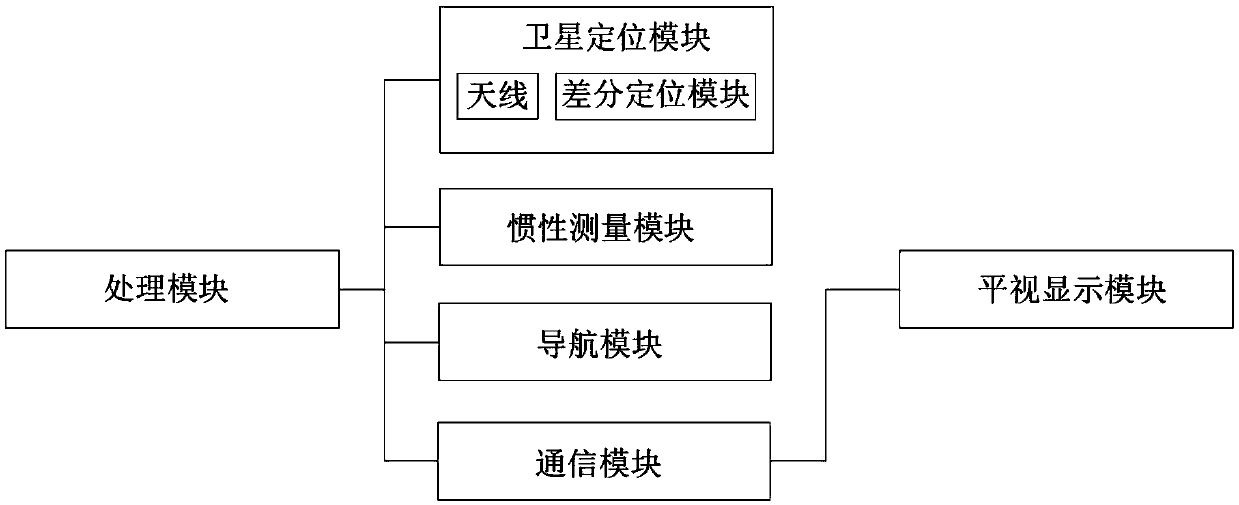

Vehicle-mounted navigation system

ActiveCN109540157AImprove securityEasy accessInstruments for road network navigationHead-up displayMarine navigation

The invention relates to the technical field of navigation and positioning, and discloses a vehicle-mounted navigation system. The vehicle-mounted navigation system comprises a docking device and a head-up display module, wherein the docking device comprises a processing module, a satellite positioning module, an inertial measurement module, a navigation module and a communication module; and thedocking device is operatively coupled to the head-up display module, and through the head-up display module, the high-precision navigation information is displayed. Accordingly, the invention also discloses a control method for the vehicle-mounted navigation system. The system and the method disclosed in the invention have certain technical effects that the high-precision navigation information can be displayed through the head-up display module, a driver can quickly, intuitively and conveniently acquire the lane-level positioning and navigation information, and the safety of a driving processcan be improved.

Owner:广东星舆科技有限公司

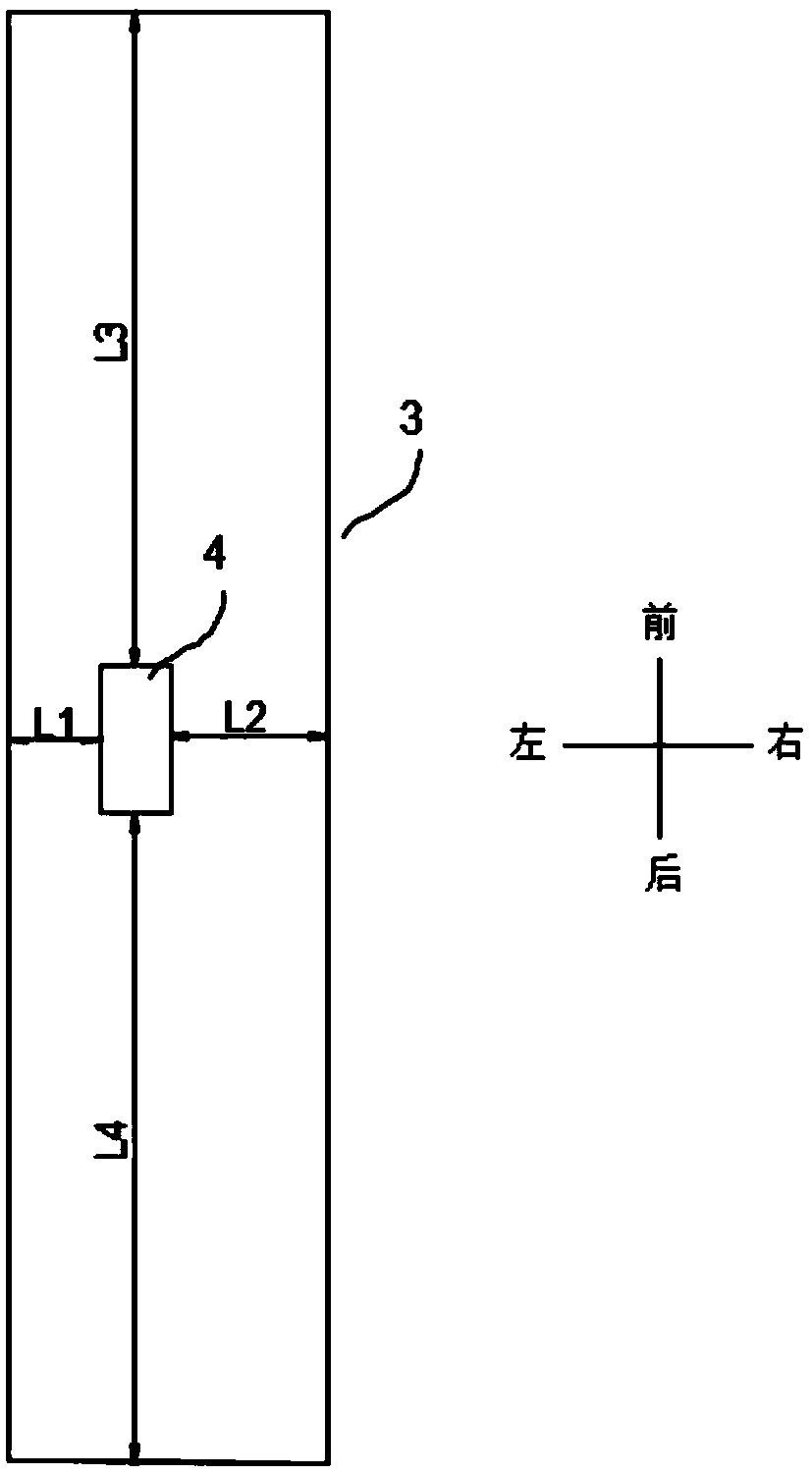

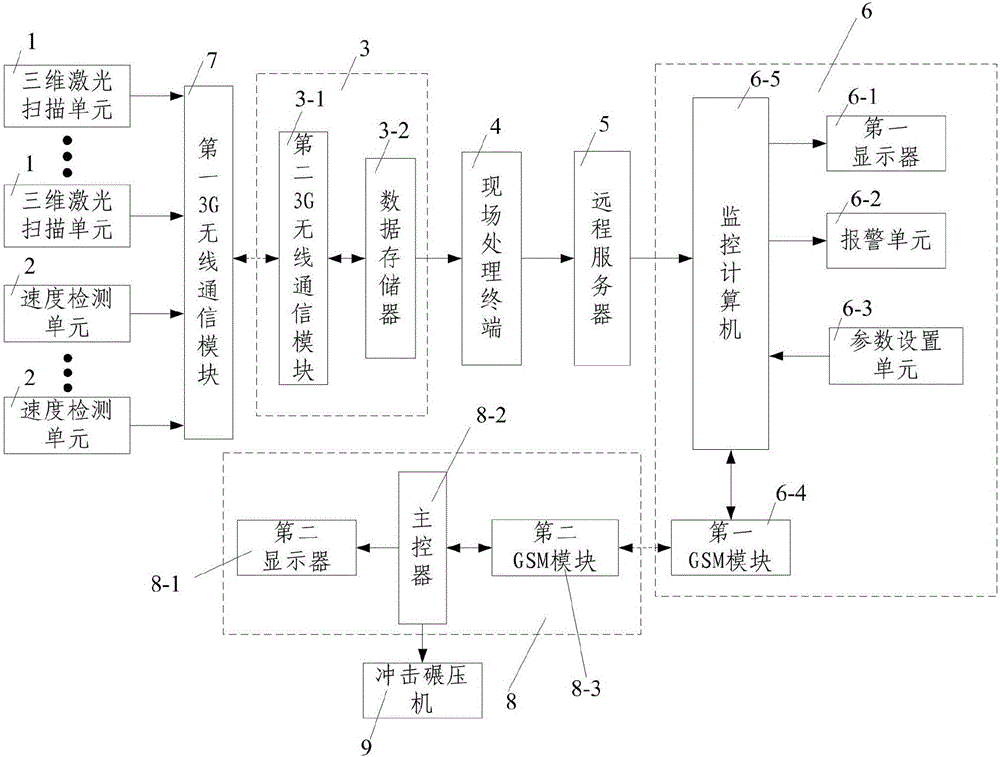

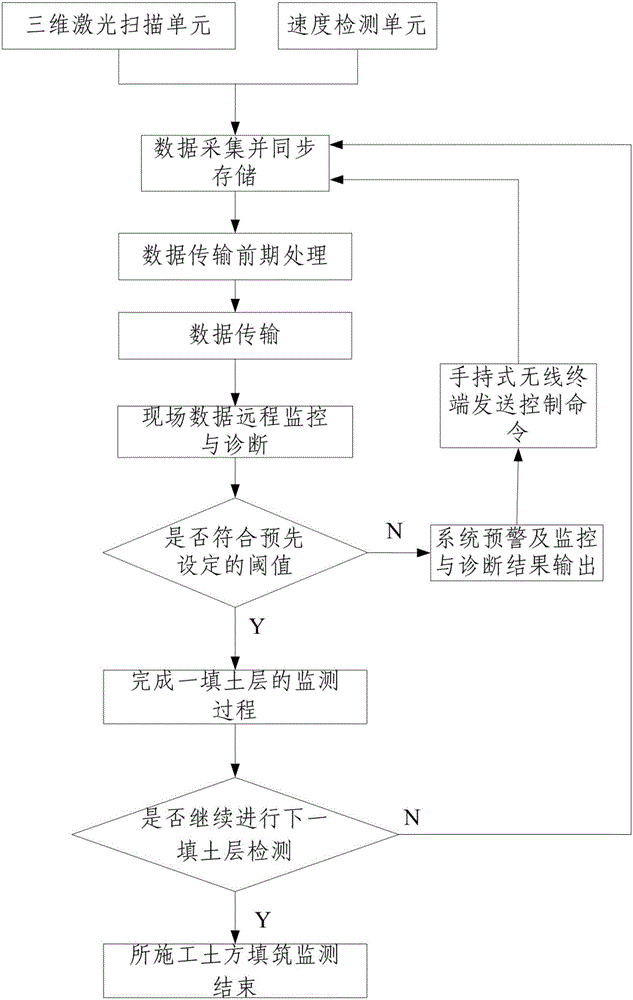

Earthwork filling monitoring device and method based on three-dimensional laser scanning

ActiveCN106774069ASimple structureReasonable designProgramme controlVolume measurement apparatus/methodsProcess moduleLaser scanning

The invention discloses an earthwork filling monitoring device and method based on three-dimensional laser scanning. The monitoring device comprises a data detecting module and a monitoring module. The monitoring module comprises a field processing module, a remote monitoring module and a handhold wireless terminal. The field processing module comprises a field server and a field processing terminal. The remote monitoring module comprises a remote server and a remote monitoring terminal. The monitoring method comprises the following steps: step one, collecting data and synchronously storing; step two, pre-processing of the data transmission; step three, the data transmission; step four, field data remote monitoring and diagnosing; and step five, repeatedly executing the step one to the step four for several times, until finishing the monitoring process of the construction earthwork filling. The monitoring device and method have the characteristics of rational design, simple and convenient operation and good using effect, and are capable of accurately monitoring the construction earthwork filling in real time, and the detection result is accurate.

Owner:CHINA JK INST OF ENG INVESTIGATION & DESIGN

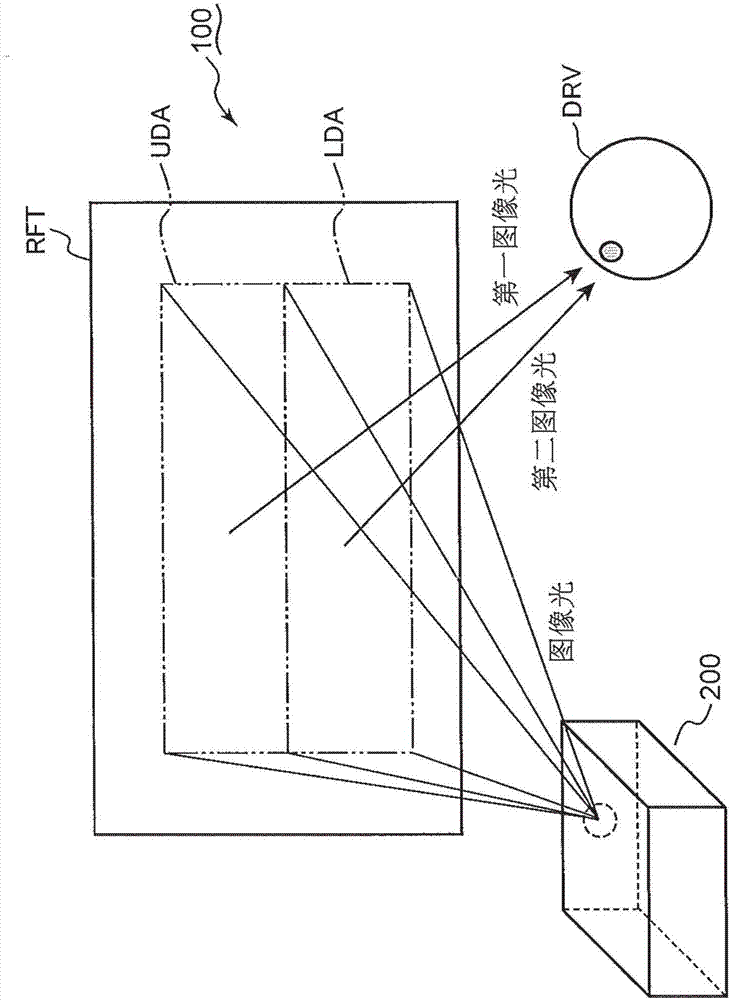

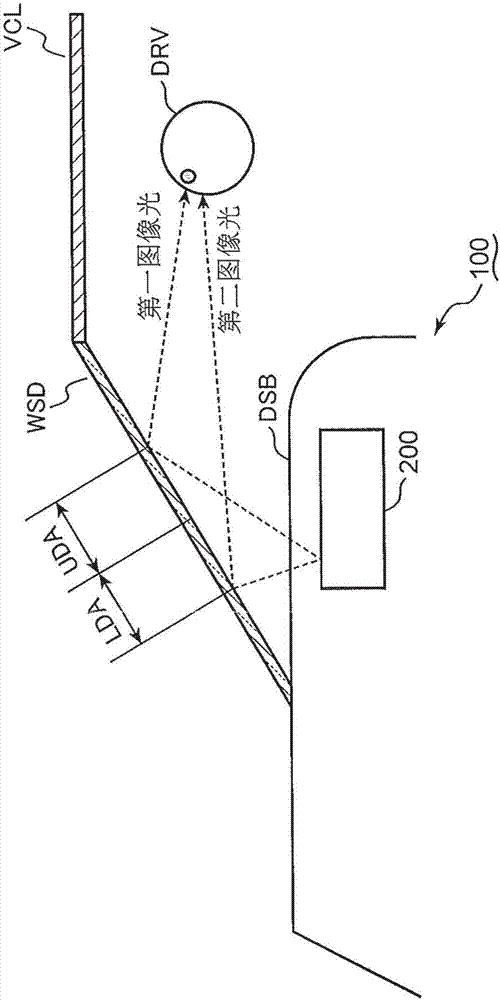

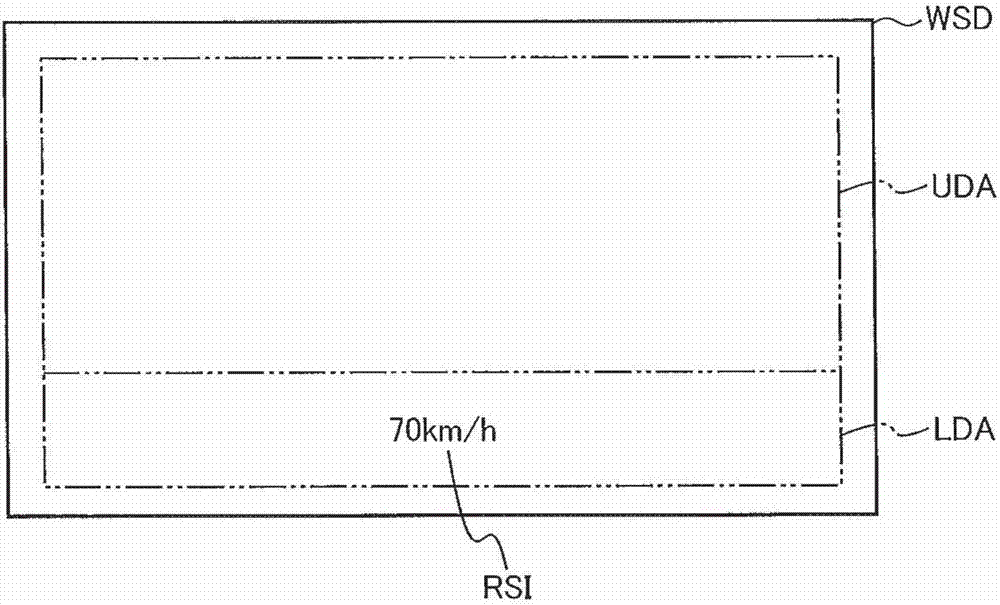

Head-up display device

InactiveCN107428293AObtain intuitivelyInstruments for road network navigationAnti-collision systemsHead-up displayComputer science

The present application discloses a head-up display device installed in a vehicle. This head-up display device is provided with a projection device for emitting projected image light onto a reflective surface that includes a first region and a second region below the first region. The projected image light includes first projected image light indicating first information that includes information pertaining to external factors outside of the vehicle, and second projected image light indicating second information pertaining to the vehicle itself. The projection device emits the first projected image light onto the first region, and emits the second projected image light onto the second region.

Owner:MAZDA MOTOR CORP

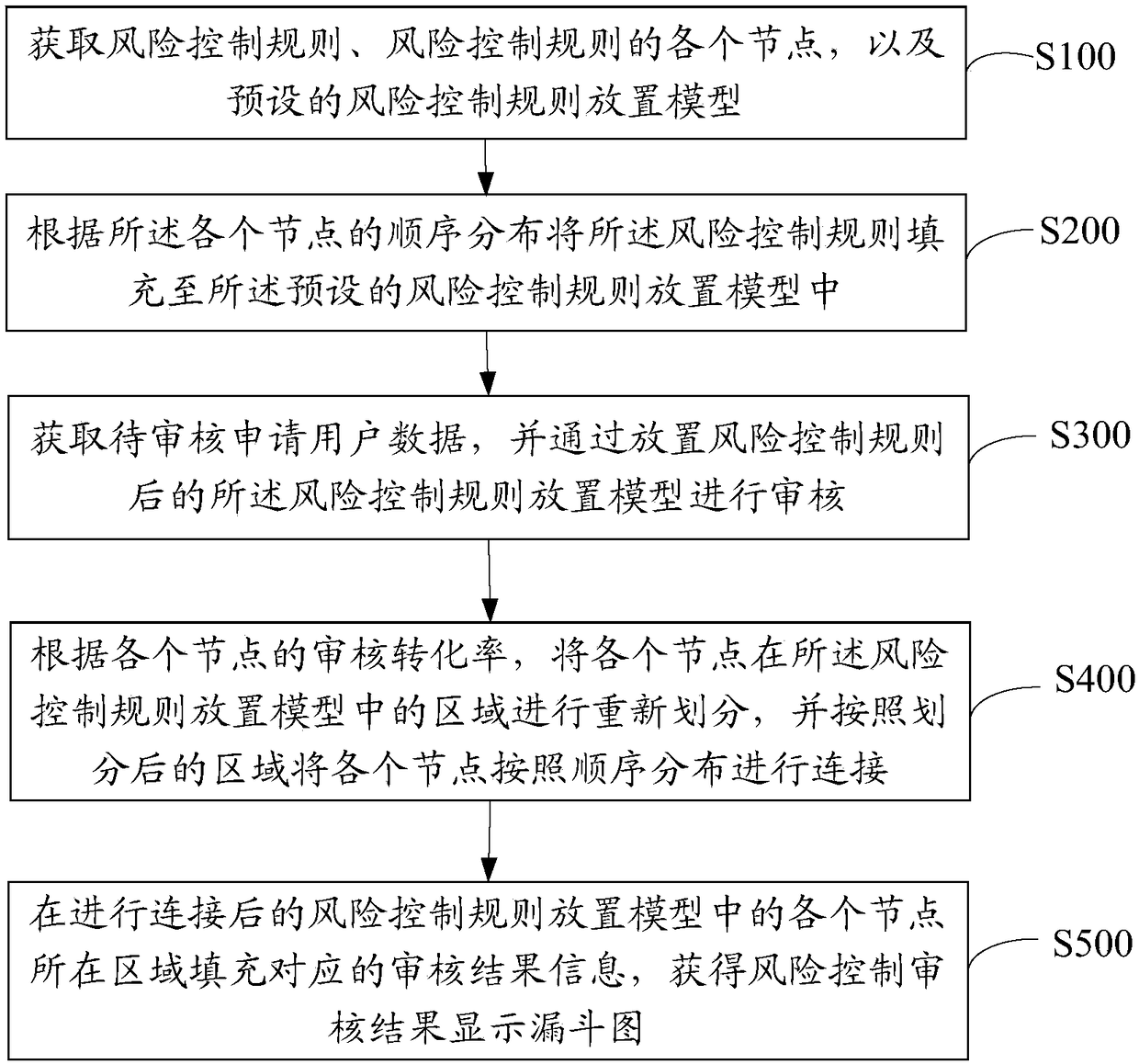

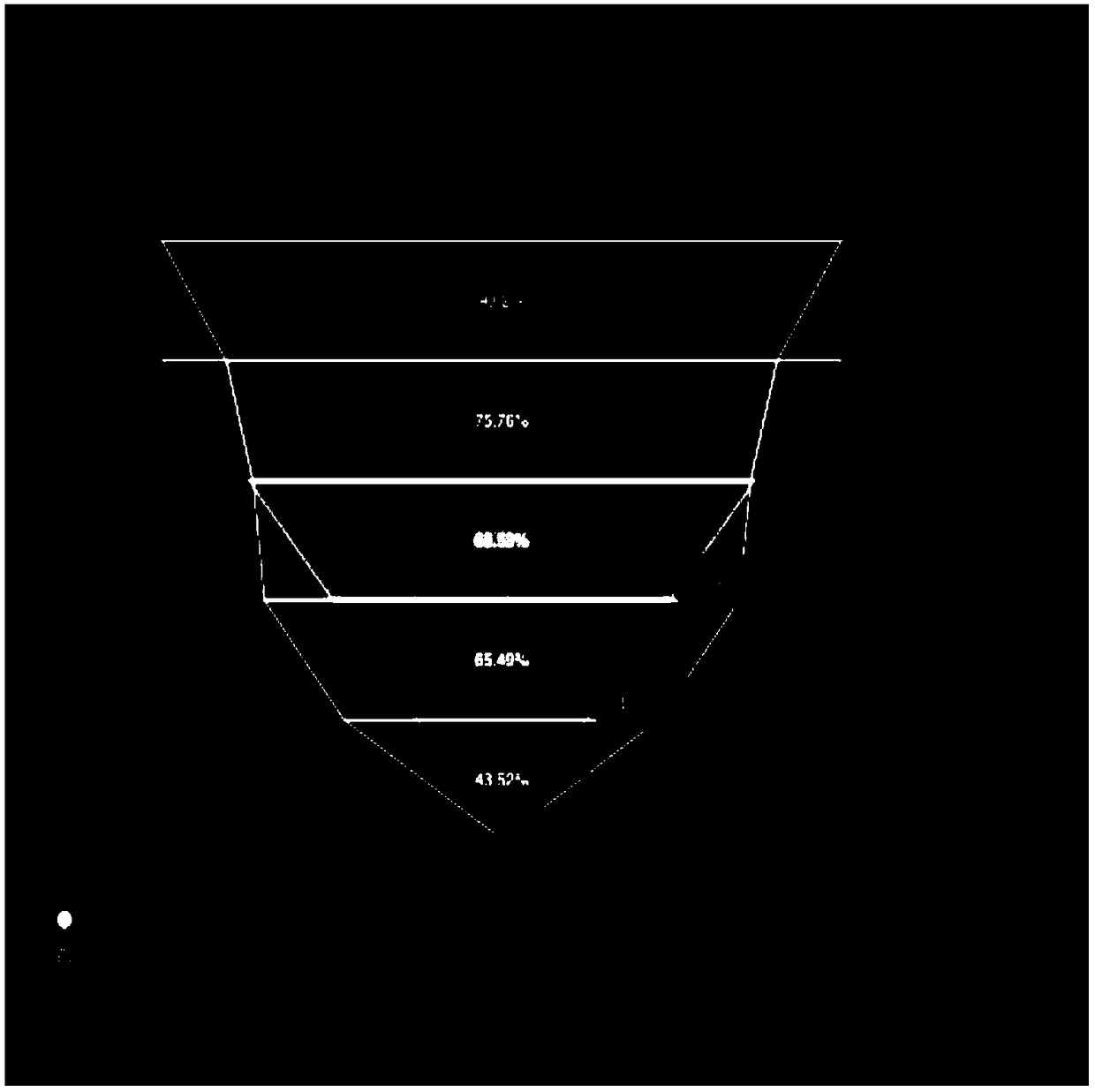

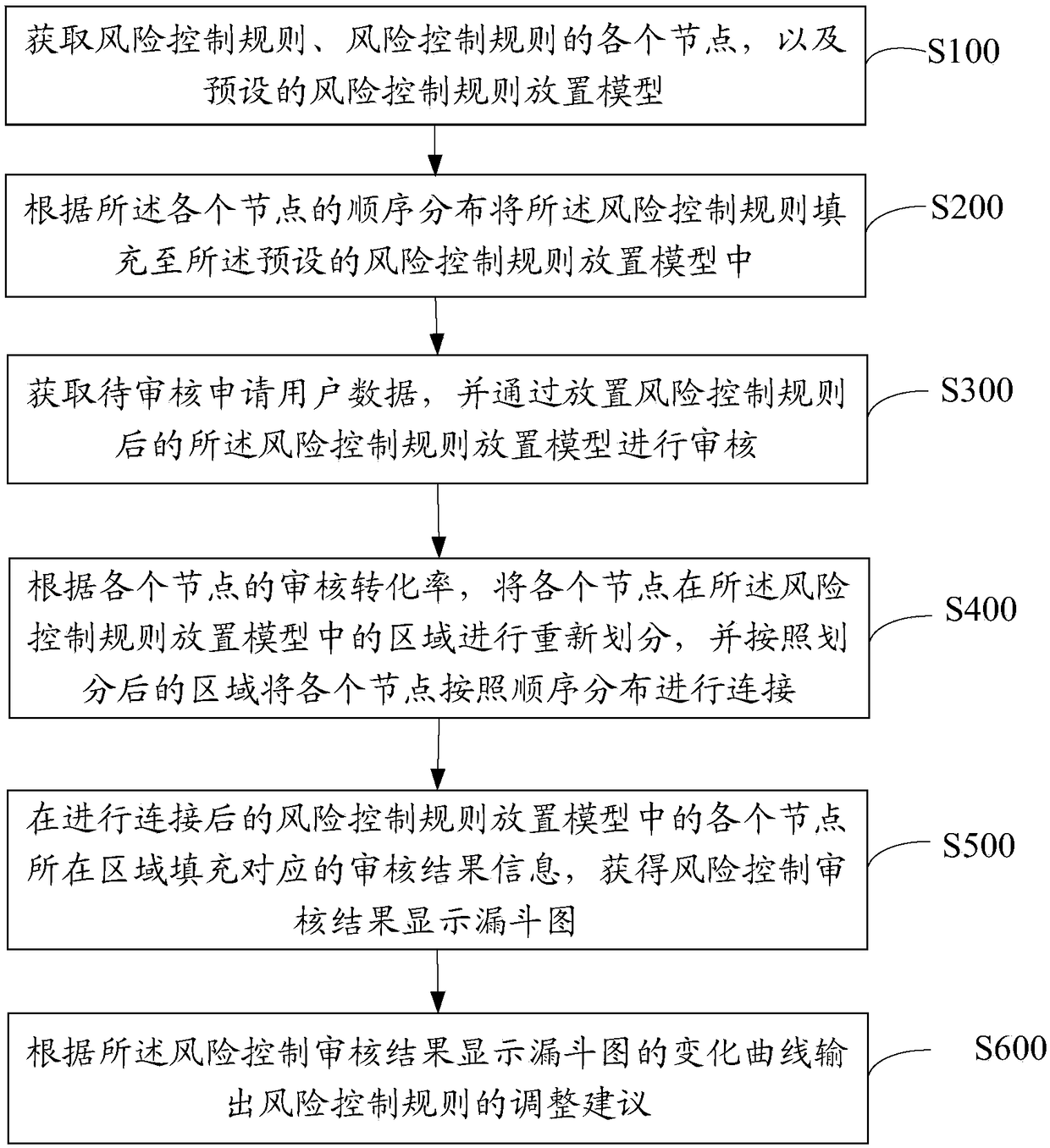

Intelligent display method, device, equipment for risk control audit result and storage medium

PendingCN108564464AObtain intuitivelyImprove processing efficiencyFinanceRisk ControlComputer science

Owner:ONE CONNECT SMART TECH CO LTD SHENZHEN

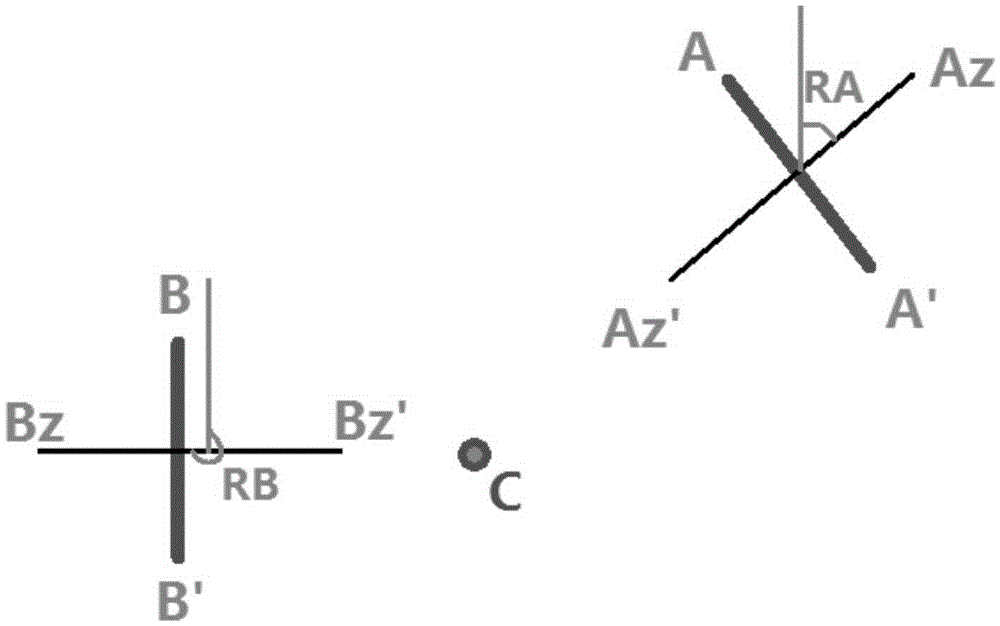

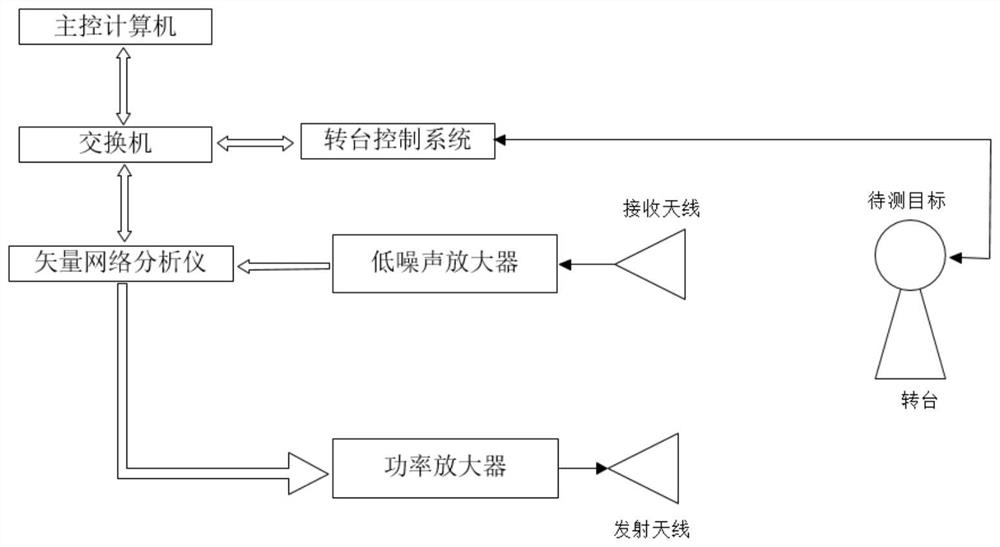

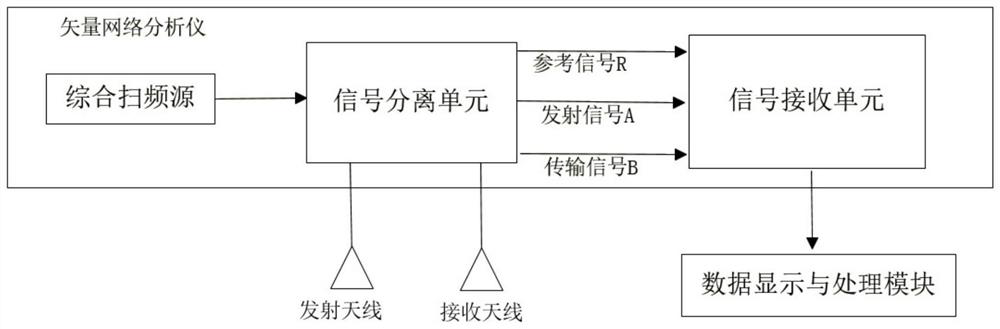

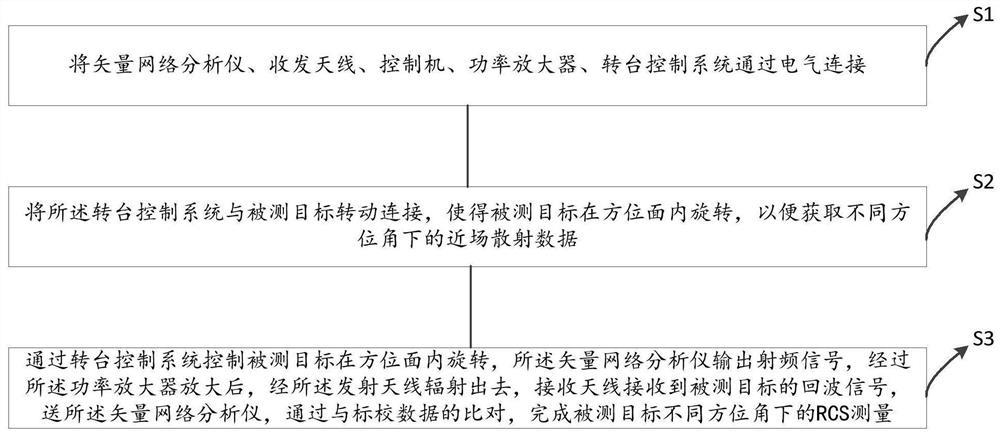

RCS measurement system and method

PendingCN113156388AWide measurement rangeLarge measurement field of viewWave based measurement systemsEcho signalNear field scattering

The invention discloses an RCS measurement system and method. The system comprises a vector network analyzer, a transceiving antenna, a control machine, a power amplifier and a rotary table control system which are electrically connected. The vector network analyzer is used for transmitting and receiving radio frequency signals; the control machine controls the vector network analyzer through an LAN (Local Area Network) bus; the turntable control system is used for controlling a to-be-measured target to rotate in an azimuth plane so as to acquire near-field scattering data under different azimuth angles; and a to-be-measured target is controlled by the turntable control system to rotate in an azimuth plane, the vector network analyzer outputs a radio frequency signal, the radio frequency signal is amplified by the power amplifier and then radiated by the transmitting antenna, the receiving antenna receives an echo signal of the to-be-measured target, the echo signal is sent to the vector network analyzer and compared with calibration data, and RCS measurement of the to-be-measured target under different azimuth angles is completed. The measurement range is wide, the measurement field of view is large, the RCS scattering matrix and target broadband multi-dimensional imaging characteristics can be measured, and electromagnetic scattering characteristic data can be visually obtained.

Owner:佛山蓝谱达科技有限公司

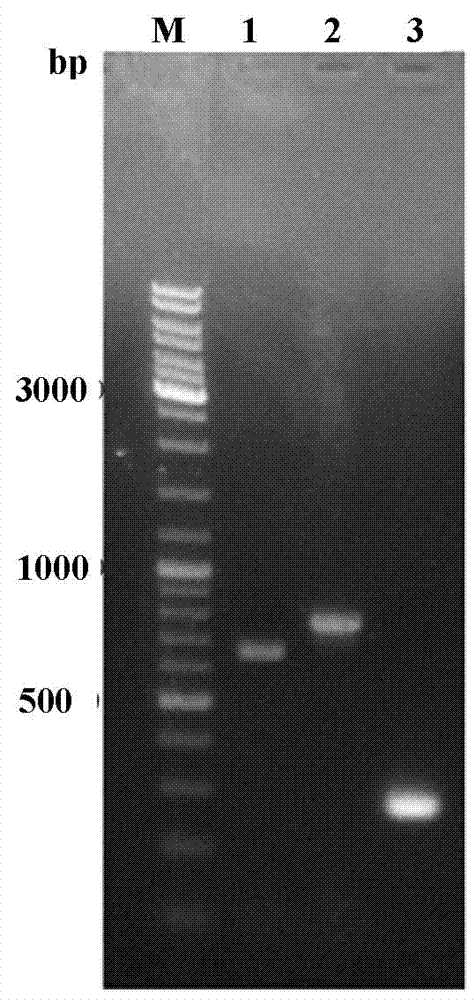

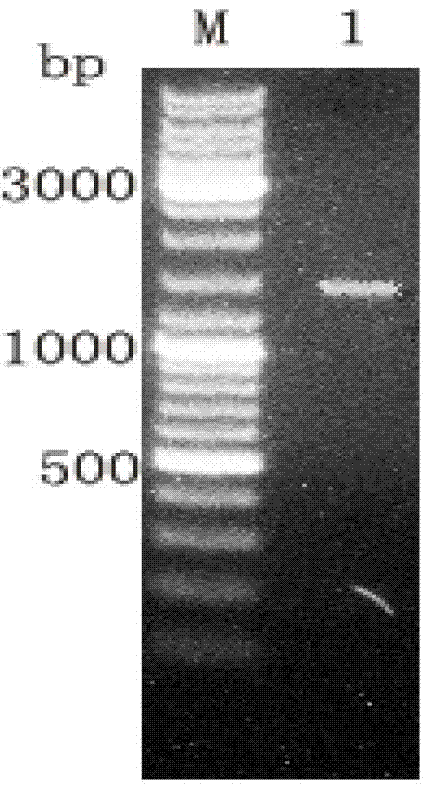

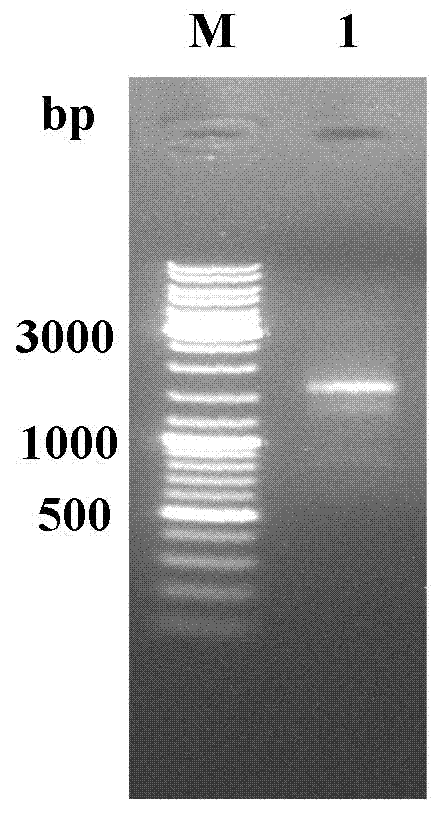

Method for targeted knockout of non-essential genes for Bombyx mori nuclear polyhedrosis virus replication

ActiveCN103589745AEasy accessObtain intuitivelyDsDNA virusesVector-based foreign material introductionPUC19Genomic DNA

The present invention relates to a method for targeted knockout of non-essential genes for replication of the Bombyx mori nuclear polyhedrosis virus BmNPV. The method is as below: using BmNPV as a material to amplify a homologous sequence at both ends of a non-essential region for replication by PCR and cloning it into a vector pUC19; splicing successively an IE1 early promoter, a marker gene (EGFP) and a termination sequence SV40polyA of BmNPV by an overlapping PCR method and cloning them to the abovementioned vector pUC19 to obtain a recombinant transfer vector pUC19-lef7-IE1-EGFP-SV40polyA-gp64; co-transfecting BmN cells using the vector and the genome of wild BmNPV and carrying out homologous recombination to obtain a recombinant virus RBmNPV-EGFP with a fluorescent marker; and co-transfecting BmN cells using genomic DNA thereof and a transfer vector pUC19-lef7-gp64 without marker gene and carrying out homologous recombination to obtain a recombinant virus RBmNPV without fluorescent marker gene. The present invention solves the problem of the presence of marker genes in recombinant virus genomes and improves the screening efficiency of positive recombinant viruses, and thus the marker genes can be reused.

Owner:TIANJIN YAOYU BIOLOGICAL TECH

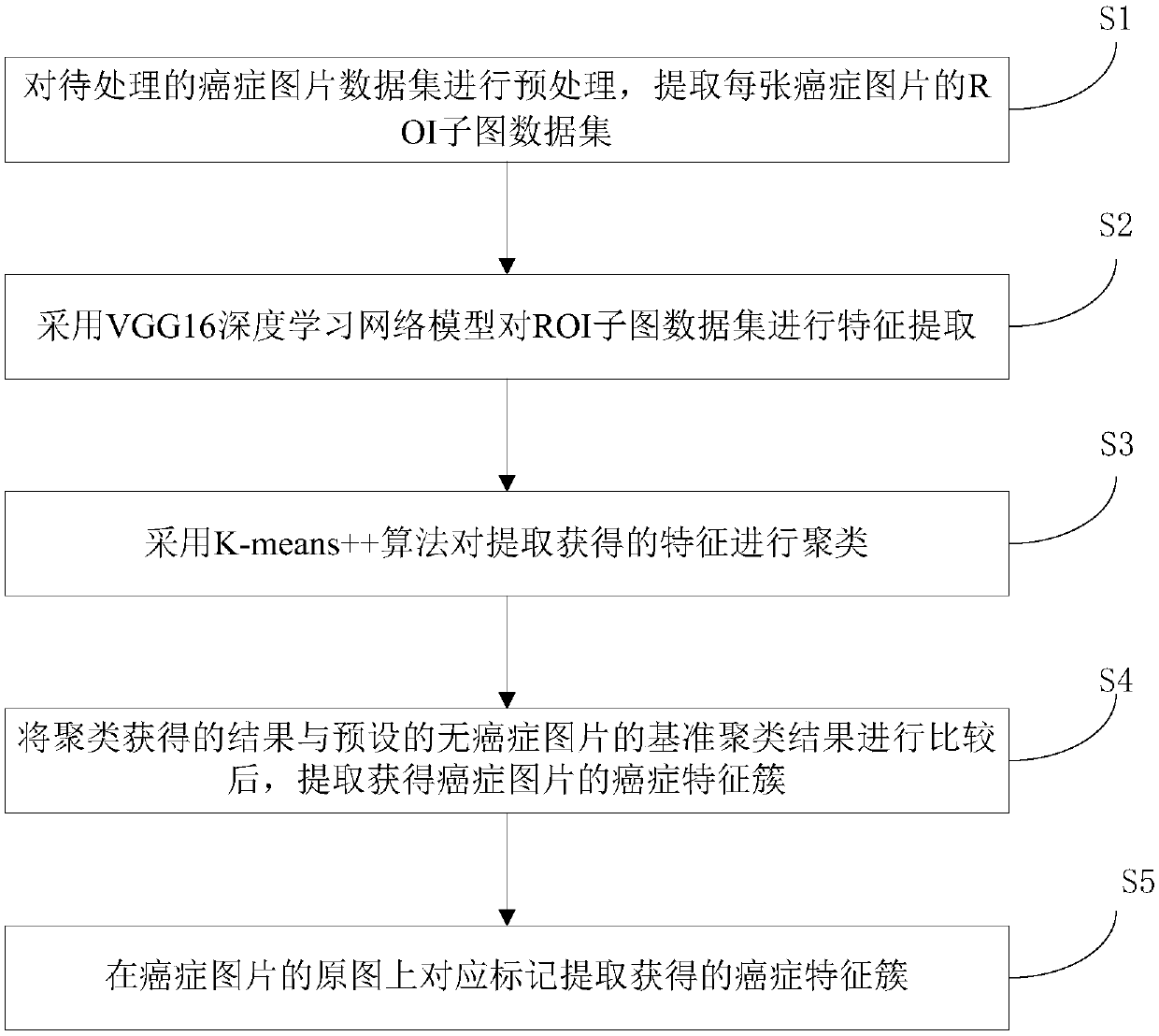

Thyroid cancer ultrasonic image automatic labeling method and system

InactiveCN108681731AEasy accessObtain intuitivelyCharacter and pattern recognitionAcquired characteristicData set

The invention discloses a thyroid cancer ultrasonic image automatic labeling method and system. The method includes the following steps that: a cancer image data set to be processed is preprocessed, so that the ROI sub-image data set of each cancer image is extracted; a VGG16 deep learning network model is adopted to perform feature extraction on the ROI sub-image data set; a K-means++ algorithm is used to cluster extracted features; clustering results are compared with the reference clustering results of preset cancer-free images, so that the cancer feature clusters of the cancer images are obtained; and the obtained cancer feature clusters are correspondingly labeled on the original images of the cancer images. The method and system of the invention have the advantages of high work efficiency, high accuracy and low application cost. The method and system can assist in saving a large quantity of financial and material resources and can be widely used in the medical image data processing field.

Owner:SUN YAT SEN UNIV

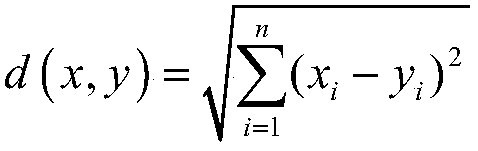

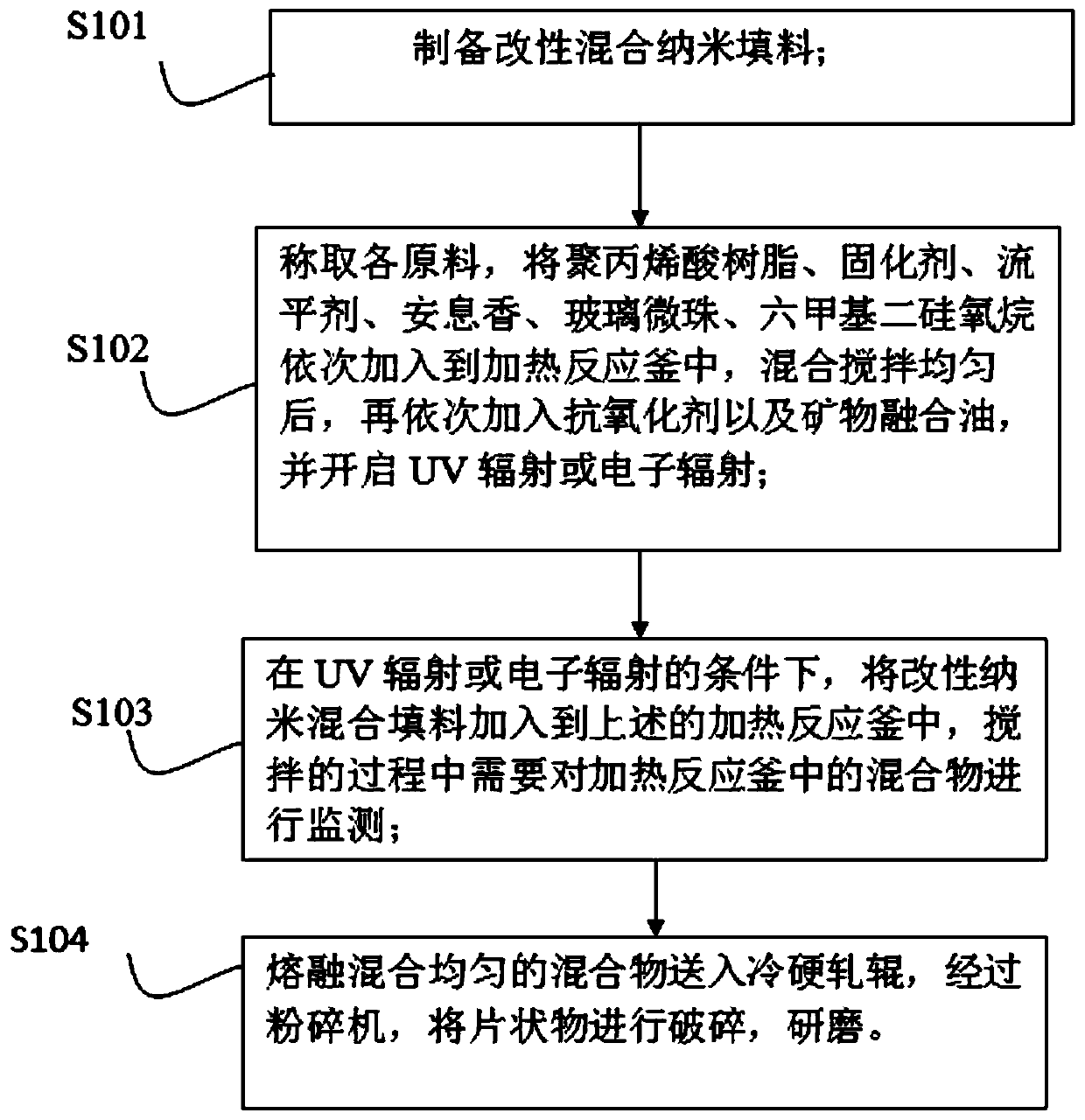

Reflective powder coating for traffic signs and preparation method thereof

InactiveCN110746830AImprove finenessGood film formingChemical/physical/physico-chemical stationary reactorsEnergy based chemical/physical/physico-chemical processesWeather resistanceElectron radiation

The invention provides a reflective powder coating for traffic signs and a preparation method thereof. In the preparation process of the coating, a mixed filler is subjected to nano-modification and then added into a heating reaction kettle to interact with other components together, so that a more uniform molten-state mixture can be formed, and the fineness of the powder coating is promoted; a UVradiation or electron radiation apparatus is arranged to promote the mixture to have smaller particles and to promote the combination degree of the mixture; and further a monitoring apparatus is arranged and can monitor the real-time morphology of the mixture in the reactor in time, and thereby the stirring degree during the whole production process is more accurately controlled, the quality of production is ensured, not only the production process is simplified, but also the quality of production is ensured, and the production cost is reduced. The problems that agglomeration is easy to occur, and the process is difficult to accurately control in the production process of the powder coating are solved. The powder coating is used as a reflective material for traffic signs, and has the advantages of environmental protection, strong adhesion and weather resistance.

Owner:佛山市涂亿装饰材料科技有限公司 +1

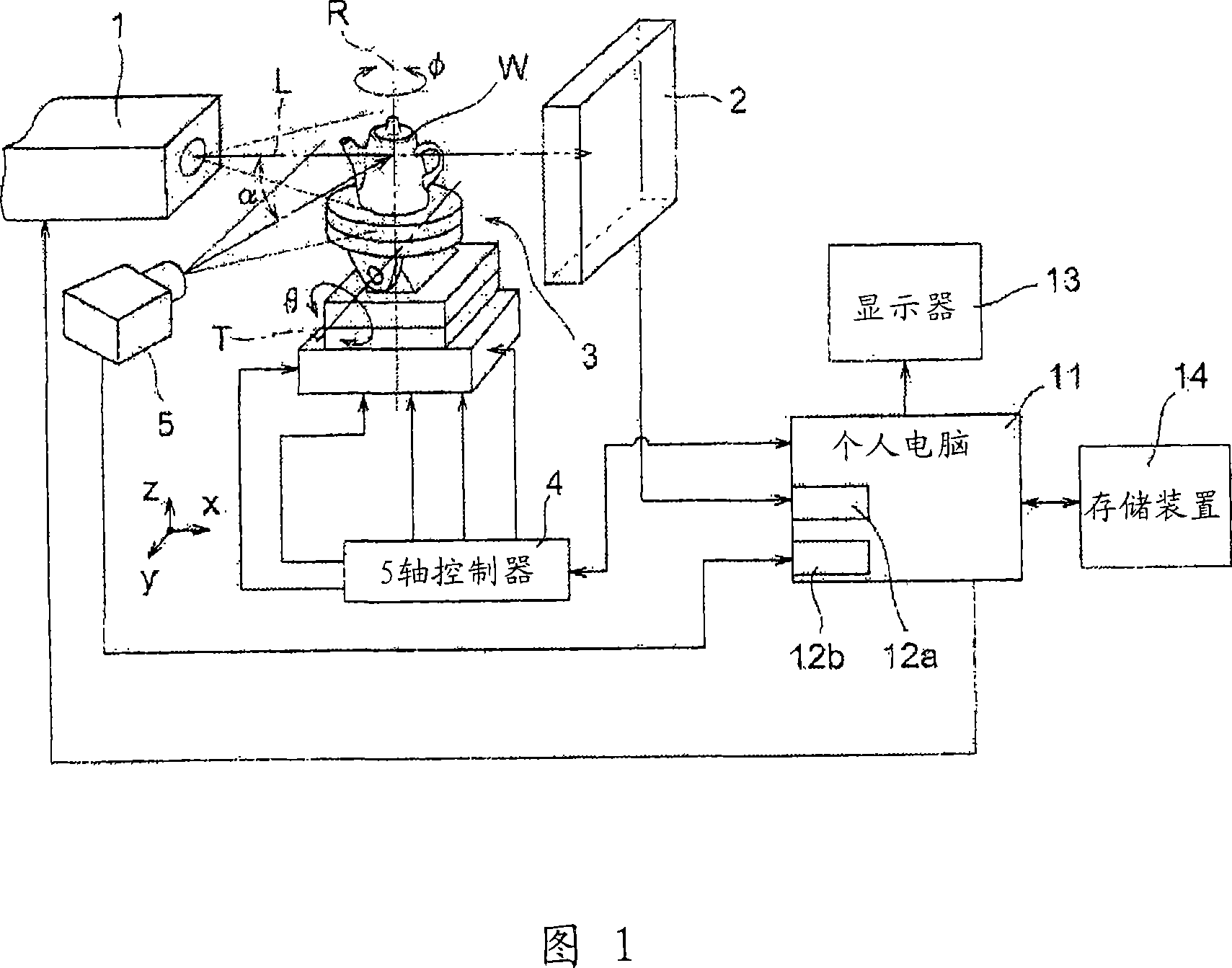

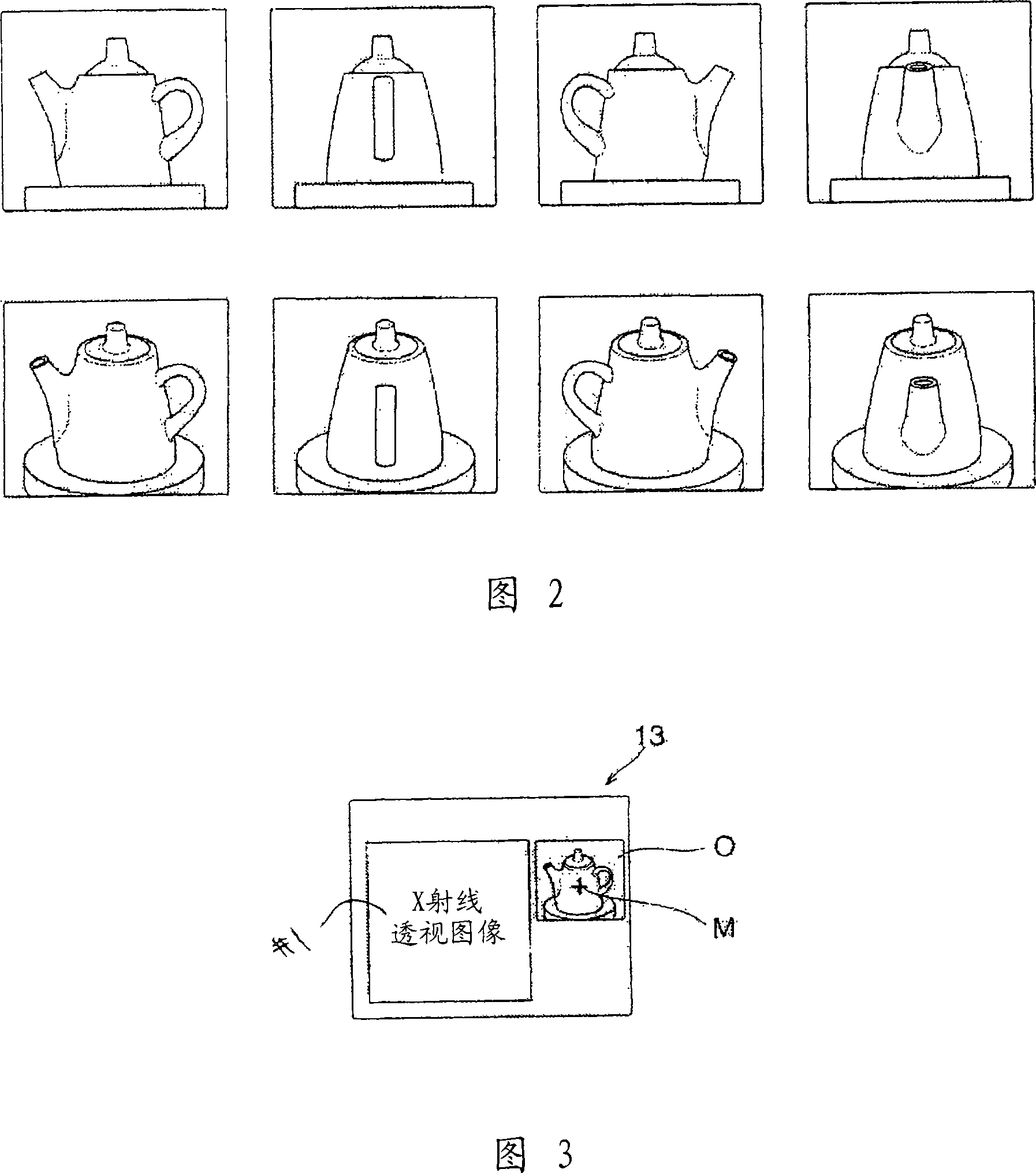

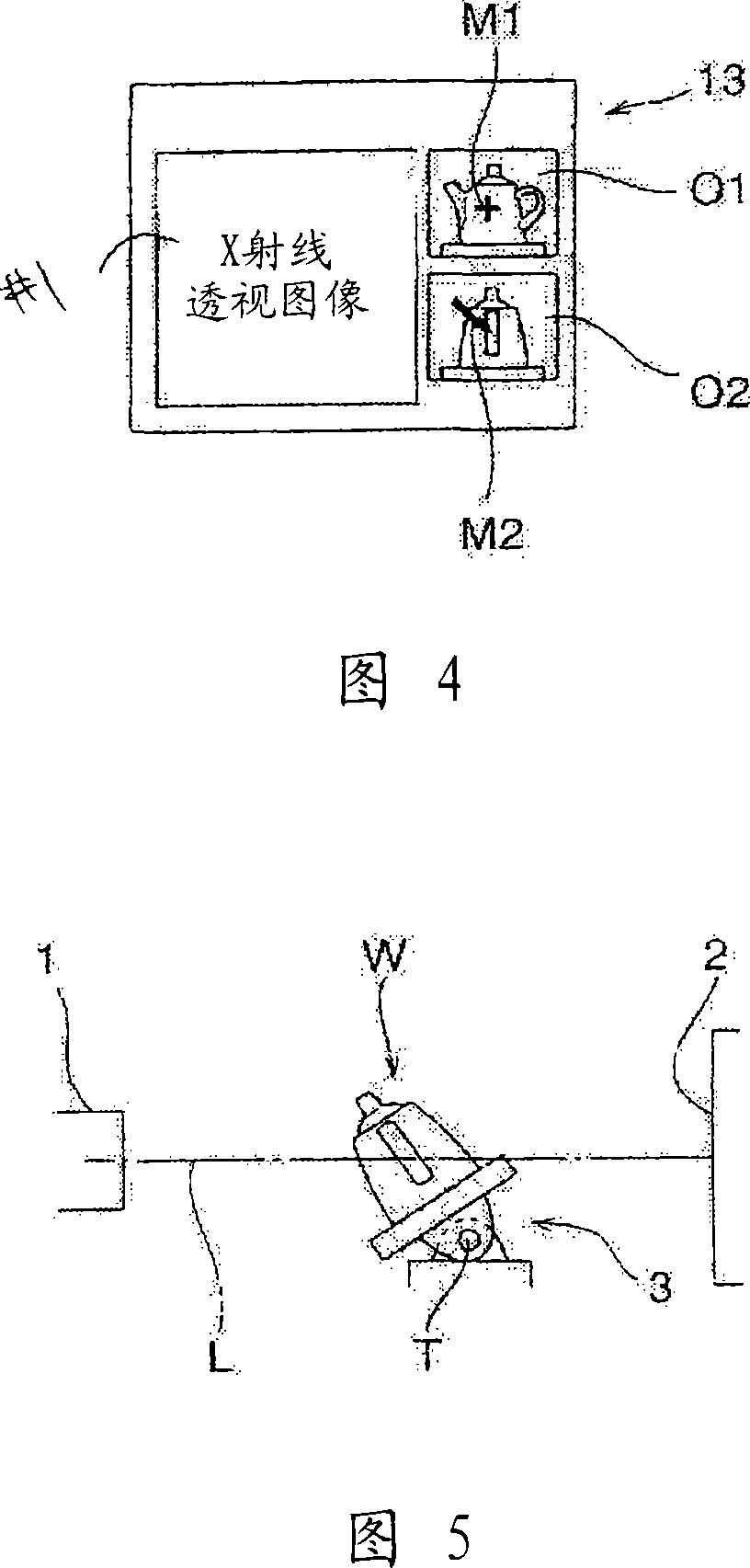

X-ray fluroscopic device

InactiveCN101023341AObtain intuitivelyChange positionMaterial analysis by transmitting radiationOptical axisX-ray

A fluoroscope capable of recognizing the examining direction or position of a fluoroscopic object intuitively and easily at all times without requiring a work for confirming the examining position or direction by reducing the fluoroscopic magnification. An optical camera (5) for photographing a fluoroscopic object W on a sample stage (3) is provided, the fluoroscopic object W is photographed by the optical camera (5) in a plurality of postures by driving the sample stage (3) prior to fluoroscopic work and the optical images are stored in a storage device (14). During fluoroscopic operation, an optical image O closest to the image of the fluoroscopic object W viewed from the examining direction at the current moment in time is selected from among the optical images stored in the storage device (14) and displayed on a display (13) so that the examining direction can be recognized intuitively. The examining direction can also be recognized intuitively when a marker M indicative of the position of the optical axis L of X-rays is displayed superimposingly in addition to the optical image O.

Owner:SHIMADZU SEISAKUSHO CO LTD

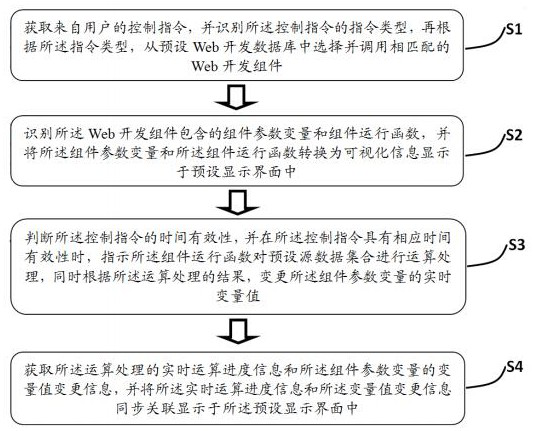

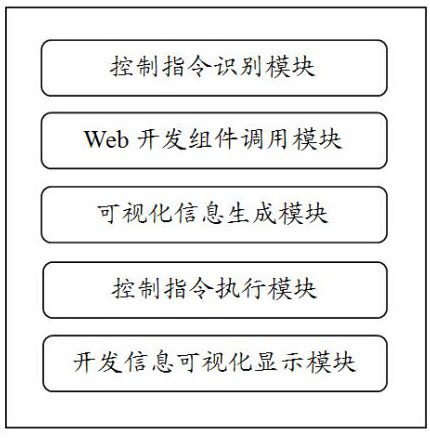

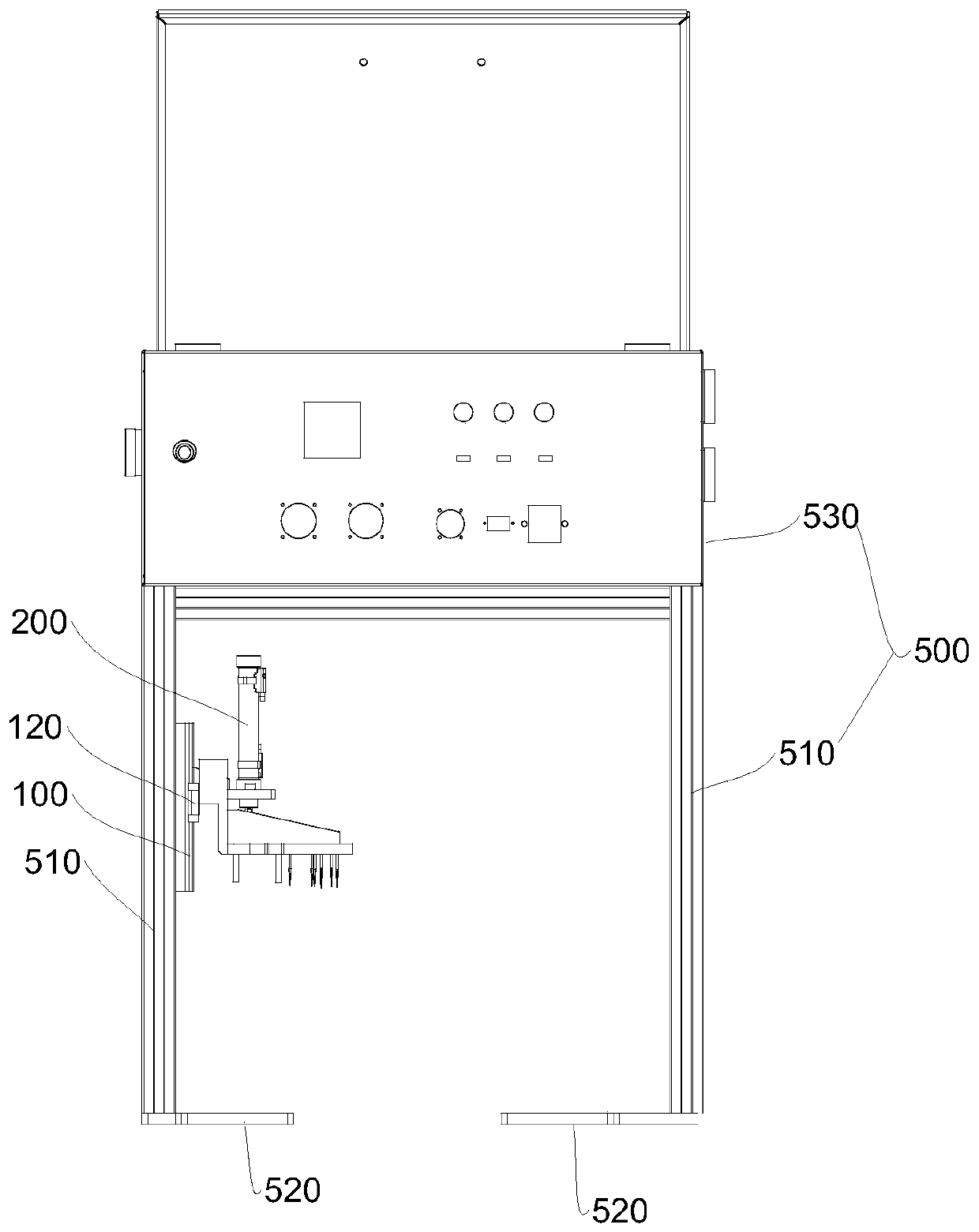

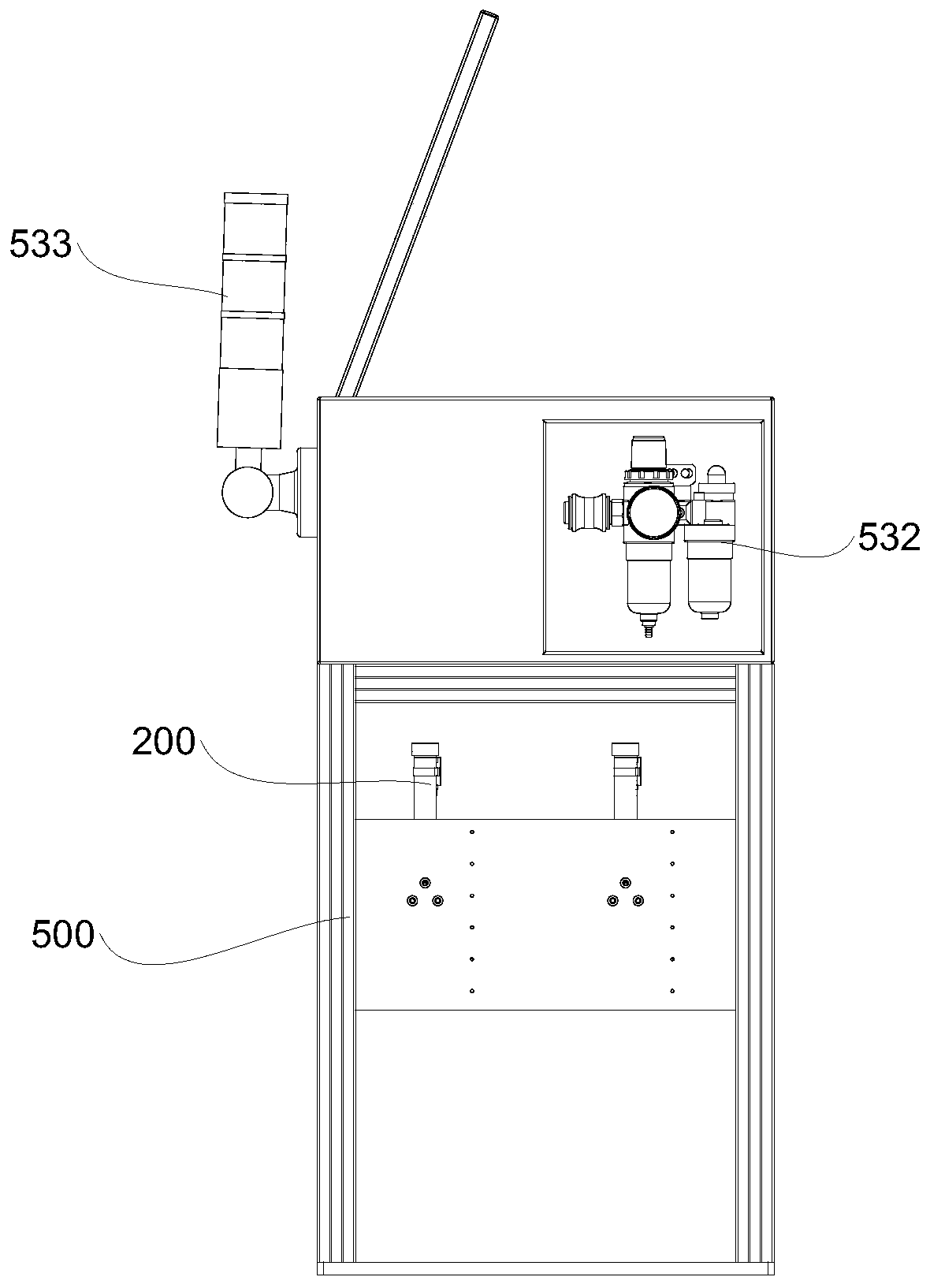

Configurable visual development method and system

ActiveCN112114797AEasy accessObtain intuitivelyVisual/graphical programmingSoftware engineeringWeb development

The invention provides a configurable visual development method and system, which can select an appropriate Web development component according to a control instruction of a user and convert componentparameter variables and component operation functions in the Web development component into visual information. Meanwhile, corresponding operation progress information and parameter variable value change information can be displayed in real time according to an operation processing result of the source data in the development process, so that a developer can quickly and intuitively obtain corresponding page development related information in real time from numerous data in the development process; therefore, the development efficiency and the development reliability of Web page development are improved to the maximum extent.

Owner:CHENGDU ZHONGKE HEXUN TECH CO LTD

POS machine battery electric leakage detection device and POS machine production line

PendingCN111007403ARealization of leakage detectionImplement automatic detectionShort-circuit testingProduction lineButton battery

The invention discloses a POS machine battery electric leakage detection device and a POS machine production line, and relates to the technical field of POS machine production equipment. The POS machine battery electric leakage detection device comprises a fixing plate, a driving mechanism and an electric leakage detection mechanism. The driving mechanism is installed on the fixing plate, and thefixing plate is provided with a guide rail. The electric leakage detection mechanism comprises a probe plate and a probe, the probe plate is connected with the driving mechanism, the driving mechanismis used for driving the probe plate to directionally move along the guide rail so as to enable the probe to move towards or away from a semi-finished POS machine product, and the probe is used for making contact with a circuit board of the semi-finished POS machine product. According to the invention, automatic detection for a button cell of a POS machine is realized, the process is completed bythe action of the driving mechanism, manual holding is not needed, the operation is convenient, the detection efficiency is improved, the labor is saved, and the labor cost is reduced.

Owner:厦门宏泰智能制造有限公司

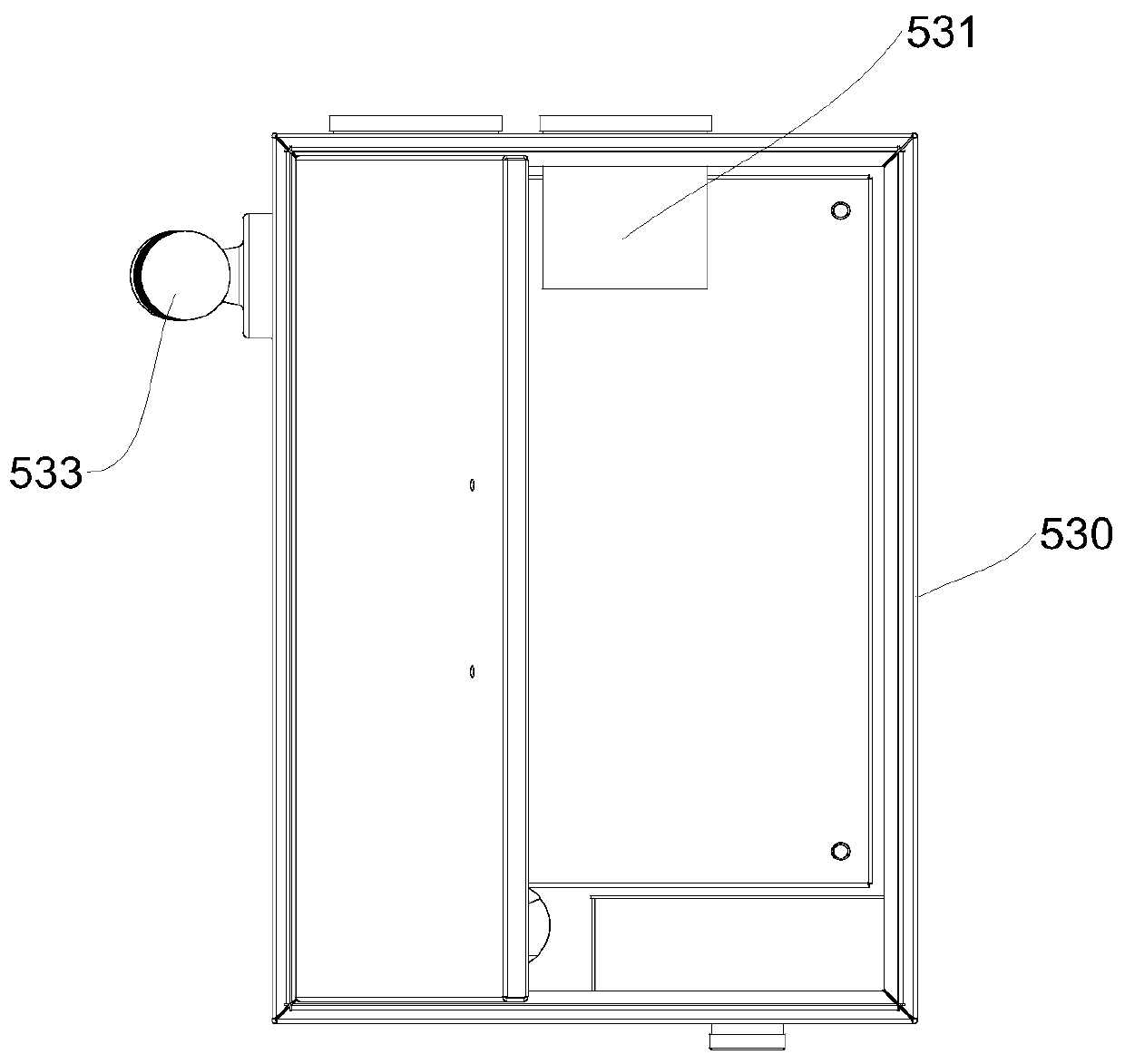

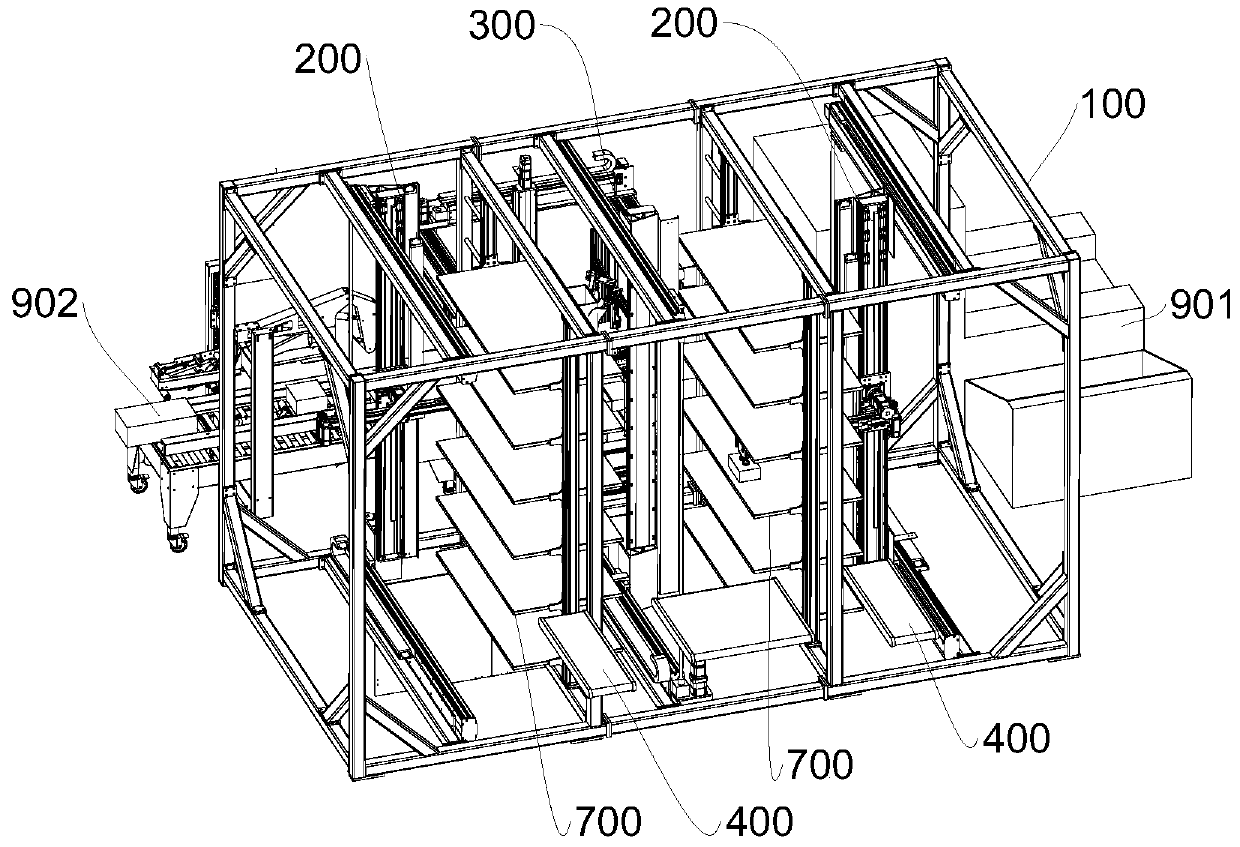

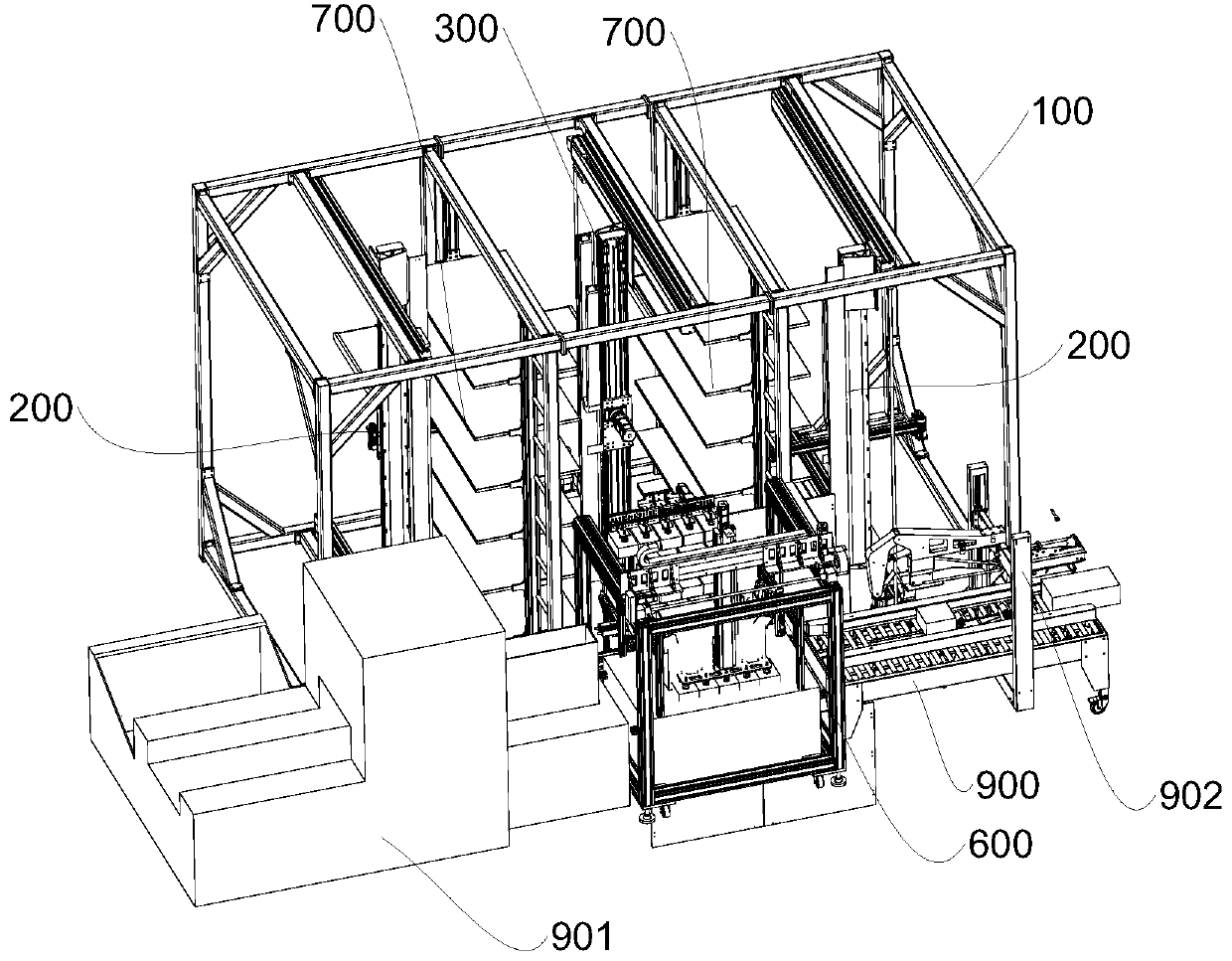

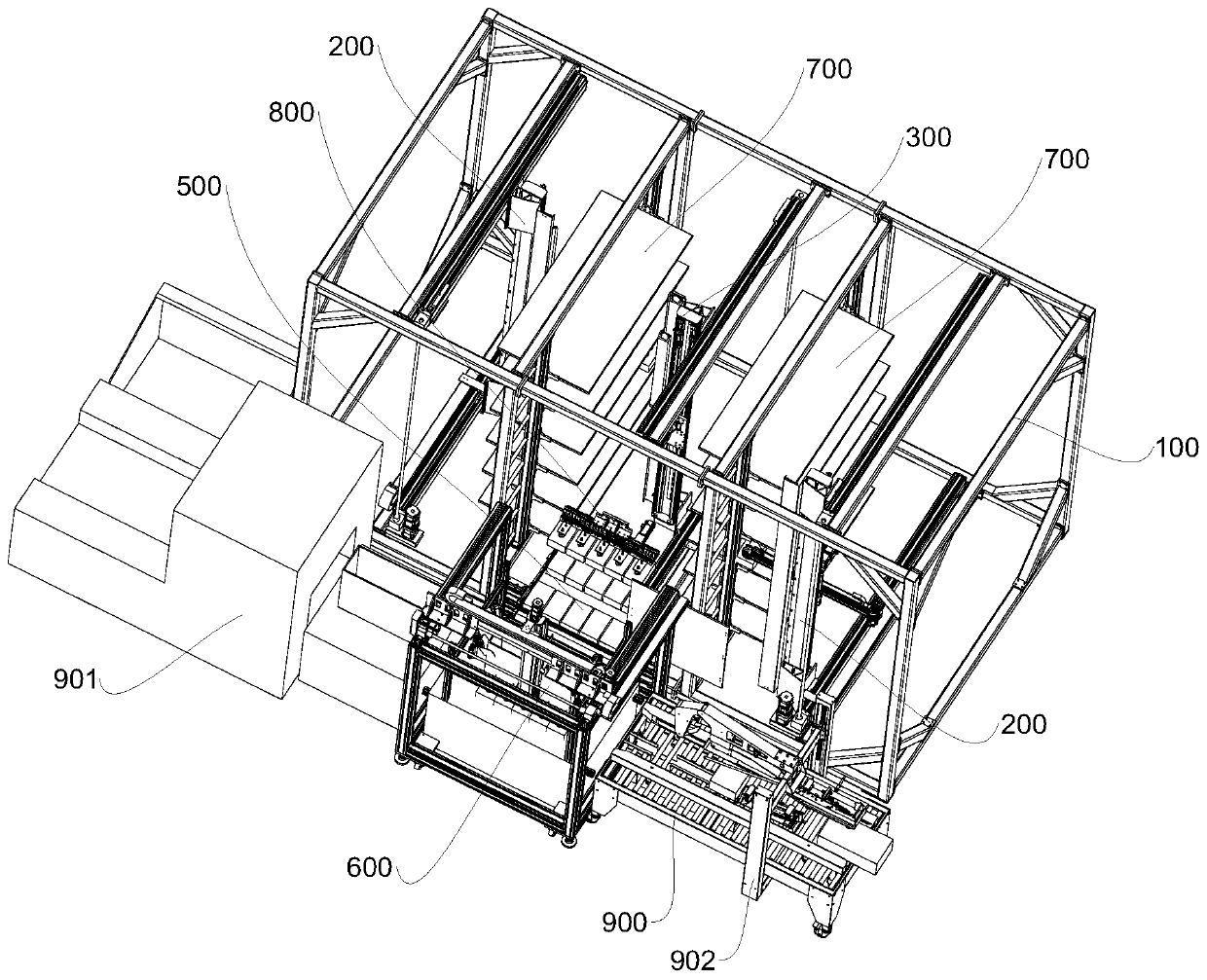

POS machine sorting device and production system

PendingCN110937372AReduce human involvementReduce labor costsConveyorsPackagingProcess engineeringMachine

The invention discloses a POS machine sorting device and a production system, and relates to the technical field of POS machine production equipment. The POS machine sorting device comprises a vertical material rack, a first gantry module, a defective product conveying mechanism, a second gantry module, a discharging conveying mechanism and a boxing mechanism, wherein a plurality of qualified product caching layers are sequentially arranged on the vertical material rack from top to bottom. According to the POS machine sorting device and the production system, the conveying mechanism and the vertical material frame are combined through the first gantry module and the second gantry module, so that sorting of POS machines can be automatically completed through mechanical operation, the manualparticipation degree is reduced, and the labor cost and the labor intensity are reduced.

Owner:厦门宏泰智能制造有限公司

Method for detecting and evaluating continuously cast steel billet primary cooling effects

InactiveCN106093045AEasy accessObtain intuitivelyMaterial analysis by optical meansAlcoholCooling effect

The invention relates to a method for detecting and evaluating continuously cast steel billet primary cooling effects. The method includes 1, taking samples; 2, preparing and treating test specimens, to be more specific, accurately grinding and machining detection surfaces of test specimen blocks, corroding the detection surfaces of the test specimen blocks in nitric acid solution and absolute ethyl alcohol corrosive agents with the concentration equal to or higher than 96% for approximately 30-120 seconds, taking the detection surfaces of the test specimens out of the nitric acid solution and absolute ethyl alcohol corrosive agents, washing the detection surfaces of the test specimens by the aid of distilled water, cleaning the detection surfaces of the test specimens by the aid of absolute ethyl alcohol and then drying the detection surfaces of the test specimens; 3, imaging the test specimens, to be more specific, observing the detection surfaces of the treated test specimens by the aid of a research-grade stereo microscope under appropriate multiple conditions and measuring and photographing typical positions; 4, evaluating the primary cooling effects, to be more specific, observing and computing the thicknesses of chilled fine grain layers of cast billets and the sizes and the morphology of each single crystalline grain according to obtained images, analyzing the appropriateness and the uniformity of the thicknesses of the chilled fine grain layers and evaluating the primary cooling effects. The method has the advantages that the clear images of solidification structures of samples can be quickly and visually obtained, the thicknesses of the chilled fine grain layers of the cast billets can be further measured and analyzed according to the images, and accordingly the continuous casting primary cooling effects can be reliably and comprehensively analyzed and evaluated.

Owner:JIANGYIN XINGCHENG GOLD MATERIALS CO LTD

Acoustic detection system for cast iron material defects

ActiveCN103336057AEasy accessObtain intuitivelyAnalysing solids using sonic/ultrasonic/infrasonic wavesMaterial defectUltrasound attenuation

The invention relates to an acoustic detection system for cast iron material defects. The acoustic detection system comprises an excitation module, a reception module, a calibration module, a calculation module, a display module and a storage module. The calibration module is used for determining the coordinate system of the surface of a plate to be detected. The calculation module is used for calculating an amplitude of a scanning probe at a real-time position, comparing the amplitude with a standard attenuation amplitude corresponding to the position, and calculating a difference percentage of the two amplitudes. The display module is used for displaying the difference percentage, a given permissible difference percentage threshold value and the coordinate system determined by the calibration module, and displaying the surface of the cast iron plate to be detected, real-time position of an excitation probe, and real-time position of the scanning probe in the coordinate system. Detection results can be visually, rapidly and accurately obtained by the acoustic detection system provided by the invention.

Owner:CHINA SPECIAL EQUIP INSPECTION & RES INST +1

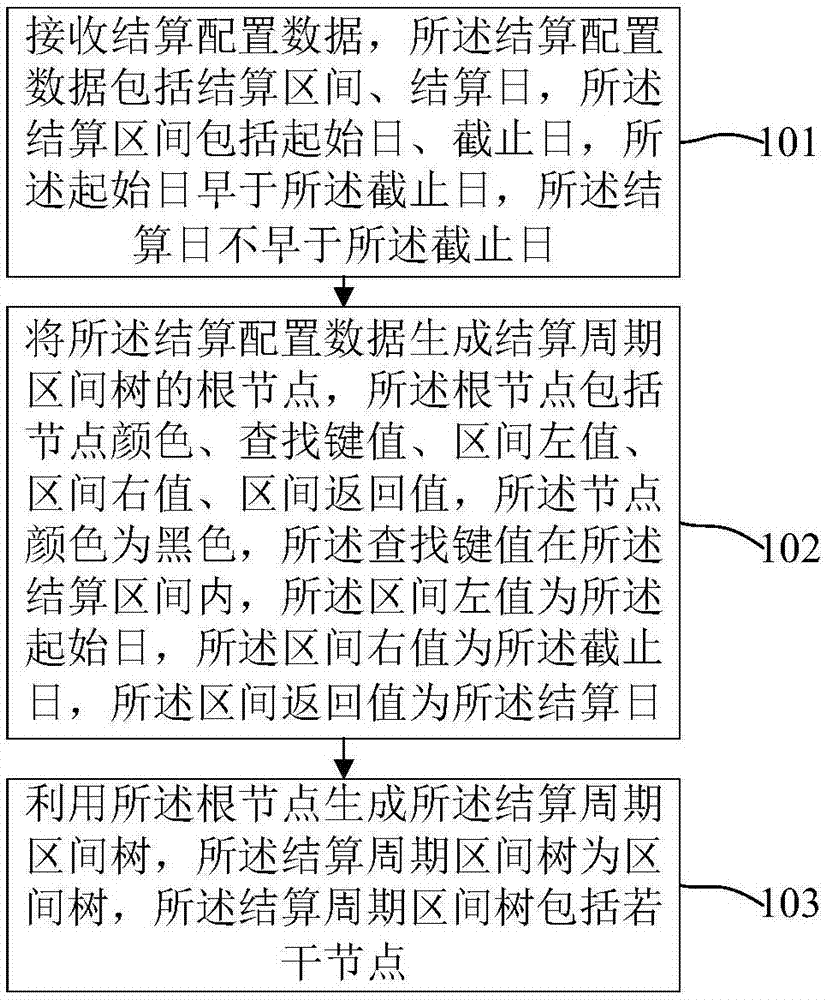

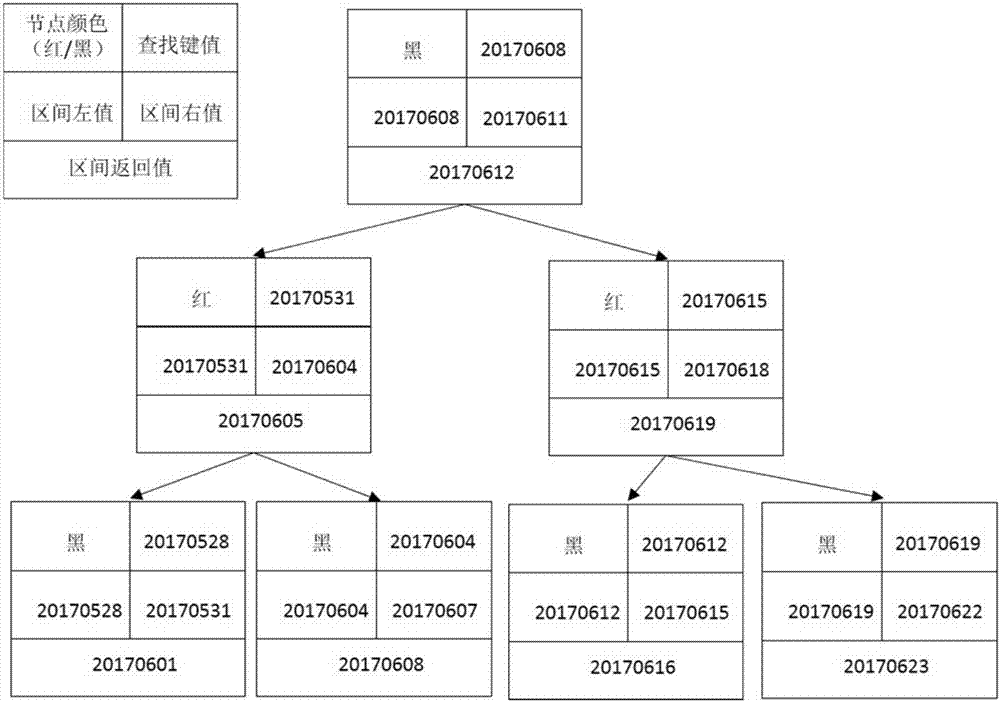

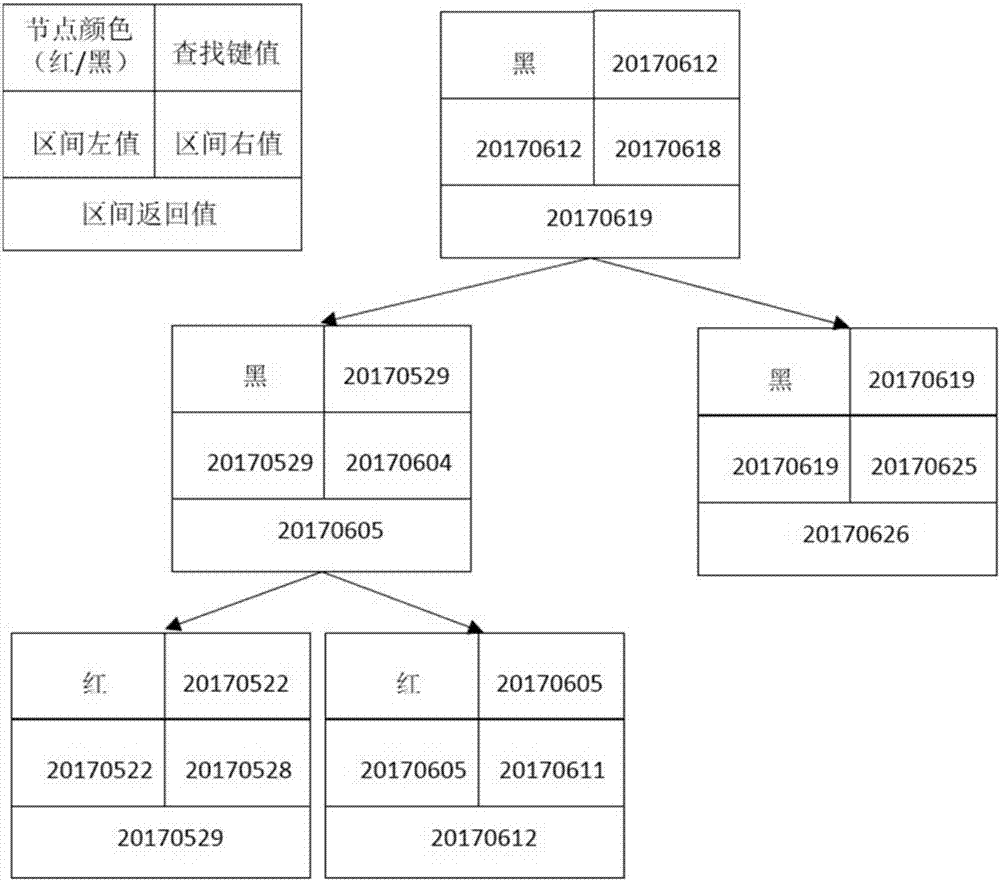

Settlement cycle generating method and system based on interval tree search algorithm

InactiveCN107341243AEasy to getObtain intuitivelyFinanceOffice automationExpiration dateSearch algorithm

The invention discloses a settlement cycle generating method and system based on an interval tree search algorithm. The method includes: S1, receiving settlement configuration data, wherein the settlement configuration data includes settlement intervals and settlement dates, each settlement interval includes an initiation date and an expiration date, the initiation date is earlier than the expiration date, and the settlement date is not earlier than the expiration date. S2, using the settlement configuration data to generate a root node of a settlement cycle interval tree, wherein the root node includes a node color, a search key value, an interval left value, an interval right value and an interval return value, the node color of the root node is black, the search key value is in the settlement interval, the interval left value is the initiation date, the interval right value is the expiration date, and the interval return value is the settlement date; and S3, utilizing the root node to generate the settlement cycle interval tree, wherein the settlement cycle interval tree is an interval tree, and the settlement cycle interval tree includes a plurality of nodes. According to the method and system, only simply configuring the settlement intervals and the settlement dates is needed for simply, intuitively and quickly obtaining the concerned settlement cycles and settlement dates.

Owner:CTRIP TRAVEL NETWORK TECH SHANGHAI0

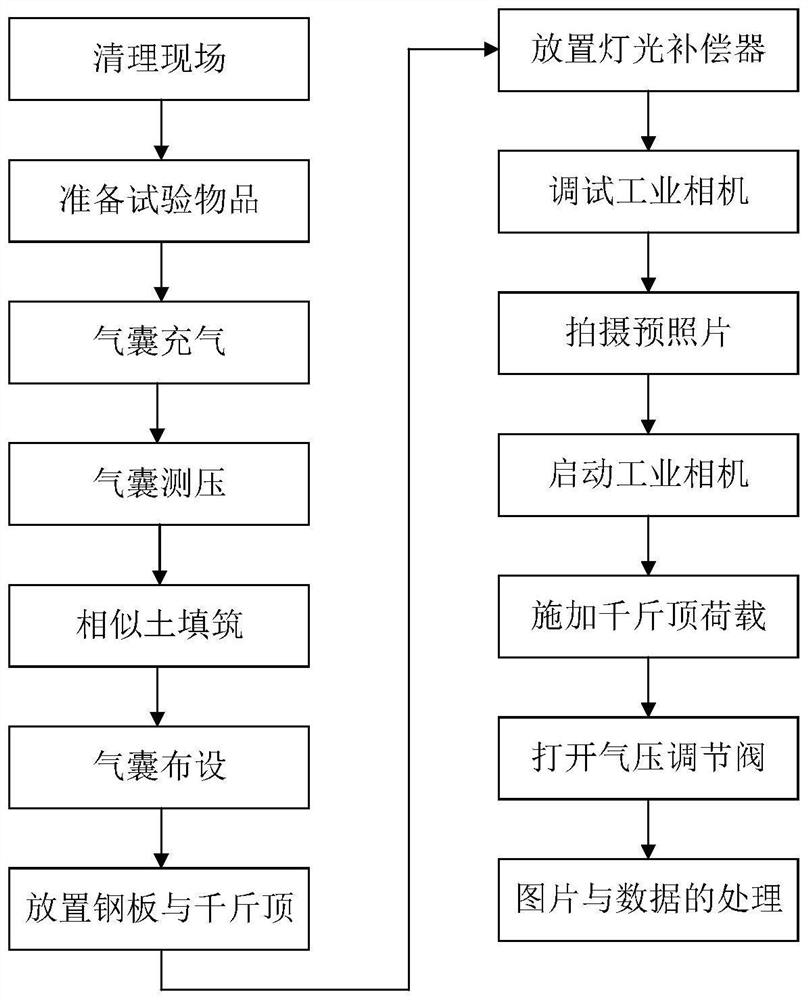

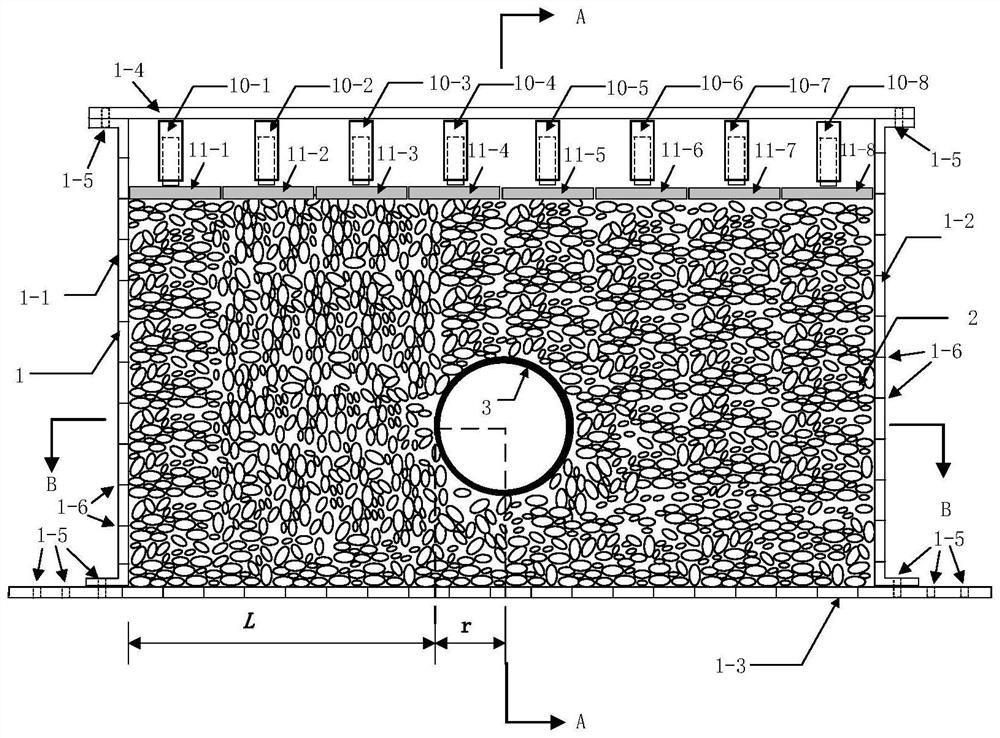

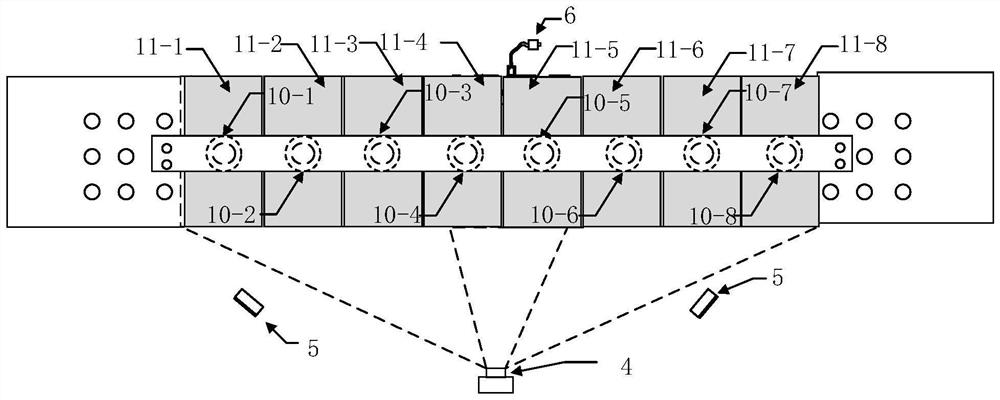

Two-dimensional test model and method for simulating tunnel excavation stratum loss

PendingCN114518441ARealize Simulation StudiesEasy to operateEarth material testingHeight/levelling measurementMonitoring systemSteel frame

The invention discloses a two-dimensional test model for simulating tunnel excavation stratum loss. The two-dimensional test model comprises a model box and soil layer system, a stratum loss simulation system, a loading system and a monitoring system, wherein the model box and soil layer system comprises a U-shaped movable steel frame and similar soil filled in the U-shaped movable steel frame; the stratum loss system comprises an air bag, a barometer is arranged on the air bag, and the air bag is connected with an air pressure regulating valve and an inflator pump; the loading system is arranged at the upper part of the U-shaped movable steel frame and comprises a component force plate above the similar soil, and a plurality of jacks are arranged on the component force plate; the monitoring system comprises an industrial camera, the industrial camera is arranged on a tripod, and a light compensator is arranged beside the industrial camera. The invention further discloses a two-dimensional test method for simulating the tunnel excavation stratum loss. The method is easy to operate, convenient and fast, the stratum loss rate can be accurately obtained, data can be more visually obtained, and the test phenomenon can be visually described.

Owner:WUHAN UNIV OF TECH +1

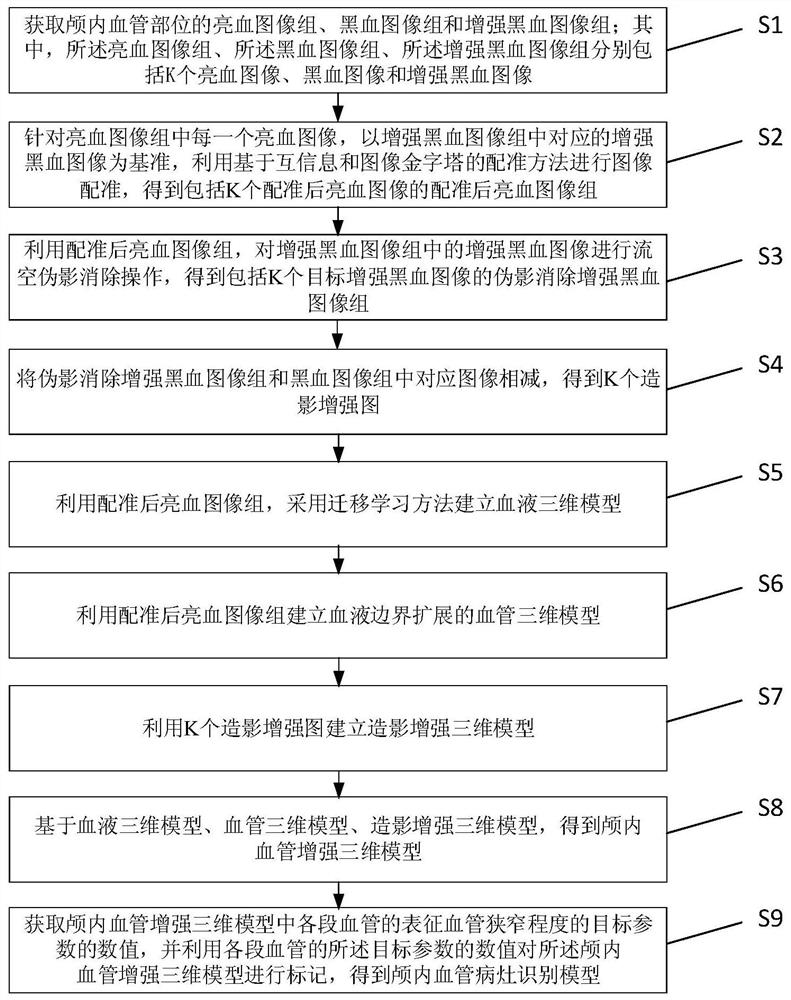

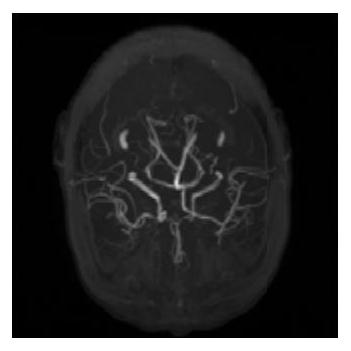

Intracranial vascular focus identification method based on transfer learning

InactiveCN112669398AImprove registration efficiencyImprove registration accuracyImage enhancementImage analysisComputer visionNuclear medicine

The invention discloses an intracranial blood vessel focus identification method based on transfer learning. The method comprises the following steps: acquiring a bright blood image group, a black blood image group and an enhanced black blood image group of an intracranial blood vessel part; carrying out registration on each bright blood image by using a registration method based on mutual information and an image pyramid by taking the corresponding enhanced black blood image as a reference to obtain a registered bright blood image group; using the registered bright blood image group to perform flow empty artifact elimination operation on the enhanced black blood images in the enhanced black blood image group to obtain an artifact-eliminated enhanced black blood image group; subtracting the corresponding images in the artifact elimination enhanced black blood image group from the corresponding images in the black blood image group to obtain K contrast enhanced images; establishing a blood three-dimensional model by using the registered bright blood image group and adopting a transfer learning method; and establishing a blood vessel three-dimensional model of blood boundary expansion by using the registered bright blood image group; the focus area of the intracranial blood vessel can be simply, conveniently, quickly and visually recognized clinically.

Owner:XIAN CREATION KEJI CO LTD

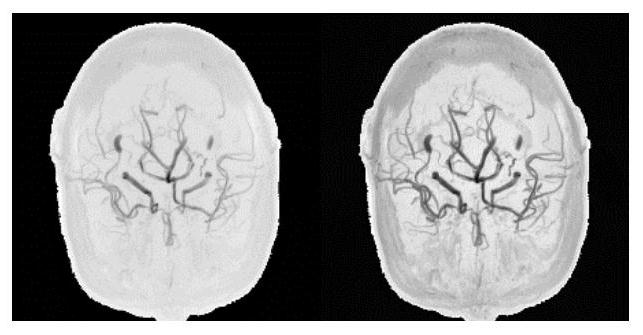

An automatic recording system and automatic recording method for an anchor chain tensioner

ActiveCN104713785BAvoid Manual MeasurementsAvoid recordingMaterial strength using tensile/compressive forcesTransducerDisplay device

Owner:FOSHAN MARINE ANCHOR CHAIN

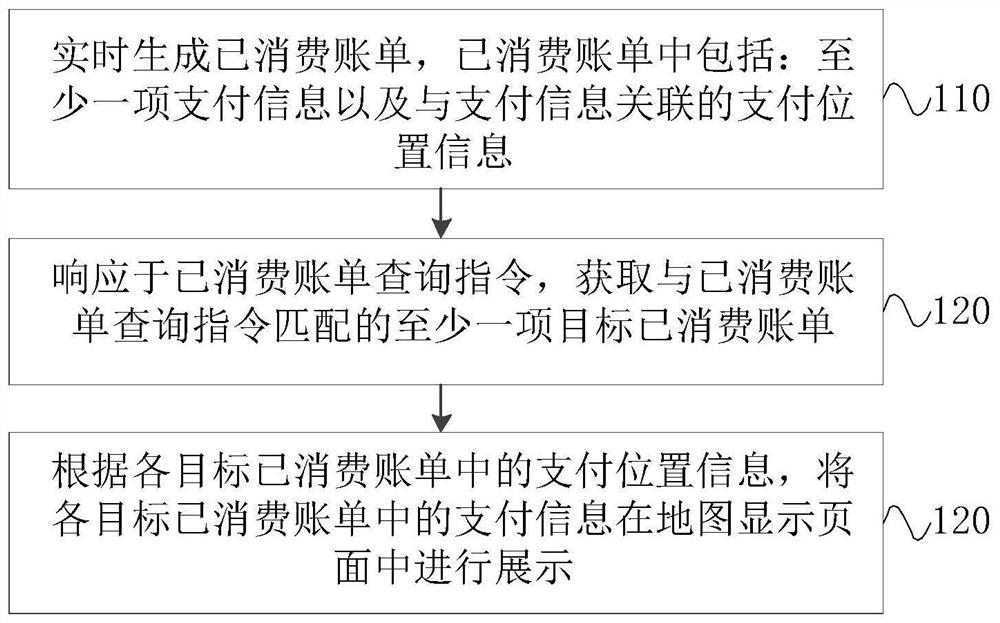

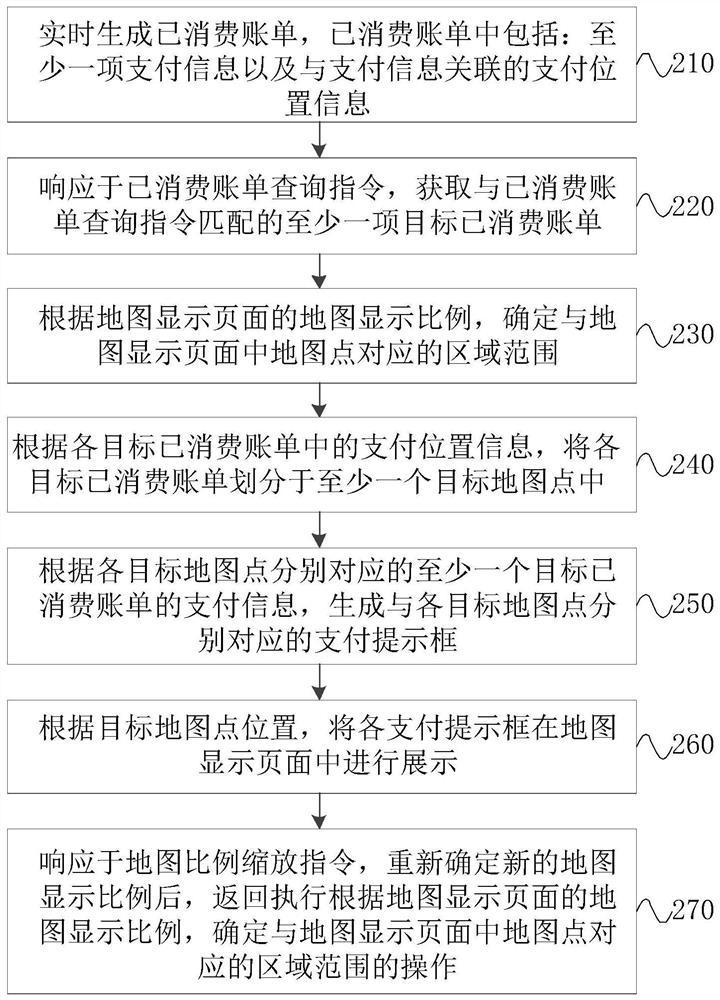

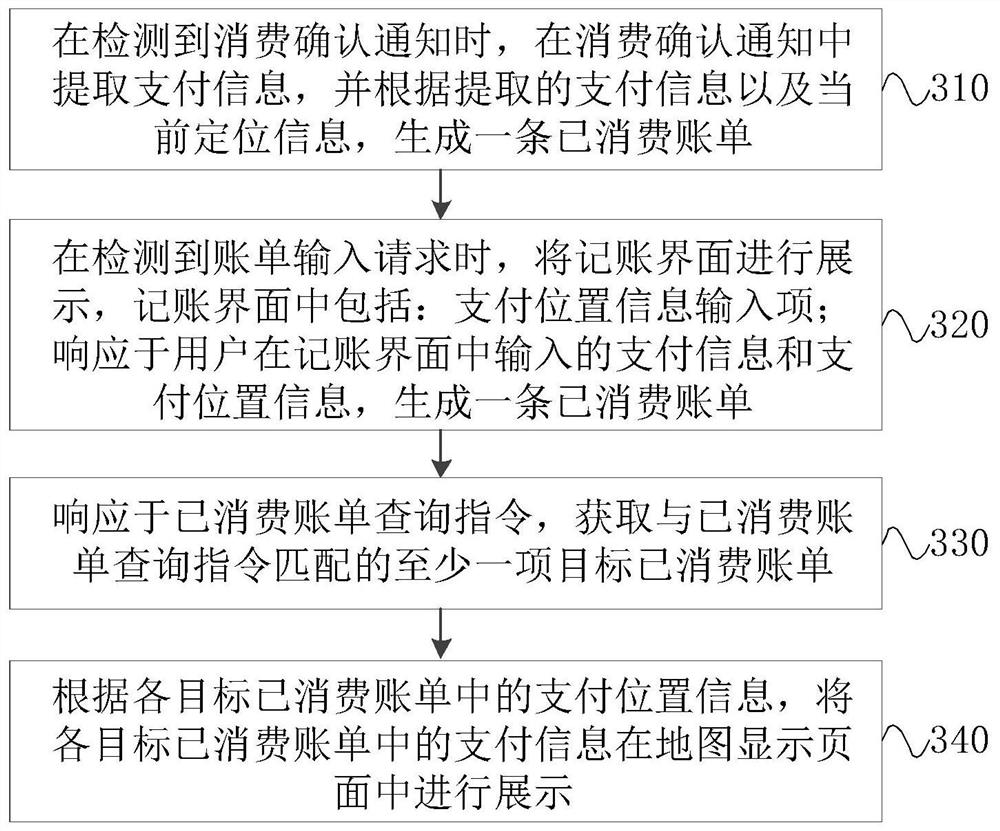

Accounting processing method and device, equipment and medium

PendingCN111950996AObtain intuitivelySolve problems with a single type and a small amount of informationPayment architecturePaymentDatabase

The embodiment of the invention discloses an accounting processing method and device, equipment and a medium. The accounting processing method comprises the steps of generating a consumed bill in realtime, wherein the consumed bill comprises at least one piece of payment information and payment position information associated with the payment information; in response to a consumed bill query instruction, obtaining at least one target consumed bill matching the consumed bill query instruction; and according to the payment position information in each target consumed bill, displaying the payment information in each target consumed bill in a map display page. According to the technical scheme of the embodiment of the invention, the problems of single type and small information amount of billinformation recorded by an accounting tool in the prior art are solved, and intuitive and multi-dimensional consumption bill information is provided for a user by displaying the payment information of the consumed bill in the map display page.

Owner:深圳市铭数信息有限公司

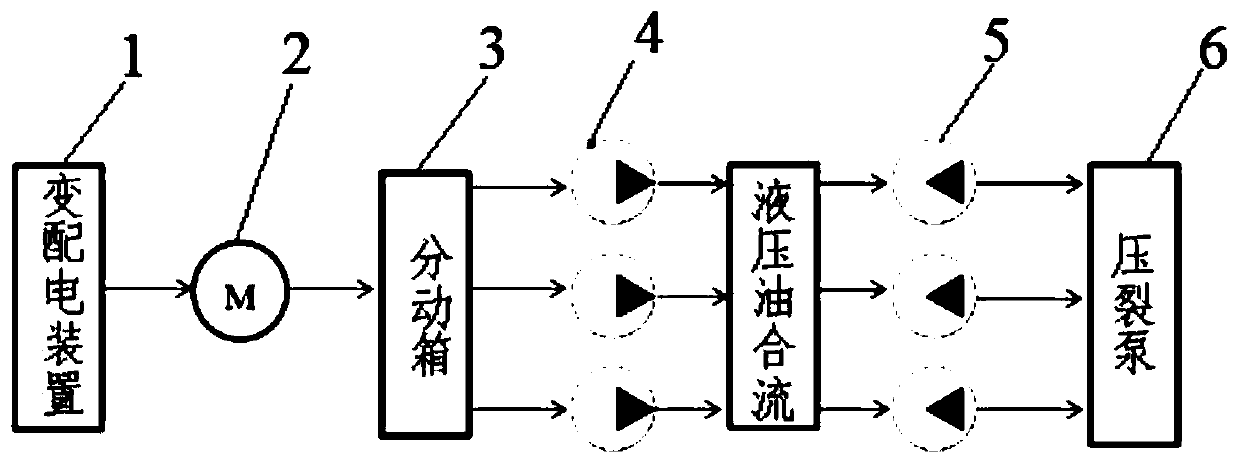

Electrically-driven fracturing driving system and electrically-driven fracturing device

PendingCN110645159ALow costOptimize layoutFluid removalPiston pumpsElectric machineFrequency conversion

The invention provides an electrically-driven fracturing driving system and an electrically-driven fracturing device, and relates to the technical field of fracturing pump driving equipment. The electrically-driven fracturing driving system comprises an electric motor, a fracturing pump, at least one hydraulic pump and at least one hydraulic motor, wherein the motor is electrically connected withhigh voltage so as to enable the high voltage to supply power to the motor, and the motor is connected with the hydraulic pump and used for driving the hydraulic pump; an oil outlet of the hydraulic pump is connected with an oil inlet of the hydraulic motor and used for driving the hydraulic motor; and the hydraulic motor is in transmission connection with the fracturing pump to drive the fracturing pump. According to the system, the hydraulic fracturing pump is provided with a hydraulic transmission mode, instead of a frequency conversion system and a frequency conversion motor to carry out the rotation speed adjustment, to realize the rotation speed adjustment of the fracturing pump, so that a frequency conversion system with higher cost is not needed, the cost of the hydraulic motor andthe hydraulic pump is low, the pipeline arrangement is simple; and compared with a traditional mode of adopting an electric driving fracturing device of the frequency conversion system, the system reduces the equipment cost.

Owner:SANY PETROLEUM INTELLIGENT EQUIP CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com